Description

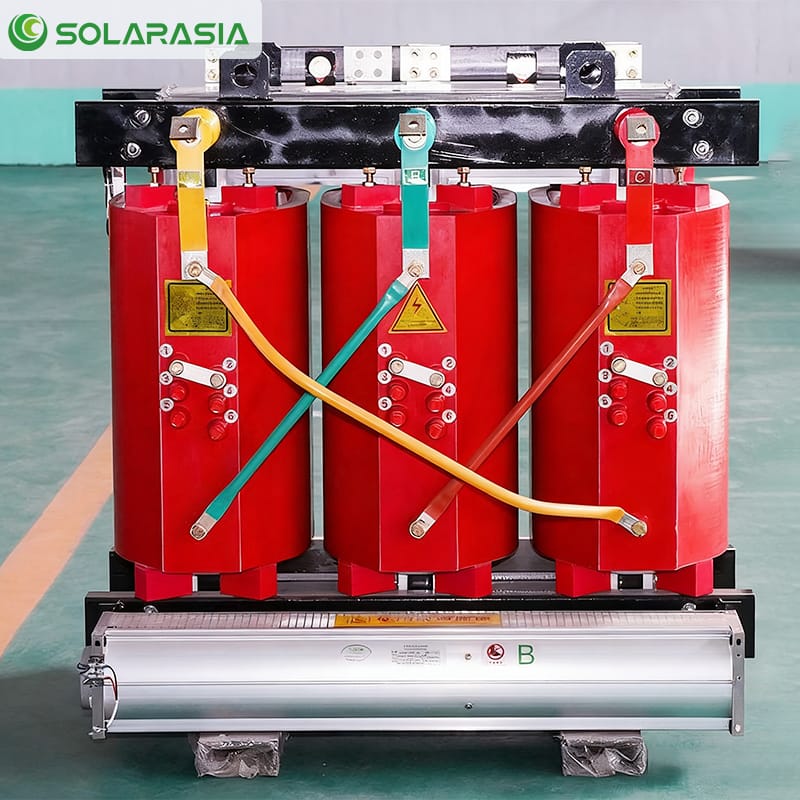

1250KVA Dry Type Transformer

Our 1250KVA dry-type transformer features a fully enclosed design with IP54 protection rating, effectively preventing dust and moisture intrusion to ensure stable operation in harsh environments. Utilizing Class H insulation materials with a temperature resistance of 180°C, it significantly extends equipment service life.

The compact structure saves installation space, making it particularly suitable for confined electrical rooms. The surface is treated with environmentally friendly coating offering excellent corrosion resistance and aesthetic appeal. Operating at below 60 dB noise level, it far exceeds national standards, creating a quiet working environment. Our transformer is especially ideal for hospitals, schools, commercial centers and other applications demanding highest safety and reliability requirements.

