1. Introduction: Why Transformer Capacity Planning Matters in a Growing Power System

Transformer capacity planning is no longer a purely technical calculation performed at the design stage. In modern power systems, it has become a long-term strategic decision that directly affects reliability, operational cost, and future expansion flexibility. Many transformer failures, premature replacements, and system bottlenecks are not caused by manufacturing defects, but by poor alignment between transformer capacity and actual load growth over time. Many early-stage design issues can be avoided by following a structured transformer sizing and selection guide, especially when long-term load growth is expected.

In practice, electrical loads rarely remain static. Industrial facilities expand production lines, commercial buildings add new equipment, and renewable energy systems introduce new power flow patterns. When transformer capacity planning is based only on current demand, the result is often either undersizing—leading to overheating, reduced lifespan, and forced upgrades—or oversizing, which increases initial investment and reduces efficiency under low-load operation.

This article provides a practical, engineering-oriented guide to transformer capacity planning with load growth in mind. Instead of focusing on isolated sizing formulas, it explains how to evaluate load development trends, define an appropriate planning horizon, and select transformer capacity that balances present needs with future uncertainty. The goal is to help engineers, project planners, and decision-makers avoid costly redesigns while maintaining system reliability throughout the transformer’s service life. Transformer overheating and accelerated insulation aging are well documented in international standards such as IEC 60076 transformer loading standard.

Table of Contents

- Introduction: Why Transformer Capacity Planning Matters in a Growing Power System

- What Is Transformer Capacity Planning?

- Understanding Load Growth in Electrical Systems

- Key Data Required for Effective Transformer Capacity Planning

- Key Factors in Transformer Capacity Planning

- Transformer Capacity Calculation with Load Growth Considered

- Common Transformer Capacity Planning Mistakes

- Standard vs Oversized Transformers in Capacity Planning

- Transformer Capacity Planning by Application

- Planning for Future Expansion and System Flexibility

- Working with a Transformer Supplier in Capacity Planning

- Conclusion: Reducing Long-Term Risk Through Smart Transformer Capacity Planning

- Frequently Asked Questions on Transformer Capacity Planning

2. What Is Transformer Capacity Planning?

2.1 Definition and Scope of Transformer Capacity Planning

Transformer Rating Selection refers to the systematic process of determining transformer rated capacity based on both current electrical demand and anticipated future load growth. Unlike basic transformer sizing, which often focuses on meeting immediate peak load requirements, capacity planning considers how the load profile will evolve over a defined period—typically 10, 15, or even 20 years.

Effective transformer capacity planning includes several interrelated factors:

- Present load demand and peak operating conditions

- Expected load growth rate and expansion phases

- Environmental and installation conditions

- Transformer cooling method and permissible overload capability

- Asset lifespan and replacement strategy

By integrating these elements, Transformer Rating Selection ensures that the selected transformer operates within acceptable thermal limits while maintaining sufficient margin for future growth.

2.2 Transformer Capacity Planning vs. Simple Transformer Sizing

A common misconception is that Transformer Rating Selection is simply a more conservative version of transformer sizing. In reality, the two serve different purposes. Transformer sizing answers the question: “What capacity is required to safely supply today’s load?” Capacity planning, on the other hand, asks: “What capacity will continue to perform reliably as the load increases over time?”

For example, a transformer sized exactly to match current demand may comply with standards at commissioning but become overloaded within a few years as load increases. Conversely, capacity planning evaluates whether selecting the next standard rating—or designing for parallel operation—will reduce long-term risk and total ownership cost.

3. Understanding Load Growth in Electrical Systems

Load growth is the central variable in transformer capacity planning. Accurately understanding how and why loads increase is essential for selecting a transformer that remains suitable throughout its intended service life.

