As a professional supplier and solution provider of box-type substations and medium-voltage power equipment, we support EPC contractors, industrial developers, and renewable energy investors worldwide.

This article explains how a Power Distribution Layout is designed and implemented using box-type substations, highlighting system structure, engineering logic, and real-world applications.

Through practical diagrams, technical explanations, and industry best practices, we help you understand how to build a safe, reliable, and scalable power distribution layout for industrial facilities, commercial buildings, and renewable energy projects. Whether you are at the planning or execution stage, this guide provides actionable insights to support better engineering and procurement decisions.

Table of Contents

Introduction: Why Power Distribution Layout Matters in Modern Projects

Understanding a Power Distribution Layout

Core Components of a Box-Type Substation Within the Power Distribution Layout

How Does a Power Distribution Layout Work with a Box-Type Substation?

Application Scenarios and Power Distribution Layout Adaptations

Advantages of Box-Type Substations in Power Distribution Layout Design

Key Design Considerations for Power Distribution Layouts Using Box-Type Substations

Common Mistakes in Power Distribution Layout Design and How to Avoid Them

How to Select the Right Box-Type Substation for Your Power Distribution Layout

Conclusion: Optimizing Power Distribution Layouts with Box-Type Substations

Frequently Asked Questions (FAQ)

Why Is Power Distribution Layout Design So Important?

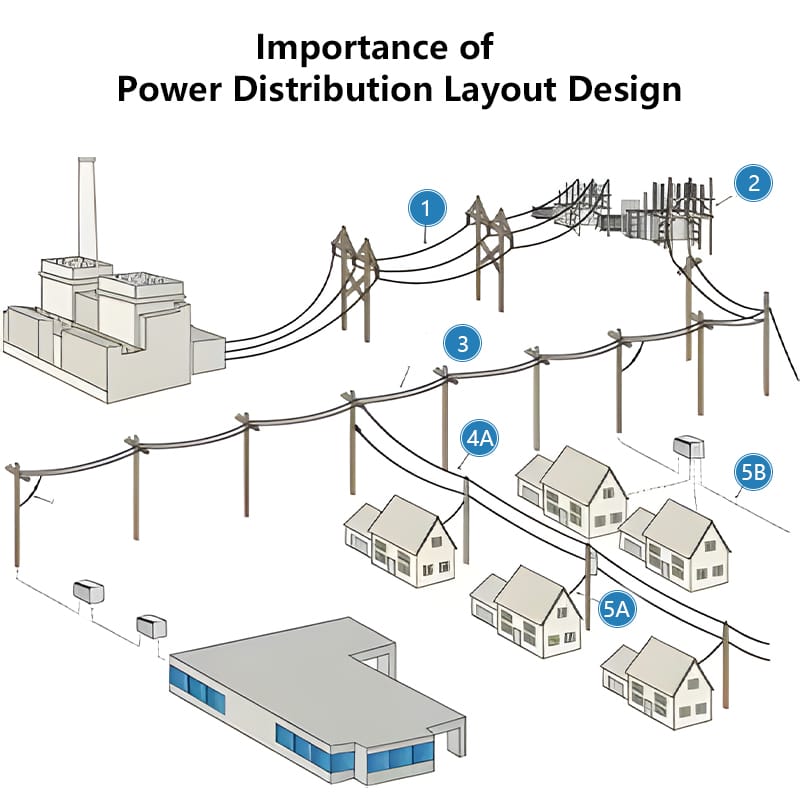

A well-planned Power Distribution Layout is the foundation of electrical system reliability, safety, and long-term operational efficiency. It defines how electricity flows from utility grids or on-site generation sources to end users, determining voltage levels, protection coordination, equipment placement, and expansion capability.

In industrial and commercial projects, the power distribution layout directly influences construction cost, commissioning time, and operational risk. Poor layout design may lead to excessive voltage drops, frequent faults, safety hazards, and high maintenance expenses. In contrast, a properly engineered Power Distribution Layout ensures stable power delivery, simplified operation, and compliance with international standards.

With the increasing adoption of box-type substations, modern layouts are becoming more compact, modular, and adaptable. This approach is especially valuable in projects where space is limited, installation schedules are tight, or future capacity expansion is required.

What Is a Power Distribution Layout?

