Table of Contents

- Introduction: Why Datasheets Decide Project Success

- What Is a Datasheet and How Buyers Should Use It

- How to Read a Transformer Datasheet

- How to Read a Substation Datasheet

- How to Read a Switchgear Datasheet

- Common Buyer Mistakes When Reviewing Datasheets

- Procurement Checklist: Key Parameters to Verify Before Ordering

- How Experienced Manufacturers Support Datasheet Review

- Conclusion: Datasheet Literacy as a Competitive Advantage

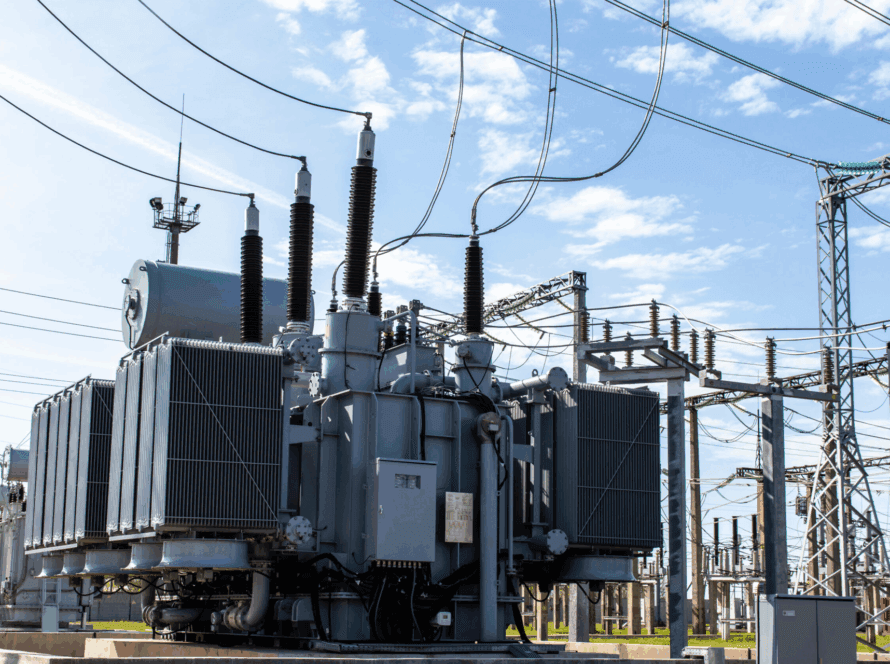

1. Introduction: Why transformer Datasheet Decide Project Success

In power distribution and industrial energy projects, procurement decisions are rarely reversed easily. Once a transformer, substation, or switchgear system is manufactured, shipped, and installed, correcting a technical mismatch becomes expensive and time-consuming. For this reason, a transformer datasheet, along with other equipment datasheets, plays a far more critical role than many buyers initially realize, serving as the technical blueprint for proper specification and system compatibility.

In real-world projects, most disputes between buyers and suppliers do not originate from intentional quality issues. Instead, they stem from assumptions made during the datasheet review stage. A voltage rating interpreted incorrectly, a cooling method overlooked, or a short-circuit level underestimated can cascade into redesigns, delayed commissioning, and even failed grid acceptance.

For EPC contractors and industrial buyers, a datasheet is not simply a formal attachment for record keeping. It is the technical foundation upon which pricing, compliance, safety, and long-term reliability are built. Buyers who can read and interpret datasheets accurately gain a clear advantage during supplier comparison and technical negotiations.

This article provides a structured, buyer-focused explanation of how to read a transformer datasheet, substation datasheet, and switchgear datasheet. Rather than repeating textbook definitions, it explains how each parameter affects real project outcomes, including installation feasibility, operating stability, and maintenance cost over the equipment lifecycle.

2. What Is a Transformer Datasheet and How Buyers Should Use It

A datasheet is a condensed technical declaration that summarizes the essential characteristics of electrical equipment. For transformers, substations, and switchgear, it defines how the equipment is designed to operate under specified electrical, environmental, and mechanical conditions.

