As a transformer manufacturing company focused on international markets, our 2026 annual meeting provided an opportunity to review operational performance, product quality progress, and team coordination behind overseas transformer projects. Beyond a yearly summary, the meeting reflected how manufacturing discipline, engineering standards, and people development work together to support reliable transformer and substation deliveries for global customers.

Table of Contents

- Introduction: Purpose of the 2026 Annual Meeting

- Review of 2025 Overseas Transformer Projects

- Our Team and Manufacturing Expertise

- Quality Control and Testing Systems

- Export Standards and Compliance for Global Markets

- Insights from Overseas Customer Feedback

- Key Discussion Topics from the 2026 Annual Meeting

- Plans for Supporting Global Projects in 2026

- Conclusion: Commitment to Long-Term Cooperation

1. Introduction: Purpose of the 2026 Annual Meeting

The 2026 annual company meeting was held as a structured internal review focused on improving the way our transformer manufacturing company supports overseas customers. Rather than serving as a ceremonial event, the meeting brought together engineering, quality, production, and export coordination teams to evaluate processes that directly affect transformer performance, delivery reliability, and project communication.

For international customers, consistency and accountability are as important as product specifications. This annual meeting allows us to review operational experience, identify risks, and align our teams around the shared goal of delivering reliable power transformer solutions for global projects.

2. Review of 2025 Overseas Transformer Projects

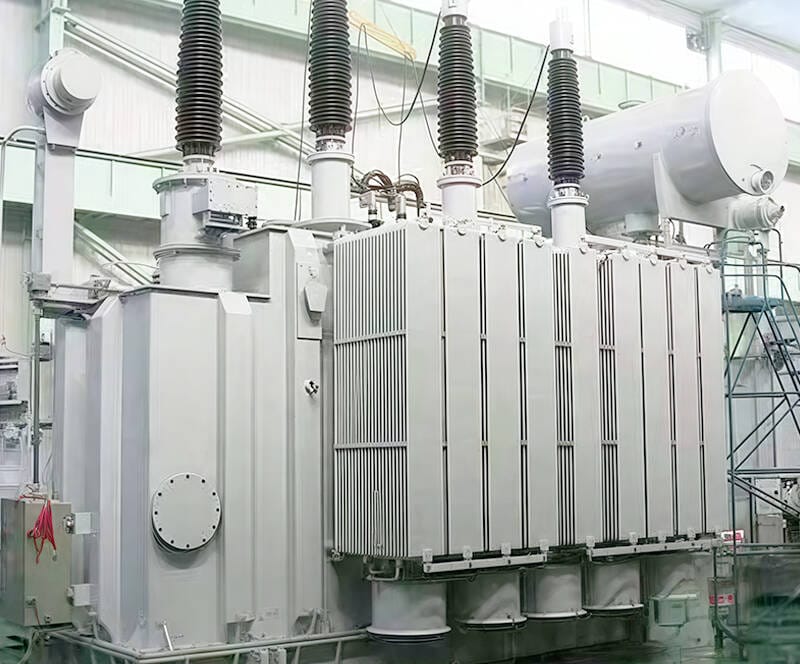

During the meeting, we reviewed transformer export projects completed in 2025 across different regions and application scenarios. These projects involved a range of power transformer products, including oil immersed transformers for utility distribution, dry type transformers for indoor industrial facilities, and prefabricated box type substations for compact power solutions.

Instead of focusing on sales volume, the discussion emphasized project execution quality, delivery coordination, and technical alignment with customer requirements. As a transformer manufacturing company serving overseas markets, each project provides practical feedback that helps refine design assumptions, production planning, and export logistics.

Typical Project Applications Reviewed

| Application Type | Transformer Products Involved | Key Focus Areas |

|---|---|---|

| Utility power distribution | Oil immersed power transformers | Stability, IEC compliance |

| Industrial facilities | Dry type transformers | Safety, thermal performance |

| Renewable energy projects | Step-up transformers | Grid compatibility |

| Compact substations | Box type substations | Space efficiency, delivery |

3. Our Team and Manufacturing Expertise

Reliable transformer delivery depends on more than equipment; it depends on people and defined responsibilities. One of the core topics of the annual meeting was cross-department coordination within our transformer manufacturing company.

