As a trusted supplier and engineering consultant specializing in oil-immersed transformers, we help clients select the best solutions for their power distribution projects. This article explores Oil Transformer Cooling Methods, focusing on ONAN and ONAF systems, their performance differences, and practical applications in real projects. By understanding these cooling methods, clients can optimize transformer efficiency, ensure long-term reliability, and make informed decisions that reduce lifecycle costs.

Table of Contents

- Introduction: Why Understanding Oil Transformer Cooling Methods Matters in Real Projects

- Overview of Oil Transformer Cooling Methods: What Are the Main Types?

- How ONAN Cooling Works in Oil Transformer Cooling Methods

- How ONAF Cooling Improves Oil Transformer Cooling Methods Performance

- ONAN vs ONAF: Key Differences in Oil Transformer Cooling Methods

- Choosing the Right Oil Transformer Cooling Method in Real Projects

- How Oil Transformer Cooling Methods Affect Transformer Selection and Sizing

- Common Misunderstandings About Oil Transformer Cooling Methods

- How Experts Help Clients Select the Optimal Oil Transformer Cooling Method

- FAQ: Questions About Oil Transformer Cooling Methods and ONAN vs ONAF

- Conclusion: Ensuring Long-Term Performance with the Right Oil Transformer Cooling Method

- Get Project-Specific Advice on Oil Transformer Cooling Methods

1. Introduction: Why Oil Transformer Cooling Methods Matter in Real Projects

Oil Transformer Cooling Methods play a decisive role in how oil-immersed transformers perform under real operating conditions. In power distribution projects, heat is not just a by-product of electrical losses—it is one of the main limiting factors that determines transformer loading capability, insulation aging rate, operational reliability, and long-term maintenance cost. When cooling is improperly selected, even a correctly rated transformer can experience accelerated aging, unexpected derating, or reduced service life.

In practice, many project issues related to oil-immersed transformers are not caused by design defects, but by a mismatch between the cooling method and the actual operating environment. Ambient temperature, load profile, installation space, ventilation conditions, and future load growth all interact with the transformer’s cooling system. Among all available options, ONAN and ONAF remain the most widely applied and most frequently misunderstood cooling methods in oil transformers.

This article explains Oil Transformer Cooling Methods from a real project perspective, focusing on how ONAN and ONAF cooling work, how they differ in performance and cost, and how engineers should select the appropriate method based on actual operating conditions rather than nameplate assumptions. The goal is not to promote a specific configuration, but to provide practical guidance that supports safer operation, optimized sizing, and long-term reliability in oil-immersed transformer applications.