From a buyer’s perspective, the datasheet serves several purposes simultaneously. In the early design phase, engineers can use it to confirm compatibility with the grid and downstream loads. When moving into procurement, the datasheet allows buyers to objectively compare different suppliers. Later, during inspection and commissioning, it serves as the primary reference document for verifying equipment performance.

It is important to distinguish a datasheet from other documents commonly provided by manufacturers:

| Document Type | Primary Purpose | Buyer Value |

|---|---|---|

| Datasheet | Defines key performance parameters | Selection and comparison |

| Technical Drawings | Show physical layout and dimensions | Installation planning |

| Test Reports | Verify performance after production | Quality assurance |

| Operation Manuals | Explain usage and maintenance | Long-term operation |

Buyers should treat the datasheet as the first technical gate. Before discussing price, delivery, or commercial terms, all critical parameters must be aligned with project requirements. Any ambiguity at this stage should be clarified in writing to avoid disputes later.

3. How to Read a Transformer Datasheet

A transformer datasheet is the most critical technical document in the entire power distribution chain. For buyers, EPC contractors, and project engineers, this single document often determines whether a project proceeds smoothly or becomes trapped in cycles of redesign, clarification, and dispute. Unlike marketing brochures, a transformer datasheet represents a technical commitment: it defines how the transformer will perform electrically, thermally, and mechanically under defined conditions.

Many procurement risks arise not because the datasheet is incorrect, but because it is misunderstood. Parameters are reviewed in isolation rather than as part of a system. This section explains how buyers should read a transformer datasheet step by step, focusing on what each parameter means in practice, why it matters during procurement, what can go wrong if it is misunderstood, and how to verify it correctly.

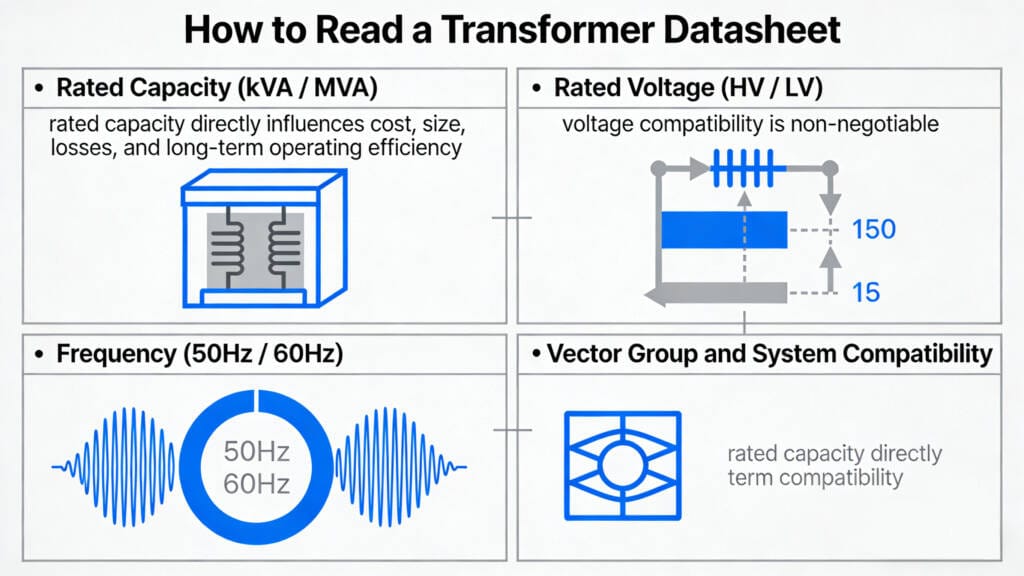

3.1 Rated Capacity (kVA / MVA)

What it is

Rated capacity indicates the apparent power a transformer can deliver continuously under specified reference conditions. It is typically expressed in kVA for distribution transformers and MVA for power transformers. On a datasheet, this value is often the first parameter buyers notice, yet it is also one of the most frequently misunderstood.

Why buyers should care

From a procurement perspective, rated capacity directly influences cost, size, losses, and long-term operating efficiency. Selecting a transformer purely based on peak load demand is rarely optimal. Transformers operate most efficiently when loaded within a specific range, usually between 50% and 80% of rated capacity.