Our engineering team focuses on transformer selection, thermal design, and standard compliance. The production team ensures process consistency and material control, while the quality inspection team verifies performance through structured testing. Export coordination specialists manage documentation, packaging, and transportation planning to support long-distance delivery.

This clear division of responsibility helps overseas customers communicate efficiently and reduces misunderstandings during project execution.

4. Quality Control and Testing Systems

Quality assurance remains a central pillar of our manufacturing process. During the meeting, we reviewed routine testing data and factory inspection experience related to different transformer product categories, including distribution transformers, power transformers, and packaged substation equipment.

As an experienced transformer manufacturing company, we implement structured routine and type testing procedures for oil immersed transformers, dry type transformers, and prefabricated substations. These processes are aligned with recognized IEEE transformer standards, helping ensure consistent performance, regulatory compliance, and smoother project acceptance for international customers.

Core Quality Control Measures

| Quality Stage | Purpose | Related Transformer Products |

| Incoming material inspection | Verify core, winding, and insulation materials | All transformer types |

| Routine tests | Confirm electrical and thermal parameters | Power & distribution transformers |

| Pre-shipment inspection | Final verification before delivery | Transformers & substations |

This structured approach supports consistent quality across different transformer ratings and applications.

5. Export Standards and Compliance for Global Markets

Another key topic at the 2026 annual meeting was international standard compliance. Overseas transformer projects often involve region-specific technical and documentation requirements, which must be addressed during the manufacturing and export stages.

Our transformer manufacturing company primarily aligns with IEC standards, while also adapting to local grid codes and project specifications. Documentation accuracy, nameplate information, and testing reports were reviewed as part of the export compliance discussion to ensure smoother customs clearance and site acceptance.

6. Insights from Overseas Customer Feedback

Customer feedback collected from overseas projects in 2025 was analyzed during the meeting. The discussion focused on practical aspects such as technical response speed, clarity of drawings, and delivery coordination rather than promotional metrics.

This feedback provides direct insight into how our transformer manufacturing company can better support EPC contractors, utilities, and distributors. Identified improvement areas were documented and integrated into internal workflow updates for 2026.

7. Key Discussion Topics and On-Site Sessions from the 2026 Annual Meeting

In addition to technical and operational reviews, the 2026 annual meeting included several structured on-site sessions designed to strengthen organizational alignment and execution capability.

- Management summary address: Senior management reviewed overall performance, key risks identified in overseas transformer projects, and priorities for quality, delivery, and customer communication in 2026.

- Outstanding employee recognition: Employees demonstrating strong performance in engineering support, quality control, and export coordination were formally recognized. This reflects the company’s emphasis on accountability and responsibility in project execution.

- Experience sharing sessions: Awarded employees shared practical experience related to transformer testing, documentation accuracy, and cross-department cooperation, helping standardize best practices across teams.

The meeting also included team-building activities such as performances and interactive sessions, designed to enhance internal collaboration and communication efficiency and support smoother coordination for overseas customer projects.

These combined discussions and activities aim to reduce uncertainty for customers and improve overall project predictability.

8. Plans for Supporting Global Projects in 2026

Based on the conclusions of the annual meeting, our transformer manufacturing company defined several priorities for 2026, focusing on customer-facing improvements across core transformer product lines.

These plans cover oil immersed transformers, dry type transformers, and box type substations used in utility, industrial, and renewable energy projects.

2026 Support Priorities

| Focus Area | Planned Improvement | Applicable Products |

| Technical support | Faster selection guidance and clearer drawings | Power & distribution transformers |

| Production planning | Improved schedule transparency | Oil immersed transformers |

| Export packaging | Enhanced protection solutions | Transformers & substations |

| Communication | Clearer responsibility assignment | All product categories |

These measures are designed to support long-term cooperation with overseas partners.

9. Conclusion: Commitment to Long-Term Cooperation

The 2026 annual company meeting reinforced our commitment to operating as a reliable transformer manufacturing company for global customers. We review real project experience and strengthen quality systems. Our teams align around customer needs to support overseas transformer and substation projects.

We welcome continued cooperation with international partners. We remain focused on delivering reliable transformer solutions on time.