2. Overview of Oil Transformer Cooling Methods: What Are the Main Types?

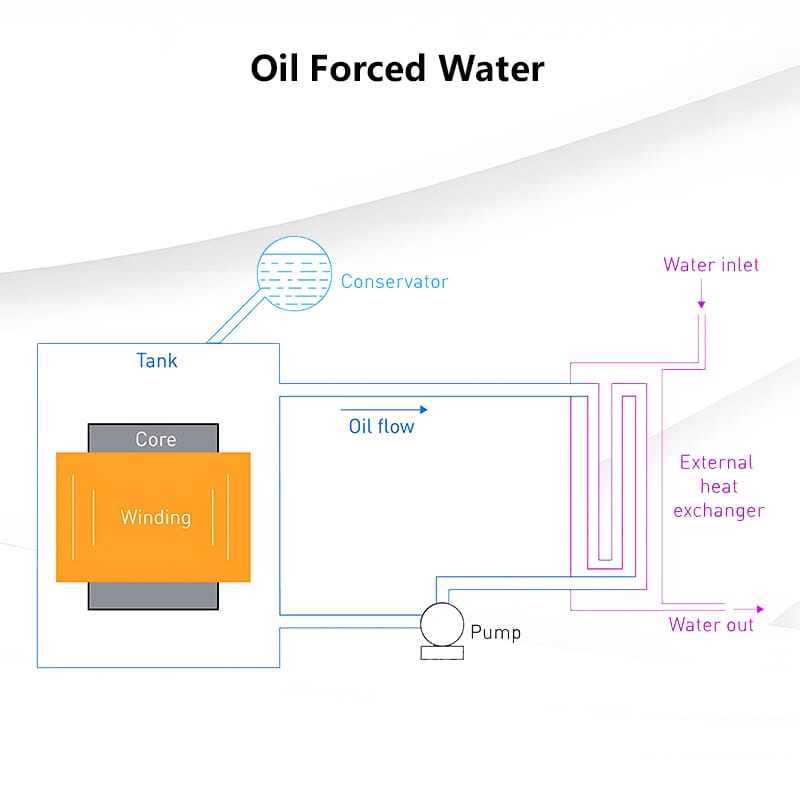

Oil Transformer Cooling Methods are designed to control internal temperature rise by transferring heat from the transformer core and windings to the surrounding environment. In oil-immersed transformers, mineral oil or synthetic insulating fluid serves two primary purposes: electrical insulation and heat transfer. The effectiveness of a cooling method depends on how efficiently this heat can be moved from the active parts to the oil, from the oil to the tank or radiators, and finally from the external surfaces to the ambient air.

International standards such as IEC 60076 and IEEE C57 classify transformer cooling methods using standardized letter codes. These codes describe the circulation method of the insulating liquid and the cooling medium, as well as whether circulation is natural or forced. Understanding this classification is essential for interpreting transformer nameplates and technical documentation.

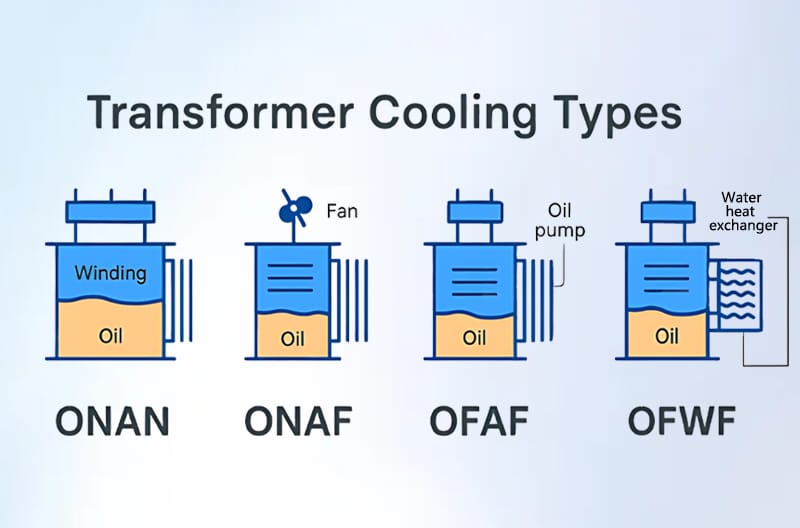

Common oil transformer cooling methods include:

- ONAN (Oil Natural Air Natural)

- ONAF (Oil Natural Air Forced)

- OFAF (Oil Forced Air Forced)

- ODAF (Oil Directed Air Forced)

Among these, ONAN and ONAF are by far the most commonly used in distribution and medium-power transformers. They represent a balance between simplicity, reliability, and cooling performance, making them suitable for a wide range of industrial and utility projects.

The table below summarizes the basic characteristics of common oil transformer cooling methods:

| Cooling Method | Oil Circulation | Air Cooling | Typical Application Range |

|---|---|---|---|

| ONAN | Natural | Natural | Small to medium distribution transformers |

| ONAF | Natural | Forced (Fans) | Medium to large power transformers |

| OFAF | Forced (Pumps) | Forced (Fans) | High-capacity or compact installations |

| ODAF | Directed Forced | Forced (Fans) | Large utility and power plant transformers |

In real projects, ONAN and ONAF are often compared because they share the same basic oil circulation principle while differing in air-side cooling performance. This makes them suitable for staged cooling designs, where a transformer may operate under ONAN conditions at normal load and transition to ONAF when higher thermal capacity is required.

