UN prefabricated box substation is transforming how power projects are delivered by significantly reducing installation time and on-site risk. Unlike traditional substations that require extensive on-site assembly, a prefabricated substation comes factory-built, fully tested, and ready for rapid deployment. This approach not only accelerates project schedules but also minimizes construction errors, making it an ideal solution for industrial, commercial, and renewable energy applications.

Table of Contents

- Introduction: Why Time and Risk Dominate Modern Power Projects

- What Is a Prefabricated Box Substation?

- How Prefabricated Box Substations Shorten Project Timelines

- How Prefabricated Box Substations Reduce On-Site Construction Risk

- Coordination & Interface Risk Reduction with Prefabricated Box Substations

- Factory Testing, Quality Control, and Compliance Assurance

- Applications Where Prefabricated Box Substations Deliver the Highest Value

- When a Prefabricated Box Substation Is the Right Choice

- How to Select a Reliable Prefabricated Box Substation Supplier

- Conclusion & Project Decision Guidance

1. Introduction: Why Time and Risk Dominate Modern Power Projects

In modern power infrastructure projects, time overruns and uncontrolled risk have become two of the most significant cost drivers. Whether the project involves renewable energy plants, industrial facilities, commercial developments, or utility grid extensions, delays in substation installation often lead to cascading consequences—missed grid connection deadlines, contractual penalties, idle equipment, and extended financing costs.

Traditionally, substations were built largely on-site, with separate suppliers delivering transformers, medium-voltage switchgear, low-voltage panels, protection systems, and enclosures. While this approach allows flexibility, it also introduces multiple layers of uncertainty. Coordination among vendors, inconsistent installation quality, weather exposure, and labor availability can significantly impact project schedules.

In response to these challenges, the prefabricated box substation has emerged as a proven solution that fundamentally changes how electrical substations are delivered. By shifting critical assembly, integration, and testing activities from the construction site to a controlled factory environment, prefabricated box substations enable project developers and EPC contractors to compress timelines, reduce risks, and improve overall project predictability.

This article explains, from an engineering and project management perspective, why prefabricated box substations reduce project time and risk, and how they support more reliable power project execution.

2. What Is a Prefabricated Box Substation?

UN prefabricated box substation is a compact, factory-assembled electrical substation in which major components are fully integrated, tested, and commissioned before delivery to site. Unlike conventional substations that require extensive on-site installation, a prefabricated box substation arrives as a largely complete system, ready for rapid installation and energization.

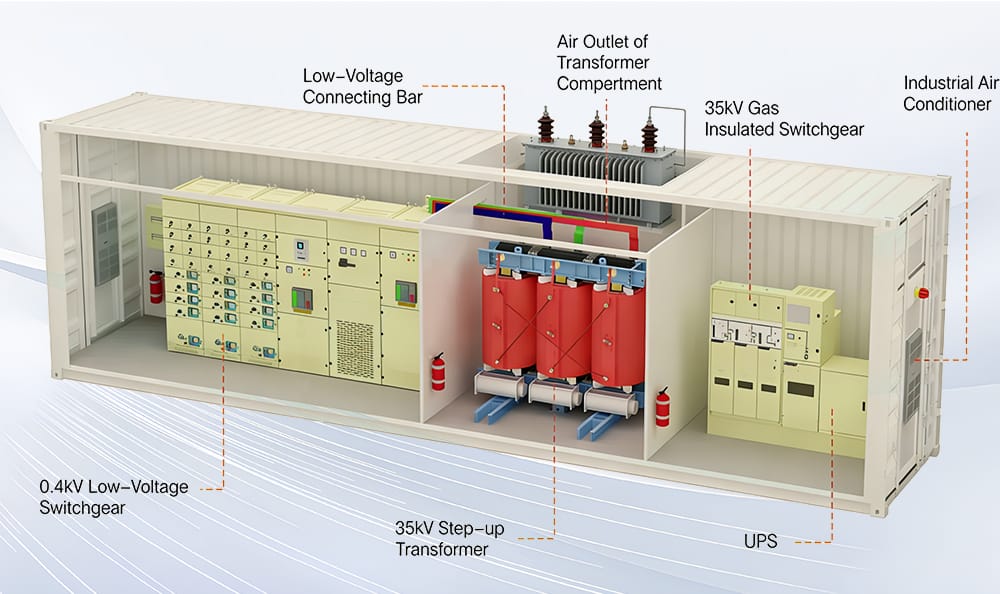

Key Components of a Prefabricated Box Substation

A typical prefabricated box substation integrates the following systems within a single enclosure or modular housing:

- Medium-voltage (MV) switchgear

- Distribution or power transformer

- Low-voltage (LV) distribution panel

- Protection, control, and metering systems

- Auxiliary systems (ventilation, lighting, fire protection)

All components are engineered to work as a unified system, reducing interface mismatches and design conflicts.

How Prefabricated Box Substations Differ from Traditional On-Site Substations

| Aspect | Traditional On-Site Substation | Prefabricated Box Substation |

|---|---|---|

| Assembly location | Mostly on-site | Factory-based |

| Installation time | Long, sequential | Short, parallel |

| Supplier coordination | Multiple vendors | Single integrated supplier |

| Quality control | Site-dependent | Factory-controlled |

| Commissioning | Extensive on-site testing | Pre-tested before delivery |

By consolidating design, manufacturing, and testing into a single workflow, prefabricated box substations dramatically simplify project execution.

3. How Prefabricated Box Substations Shorten Project Timelines

One of the most compelling advantages of a prefabricated box substation is its ability to significantly reduce total project duration. This time-saving effect is not limited to installation alone—it impacts the entire project lifecycle.

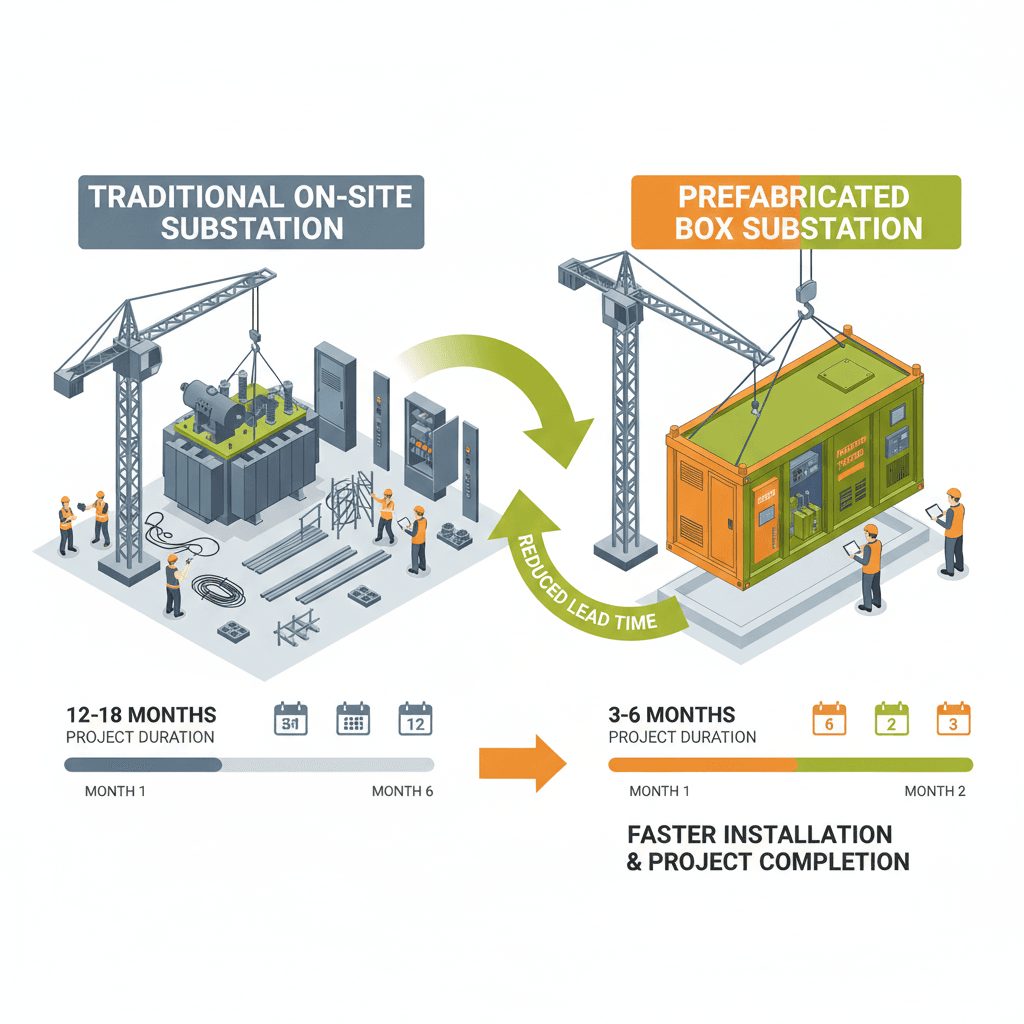

3.1 Parallel Manufacturing and Site Preparation

In conventional projects, substation installation often begins only after civil works are substantially completed. With a prefabricated box substation, equipment manufacturing and site preparation proceed in parallel.

While foundations, cable trenches, and access roads are being constructed on-site, the prefabricated box substation is simultaneously being assembled and tested in the factory. This parallel execution can shorten overall project schedules by several weeks or even months.

3.2 Reduced On-Site Installation Time

Once delivered, a compact box substation typically requires:

- Placement on foundation

- Cable termination

- External connection to MV and LV networks

Because internal wiring, equipment alignment, and system integration are already completed, on-site work is minimal compared to traditional substations.

| Installation Phase | Traditional Substation | Prefabricated Box Substation |

|---|---|---|

| Equipment mounting | Several weeks | Not required |

| Internal wiring | Extensive | Completed in factory |

| System integration | On-site | Pre-integrated |

| Total site work | Long | Significantly reduced |

3.3 Faster Commissioning and Energization

Commissioning is another critical phase where prefabricated box substations save time. Factory acceptance tests (FAT) verify protection logic, interlocking, and system performance before shipment. As a result, on-site commissioning focuses primarily on final verification rather than troubleshooting.

This approach allows projects to reach earlier energization milestones, which is particularly valuable in revenue-driven projects such as solar plants or industrial expansions.