Detailed Photos

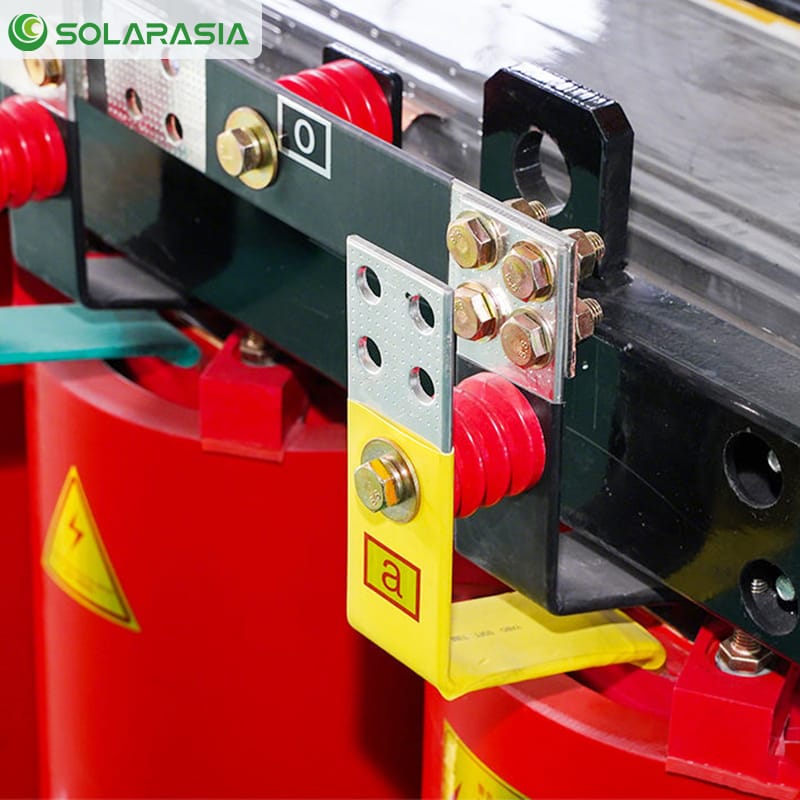

This detailed cutaway diagram reveals the transformer’s internal precision structure:

Phase A Winding: Uses 99.99% high-purity electrolytic copper conductors with vacuum pressure impregnation treatment, effectively reducing eddy current losses

Phase Connection System: Features double-layer insulation design with inter-phase isolation exceeding 3000V, ensuring safe operation

Epoxy Resin Encapsulation: Employing imported epoxy resin material with excellent thermal conductivity and mechanical strength, seismic resistance up to level 9

Copper Coil System: Nomex paper insulation, Class F insulation rating, temperature rise controlled within 80K

Cross-Flow Cooling System: Unique axial-radial composite ventilation design improves heat dissipation efficiency by 35%

These detailed design features ensure stability and efficiency during full-load operation.

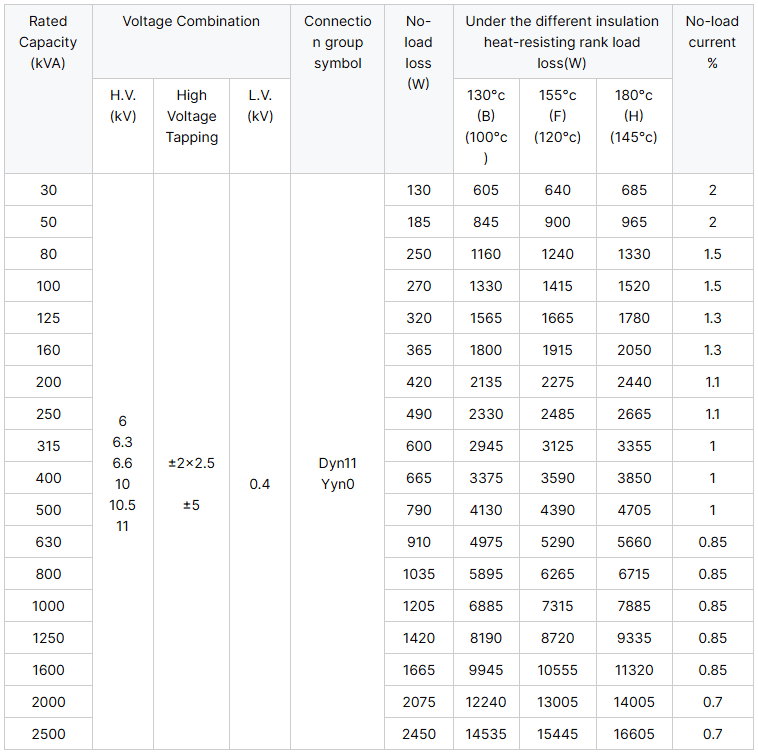

1250KVA Dry Type Transformer Parameters

Our 1250KVA dry-type transformer delivers exceptional performance parameters:

Rated Capacity: 1250kVA with short-term overload capability up to 150%

Voltage Combination: High voltage side 10kV(±2×2.5%), low voltage side 0.4kV, customizable per customer requirements

Connection Group: Dyn11, effectively suppressing harmonic interference

No-load Loss: ≤1420W, 20% lower than national standards, saving approximately $700 annually in electricity costs

Load Loss: ≤9500W (at 120°C conditions)

No-load Current: ≤0.85%, excellent magnetization characteristics

All parameters are certified by National Transformer Quality Supervision and Inspection Center, ensuring data reliability.