3. How ONAN Cooling Works in Oil Transformer Cooling Methods

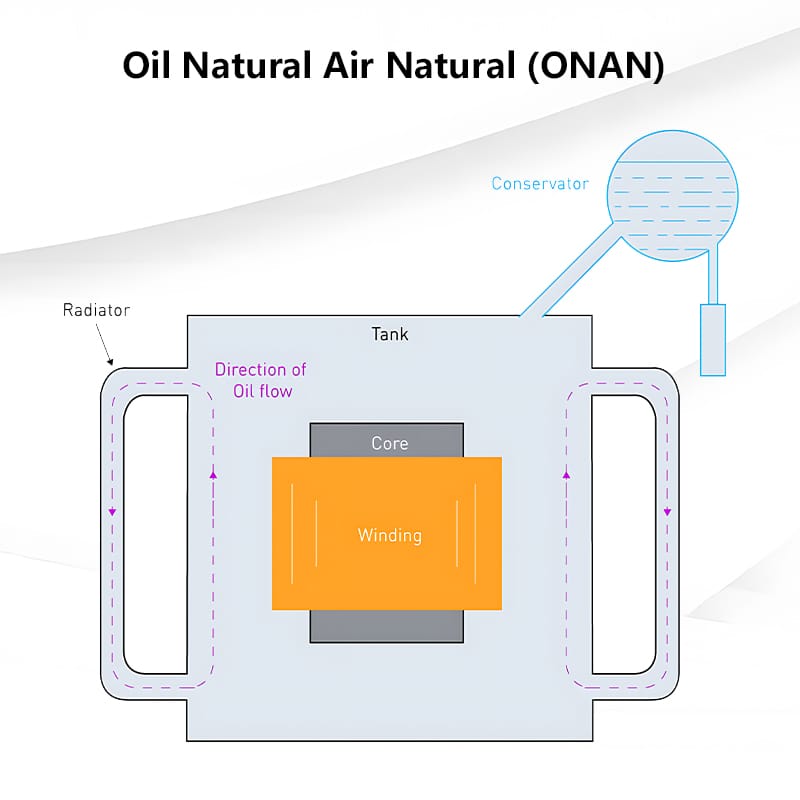

ONAN cooling, short for Oil Natural Air Natural, is the most basic and widely used cooling method for oil-immersed transformers. In an ONAN system, both oil circulation inside the transformer and air circulation outside the tank occur naturally, without the use of pumps or fans. This simplicity is one of the main reasons ONAN remains popular in distribution networks and industrial power systems.

Working Principle of ONAN Cooling

In ONAN-cooled oil transformers, heat generated by the core and windings is transferred directly to the surrounding insulating oil. As the oil temperature rises, its density decreases, causing the warm oil to rise naturally toward the top of the transformer tank. Cooler oil then flows downward to replace it, creating a continuous natural convection cycle.

The heated oil transfers its thermal energy to the tank walls or external radiators. From there, heat is dissipated into the surrounding air through natural convection and radiation. No external mechanical devices are required to support this process, which makes ONAN cooling inherently reliable.

Structural Features of ONAN Oil Transformers

Typical ONAN oil transformers include:

- Sealed or conservator-type oil tanks

- Corrugated tank walls or external radiators

- Adequate oil channels between windings

- Sufficient clearance for natural air circulation

The effectiveness of ONAN cooling depends heavily on installation conditions. Adequate spacing around radiators, proper ventilation of the transformer room, and reasonable ambient temperatures are critical to maintaining acceptable temperature rise.

Typical Applications of ONAN Cooling

ONAN transformer cooling is commonly applied in the following scenarios:

- Distribution transformers with stable load profiles

- Industrial facilities with predictable operating conditions

- Indoor or outdoor installations with good natural ventilation

- Projects where low noise and minimal maintenance are priorities

Because ONAN cooling does not rely on auxiliary power or moving components, it offers high operational reliability and low lifecycle cost. However, its cooling capacity is inherently limited by natural heat transfer, which means ONAN may not be suitable for high-load or high-temperature environments without sufficient design margin.

In the broader context of Oil Transformer Cooling Methods, ONAN represents the baseline configuration against which more advanced cooling solutions such as ONAF are evaluated.