Overestimating required capacity leads to higher no-load losses, larger footprints, increased shipping costs, and unnecessary capital expenditure. Underestimating capacity, on the other hand, results in persistent overloading, higher operating temperatures, accelerated insulation aging, and reduced service life.

What can go wrong in real projects

In industrial projects, it is common for buyers to specify a capacity margin “just to be safe.” However, this approach often backfires. An oversized transformer may appear safe on paper, but in practice it operates far below optimal load, increasing energy losses over its lifetime. In grid-connected projects, utilities may also reject oversized transformers due to inefficiency requirements.

Conversely, undersized transformers frequently pass initial commissioning but fail prematurely after load growth or seasonal demand increases.

How to check it in a datasheet

Buyers should verify not only the rated capacity value but also the reference conditions under which it applies. Pay attention to ambient temperature assumptions, cooling method, and permissible overload duration.

| Item to Verify | Why It Matters |

| Rated Capacity | Must match realistic load demand |

| Reference Temperature | Affects usable capacity |

| Cooling Method | Determines overload capability |

| Load Profile Assumptions | Prevents oversizing or undersizing |

3.2 Rated Voltage (HV / LV)

What it is

Rated voltage defines the designed operating voltage on the high-voltage and low-voltage sides of the transformer. Datasheets usually list nominal voltage values along with tapping ranges that allow voltage adjustment.

Why buyers should care

Voltage compatibility is non-negotiable. Even small mismatches between transformer rated voltage and grid voltage can lead to inefficient operation, overheating, and non-compliance with utility standards. For buyers operating in multiple regions, voltage conventions may differ subtly, increasing the risk of misinterpretation.

What can go wrong in real projects

A common issue occurs when buyers focus only on nominal voltage and overlook tapping configuration. In some projects, transformers are delivered with tapping ranges unsuitable for local voltage fluctuations, resulting in unstable secondary voltage during operation.

Another frequent mistake is assuming that voltage tolerance on the low-voltage side can compensate for upstream inconsistencies. In reality, improper voltage matching can propagate issues throughout the distribution system.

How to check it in a datasheet

Buyers should confirm nominal voltage, maximum system voltage, and tapping method (off-circuit or on-load). All values must align with local grid codes and downstream equipment ratings.

| Voltage Parameter | Buyer Checkpoint |

| Nominal HV / LV Voltage | Matches grid requirements |

| Tapping Range | Covers expected fluctuations |

| Tapping Method | Suitable for operation strategy |

| Insulation Level | Compatible with system voltage |

3.3 Frequency (50Hz / 60Hz)

What it is

Frequency specifies the designed operating frequency of the transformer, typically 50Hz or 60Hz. While it appears straightforward, frequency compatibility is a critical consideration in international projects.

Why buyers should care

Transformers are optimized for a specific frequency. Operating a transformer at the wrong frequency alters magnetic flux density, increases core losses, and raises operating temperature. These effects are cumulative and significantly reduce service life.

What can go wrong in real projects

In export projects, frequency mismatches often go unnoticed until commissioning. A transformer designed for 50Hz may operate temporarily on a 60Hz system but experience excessive noise, overheating, or insulation stress over time.

How to check it in a datasheet

Frequency should be clearly stated on the datasheet. Buyers should never assume compatibility based on voltage alone and should request written confirmation for export projects.

3.4 Vector Group and System Compatibility

What it is

The vector group defines the phase relationship between the high-voltage and low-voltage windings. It is represented by standardized codes such as Dyn11 or Yyn0.

Why buyers should care

Vector group selection affects grounding methods, harmonic behavior, and the ability to operate transformers in parallel. In systems with existing infrastructure, vector group compatibility is essential for stable operation.

What can go wrong in real projects

Projects involving system expansion frequently encounter issues when new transformers are ordered without verifying vector group compatibility with existing units. Mismatched vector groups prevent parallel operation and may require costly system redesign.

How to check it in a datasheet

Buyers should verify vector group designation and confirm compatibility with system grounding and protection schemes.

3.5 Impedance and Short-Circuit Considerations

What it is

Transformer impedance represents the opposition to current flow under short-circuit conditions and is usually expressed as a percentage.