4. How Prefabricated Box Substations Reduce On-Site Construction Risk

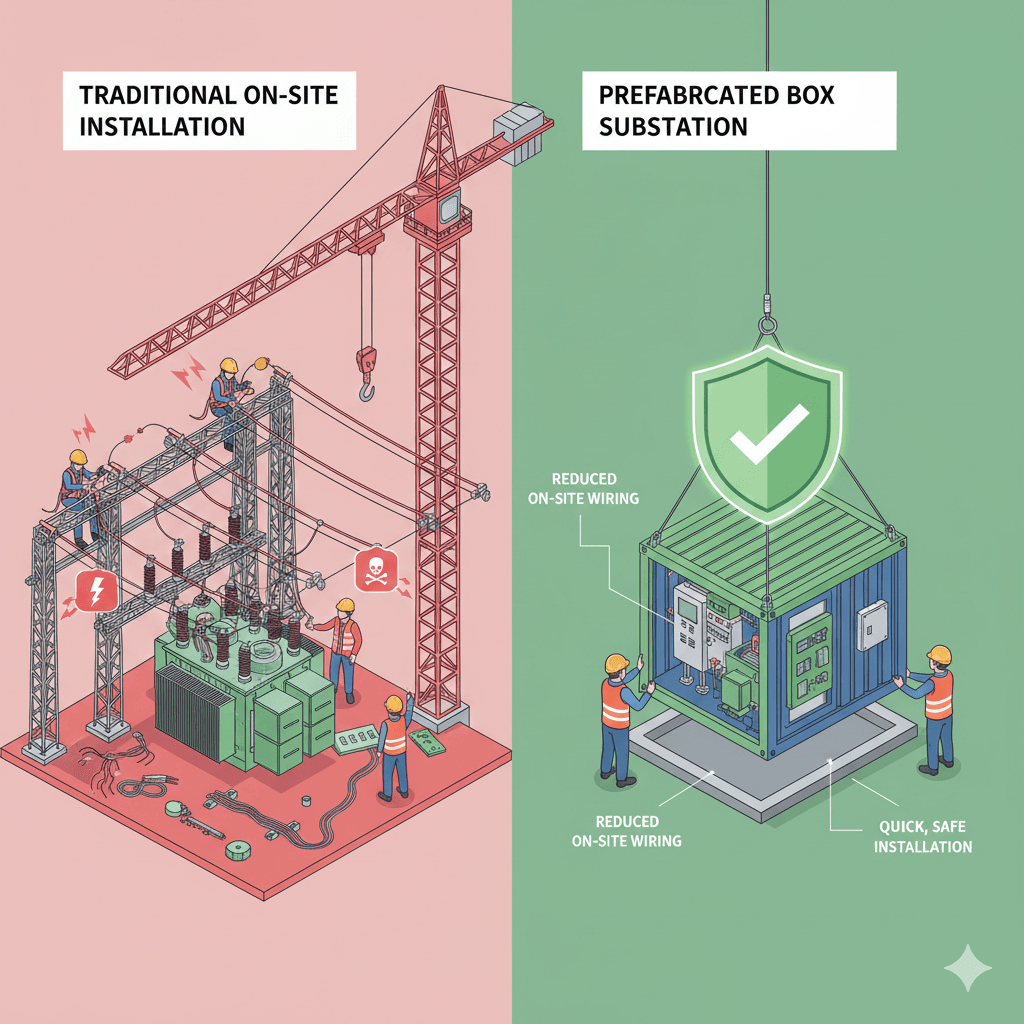

Beyond time savings, a prefabricated box substation significantly lowers construction and safety risks—a key concern for project managers and EPC contractors.

4.1 Reduced Exposure to High-Risk Electrical Work

On-site electrical installation carries inherent risks, including incorrect wiring, insulation damage, and unsafe working conditions. By relocating most electrical assembly to the factory, prefabricated box substations reduce on-site exposure to high-voltage work.

This shift improves overall site safety performance and reduces the likelihood of costly accidents or rework.

4.2 Lower Dependence on Skilled Local Labor

In many regions, access to experienced electrical technicians can be limited or unpredictable. Prefabricated box substations minimize dependence on local labor by delivering a ready-to-install system, ensuring consistent quality regardless of site location.

4.3 Reduced Weather and Environmental Impact

Weather-related delays are a common cause of project overruns. Rain, extreme temperatures, and dust can all disrupt on-site electrical installation. Factory assembly of prefabricated box substations eliminates these variables, enabling reliable schedules independent of local environmental conditions.

5. Coordination & Interface Risk Reduction with Prefabricated Box Substations

5.1 Single-Supplier Responsibility

One of the most underestimated risks in substation projects is interface responsibility. When multiple suppliers are involved, determining accountability for faults or delays can become complex.