4. How ONAF Cooling Improves Oil Transformer Cooling Methods Performance

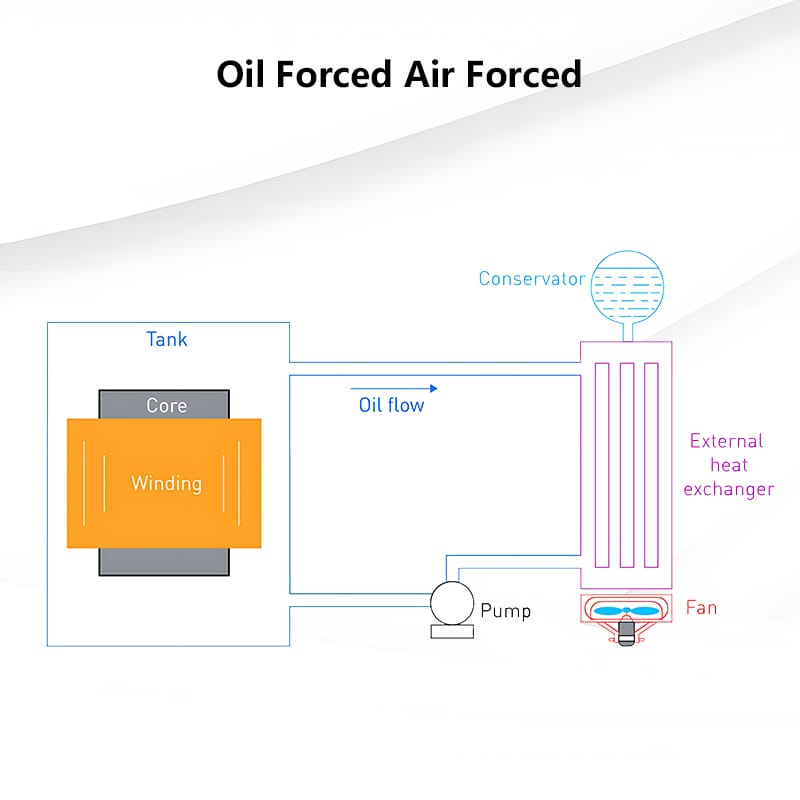

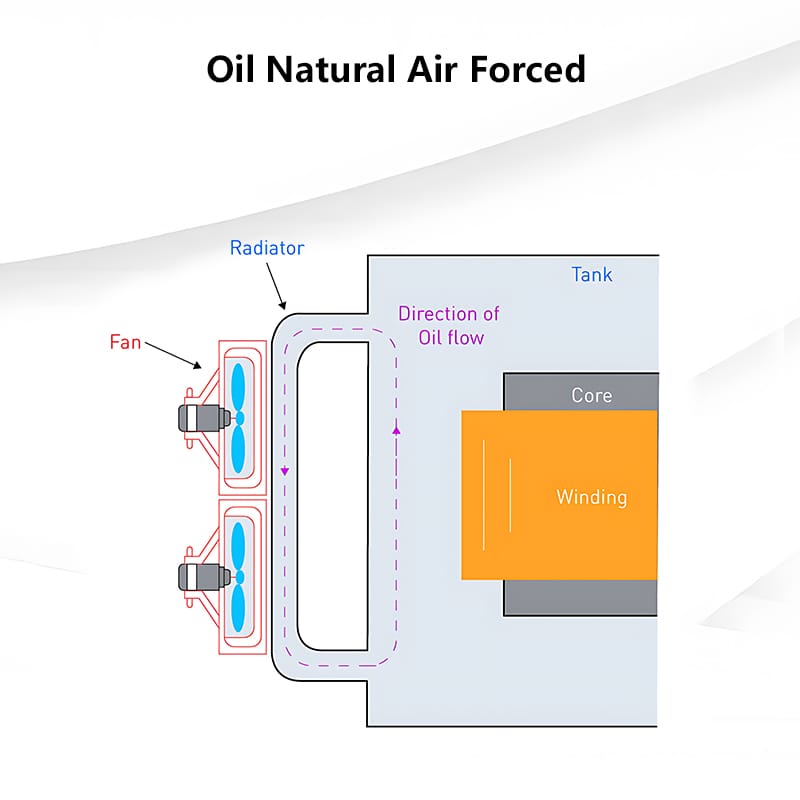

ONAF cooling, defined as Oil Natural Air Forced, builds upon the same internal oil circulation principle used in ONAN systems while significantly enhancing heat dissipation on the air side. In an ONAF-cooled oil transformer, the insulating oil still circulates naturally inside the tank, but external cooling fans are added to force air across radiators or cooling fins. This hybrid approach allows the transformer to handle higher thermal loads without introducing the complexity of oil pumps.