Why buyers should care

Impedance directly influences fault current levels and voltage regulation. Low impedance reduces voltage drop but increases short-circuit current, placing greater stress on switchgear. High impedance limits fault current but may negatively affect voltage stability.

What can go wrong in real projects

In many projects, impedance is treated as a secondary parameter and left to the manufacturer’s standard design. This approach can result in mismatches between transformer fault contribution and switchgear short-circuit ratings, creating safety risks.

How to check it in a datasheet

Impedance values should be reviewed in coordination with system protection design. Buyers should confirm acceptable impedance ranges rather than a single nominal value.

| Impedance Level | System Impact |

| Too Low | Excessive fault current |

| Too High | Voltage instability |

| Optimized | Balanced protection and performance |

3.6 Cooling Method and Thermal Design

What it is

Cooling method defines how heat is dissipated from the transformer. Common methods include ONAN, ONAF, AN, and AF.

Why buyers should care

Cooling design affects transformer size, noise level, overload capability, and maintenance requirements. In constrained or high-temperature environments, cooling method selection becomes a decisive factor.

What can go wrong in real projects

Transformers selected without considering ambient temperature and ventilation conditions often operate at elevated temperatures, accelerating insulation aging.

How to check it in a datasheet

Buyers should verify cooling method, reference ambient temperature, and permissible temperature rise.

3.7 Insulation Class, Temperature Rise, and Service Life

What it is

Insulation class defines the thermal endurance of insulating materials, while temperature rise specifies the allowable increase above ambient temperature during operation.

Why buyers should care

These parameters directly influence transformer lifespan. Higher temperature rise reduces service life, even if short-term performance appears acceptable.

What can go wrong in real projects

Projects that prioritize low initial cost often accept minimum insulation specifications, resulting in higher failure rates over time.

How to check it in a datasheet

Buyers should confirm insulation class, temperature rise limits, and compliance with relevant standards, ensuring suitability for expected operating conditions.

Rated Voltage (HV / LV)

Rated voltage defines the designed operating voltage on both high-voltage and low-voltage sides. Datasheets typically list nominal voltage along with tapping ranges.

A common procurement mistake is assuming that minor voltage deviations are acceptable. In reality, mismatched voltage levels can cause inefficiencies, overheating, and non-compliance with grid codes. Buyers must verify that rated voltage aligns precisely with utility requirements and downstream equipment ratings.

Frequency (50Hz / 60Hz)

Frequency is often overlooked, especially in export projects. Transformers are designed specifically for either 50Hz or 60Hz operation. Using a transformer outside its designed frequency range affects magnetic flux density, losses, and temperature rise.

Buyers should confirm frequency compatibility explicitly, even when voltage ratings appear correct.

Vector Group and System Compatibility

The vector group defines the phase displacement and winding configuration of a transformer. It directly affects system grounding, harmonic behavior, and parallel operation.

For projects involving multiple transformers, vector group compatibility is essential. Mismatched vector groups can prevent parallel operation or introduce circulating currents.

Impedance and Short-Circuit Considerations

Transformer impedance influences voltage regulation and fault current levels. A lower impedance reduces voltage drop but increases short-circuit current, placing higher stress on switchgear.

Buyers should evaluate impedance values in coordination with system protection design to ensure safety and compliance.

Cooling Method and Thermal Design

Cooling methods such as ONAN, ONAF, AN, and AF define how heat is dissipated. The chosen cooling method affects installation space, noise levels, and overload capability.

In high-ambient or confined environments, cooling method selection becomes especially critical.

Insulation Class, Temperature Rise, and Service Life

Insulation class and temperature rise determine how a transformer ages over time. Higher temperature rise accelerates insulation degradation, reducing lifespan.

Buyers should assess whether insulation specifications match expected operating conditions rather than relying solely on minimum standards.

4. How to Read a Substation Transformer Datasheet

Unlike a transformer datasheet, which focuses on a single piece of equipment, a substation datasheet describes an integrated power distribution system. For buyers, this difference is critical. A substation datasheet does not merely state how each component performs individually; it defines how transformers, switchgear, protection devices, and enclosures work together as a coordinated unit under real operating conditions.