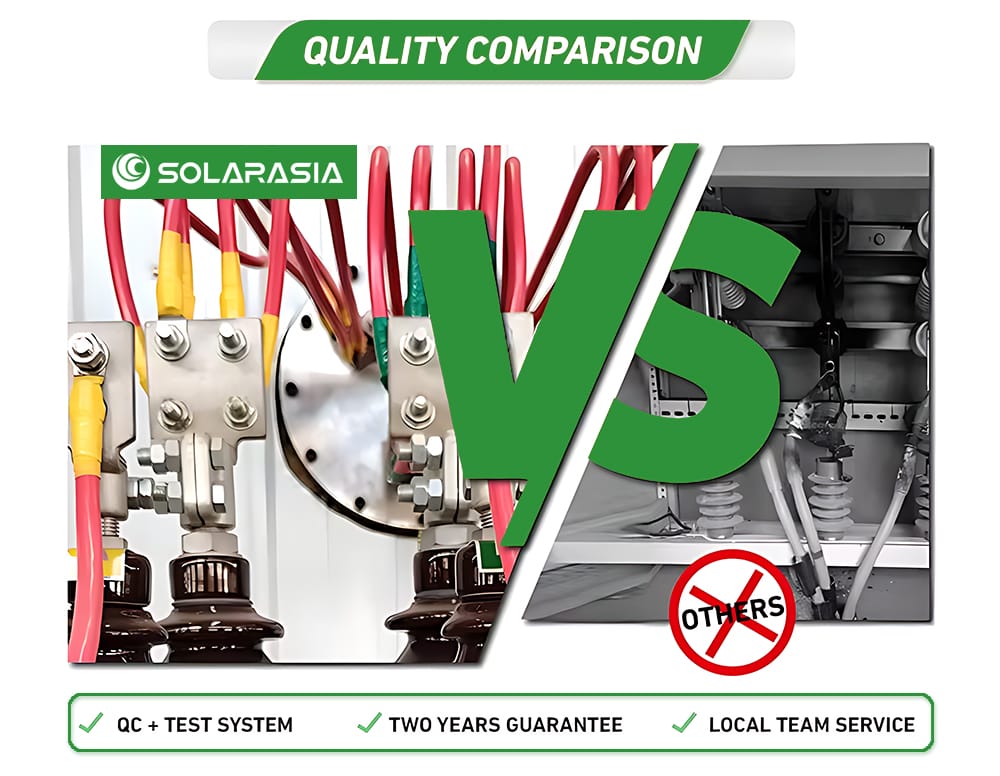

Quality Comparison

We have established a comprehensive quality assurance system:

QC Testing System: 13 quality inspection procedures including partial discharge test (≤5pC), lightning impulse test, sudden short-circuit test

Two-Year Warranty: 24-month extended warranty with lifetime maintenance, 48-hour response time for quality issues

Local Service: Service networks in 20 countries worldwide providing local technical support and parts supply

Our transformers average over 200,000 hours of trouble-free operation with failure rate below 0.5%, ensuring your complete peace of mind.