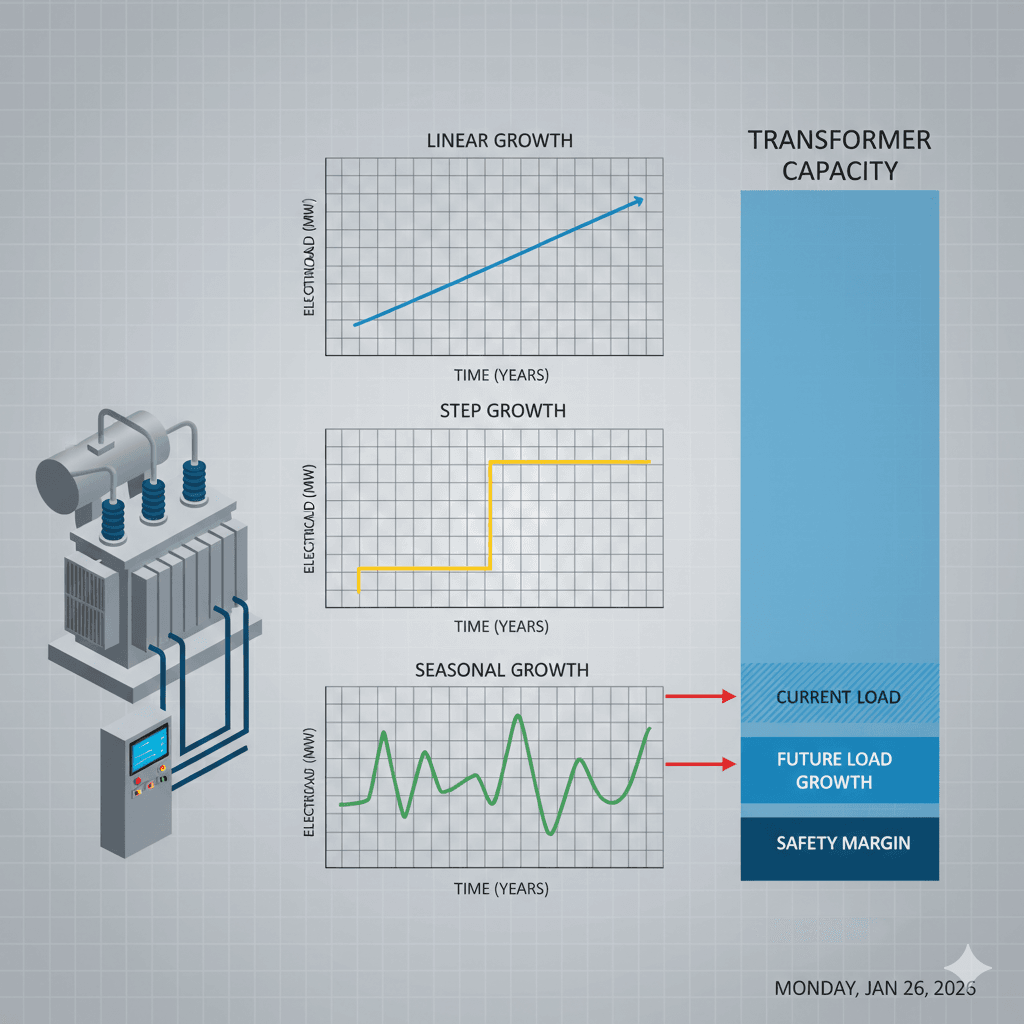

3.1 Types of Load Growth

Electrical load growth generally falls into three main categories:

Gradual Load Growth This type of growth occurs steadily over time, often driven by incremental increases in production, occupancy, or equipment utilization. Industrial plants and commercial facilities commonly experience annual load growth rates between 2% and 5%.

Step Load Growth Step growth happens when major equipment or new facilities are added in a short period. Examples include installing additional production lines, large motors, or fast-charging infrastructure. Step growth is often underestimated during initial transformer capacity planning.

Uncertain or Variable Growth Renewable energy integration, energy storage systems, and changes in operational strategy can create unpredictable load patterns. In these cases, Transformer Rating Selection must account for uncertainty and operational flexibility rather than fixed forecasts.