In procurement practice, substation-related risks are often underestimated. Buyers may assume that if each individual component meets specifications, the complete substation will also perform correctly. In reality, most substation failures and project delays occur at the interfaces—between transformer and switchgear, between electrical design and enclosure design, or between equipment ratings and site conditions.

This section explains how to read a substation datasheet from a buyer’s perspective, focusing on configuration logic, system coordination, environmental adaptation, and long-term operability.

4.1 Understanding Substation Types and Layouts

What it is

Substation type refers to the physical and functional configuration of the system. Common types include pad-mounted substations, American box substations, European compact substations, and containerized substations. Each type reflects a different design philosophy and maintenance approach.

Why buyers should care

The choice of substation type directly affects installation cost, land use, safety, and maintenance strategy. Selecting the wrong type may not be immediately apparent during procurement but can create long-term operational constraints.

For example, American-style box substations emphasize sealed compartments and front-access operation, making them suitable for public or utility environments. European compact substations often allow greater flexibility in internal layout but require more controlled installation conditions.

What can go wrong in real projects

A common mistake occurs when buyers specify a substation type based solely on precedent rather than site conditions. Projects have been delayed because a selected enclosure could not be installed within available space or failed to meet local fire or access regulations.

How to check it in a datasheet

Buyers should review the stated substation type, compartment layout, access method, and compliance with relevant standards.

| Substation Type | Typical Application | Buyer Consideration |

| Pad-Mounted | Utility distribution | Public safety, sealed design |

| American Box | Urban / utility | Front access, maintenance safety |

| European Compact | Industrial | Flexible layout, space planning |

| Containerized | Temporary / remote | Transport and relocation |

4.2 Electrical Ratings and System Integration

What it is

Electrical ratings define the operating limits of the entire substation, including rated voltage, frequency, current, and short-circuit levels on both primary and secondary sides.

Why buyers should care

In substations, electrical ratings must be evaluated as a system rather than as isolated values. A mismatch between transformer fault contribution and switchgear withstand capability can compromise safety and lead to rejection during grid acceptance.

What can go wrong in real projects

Buyers sometimes focus on transformer ratings while assuming that switchgear ratings will automatically match. In reality, switchgear short-circuit ratings may be lower than transformer fault levels, requiring redesign or equipment replacement.

How to check it in a datasheet

Buyers should verify that rated voltage, frequency, and short-circuit capacity are clearly stated for the complete substation and that internal components are properly coordinated.

| Electrical Parameter | Buyer Verification |

| Rated Voltage | Matches grid requirements |

| Frequency | Compatible with local system |

| Short-Circuit Level | Coordinated across components |

| System Configuration | Clear primary and secondary paths |

4.3 Transformer and Switchgear Coordination

What it is

Coordination refers to how the transformer and switchgear are electrically and functionally matched within the substation. This includes protection settings, fault isolation logic, and physical interfacing.

Why buyers should care

Proper coordination ensures that faults are isolated quickly and safely without unnecessary outages. Poor coordination increases the risk of cascading failures and extended downtime.

What can go wrong in real projects

Inadequate coordination may result in protection devices failing to operate in the correct sequence. This can cause excessive equipment damage during faults or complicate fault investigation.

How to check it in a datasheet

Buyers should look for clear descriptions of protection schemes, interlocking mechanisms, and interface definitions between transformer and switchgear.

4.4 Enclosure Design, IP Rating, and Environmental Adaptation

What it is

Enclosure design defines how the substation protects internal equipment from environmental influences such as dust, moisture, temperature extremes, and corrosion. IP rating is a standardized indicator of enclosure protection level.

Why buyers should care

Environmental conditions have a direct impact on equipment reliability. Substations installed in coastal, desert, or industrial environments require specialized enclosure designs to maintain performance over time.

What can go wrong in real projects

Substations designed without adequate environmental protection may pass initial inspection but suffer premature corrosion, insulation degradation, or overheating.

