Table of Contents

I. Introduction: Why Dry-Type Transformers Matter in Modern Critical Infrastructure

II. What Is a Dry Type Transformer?

III. Types of Dry Type Transformer

IV. Why Dry-Type Transformers Are Preferred in High-Rise Buildings

V. Dry-Type Transformers in Data Centers

VI. Offshore Installations and Marine Environments

VII. Dry Type vs Oil-Immersed Transformers: Practical Comparison

VIII. Dry Type Transformer Insulation and Its Impact on Performance

IX. Role of Dry Type Transformer Manufacturers

X. Common Misconceptions About Dry Transformers

XI. Typical Applications Summary

XII. Conclusion: Choosing the Right Dry-Type Transformer

I. Introduction: Why Dry-Type Transformers Matter in Modern Critical Infrastructure

In modern critical infrastructure, selecting the right solution is key. Dry Type Transformer Applications span high-rise buildings, data centers, and offshore installations. In environments such as high-rise buildings, data centers, and offshore installations, transformer selection directly impacts fire safety, system reliability, maintenance costs, and regulatory compliance. Among the available technologies, dry type transformers have become an increasingly preferred solution for these demanding applications.

So, what is a dry type transformer, and why are engineers, consultants, and EPC contractors choosing them over traditional oil-filled units? Simply put, a dry type transformer uses air or solid insulation systems instead of liquid dielectric oil, eliminating the risks associated with oil leakage, fire propagation, and environmental contamination.

As urban buildings grow taller, data centers become more power-dense, and offshore installations face stricter environmental regulations, dry transformers are no longer a niche product. They are now a strategic infrastructure component.

This article provides a deep technical and practical analysis of:

- What are dry type transformers and how they work

- Types of dry type transformer designs

- Benefits and limitations in real-world applications

- How dry type transformer insulation affects performance

- Why cast resin transformers dominate critical installations

- How to choose reliable dry type transformer manufacturers

The goal is not to promote one technology blindly, but to help decision-makers select the right transformer for the right environment.

II. What Is a Dry Type Transformer?

To understand the growing adoption of dry transformers, it is important to start with a clear technical definition.