Operating Principle of ONAF Cooling

Under ONAF operation, heat generated in the core and windings is transferred to the oil in the same manner as ONAN cooling. The key difference lies in the external heat exchange process. When transformer load or oil temperature reaches a predefined threshold, cooling fans automatically activate and increase airflow over the radiators. This forced airflow accelerates heat transfer from the oil to the surrounding air, reducing top-oil and winding temperatures.

Because oil circulation remains natural, ONAF cooling avoids many of the reliability concerns associated with forced oil systems. The fans operate only when required, making ONAF an efficient and flexible solution for projects with variable load profiles.

Thermal Capacity and Load Flexibility

One of the main advantages of ONAF cooling is its ability to increase the effective thermal capacity of an oil transformer. Compared with pure ONAN operation, ONAF cooling can typically support an additional 25% to 40% load, depending on transformer design and ambient conditions. This increased capacity is particularly valuable in projects where:

- Peak loads occur intermittently

- Future load growth is expected

- Ambient temperatures are consistently high

By activating forced air cooling only when necessary, ONAF systems balance energy efficiency with enhanced thermal performance.

Structural and System Requirements

ONAF oil transformers require several additional components beyond standard ONAN designs:

- Axial or centrifugal cooling fans

- Fan control circuits and temperature sensors

- Auxiliary power supply for fan operation

- Protective guards and weatherproofing for outdoor installations

Despite these additions, ONAF systems remain relatively simple compared to forced oil cooling methods. Maintenance typically focuses on fan inspection and replacement rather than oil circulation equipment.

Typical Applications of ONAF Cooling

ONAF cooling is commonly applied in:

- Industrial plants with high or fluctuating loads

- Power distribution substations in hot climates

- Projects with limited installation space but higher capacity requirements

- Systems requiring short-term overload capability

Within the broader framework of Oil Transformer Cooling Methods, ONAF represents a practical upgrade path that improves performance while preserving system reliability.

5. ONAN vs ONAF: Key Differences in Oil Transformer Cooling Methods

While ONAN and ONAF share the same natural oil circulation principle, their performance characteristics differ significantly due to the method of air cooling. Understanding these differences is essential for selecting the appropriate cooling configuration in real projects.

Performance Comparison and Thermal Behavior

The most direct distinction between ONAN and ONAF lies in their heat dissipation capability. ONAN relies entirely on natural convection, which limits its effectiveness under high ambient temperatures or heavy loading. ONAF, by contrast, actively enhances air-side cooling, allowing the transformer to maintain lower operating temperatures under increased load.

The table below summarizes the key technical differences between ONAN and ONAF cooling methods:

| Parameter | ONAN Cooling | ONAF Cooling |

| Oil circulation | Natural | Natural |

| Air cooling | Natural | Forced (Fans) |

| Typical load capacity | Rated base load | Up to 125–140% of ONAN rating |

| Auxiliary power | Not required | Required for fans |

| Noise level | Very low | Moderate during fan operation |

| Maintenance focus | Minimal | Fan inspection and servicing |

Impact on Efficiency and Operating Cost

From an efficiency standpoint, ONAN cooling consumes no auxiliary energy, making it ideal for continuous base-load operation. ONAF cooling introduces additional energy consumption due to fan operation, but this impact is generally limited because fans operate only during higher load or temperature conditions.

In many real-world projects, the ability of ONAF cooling to avoid transformer derating during peak demand outweighs the modest increase in auxiliary power consumption. This trade-off becomes especially important in industrial environments where production continuity is critical.

Reliability and Risk Considerations

ONAN systems are inherently simple, with fewer components that can fail. This simplicity translates into high reliability and predictable performance. ONAF systems introduce additional components, but modern fan systems are designed with redundancy and automatic control to minimize operational risk.

It is important to note that an ONAF transformer typically remains capable of ONAN operation if fans fail, albeit at reduced load. This layered approach enhances overall system resilience.