How to check it in a datasheet

Buyers should review IP rating, material selection, ventilation design, and any specified environmental adaptations.

| Environment | Key Risk | Recommended Datasheet Feature |

| Coastal | Corrosion | Anti-corrosion coating |

| Desert | High temperature | Enhanced ventilation |

| Industrial | Dust / chemicals | Higher IP rating |

4.5 Installation, Operation, and Maintenance Factors

What it is

This aspect of the datasheet describes how the substation is installed, accessed, and maintained throughout its service life.

Why buyers should care

Installation and maintenance constraints directly affect project timelines and operating costs. A technically sound substation may still be impractical if maintenance access is limited or installation requirements are unrealistic.

What can go wrong in real projects

Projects have encountered delays because foundation requirements were not clearly defined or because maintenance access did not meet local safety regulations.

How to check it in a datasheet

Buyers should confirm installation method, access clearances, lifting points, and maintenance intervals to ensure long-term operability.

Installation, Operation, and Maintenance Factors

Buyers should review installation requirements, access points, and maintenance intervals to ensure long-term practicality.

5. How to Read a Switchgear Transformer Datasheet

If transformers define how power is converted and substations define how systems are integrated, switchgear defines how power systems are protected and controlled. From a buyer’s perspective, the switchgear datasheet is the final safety gate. It determines whether faults are contained, personnel are protected, and downtime is minimized.

Many procurement teams underestimate the importance of switchgear datasheets, assuming they are standardized or interchangeable. In reality, small differences in ratings, breaker technology, or standards compliance can have major implications for system safety and regulatory approval. This section explains how buyers should read a switchgear datasheet with a focus on risk control, compliance, and long-term operability.

5.1 Rated Voltage, Current, and Operational Limits

What it is

Rated voltage and rated current define the normal operating boundaries of the switchgear. These values indicate the maximum system voltage and continuous current the equipment can handle without degradation.

Why buyers should care

Switchgear operates continuously in live systems. If rated values are marginally undersized, thermal stress accumulates over time, reducing reliability. Over specifying ratings, on the other hand, increases cost and footprint without providing proportional benefits.

Buyers should understand that switchgear ratings must align not only with transformer output but also with system expansion plans and operating diversity.

What can go wrong in real projects

In some projects, switchgear is selected based on nominal transformer output while ignoring downstream load growth. This results in overheating, nuisance tripping, or early replacement.

How to check it in a datasheet

Buyers should verify rated voltage, rated current, and service conditions, ensuring consistency across the system.

| Parameter | Buyer Check |

| Rated Voltage | Matches system maximum |

| Rated Current | Supports continuous load |

| Ambient Conditions | Aligned with installation site |

5.2 Short-Circuit Withstand and Making Capacity

What it is

Short-circuit withstand capacity defines the maximum fault current the switchgear can safely endure for a specified duration. Making capacity indicates the maximum current the switchgear can safely close onto during a fault.

Why buyers should care

These parameters are directly linked to personnel safety and equipment protection. In systems with low transformer impedance, fault currents can be extremely high, placing significant stress on switchgear.

What can go wrong in real projects

A frequent issue arises when switchgear short-circuit ratings are lower than the transformer’s prospective fault current. This mismatch may only be identified during design review or grid inspection, leading to costly redesigns.

How to check it in a datasheet

Buyers should confirm that short-circuit ratings exceed calculated system fault levels with an appropriate safety margin.

| Fault Parameter | Buyer Focus |

| Short-Time Withstand | Thermal and mechanical stress |

| Peak Withstand | Dynamic forces during faults |

| Making Capacity | Safe fault closure |

5.3 Circuit Breaker Technologies and Selection Logic

What it is

Switchgear datasheets specify the type of circuit breaker used, such as vacuum, SF6, or air circuit breakers. Each technology has distinct performance and maintenance characteristics.

Why buyers should care

Breaker selection affects maintenance intervals, environmental compliance, and long-term operating cost. Regulatory trends and site-specific conditions increasingly influence breaker technology choice.

What can go wrong in real projects

Selecting breaker technology without considering local regulations or maintenance capability can result in compliance issues or increased lifecycle cost.

