Description

As a professional 1600kVA Oil Immersed Transformer supplier and manufacturer, we provide medium voltage transformers designed for stable operation, high efficiency, and long service life. This product page presents our 1600kVA oil type transformer for industrial, utility, and EPC projects requiring reliable medium voltage distribution.

1600KVA Oil Immersed Transformer

Do you need a transformer that truly “holds up”?

It shouldn’t just be a piece of equipment—it should be the most reassuring part of your power system.

Its core value lies in addressing the four issues you care about most:

Stability – Uninterrupted power supply, uninterrupted production

Made with high-quality cold-rolled silicon steel sheets and step-lap core technology, it features low no-load loss and stable voltage output.

Even under all-day load fluctuations, it maintains efficient operation, delivering continuous and reliable power—no unexpected downtime.

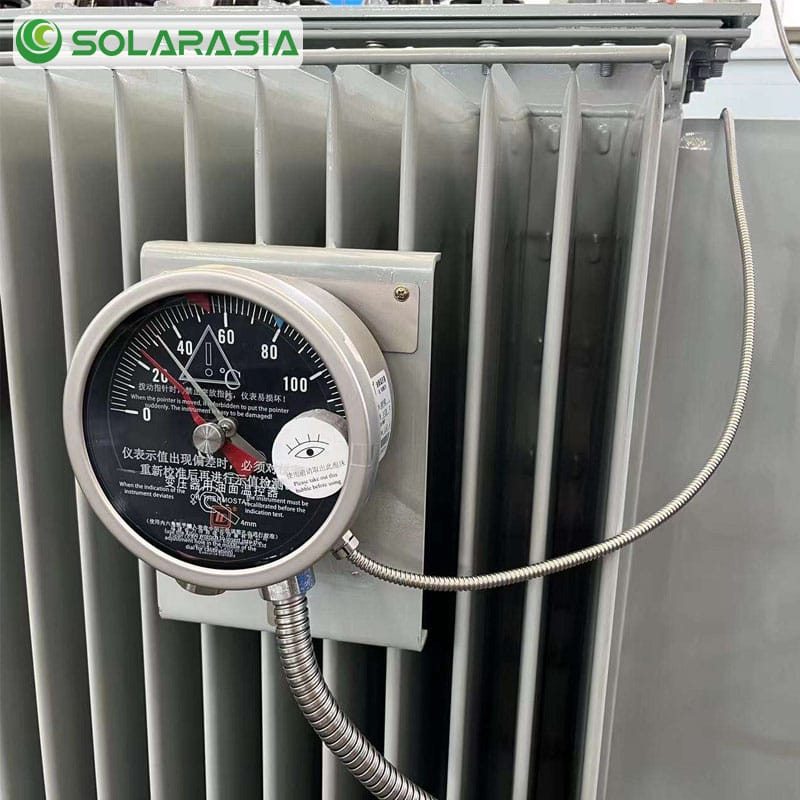

Safety – Focused protection, worry-free operation

Fully sealed tank design prevents oil leakage, moisture, and dust, suitable for outdoor and complex environments.

Equipped with built-in gas relays and pressure relief devices, it provides automatic protection in case of faults—double safety assurance.

Lifespan – Durable design, long-term investment

Insulating oil combined with vacuum impregnation technology slows insulation aging, with a design life of over 30 years.

The exterior is treated with anti-corrosion coating, and internal components are made of carefully selected materials—resistant to corrosion and high temperatures. The longer you use it, the more reliable it becomes.

After-sales Service – Professional support, always by your side

We offer technical consultation, installation guidance, and regular maintenance advice.

With 24/7 customer service response and multiple service outlets nationwide, we arrive quickly when issues arise—so you never have to wait.

We believe:

A good transformer shouldn’t always be on your mind.

It should work quietly, reliably, and consistently—and that’s exactly what our products promise.

If you’re looking for a worry-free, durable, and well-supported power partner, feel free to scroll down for more details.

We’re always here to offer you professional advice.

1600KVA Oil Immersed Transformer Process Flow Graphic

From Our Workshop to Your Site

Every Step is Designed for Your Peace of Mind

We understand what matters most to you when choosing a transformer:

“Is the quality reliable?” “Are the tests thorough?” “Will it arrive safely?” “Can it be put into use right away?”

We get it. That’s why we lay the entire process open for you—reducing your risks through stringent procedures and transparent practices.

Production Stage: Quality is Built, Not Just Inspected

Worried about inconsistent quality? Our core philosophy: control at the source, solidify during the process.

Key Component Selection

Silicon steel sheets, electromagnetic wires, insulating materials—all critical materials are sourced from top industry suppliers and undergo full inspection upon arrival. A strong “foundation” ensures a stable structure.

Winding and Assembly

Fully automatic winding equipment ensures tight and uniform coils. The core uses step-lap lamination technology to effectively reduce losses and noise. Every assembly step follows process cards and includes self-inspection—no substandard work moves forward.