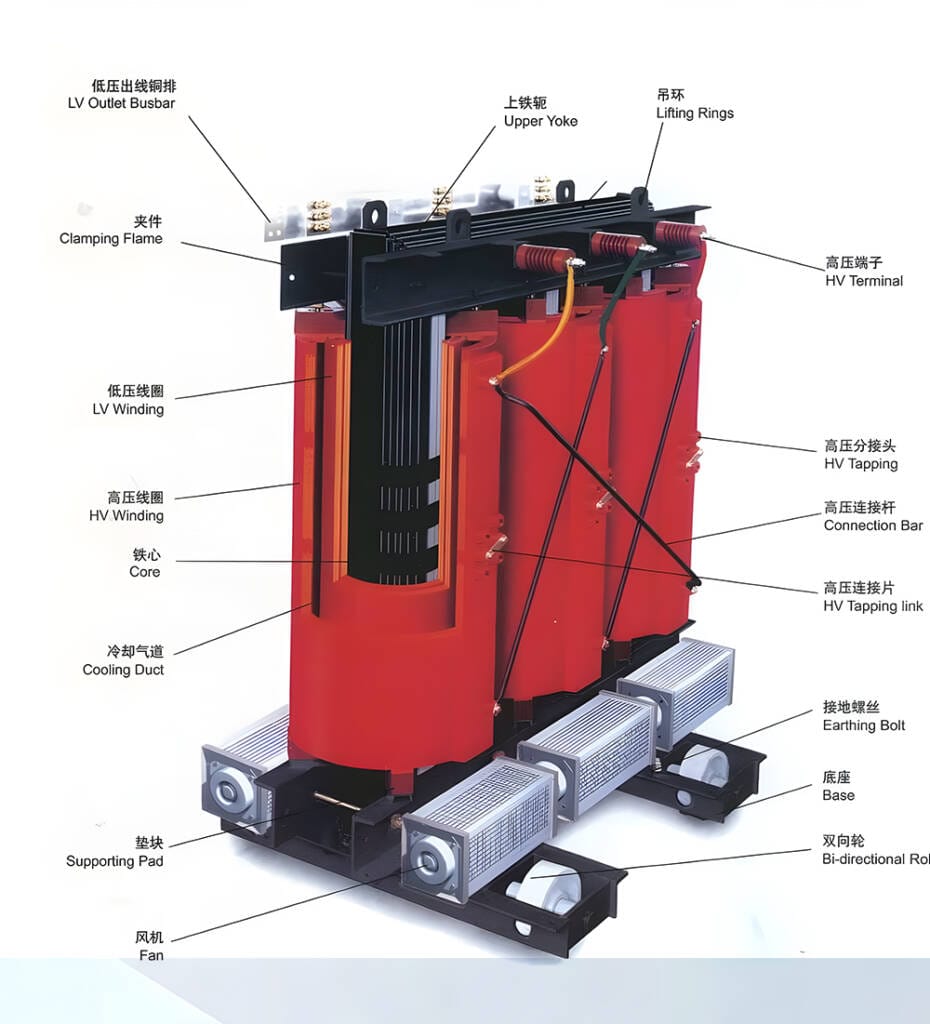

A dry type transformer is a power or distribution transformer in which the core and windings are not immersed in insulating oil. Instead, electrical insulation and thermal management rely on solid insulation materials and ambient air or forced-air cooling.

Working Principle

The fundamental electromagnetic principle is the same as any transformer:

- An alternating current in the primary winding generates a magnetic field

- The magnetic field induces voltage in the secondary winding

- Voltage transformation occurs based on turns ratio

The key difference lies in insulation and cooling.

Dry Type Transformer Insulation Systems

Dry type transformer insulation is critical to performance and longevity. Common insulation materials include:

- Epoxy resin

- Polyester resin

- Nomex paper

- Fiberglass

- Silicone-based compounds

These materials provide:

- Electrical insulation

- Mechanical strength

- Moisture resistance

- Thermal endurance

Unlike oil-filled transformers, dry type units do not rely on liquid circulation for cooling, which fundamentally changes their installation and maintenance characteristics.

III. Types of Dry Type Transformer

Understanding the different types of dry type transformer is essential for selecting the correct design for each application.

Cast Resin Transformers

Cast resin transformers are the most widely used dry type transformers in critical environments.

- Windings are encapsulated in epoxy resin under vacuum

- Excellent moisture and contamination resistance

- High mechanical strength

- Low partial discharge

These characteristics make cast resin transformers ideal for:

- High-rise buildings

- Data centers

- Hospitals

- Offshore platforms

Vacuum Pressure Impregnated (VPI) Transformers

VPI dry transformers use varnish impregnation rather than full encapsulation.

- Lower cost than cast resin

- Good thermal performance

- Less moisture resistance compared to cast resin

Often used in:

- Industrial plants

- Indoor substations with controlled environments

Open-Wound Dry Transformers

- Air-insulated windings

- Lowest cost

- Limited environmental protection

Typically applied in:

- Electrical rooms with low humidity

- Non-critical indoor installations

Dry Type Triplex Transformers

Dry type triplex transformers are commonly used in low-voltage, high-current applications, particularly in North American markets.

Key characteristics:

- Three single-phase units integrated into one assembly

- Improved load balancing

- Compact footprint

- Enhanced redundancy in certain designs

They are widely used in:

- Commercial buildings

- Data centers

- Utility distribution systems

IV. Why Dry-Type Transformers Are Preferred in High-Rise Buildings

High-rise buildings present unique electrical challenges: limited space, high occupant density, and strict fire safety codes.

Fire Safety Advantages

One of the strongest arguments for dry type transformers in high-rise buildings is fire risk reduction.

- No flammable oil

- No oil explosion risk

- Lower smoke generation

- Easier compliance with building fire regulations

In many jurisdictions, oil-filled transformers are restricted or prohibited inside tall buildings, making dry transformers the default solution.

Indoor Installation Flexibility

Dry type transformers can be installed:

- In basements

- On mechanical floors

- Close to load centers

This reduces:

- Cable length

- Voltage drop

- Power losses

Maintenance and Lifecycle Benefits

Compared to oil-filled units:

- No oil testing

- No oil replacement

- Fewer environmental inspections

- Lower long-term operational risk

Limitations in High-Rise Use

Despite their advantages, dry type transformers have limitations:

- Higher initial cost

- Larger physical size at higher ratings

- Noise management requirements

These advantages make Dry Type Transformer Applications highly suitable for high-rise building electrical rooms and mechanical floors.