A prefabricated box substation is typically supplied as a turnkey solution, meaning a single manufacturer is responsible for system design, integration, and testing. This single-point responsibility simplifies communication and reduces contractual disputes.

5.2 Factory-Verified System Compatibility

Interface mismatches between switchgear, transformers, and protection systems are a common cause of commissioning delays. In a prefabricated box substation, all interfaces are validated in the factory, ensuring seamless operation upon installation.

| Risk Type | Traditional Approach | Prefabricated Box Substation |

|---|---|---|

| Interface mismatch | High | Low |

| Responsibility clarity | Fragmented | Clear |

| Design consistency | Variable | Controlled |

6. Factory Testing, Quality Control, and Compliance Assurance

Quality assurance is central to the value proposition of a prefabricated box substation. Factory-controlled assembly allows for standardized processes, documented inspections, and repeatable quality outcomes.

6.1 Factory Acceptance Testing (FAT)

FAT verifies that the prefabricated box substation meets technical specifications, protection requirements, and applicable standards before shipment. Typical FAT activities include:

- Electrical continuity checks

- Protection relay testing

- Functional interlocking verification

- Insulation and dielectric tests

6.2 Compliance with International Standards

Prefabricated box substations are typically designed in accordance with IEC standards and relevant local grid codes. Factory testing ensures compliance before deployment, reducing approval risks during grid connection.