Vacuum Impregnation and Sealing

This is the crucial step for longevity. Windings are thoroughly impregnated with insulating oil under vacuum to eliminate air bubbles, ensuring high insulation strength and better heat dissipation. Fully sealed welding follows, eliminating future leakage risks.

Testing Stage: Simulating Extreme Conditions, Keeping Problems to Ourselves

Concerned about superficial tests? Our principle: meeting standards is the baseline, reliability is the goal.

Factory Tests: National Standards Are the Minimum

We 100% comply with GB/T 6451 national standards and IEC international standards, conducting full tests including no-load loss, load loss, ratio, and winding resistance. Test reports accompany the product for your verification.

We Go Further: Rigorous Environmental Simulation Tests (Partial Sampling)

Temperature Rise Test: Operate at 1.1 times rated load for extended periods, monitoring hot-spot temperatures to ensure safety under normal overloads.

Lightning Impulse Simulation Test: Verify the insulation system’s ability to withstand sudden high-voltage surges, ensuring resilience in harsh grid conditions.

Partial Discharge Detection: Use high-sensitivity instruments to detect faint internal discharge signals, identifying potential insulation defects early.

“We strive to put the transformer through every extreme situation it might encounter in the future—right here in our factory.”

Shipping and Delivery Stage: Escorting It Like Precision Instrumentation

Worried about transport damage or delays? We’ve established a standardized delivery process.

Secure Packaging

Custom packaging based on transport mode (land/sea). The main unit is fixed to a wooden base with waterproof and impact-resistant casing. Key components and instruments are individually protected against vibration damage.

Status Tracking and Document Synchronization

After shipment, you’ll receive notifications with packaging photos, equipment serial numbers, and estimated arrival times. Certificates, test reports, installation manuals, warranty cards, and other documents are sent in advance for your review.

Delivery Isn’t the End—Installation Support Is

Upon arrival, we provide free remote installation guidance. If needed, we can coordinate on-site support from professional engineers to ensure smooth placement and commissioning.

We firmly believe:

The best delivery isn’t just handing over a piece of equipment—it’s delivering peace of mind.

We handle the complex process control so you can enjoy a simple, reliable experience.

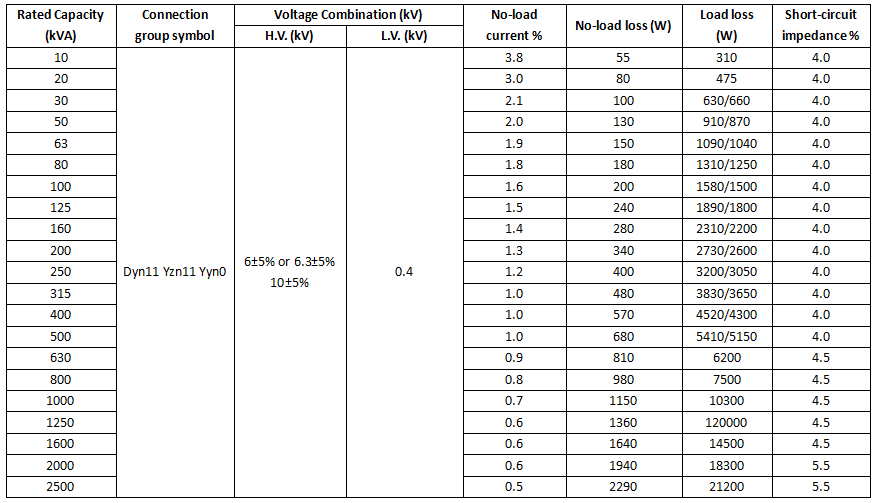

1600KVA Oil Immersed Transformer Parameters

Our Advantages

Why Choose Us?

Because We Prioritize Your Long-Term Interests

When selecting a transformer, you’re not just looking for a product that meets your immediate needs—you’re seeking a partner who can help mitigate future risks and create lasting value. This isn’t just an equipment purchase; it’s a foundational investment with long-lasting impact.

Here are our core strengths and how they deliver genuine peace of mind and tangible returns:

✅ Hassle-Free After-Sales Service | Your Dedicated Support Team is Always Ready

“The last thing you want is to be left stranded after the purchase, where minor issues turn into major headaches.”

Our Approach:

We provide 24/7 technical support and clear service commitments. Beyond standard warranties, we maintain an equipment tracking system that proactively reminds you of key maintenance milestones. With service networks in major cities nationwide, we ensure rapid response whenever needed.

Your Benefit:

A long-term, reliable “power management partner.” Faster troubleshooting, guided routine maintenance, and significantly reduced operational risks and hidden costs from unexpected downtime.

✅ Complete Professional Certifications | A Solid Backing for Your Compliance

“Incomplete certifications can lead to painful project approvals and pose risks during future audits.”

Our Approach:

Our products not only meet national standards (GB) but also hold full international certifications such as CE and ISO9001. All certification documents are complete and available for verification at any time.

Your Benefit:

Streamlined project acceptance and quality credentials that stand up to any scrutiny. You can focus on your core business without worrying about compliance issues.

✅ Robust Weather-Resistant Design | A Reliable Partner for Harsh Environments

“Concerned about outdoor installation? Worried that wind, rain, and sun will degrade performance in just a few years?”