How to check it in a datasheet

Buyers should verify breaker type, rated operations, and maintenance requirements.

| Breaker Type | Key Advantage | Buyer Consideration |

| Vacuum | Low maintenance | Medium voltage systems |

| SF6 | Compact design | Environmental regulation |

| Air | Simplicity | Space and maintenance |

5.4 Protection, Control, and Automation Parameters

What it is

Modern switchgear integrates protection relays, control logic, and communication interfaces. Datasheets outline protection functions and automation capabilities.

Why buyers should care

Protection and control features influence fault response time, system visibility, and integration with SCADA or energy management systems.

What can go wrong in real projects

Inadequate protection coordination can lead to unnecessary outages or delayed fault isolation.

How to check it in a datasheet

Buyers should confirm supported protection functions, communication protocols, and expandability.

5.5 Applicable Standards and Market Compliance

What it is

Standards compliance indicates which international or regional standards the switchgear meets, such as IEC, ANSI, or IEEE.

Why buyers should care

Compliance affects regulatory approval, inspection acceptance, and insurance requirements. Mismatched standards can delay commissioning.

What can go wrong in real projects

Switchgear compliant with one standard may not be accepted in markets governed by another, even if technical performance is similar.

How to check it in a datasheet

Buyers should verify applicable standards and ensure alignment with project location and utility requirements.

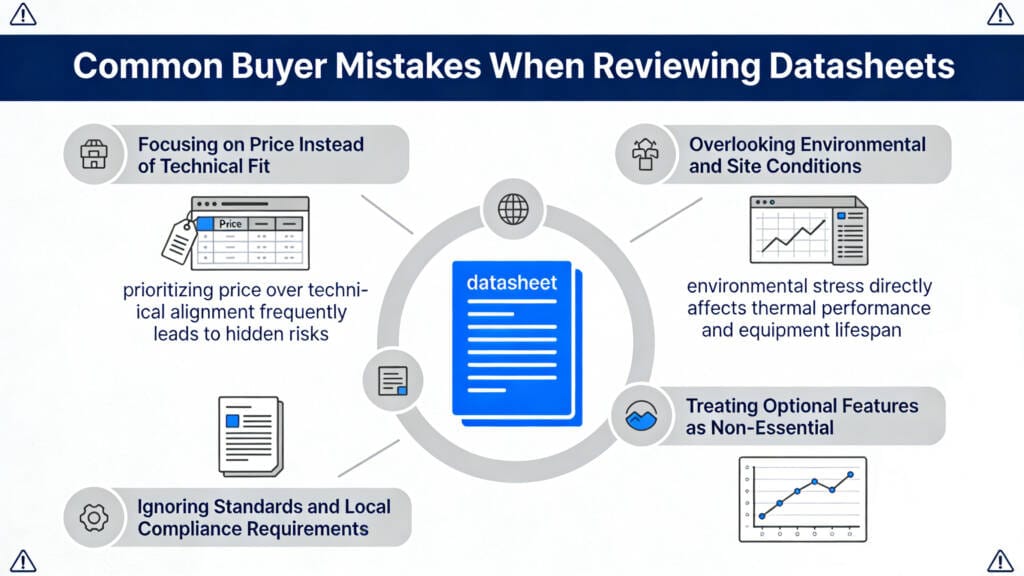

6. Common Buyer Mistakes When Reviewing Transformer Datasheet

Even well-established procurement teams and EPC contractors can make costly mistakes when reviewing transformer, substation, and switchgear datasheets. These errors rarely come from a lack of effort; instead, they are usually caused by time pressure, price-driven decision-making, or an incomplete understanding of how individual parameters interact at system level.

One of the most common issues is treating the datasheet review as a formality rather than a risk-control process. When this happens, critical details are overlooked, assumptions go unchallenged, and problems only surface during manufacturing, installation, or commissioning—when corrective actions are far more expensive.

Below are the most frequent buyer mistakes observed in real projects, along with the underlying reasons they occur.

6.1 Focusing on Price Instead of Technical Fit

Price pressure often pushes buyers to compare quotations before fully validating datasheets. While cost is an important factor, prioritizing price over technical alignment frequently leads to hidden risks.

A lower-priced transformer or switchgear may meet basic ratings but lack sufficient margin for environmental conditions, fault levels, or future expansion. These gaps typically result in higher lifecycle costs through retrofits, accelerated aging, or operational downtime.