Selection Implications for Real Projects

Choosing between ONAN and ONAF within Oil Transformer Cooling Methods is rarely a matter of which option is better in absolute terms. Instead, it depends on:

- Load profile and peak demand duration

- Ambient temperature and ventilation conditions

- Noise constraints at the installation site

- Maintenance strategy and lifecycle cost priorities

A well-informed selection considers not only initial rating, but also how the transformer will operate throughout its service life.

6. Real Project Scenarios: Choosing the Right Oil Transformer Cooling Method

In real-world applications, Oil Transformer Cooling Methods must be selected based on how the transformer will actually be operated, not just on nameplate ratings or catalog descriptions. Project conditions such as load variability, ambient temperature, installation environment, and future expansion plans all influence whether ONAN or ONAF cooling is the more appropriate choice.

Scenario 1: Industrial Facilities with Stable Load Profiles

Many manufacturing plants, processing facilities, and industrial workshops operate with relatively stable electrical loads over long periods. In these projects, transformers often run at a consistent percentage of their rated capacity, with limited peak demand fluctuations.

For such environments, ONAN cooling is often sufficient and economically justified. Natural oil and air circulation can maintain acceptable temperature rise when:

- Average load remains below 70–80% of rated capacity

- Ambient temperature is moderate and predictable

- Transformer rooms are well ventilated

In these cases, ONAN cooling offers simplicity, low noise, and minimal maintenance requirements. Selecting ONAF cooling for these projects may result in unnecessary upfront cost without delivering meaningful operational benefits.

Scenario 2: High-Temperature or Poorly Ventilated Installations

Projects located in hot climates or confined indoor spaces present additional thermal challenges. High ambient temperature reduces the temperature gradient between the transformer surface and surrounding air, directly limiting natural heat dissipation.

In such conditions, ONAF cooling becomes a practical solution. Forced air circulation compensates for reduced natural convection and helps maintain stable oil and winding temperatures. This approach is commonly applied in:

- Substations in tropical or desert regions

- Indoor installations with limited airflow

- Underground or containerized substations

Here, the choice of Oil Transformer Cooling Methods directly affects operational safety margins and long-term insulation life.

Scenario 3: Projects with Variable or Seasonal Load Peaks

Some power distribution projects experience significant load variation due to seasonal demand, intermittent processes, or phased commissioning. Examples include commercial complexes, infrastructure projects, and mixed-use industrial zones.

In these scenarios, ONAF cooling provides valuable flexibility. The transformer can operate under ONAN conditions during normal load periods and switch to ONAF operation during peak demand. This staged cooling approach allows engineers to optimize transformer sizing while maintaining adequate thermal performance.

Scenario 4: Future Expansion and Capacity Planning

In projects where future load growth is anticipated but not immediate, selecting a transformer with ONAF cooling can offer long-term advantages. Rather than oversizing the transformer initially, engineers can rely on enhanced cooling capacity to accommodate gradual load increases.

This strategy reduces initial capital expenditure while preserving expansion capability, making ONAF cooling an effective tool in long-term capacity planning.

7. How Oil Transformer Cooling Methods Affect Transformer Selection

Oil Transformer Cooling Methods are a fundamental part of transformer selection and sizing. Cooling configuration influences not only thermal performance, but also rated capacity, installation requirements, and lifecycle cost. Ignoring the impact of cooling method during selection can lead to overdesign, underutilization, or operational constraints.

Relationship Between Cooling Method and Rated Capacity

Transformer ratings are closely tied to allowable temperature rise, which is directly influenced by cooling effectiveness. An ONAN-rated transformer is designed to operate continuously at its rated capacity using natural cooling alone. When ONAF cooling is applied, additional thermal headroom becomes available.

In practice, this means:

- An ONAN transformer operates safely at base rated load

- The same transformer design may support higher loads under ONAF cooling

This relationship allows engineers to evaluate whether enhanced cooling can replace the need for a larger transformer unit in certain applications.