3.2 Why Load Growth Is Often Underestimated

Underestimating load growth is one of the most common causes of transformer capacity mismatch. This typically happens for several reasons:

- Planning focuses on immediate budget constraints rather than long-term operation

- Expansion plans are incomplete or uncertain during early project stages

- Conservative growth assumptions are used to minimize initial capital cost

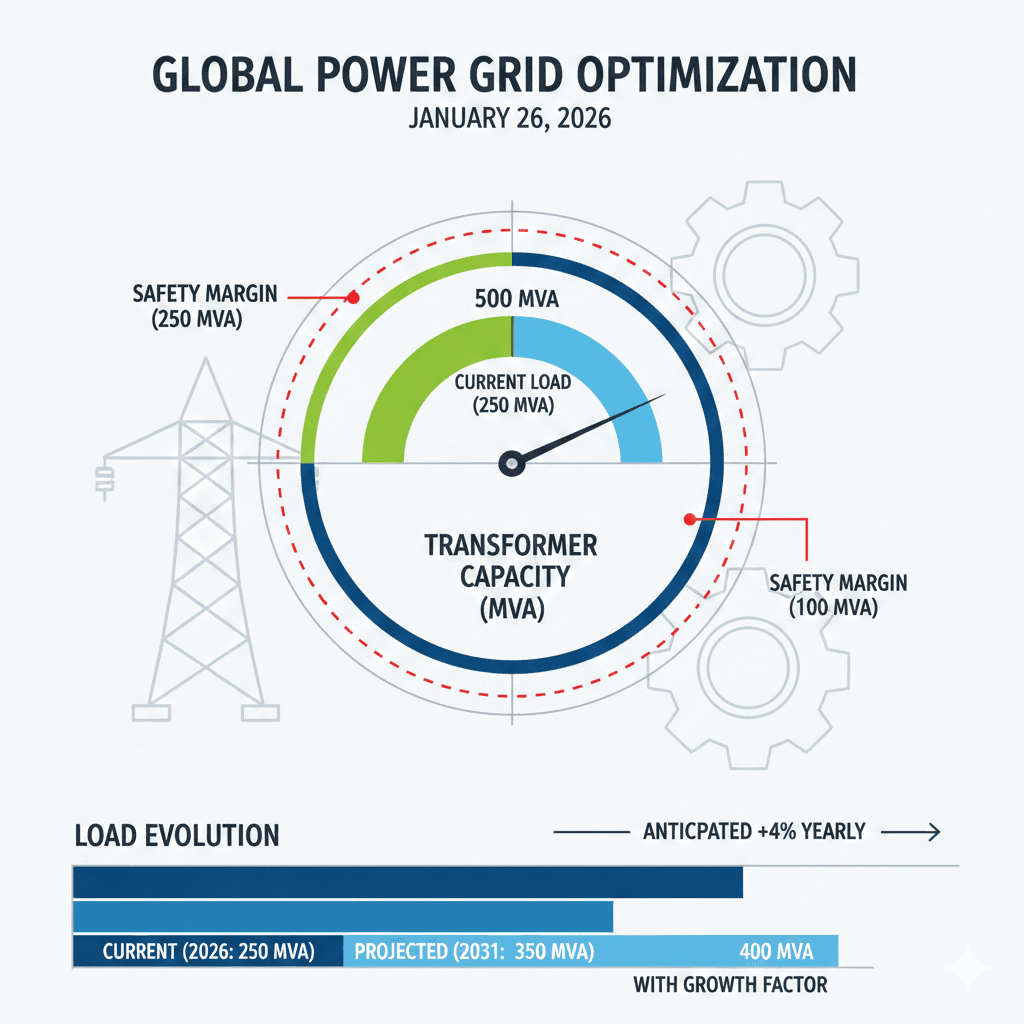

However, even modest annual load growth can significantly impact transformer utilization over time. The table below illustrates how a seemingly small growth rate can consume spare capacity faster than expected.

| Annual Load Growth Rate | Load Increase Over 10 Years |

|---|---|

| 2% | ~22% |

| 4% | ~48% |

| 6% | ~79% |

This simple comparison highlights why transformer capacity planning must consider compounding effects rather than relying on short-term demand figures. Long-term demand forecasting methods are commonly referenced in public energy planning resources such as electrical load forecasting methods.