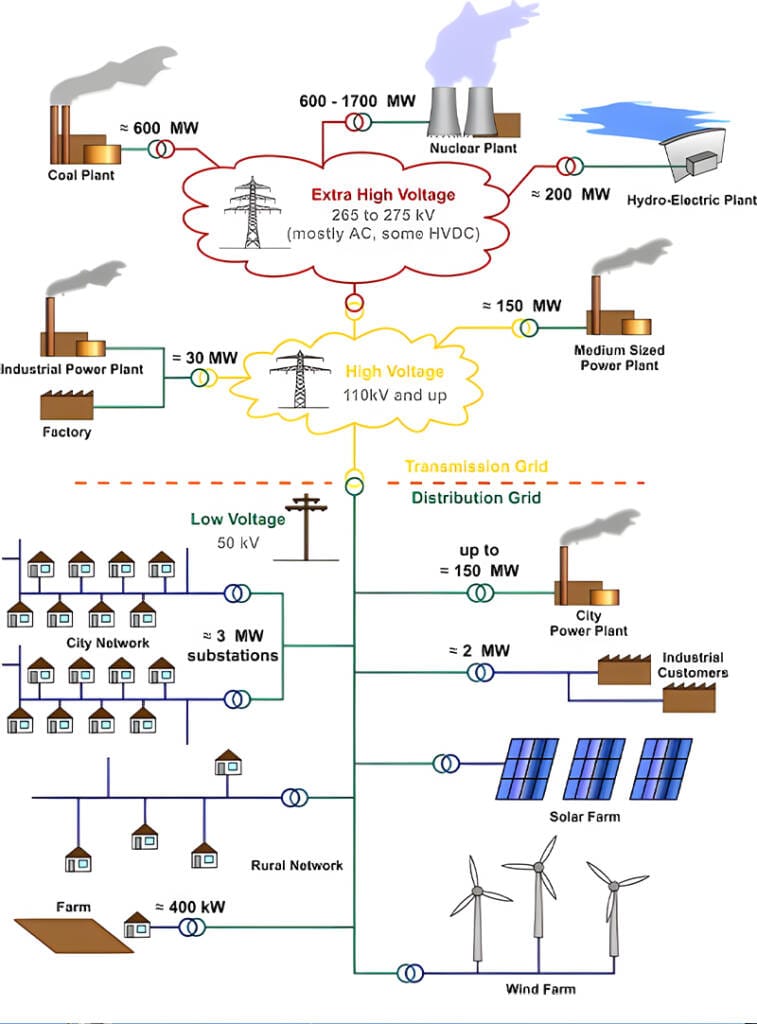

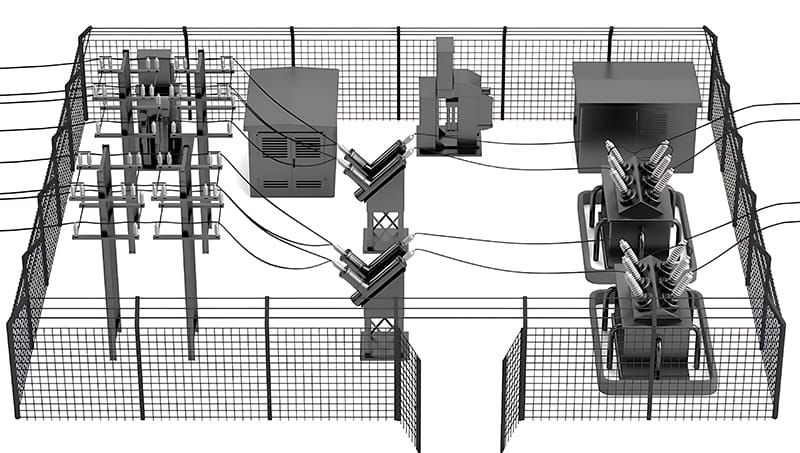

A Power Distribution Layout refers to the structured arrangement of electrical equipment and distribution paths that deliver electricity from a power source to multiple loads. It integrates substations, transformers, switchgear, protection devices, and cables into a coordinated system.

Beyond a simple wiring diagram, the layout represents a strategic engineering decision. Designers must evaluate load characteristics, voltage levels, redundancy requirements, environmental conditions, and long-term scalability. In decentralized or fast-deployment projects, a well-designed Power Distribution Layout minimizes losses, improves safety, and enhances system flexibility.

When box-type substations are incorporated, the layout becomes more efficient and space-saving. Prefabricated substations allow engineers to position voltage transformation closer to load centers, reducing cable length and simplifying installation and maintenance.

What Is a Box-Type Substation?