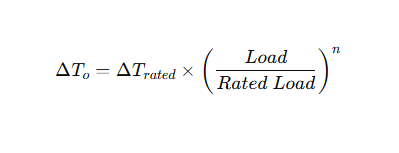

Practical Calculation Example: ONAN vs ONAF Thermal Performance

To illustrate the impact of cooling method on transformer operation, consider the following calculation for top-oil temperature rise (ΔTo) under overload conditions:

Formula:

Where:

- ΔTrated = rated temperature rise (°C)

- Load / Rated Load = actual load ratio

- n = empirical exponent (ONAN ≈ 1.6, ONAF ≈ 1.0–1.2)

Example:

- Transformer rated 10 MVA, ONAN ΔT_rated = 65°C

- Load = 125% of rated capacity

- n_ONAN = 1.6, n_ONAF = 1.2

Calculation:

- ONAN: ΔT_o = 65 × (1.25)^1.6 ≈ 95°C → exceeds safe operating limit

- ONAF: ΔT_o = 65 × (1.25)^1.2 ≈ 78°C → within acceptable range

Conclusion: ONAF cooling provides higher thermal capacity and allows short-term overload without compromising insulation life, demonstrating the practical advantage in selection and sizing decisions.

Impact on Installation and Space Requirements

Cooling method selection also affects physical layout and installation design. ONAN transformers typically require sufficient clearance around radiators to ensure natural airflow. ONAF transformers require additional considerations, including:

- Fan mounting and access space

- Electrical connections for auxiliary power

- Noise control measures in sensitive environments

These factors should be evaluated early in the project design phase to avoid installation constraints or retrofitting challenges.

Lifecycle Cost Considerations

While ONAF cooling introduces additional components and auxiliary power consumption, its impact on lifecycle cost should be evaluated holistically. In many cases, the ability to maintain acceptable operating temperatures under higher load conditions can reduce thermal stress, slow insulation aging, and improve overall system reliability.

The table below summarizes key selection considerations related to Oil Transformer Cooling Methods:

| Selection Factor | ONAN Cooling | ONAF Cooling |

| Initial equipment cost | Lower | Higher |

| Installation complexity | Low | Moderate |

| Operating flexibility | Limited | High |

| Auxiliary energy use | None | Low (intermittent) |

| Suitability for load growth | Limited | Strong |

Integrating Cooling Method into Project Decision-Making

Effective transformer selection integrates cooling method evaluation into the broader project context. Rather than treating cooling as an afterthought, engineers should consider how Oil Transformer Cooling Methods interact with load forecasts, environmental conditions, and operational priorities.

A balanced approach ensures that the selected cooling configuration supports both current requirements and future operational demands without unnecessary complexity or cost.

8. Common Misunderstandings About Oil Transformer Cooling Methods

Even experienced engineers and project managers can fall into common misconceptions when dealing with Oil Transformer Cooling Methods. Addressing these misunderstandings helps ensure transformers are correctly specified, safely operated, and optimally maintained.

Misunderstanding 1: ONAF is Always Better than ONAN

Some believe that any transformer with ONAF cooling is automatically superior to ONAN. In reality, the performance advantage of ONAF only matters when the transformer operates near or above the base rated load, or in environments with poor natural airflow. Using ONAF in all projects may unnecessarily increase initial cost and introduce maintenance requirements without practical benefit.

Misunderstanding 2: ONAN Cannot Handle Industrial Loads

Another common misconception is that ONAN-cooled transformers are unsuitable for industrial applications. While ONAN has a lower peak thermal capacity compared with ONAF, it remains entirely sufficient for facilities with stable load profiles and moderate ambient conditions. ONAN also provides the benefits of low noise, minimal maintenance, and higher inherent reliability.

Misunderstanding 3: Fans Must Run Continuously in ONAF Systems

Some assume that ONAF cooling requires continuous fan operation, increasing operational costs unnecessarily. Modern ONAF systems activate fans only when oil or winding temperature exceeds predefined thresholds. This intermittent operation balances energy consumption with thermal performance, ensuring both efficiency and reliability.

Misunderstanding 4: Cooling Method Does Not Affect Lifecycle Cost

Ignoring the impact of the cooling method on insulation life and thermal stress is another common error. ONAN and ONAF affect oil and winding temperatures differently, which in turn influences transformer aging rates and long-term maintenance needs. Selecting the appropriate cooling method can prevent early insulation degradation and reduce total lifecycle cost.