Our Approach:

We use corrosion-resistant stainless-steel components, dual-layer sealing technology, and specialized outdoor coatings. Our designs account for extreme conditions like windblown sand, salt spray, and wide temperature ranges (-25°C to 40°C).

Your Benefit:

An “all-weather performer.” Whether installed along the coast, on plateaus, or in industrial zones, it maintains stable performance, reducing environment-related degradation and maintenance frequency.

✅ Integrated Production & Sales | Direct and Efficient Problem-Solving Channels

“Too many middlemen mean poor communication, opaque costs, and difficulty realizing custom needs.”

Our Approach:

We operate our own factory, conduct in-house R&D, and sell directly. From design to delivery, there are no intermediaries—ensuring seamless information flow.

Your Benefit:

More transparent pricing and highly efficient communication. Any technical questions or customization requests go straight to our engineers, avoiding delays and miscommunication through multiple layers.

✅ Support for Deep Customization | Solutions Truly Tailored to Your Unique Needs

“Off-the-shelf products often fail to perfectly match your site layout or special technical requirements.”

Our Approach:

Based on a modular platform, we offer flexible customization in voltage levels, interface positions, protection ratings, dimensions, and more. Our dedicated team works directly with you to translate your on-site needs into feasible design solutions.

Your Benefit:

A transformer “born for your needs.” It integrates seamlessly into your overall system, optimizes space usage, meets special process requirements, and maximizes overall efficiency.

✅ Extended Design Lifespan | Locking in Long-Term Value and Reducing Annual Costs

“If equipment fails frequently after just a few years, high repair costs can make replacement seem cheaper—driving up total cost of ownership.”

Our Approach:

We design from the outset for a lifespan exceeding 30 years. Using high-quality insulation systems, low-loss materials, and conservative temperature-rise designs, we slow aging at the root.

Your Benefit:

Minimal annual ownership costs and exceptional return on investment. This isn’t just an upfront purchase—it’s decades of stable power supply, avoiding the huge expenses and downtime of frequent replacements.

1600KVA Oil Immersed Transformer Factory Scene

Step into Our Warehouse

Every Detail is Designed to Protect Your Order

After you place an order, what matters most to you? Knowing “where is the shipment?”, “could it be sent incorrectly?”, or “might it get damaged during transit?”

— We fully understand these concerns about traceability and safe delivery. That’s why we’ve built a transparent and rigorous warehousing management system to give you peace of mind at every step.

Strict Management: Every Transformer Has Its Own “ID”

We know that standardization is the foundation of efficiency and safety.

- Clear Zoning for Effortless Oversight: We strictly separate our warehouse into dedicated areas for raw material storage, work-in-progress, finished goods inspection, and qualified shipping. This clear division ensures an orderly flow of materials and products and eliminates any potential mix-ups.

- One Unit, One File for Full Traceability: We assign every transformer a unique serial number and a dedicated record file as soon as its core components enter our warehouse. This system lets you trace key information: you can access production batches of main parts, review inspection records and factory test data, and even identify the operators involved in critical processes. We document everything to make quality fully verifiable.

- A Controlled Environment for Consistent Quality: We maintain constant temperature and humidity in our finished goods warehouse and treat the floors with special dust-prevention measures. We store every transformer on custom wooden pallets to avoid direct ground contact and cover each unit with protective shrouds. These steps ensure your equipment remains in optimal condition until we deliver it to you.

Outbound Process: Your Equipment is Fully Tracked from Warehouse to Site

We ensure every step is clear and precise:

Smart Picking & Matching: The system automatically generates picking instructions based on your order, ensuring precise location and zero errors.

Pre-Shipment Re-inspection: Before dispatch, a final check is conducted on the equipment’s appearance and all accompanying documents (packaged materials).

Professional Loading: An experienced team uses specialized tools to load the equipment and secures it carefully to prevent any damage during transit.

Real-Time Status Updates: Once loading is complete, you will receive a notification with real-time photos of the equipment, transportation vehicle details, and the estimated time of arrival.

1600KVA Oil Immersed Transformer Certifications

Global Cooperation

This final image moves beyond the product to showcase our successful relationships. It features our engineering and management team interacting with international clients. These moments often occur during factory inspections or project signings. This visual narrative builds immense credibility and trust.

It demonstrates that we are not just a factory but a reliable partner invested in long-term collaboration and client success. It assures potential customers that they will receive professional communication, project support, and a reliable partnership for their critical power infrastructure projects.

FAQ

What is a 1600kVA oil immersed transformer used for?

Used in medium voltage power distribution systems for industrial, utility, and EPC projects.

Can the 1600kVA transformer be customized?

Yes. We provide customized 1600kVA oil immersed transformers for specific project requirements.

Is it suitable for export?

Yes. Export-ready packaging and technical documentation are available.

Get a Quote for 1600kVA Oil Immersed Transformer

Contact our team today to receive technical specifications, pricing, and project support for your medium voltage transformer requirements.

Reviews

There are no reviews yet.