Better practice: Always complete technical datasheet alignment before commercial comparison. A technically compliant solution provides a more reliable basis for price negotiation.

6.2 Overlooking Environmental and Site Conditions

Datasheets are based on reference conditions that may differ significantly from actual installation environments. Buyers often assume standard ambient temperature, altitude, and ventilation without verifying site realities.

This mistake is particularly common in projects located in hot climates, coastal regions, or enclosed substations, where environmental stress directly affects thermal performance and equipment lifespan.

Better practice: Cross-check site conditions against datasheet reference values and request derating calculations or design adjustments when deviations exist.

6.3 Failing to Coordinate Parameters Across Equipment

A frequent error occurs when buyers review transformer, substation, and switchgear datasheets independently. Even if each device meets its own specifications, the combined system can still present electrical mismatches.

Coordination issues often arise when transformer impedance produces fault currents that exceed the switchgear’s withstand capacity, or when protection settings fail to operate in the correct sequence.

Better practice: Review datasheets as a coordinated system, ensuring alignment of fault levels, protection logic, insulation levels, and standards.

6.4 Ignoring Standards and Local Compliance Requirements

Mixing IEC-, ANSI-, or IEEE-rated equipment without formal equivalency assessment is a common cause of inspection failure. Buyers may assume technical similarity implies regulatory acceptance, which is not always the case.

Better practice: Confirm that all major equipment complies with the same standard framework or has documented approval from local authorities or utilities.

6.5 Treating Optional Features as Non-Essential

Features labeled as “optional” in datasheets—such as temperature monitoring, communication interfaces, or arc-flash mitigation—are often excluded to reduce upfront cost. In practice, these options frequently enhance safety, reduce downtime, and simplify maintenance.

Better practice: Evaluate optional features from a lifecycle perspective, considering operational reliability and future system upgrades.

7. Procurement Checklist: Key Transformer Datasheet Parameters to Verify Before Ordering

After completing a detailed datasheet review, buyers benefit from a concise checklist that ensures no critical parameter is missed before placing an order. The checklist below summarizes the most important verification points across transformers, substations, and switchgear.

| Equipment | Key Parameters Buyers Must Verify |

| Transformer | Rated capacity, voltage levels, impedance, cooling method, insulation class |

| Substation | Configuration type, system ratings, IP rating, component integration |

| Switchgear | Short-circuit withstand rating, breaker type, protection functions |

This checklist should be used during final technical approval, supplier comparison, and internal project sign-off to reduce downstream risk.

8. How Experienced Manufacturers Support Transformer Datasheet Review

Experienced manufacturers do more than simply issue datasheets; they actively support buyers throughout the specification and review process. Their role is to translate project requirements into technically sound, compliant equipment configurations.

Typical support from experienced manufacturers includes:

- Reviewing project load profiles, site conditions, and grid requirements

- Clarifying critical parameters such as impedance, fault levels, and protection coordination

- Identifying potential mismatches between transformer, substation, and switchgear specifications

- Ensuring compliance with applicable IEC, ANSI, or regional standards

By engaging manufacturers early, buyers reduce the risk of late-stage design changes and improve overall project efficiency.

9. Conclusion: Transformer Datasheet Literacy as a Competitive Advantage

The ability to read and interpret transformer, substation, and switchgear datasheets accurately is more than a technical skill—it is a strategic advantage. Buyers who understand how parameters interact at system level are better equipped to control risk, communicate effectively with suppliers, and make informed procurement decisions.

Strong datasheet literacy leads to fewer project delays, smoother commissioning, and more reliable long-term operation. In competitive markets where margins are tight and timelines are demanding, this capability distinguishes disciplined procurement teams from reactive ones.

For EPC contractors, utilities, and industrial operators, mastering datasheet review is one of the most practical ways to improve project outcomes and build resilient power systems.

If you are planning a new project or evaluating electrical equipment, take the time to review datasheets carefully and verify all critical parameters. For guidance or professional support in interpreting transformer, substation, and switchgear datasheets, you can contact our team to ensure your procurement decisions are accurate and risk-free.