7. Applications Where Prefabricated Box Substations Deliver the Highest Value

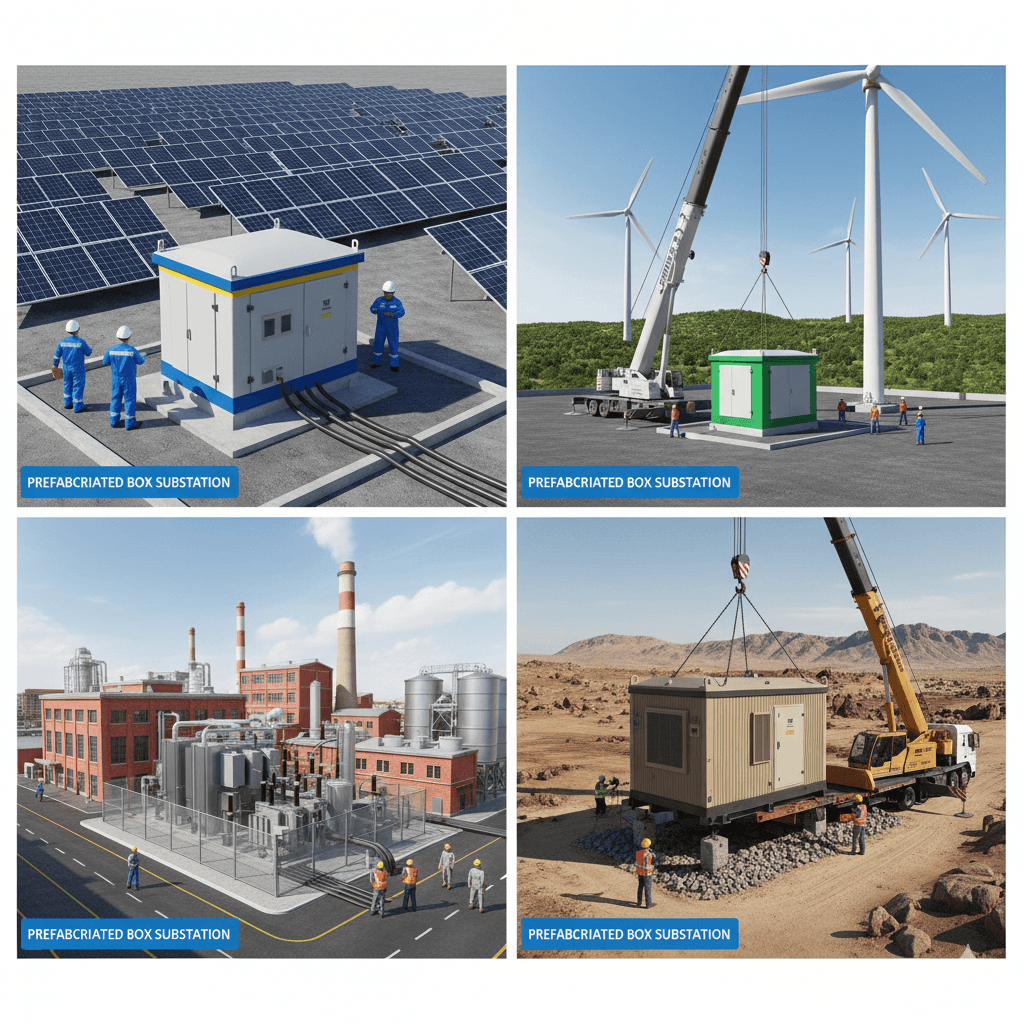

While a prefabricated box substation can be applied across a wide range of power distribution scenarios, its value becomes particularly evident in projects where time constraints, risk exposure, and coordination complexity are high.

Understanding where prefabricated box substations deliver the greatest impact helps project owners and EPC contractors make informed decisions during the early planning stage.

7.1 Renewable Energy Projects (Solar, Wind, BESS)

Renewable energy projects are highly sensitive to schedule delays. Grid connection deadlines, feed-in tariffs, and power purchase agreements (PPAs) are often strictly time-bound. A delayed substation can postpone revenue generation for months.