Misunderstanding 5: ONAF Requires Complete Redesign

Some believe switching from ONAN to ONAF necessitates a full transformer redesign. In many cases, standard ONAN transformers are designed to accommodate forced air upgrades, provided auxiliary power and fan mounting are correctly integrated. This flexibility is particularly useful in projects where load growth is expected.

9. How We Help Clients Select the Right Oil Transformer Cooling Method

Choosing the optimal Oil Transformer Cooling Method requires a comprehensive understanding of both technical requirements and project-specific constraints. Our approach combines engineering expertise, field experience, and practical project considerations to deliver tailored transformer solutions.

Step 1: Evaluate Project Load Profile

We analyze the expected load patterns over the lifetime of the transformer, identifying peak loads, seasonal variations, and potential future growth. This data allows us to determine whether ONAN, ONAF, or a staged cooling configuration is most appropriate.

Step 2: Assess Installation Environment

Ambient temperature, ventilation, space constraints, and noise considerations are evaluated. In hot climates or confined spaces, ONAF may be recommended, whereas ONAN may be sufficient in well-ventilated, moderate environments.

Step 3: Balance Operational Cost and Lifecycle Reliability

We consider not just initial investment but also operational energy consumption, maintenance requirements, and insulation longevity. Our guidance ensures that the selected cooling method minimizes total lifecycle cost while maintaining high reliability.

Step 4: Provide Custom Recommendations

Based on the above analyses, we provide clients with detailed recommendations, including:

- Cooling method selection (ONAN, ONAF, or staged approach)

- Transformer sizing adjustments to match cooling capability

- Installation requirements and fan configuration (if applicable)

- Maintenance and operational guidelines

By integrating technical expertise with real project experience, our process ensures that clients select the right Oil Transformer Cooling Methods that optimize performance, reliability, and long-term value.

10. FAQ: Oil Transformer Cooling Methods and ONAN vs ONAF

Q1: What are Oil Transformer Cooling Methods?

A: Oil Transformer Cooling Methods are the techniques used to transfer heat from transformer windings and core to the surrounding environment. In oil-immersed transformers, this involves circulating insulating oil and dissipating heat via natural or forced air.

Q2: What is the difference between ONAN and ONAF?

A: ONAN (Oil Natural Air Natural) relies entirely on natural oil circulation and air cooling. ONAF (Oil Natural Air Forced) adds fans to force airflow over radiators, increasing heat dissipation and thermal capacity under high loads.

Q3: When should ONAF cooling be used instead of ONAN?

A: ONAF is recommended for high ambient temperatures, variable load profiles, peak load conditions, or when future load growth is expected. ONAN is typically sufficient for stable load applications in moderate environments.

Q4: Can an ONAN transformer be upgraded to ONAF?

A: In many designs, ONAN transformers can be upgraded to ONAF by adding external fans and control circuits. This allows additional cooling without replacing the core and winding structure.

Q5: Does ONAF significantly increase operational costs?

A: Modern ONAF fans operate only when oil or winding temperature exceeds preset thresholds. Therefore, energy consumption is intermittent and usually minimal compared with the benefits of increased thermal capacity and reliability.

11. Conclusion: Selecting Oil Transformer Cooling Methods for Long-Term Performance

Selecting the correct Oil Transformer Cooling Method is critical for reliable, efficient, and long-lasting transformer operation. ONAN cooling offers simplicity, high reliability, and low maintenance for stable loads and moderate conditions. ONAF cooling provides additional thermal capacity and flexibility, making it ideal for high-load, high-temperature, or variable-demand projects.

A careful evaluation of load profile, installation environment, operational goals, and future expansion ensures the transformer meets project requirements throughout its service life. By considering these factors, engineers can optimize transformer performance, reduce lifecycle costs, and ensure long-term operational safety.

12. Get Project-Specific Oil Transformer Cooling Advice

Understanding Oil Transformer Cooling Methods is only the first step. Every project has unique load patterns, environmental constraints, and operational priorities. Our team provides tailored guidance for selecting ONAN, ONAF, or staged cooling configurations to match your project needs.

Submit your project parameters to receive expert recommendations, including:

- Optimal cooling method selection

- Transformer sizing adjustments

- Installation and maintenance guidance