4. Key Data Required for Effective Transformer Capacity Planning

A well-prepared transformer specification checklist helps ensure that no critical electrical or environmental parameter is overlooked during capacity planning.

Accurate transformer capacity planning depends on reliable input data. Before selecting transformer capacity, engineers should collect and validate the following information:

- Current load demand (kW and kVA)

- Peak load conditions and duty cycle

- Power factor and harmonic content

- Expected load growth rate and expansion schedule

- Ambient temperature and installation constraints

When these parameters are clearly defined, Transformer Rating SelectionTransformer Rating Selection becomes a structured decision-making process rather than a guess based on nominal values.

5. Key Factors in Transformer Capacity Planning

Effective Transformer Capacity Forecasting requires more than applying a single sizing formula. It involves evaluating several interdependent factors that together determine whether a transformer will operate reliably throughout its service life.

For projects expecting sustained load growth, selecting an ONAN oil immersed transformer can provide better thermal stability and operational flexibility.

5.1 Current Load, Average Load, and Peak Demand

One of the most common errors in transformer capacity planning is relying solely on nominal or average load values. In real operating conditions, transformers must be able to handle peak demand without excessive thermal stress.

- Average Load reflects typical operating conditions but may hide short-duration overloads.

- Peak Load determines the maximum thermal stress on transformer windings and insulation.

- Load Profile (daily, weekly, seasonal) provides a more accurate basis for capacity planning than a single load figure.

In Transformer Capacity Forecasting, peak load should always be evaluated alongside duration. Short, infrequent peaks may be acceptable, while sustained high load levels significantly reduce transformer lifespan.

5.2 Planning Horizon and Asset Lifetime

The planning horizon defines how far into the future load growth is considered. Typical transformer capacity planning horizons include:

- 5 years: Suitable for temporary or rapidly changing installations

- 10–15 years: Common for industrial and commercial projects

- 20+ years: Utility and infrastructure applications

A longer planning horizon usually justifies selecting a higher transformer capacity or designing for future parallel operation. Short-term cost savings achieved by undersizing often lead to higher total ownership cost when early replacement becomes necessary.

5.3 Cooling Method and Permissible Loading

Transformer cooling method has a direct impact on usable capacity. Oil-immersed transformers with ONAN or ONAF cooling typically offer greater overload capability compared to dry-type units.

| Cooling Method | Typical Overload Capability | Impact on Capacity Planning |

| ONAN | Moderate | Suitable for steady growth |

| ONAF | High | Supports future expansion |

| Dry Type | Limited | Requires conservative sizing |

In Transformer Capacity Forecasting, cooling should be considered a strategic variable rather than a fixed specification. Allowable temperature rise and transformer loading limits are specified in the IEEE C57.91 transformer loading guide.

6. Transformer Capacity Calculation with Load Growth Considered

Accurate Transformer Capacity Forecasting requires more than matching today’s connected load. Engineers must translate current demand, projected load growth, and safety margins into a clear and defensible capacity calculation. This section explains the full calculation logic step by step, using formulas commonly applied in real-world transformer capacity planning.