V. Dry-Type Transformers in Data Centers

Data centers demand extreme reliability, making transformer selection a strategic decision.

Why Data Centers Prefer Dry Transformers

Dry type transformers are widely used in data centers because they offer:

- Improved fire safety near IT equipment

- Clean operation with no oil contamination risk

- Compatibility with indoor electrical rooms

- Easier integration with UPS systems

Thermal and Load Considerations

Data centers operate under:

- High load density

- Continuous operation

- Strict temperature control

Dry transformers must be carefully selected with:

- Adequate ventilation

- Forced air cooling if necessary

- Thermal monitoring systems

Efficiency and Redundancy

Modern dry type transformers achieve high efficiency levels and are commonly deployed in:

- N+1 redundancy configurations

- Dual-feed architectures

Limitations in Data Center Applications

- Larger footprint compared to oil-filled transformers

- Higher cost per kVA

- Cooling design complexity

When planning indoor power distribution, understanding Dry Type Transformer Applications can help engineers optimize fire safety and reliability.

VI. Offshore Installations and Marine Environments

Offshore platforms and marine installations introduce additional challenges.

Environmental and Regulatory Drivers

Offshore regulations strongly discourage oil-filled equipment due to:

- Spill risks

- Environmental damage

- Cleanup costs

Dry transformers eliminate oil leakage risks entirely.

Design Enhancements for Offshore Use

Dry type transformers used offshore often feature:

- Anti-corrosion coatings

- High IP-rated enclosures

- Moisture-resistant insulation systems

- Vibration-resistant structures

Limitations Offshore

- Higher customization cost

- Cooling challenges in sealed environments

- Transport and installation constraints

VII. Dry Type vs Oil-Immersed Transformers: Practical Comparison

| Parameter | Dry Type Transformer | Oil-Immersed Transformer |

|---|---|---|

| Fire risk | Very low | Higher |

| Indoor installation | Excellent | Restricted |

| Maintenance | Low | High |

| Environmental risk | Minimal | Oil leakage |

| Initial cost | Higher | Lower |

| Cooling efficiency | Moderate | High |

This comparison highlights why dry transformers dominate indoor and sensitive environments, while oil-filled units remain common outdoors.

VIII. Dry Type Transformer Insulation and Its Impact on Performance

Dry type transformer insulation determines:

- Thermal class

- Partial discharge levels

- Moisture resistance

- Service life

Common Thermal Classes

| Insulation Class | Max Temperature |

|---|---|

| Class F | 155°C |

| Class H | 180°C |

Cast resin transformers often use Class F or H insulation, making them suitable for continuous high-load operation.

IX. Role of Dry Type Transformer Manufacturers

Not all dry transformers are equal. The expertise of dry type transformer manufacturers directly affects:

- Product reliability

- Compliance with IEC / IEEE standards

- Long-term serviceability

What to Look for in Manufacturers

- Proven experience with cast resin transformers

- In-house testing facilities

- Customization capability

- Offshore and data center project references

- Global certification compliance

Leading cast resin transformers manufacturers invest heavily in:

- Resin formulation

- Vacuum casting technology

- Quality control systems

X. Common Misconceptions About Dry Transformers

- “Dry transformers require no maintenance”

→ Periodic inspection is still necessary - “Dry type transformers are always safer”

→ Proper design and installation are essential - “They can replace oil-filled transformers everywhere”

→ Not suitable for all outdoor high-capacity applications

XI. Typical Applications Summary

Dry type transformers are commonly used in:

- High-rise commercial buildings

- Hospitals and airports

- Data centers

- Offshore platforms

- Marine vessels

- Urban substations

XII. Conclusion: Choosing the Right Dry-Type Transformer

Understanding:

- What is a dry type transformer

- The types of dry type transformer

- Insulation systems

- Application-specific benefits and limitations

allows engineers and project owners to make informed decisions.

By working with experienced dry type transformer manufacturers, projects can achieve long-term operational stability and regulatory compliance in even the most demanding environments.

Choosing the right model requires understanding the benefits and limitations across different scenarios. Overall, Dry Type Transformer Applications are increasingly critical in modern industrial and commercial projects.