Prefabricated box substations align well with renewable energy project requirements due to:

- Short installation timelines

- Standardized yet customizable designs

- Easy transportation to remote locations

Engineers commonly use prefabricated box substations in solar power plants for step-up transformation and power collection networks, enabling rapid deployment across large sites.

7.2 Industrial Plants and Manufacturing Facilities

Industrial facilities prioritize power reliability and predictable commissioning schedules. Unplanned delays during electrical infrastructure installation can disrupt production planning and capital investment timelines.

A prefabricated box substation provides:

- Predictable delivery and installation schedules

- Reduced interference with other construction activities

- Lower commissioning risk before plant startup

For industries such as mining, oil & gas, and heavy manufacturing, prefabricated box substations also offer robust enclosure designs suitable for harsh environments.

7.3 Commercial and Infrastructure Projects

Commercial buildings, data centers, and infrastructure projects often operate under tight construction windows and complex stakeholder coordination. Electrical infrastructure delays can cascade across multiple trades.

Prefabricated box substations help simplify these projects by minimizing on-site electrical work and reducing coordination requirements between contractors.

7.4 Overseas and Remote Projects

Projects in remote or overseas locations face additional challenges, including labor shortages, logistics complexity, and regulatory uncertainty. Prefabricated box substations reduce on-site dependency by delivering a factory-tested, ready-to-install system.

| Application Type | Key Challenge | Prefabricated Box Substation Advantage |

|---|---|---|

| Solar plants | Grid deadline pressure | Fast installation |

| Industrial plants | Startup risk | Predictable commissioning |

| Infrastructure | Multi-trade coordination | Reduced site work |

| Remote projects | Labor & logistics | Factory-assembled solution |

8. When Is a Prefabricated Box Substation the Right Choice?

While prefabricated box substations offer clear advantages, they are not a universal solution. Understanding when to choose a compact substation—and when not to—enhances project credibility and aligns with EEAT principles.

8.1 Ideal Conditions for Prefabricated Box Substations

A prefabricated box substation is particularly suitable when:

- Project timelines are compressed

- On-site skilled labor is limited or costly

- Environmental conditions are challenging

- Interface coordination risks are high

- Predictable commissioning is required

In such scenarios, the reduction in project time and risk often outweighs any initial cost premium.

8.2 Scenarios Where Traditional Substations May Be More Appropriate

Prefabricated box substations may not be ideal in projects that require:

- Extremely large or highly customized layouts

- Future expansion beyond modular limits

- Continuous on-site design changes

By openly addressing these limitations, project stakeholders demonstrate a realistic and professional evaluation approach.