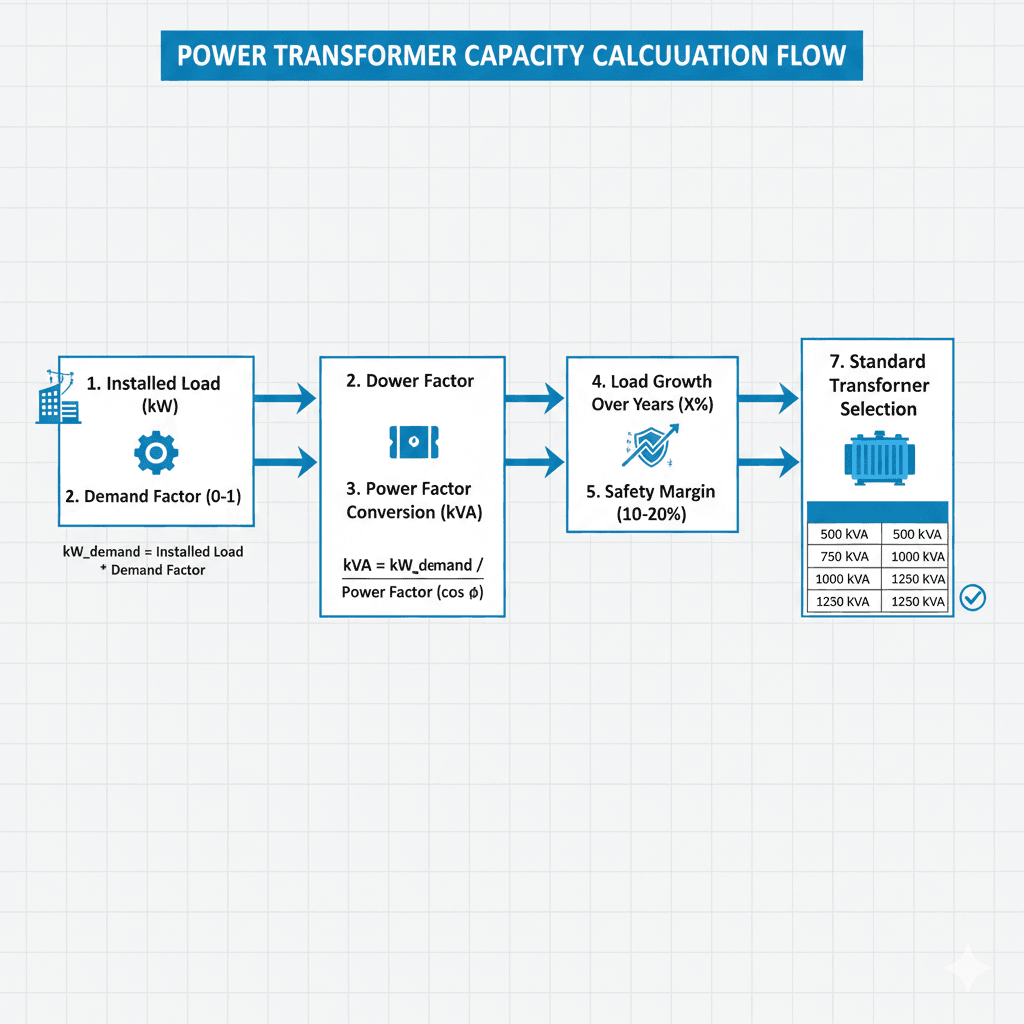

Step 1: Determine Current Maximum Load

The calculation starts with the actual maximum demand, not the total installed load.

Formula

Current Maximum Load = Installed Load × Demand Factor

Where:

- Installed Load is the total rated capacity of all connected equipment

- Demand Factor represents the percentage of equipment operating simultaneously

Using demand factor avoids oversizing caused by assuming all loads run at full capacity.

Step 2: Convert kW to kVA Using Power Factor

Transformers are rated in kVA, so electrical loads expressed in kW must be converted.

Formula

Required kVA = kW ÷ Power Factor

Typical industrial power factor values range from 0.8 to 0.9.

Using a realistic power factor improves sizing accuracy and energy efficiency.