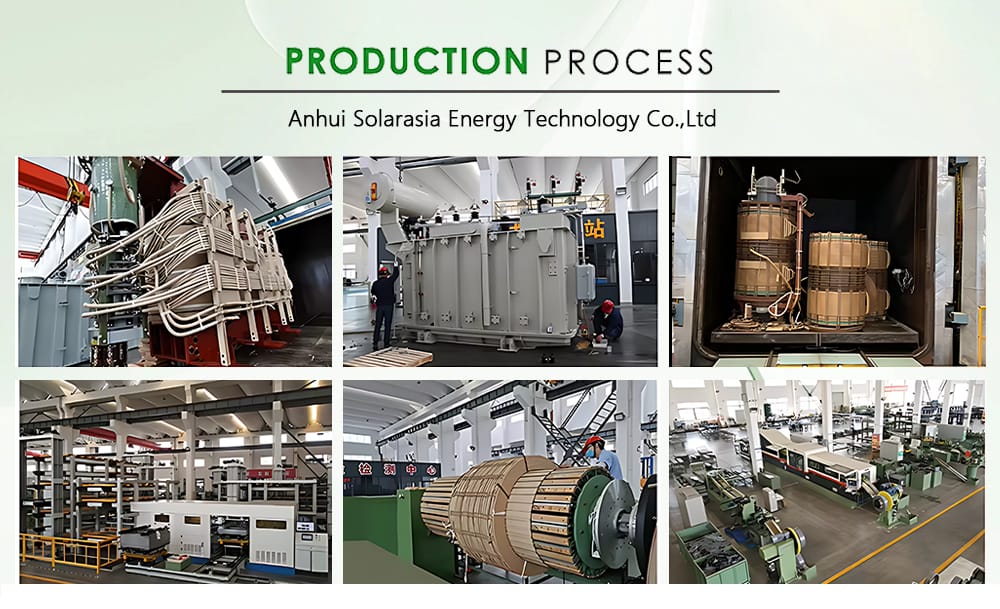

Production Process

Our manufacturing process employs advanced technology and equipment:

Winding Process: CNC numerical control winding machines with 0.1mm precision ensure winding consistency

Vacuum Casting: Epoxy resin casting in ≤5Pa vacuum environment eliminates bubble formation

Heat Treatment: Program-controlled temperature curing ovens with ±2°C temperature accuracy ensure stable insulation performance

Assembly Testing: Fully automated assembly production line with 72-hour aging test for every transformer

We strictly implement ISO9001 quality management system with quality tracking records for each production step ensuring full traceability.

Packaging & Shipping

We provide professional packaging and shipping solutions:

Shock-proof Packaging: Steel-wood structure base with internal damping materials ensures transportation safety

Moisture Protection: Built-in humidity indicator cards and desiccants for real-time monitoring

Handling Protection: Protective covers at critical points prevent damage during lifting

Global Delivery: Partnership with world-renowned logistics companies providing door-to-door service (15 days to UK, 20 days to USA, 10 days to Philippines)

We have successfully delivered products to 500+ global projects with 99.9% intact delivery rate.

1250KVA Dry Type Transformer Certifications

Global Cooperation

This photo gallery showcases our dedicated team and global partnerships behind every 1250KVA dry-type transformer. See our engineering experts with 15+ years of experience collaborating with international clients on factory acceptance tests and technical solutions.

These genuine moments demonstrate our multilingual support capabilities and commitment to building lasting relationships – not just delivering products. When you choose our transformer, you gain both superior technology and a reliable partner invested in your long-term success.

FAQ

Q1.Do you have MOQ?

The parties can reach the final agreement through negotiation, taking into account different perspectives. The larger the quantity is, the competitive the unit price will be.

Q2.Should the customer pay the delivery fee , How much is it?

We charge a delivery fee, or you provide your express account or cover the shipping cost. If you do not request, I will choose a cheap one in China.

Q3.How about the after sale service?

1)We always match the buyer’s sample quality and compensate if any quality issue occurs.

2)We will suggest our packing and take charge in our packing, we will keep the goods safe in the delivery.

3)We track goods from production to sale and resolve any issues customers face during the selling process.

Q4.When can I get a price?

We usually quote within 24 hours after we get your inquiry.

Q5: Are you a trade company or manufacturer?

We are a professional manufacturer with our own factory.

Reviews

There are no reviews yet.