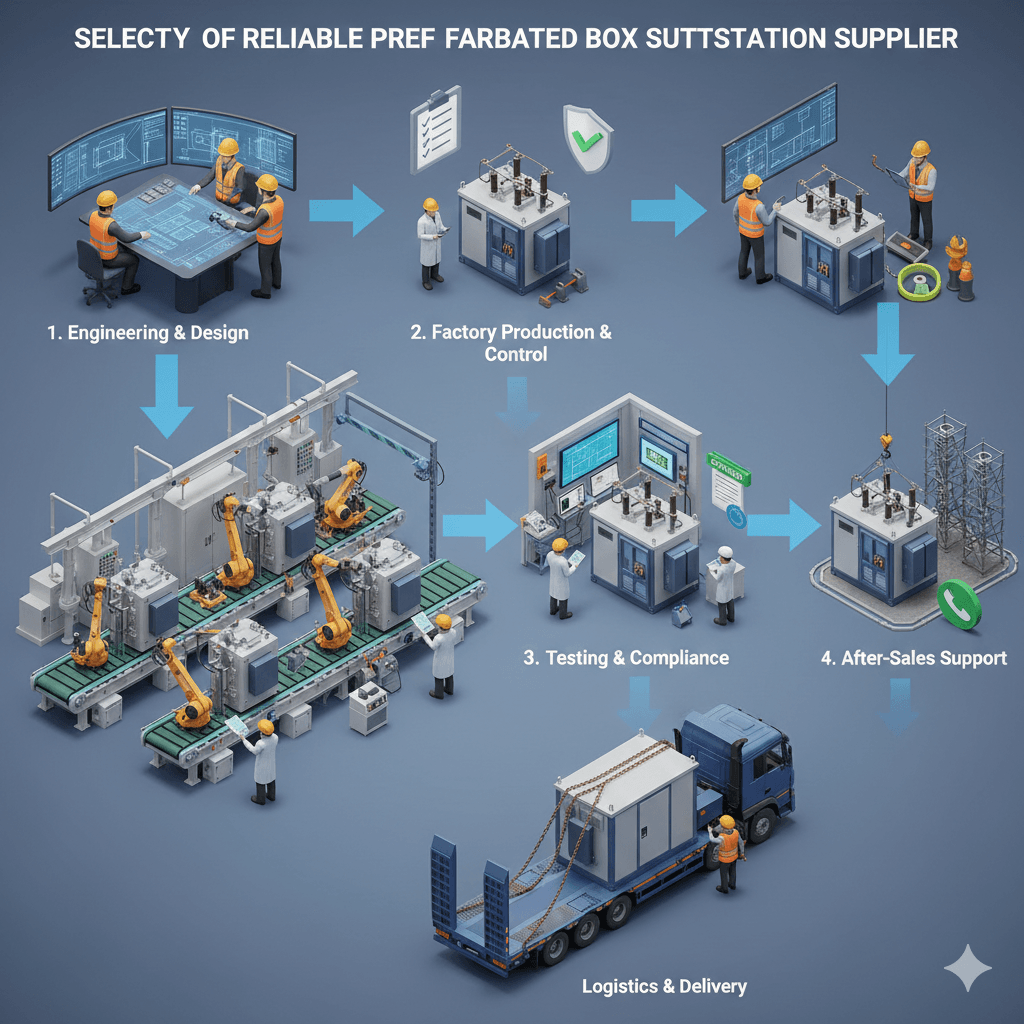

9. How to Select a Reliable Prefabricated Box Substation Supplier

Supplier selection plays a decisive role in realizing the full benefits of a prefabricated box substation. A poorly executed prefabrication strategy can negate the intended time and risk advantages.

9.1 Engineering and Design Capability

A reliable supplier should demonstrate:

- Proven experience in prefabricated box substation design

- Ability to customize layouts and ratings

- Familiarity with local grid requirements

Engineering expertise ensures that the prefabricated box substation integrates seamlessly with the overall power system.

9.2 Manufacturing and Quality Control Systems

Factory capability directly impacts delivery reliability and system quality. Look for suppliers with:

- Standardized manufacturing processes

- Documented quality inspections

- In-house testing facilities

These elements support consistent performance and reduce post-installation issues.

9.3 Testing, Certification, and Compliance

A trustworthy prefabricated box substation supplier should provide:

- Comprehensive FAT documentation

- Compliance with IEC and relevant local standards

- Clear traceability of components

These factors are critical for grid approval and long-term operational reliability.

9.4 Delivery, Logistics, and After-Sales Support

Global project execution requires robust logistics planning and responsive after-sales support. Suppliers experienced in international delivery can significantly reduce logistical risks.

| Supplier Evaluation Area | Key Considerations |

|---|---|

| Engineering | Customization & system integration |

| Manufacturing | Process control & capacity |

| Testing | FAT & compliance documentation |

| Logistics | Global delivery experience |

| Support | Technical & after-sales service |

10. Conclusion: Reducing Project Time and Risk Through Smart Substation Design

The shift toward prefabricated box substations reflects a broader transformation in power project delivery—from fragmented, site-dependent construction to integrated, factory-driven solutions.

- Shorter project timelines

- Lower construction and coordination risk

- Improved quality consistency

- More predictable commissioning outcomes

For project developers, EPC contractors, and industrial power users, selecting a prefabricated box substation is not merely an equipment choice—it is a project management strategy that enhances control, reliability, and return on investment.

If your project requires faster deployment, lower installation risk, and reliable power infrastructure, a prefabricated box substation may be the optimal solution.

Contact our engineering team to discuss a customized prefabricated box substation designed to meet your project timeline, technical requirements, and compliance standards.