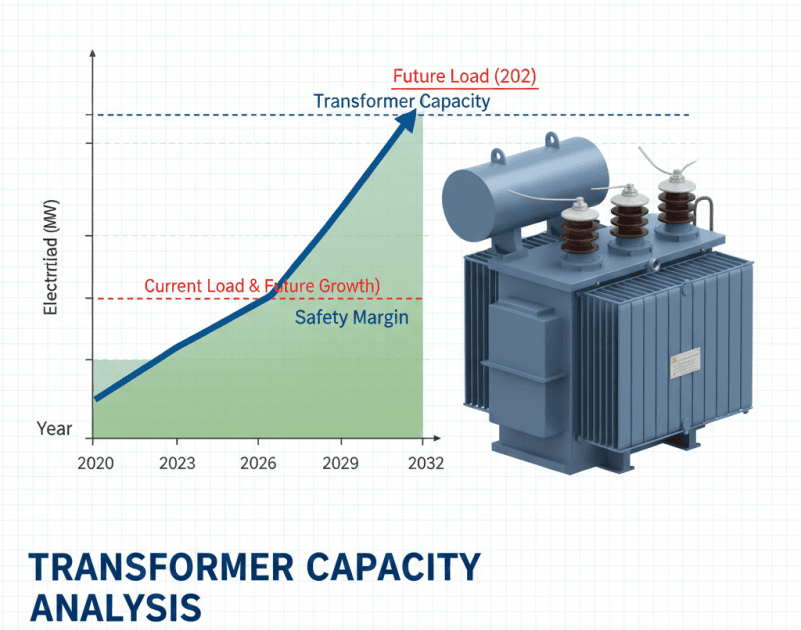

Step 3: Project Future Load Growth

Future demand is estimated using a compound annual growth model based on expansion plans or historical data.

Formula

Future Load = Current Load × (1 + g)ⁿ

Where:

- g = annual load growth rate

- n = planning horizon (years)

This approach reflects real-world expansion more accurately than linear assumptions.

Step 4: Define the Design Load

The calculated future load represents the design load the transformer must safely support near the end of the planning period.

At this stage, engineers should confirm:

- Operating temperature limits

- Cooling method capability

- Expected load profile (continuous or intermittent)

Step 5: Add Safety Margin

A safety margin compensates for forecasting uncertainty, temporary overloads, and operational flexibility.

Formula

Design Capacity = Future Load × (1 + Safety Margin)

Typical safety margins:

- 10–15% for stable, predictable loads

- 20–30% for industrial or fast-growing applications

Step 6: Select the Nearest Standard Transformer Rating

Transformers are manufactured in standardized ratings. The final selection should always round upward to the nearest standard size.

Example:

- Calculated design capacity: 742 kVA

- Selected transformer rating: 800 kVA

This ensures compliance with standards while maintaining operational headroom.

Based on the calculated result, many projects ultimately select a standard 630 kVA oil immersed transformer and 800 kVA oil immersed transformer to balance cost and future expansion needs.

For readers who want a practical calculation reference, we provide a downloadable engineering formula guide (PDF)

If you need help applying these formulas to your project, our engineers can review your load plan.

Practical Example Calculation

Assumptions:

- Installed load: 600 kW

- Demand factor: 0.8

- Power factor: 0.85

- Annual load growth rate: 5%

- Planning horizon: 10 years

- Safety margin: 20%

Calculation:

- Current maximum load = 600 × 0.8 = 480 kW

- Current kVA = 480 ÷ 0.85 ≈ 565 kVA

- Future load after 10 years = 565 × (1.05)¹⁰ ≈ 921 kVA

- Design capacity = 921 × 1.2 ≈ 1105 kVA

Final transformer selection: 1250 kVA

This example clearly shows how ignoring load growth would result in an undersized transformer within a few years.

Why This Calculation Is Critical

Including load growth in transformer capacity planning:

- Reduces premature overload risk

- Avoids costly mid-life replacements

- Improves lifecycle cost efficiency

- Supports long-term system reliability

Transformer capacity planning is therefore not a short-term sizing task, but a strategic engineering decision aligned with future load growth. Transformer capacity planning balances technical and economic considerations.

The calculation logic presented here follows principles outlined in the IEC 60076-7 transformer loading guidelines.

7. Common Transformer Capacity Planning Mistakes

Despite access to standards and calculation tools, several recurring mistakes continue to undermine transformer capacity planning outcomes.

7.1 Designing Only for Today’s Load

Selecting transformer capacity based solely on current demand often results in early overload as load grows. This approach ignores the cumulative impact of even modest annual growth.

7.2 Excessive Oversizing Without Analysis

While oversizing may appear safe, excessive capacity leads to:

- Higher initial capital cost

- Lower efficiency at light load

- Increased no-load losses over the transformer’s lifetime

Transformer capacity planning should justify oversizing based on realistic growth scenarios rather than fear of uncertainty.

7.3 Ignoring Future Expansion Pathways

Failing to plan for parallel operation, space constraints, or secondary equipment upgrades can limit future expansion options. Effective transformer capacity planning integrates these considerations from the start.

8. Standard vs Oversized Transformers in Capacity Planning

One of the most debated questions in Transformer Load Planning is whether to select a standard-rated transformer that closely matches projected demand or to intentionally choose an oversized unit. There is no universal answer; the correct decision depends on load growth uncertainty, operating conditions, and lifecycle cost considerations.

8.1 When a Standard-Rated Transformer Is the Right Choice

Standard-rated transformers are often suitable when load growth is predictable and expansion plans are well defined. In mature industrial facilities or retrofit projects with limited space and stable production processes, selecting a Transformer Load Planning closely aligned with projected demand can optimize efficiency and reduce no-load losses.

From a transformer capacity planning perspective, standard ratings are appropriate when:

- Load growth is gradual and capped

- Peak loads are short in duration

- Future expansion can be accommodated through parallel units

8.2 Strategic Oversizing and Lifecycle Cost Considerations

Oversizing becomes a rational strategy when future load growth is uncertain or expansion is likely but not yet scheduled. While oversized transformers have higher initial cost, they may reduce long-term expenses associated with early replacement, downtime, and system redesign.

Effective Transformer Load Planning evaluates oversizing using total cost of ownership rather than initial purchase price alone. Factors such as efficiency at partial load, maintenance intervals, and expected service life must all be considered.

9. Transformer Capacity Planning by Application

Different applications exhibit distinct load behaviors, making application-specific transformer capacity planning essential.

9.1 Industrial Facilities

Industrial Transformer Rating Selection must account for high starting currents, frequent load fluctuations, and long operating hours. Production expansion often occurs in phases, making it prudent to plan capacity margins that align with future equipment additions.

9.2 Commercial and Infrastructure Projects

Commercial buildings and infrastructure projects typically experience low initial load followed by accelerated growth as occupancy increases. Transformer Load Planning in these cases should balance early-stage efficiency with mid-term scalability.

9.3 Renewable Energy and Utility Systems

Renewable and utility applications introduce bidirectional power flow, intermittency, and regulatory constraints. Transformer Load Planning must consider not only load growth but also changes in power flow direction and grid interaction requirements.

10. Planning for Future Expansion and System Flexibility

Forward-looking Transformer Rating Selection integrates expansion strategies from the outset. This may include:

- Designing space and protection schemes for parallel transformers

- Selecting substations that allow modular upgrades

- Coordinating transformer ratings with downstream switchgear

Prefabricated and box-type substations are increasingly used to support flexible capacity planning by reducing installation time and simplifying future upgrades.

11. Working with a Transformer Supplier in Capacity Planning

A knowledgeable transformer supplier plays a critical role in successful Transformer Rating Selection. Beyond supplying equipment, experienced manufacturers can provide guidance on:

- Load assessment and growth modeling

- Cooling and insulation options

- Standard versus customized capacity solutions

Early collaboration helps ensure that Transformer Rating Selection decisions align with both technical requirements and long-term operational goals.

12. Conclusion: Reducing Long-Term Risk Through Smart Transformer Capacity Planning

Transformer Rating Selection is a foundational element of reliable power system design. By aligning transformer capacity with realistic load growth expectations, engineers can reduce operational risk, extend equipment lifespan, and avoid costly upgrades.

Rather than viewing capacity planning as a one-time calculation, it should be treated as an ongoing strategic process that integrates technical analysis, operational insight, and future development plans.

13. Frequently Asked Questions on Transformer Capacity Planning

What is transformer capacity planning?

Transformer capacity planning is the process of selecting transformer capacity based on current demand and anticipated future load growth to ensure reliable long-term operation.

How much spare capacity should be included?

Spare capacity typically ranges from 15% to 30%, depending on load growth uncertainty and operating conditions.

Is it better to oversize a transformer for future growth?

Oversizing can be beneficial when future expansion is likely, but it should be justified through lifecycle cost analysis rather than conservative assumptions alone.

How long should transformer capacity planning consider load growth?

Planning horizons of 10 to 20 years are common for most industrial and utility applications.