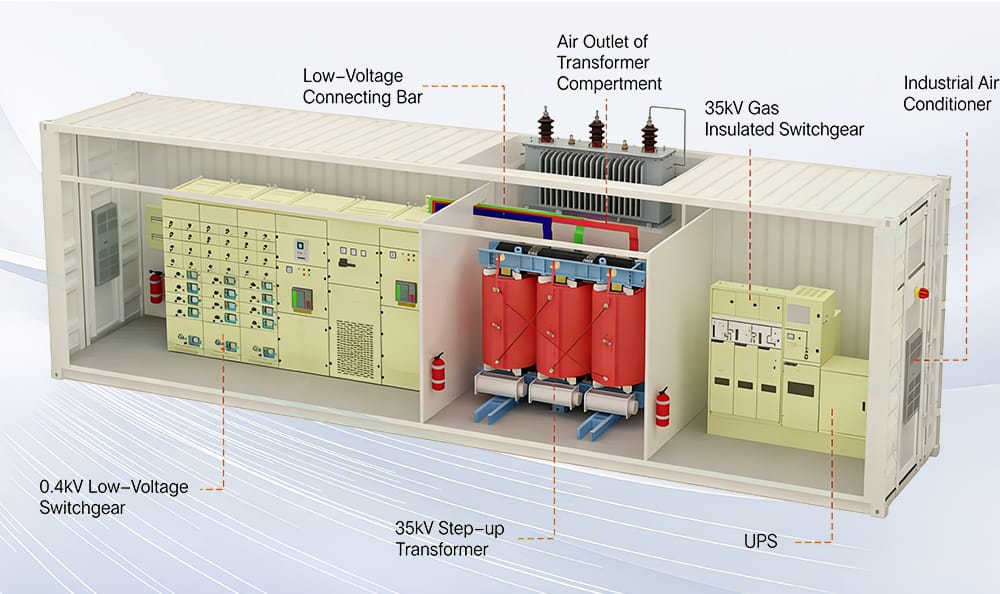

A box-type substation, also known as a compact or prefabricated substation, integrates medium-voltage switchgear, transformers, and low-voltage distribution equipment into a single enclosed unit. These systems are factory-assembled, tested, and delivered as complete solutions.

Within a Power Distribution Layout, box-type substations act as localized distribution hubs. They step down voltage close to the load, reduce transmission losses, and enhance operational safety. Their compact footprint, weather-resistant enclosure, and modular design make them ideal for industrial plants, urban infrastructure, and renewable energy projects.

From an engineering and procurement perspective, box-type substations simplify installation, shorten project timelines, and ensure consistent quality—key advantages for EPC-driven projects and overseas deployments.

How Does a Typical Power Distribution System Layout Work with a Box-Type Substation?

In a typical power distribution layout, the box-type substation functions as the critical node that connects the medium-voltage network to low-voltage end users. Its role is not isolated equipment placement, but an integral part of the overall system logic that determines power flow efficiency, protection coordination, and operational reliability.

The working principle of a power distribution layout using a box-type substation follows a clearly defined sequence. Medium-voltage electricity is supplied from the utility grid or on-site generation system and enters the substation through incoming MV cables. These cables are terminated at the medium-voltage switchgear, where switching, protection, and fault isolation are performed.

Once power passes through the MV protection stage, it is fed into the distribution transformer inside the box-type substation. Here, the transformer steps down voltage to a suitable low-voltage level for local consumption. The system then routes low-voltage power to the LV distribution panel, which distributes it through multiple outgoing feeders to different loads.

From a power distribution layout perspective, this compact and linear process offers several engineering advantages. By locating voltage transformation close to load centers, designers reduce cable length, minimize voltage drop, and control system losses. At the same time, the enclosed design enhances safety and simplifies coordination between protection devices across different voltage levels.

In larger systems, multiple box-type substations may be connected within the same power distribution layout, forming radial or ring-based distribution structures. This modular approach allows engineers to scale capacity, isolate faults quickly, and maintain stable operation even as load demand increases.

Application Scenarios and Layout Adaptations

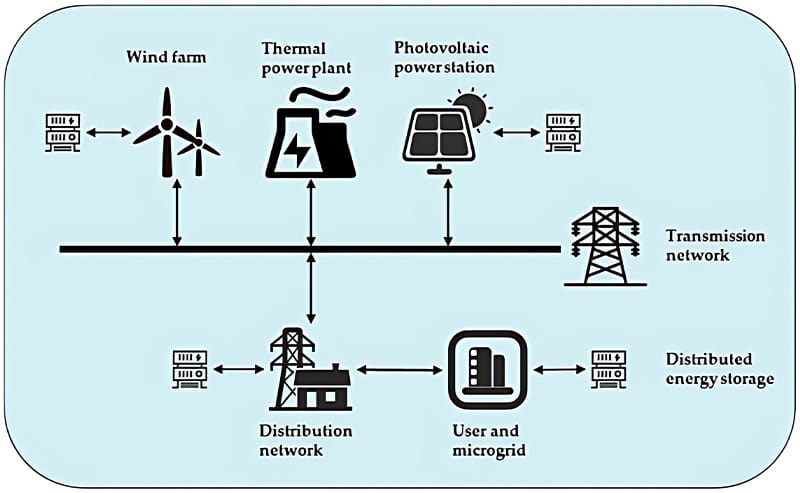

Different projects impose different requirements on a distribution layout, and one of the key strengths of box-type substations lies in their adaptability. By adjusting placement, configuration, and connection方式, engineers can tailor the layout to suit industrial, commercial, and renewable energy applications.

Industrial Power Distribution Layouts

In industrial facilities, the distribution layout is often designed around major load centers such as production lines, heavy machinery, or process equipment. Box-type substations are typically positioned close to these areas to reduce feeder length and improve voltage stability. This load-centered layout reduces power losses and enhances operational efficiency, especially in high-demand environments.

Commercial and Urban Infrastructure Layouts

For commercial complexes and urban infrastructure projects, space constraints and safety requirements dominate layout decisions. Box-type substations support compact, outdoor, or underground installation, allowing designers to integrate them seamlessly into dense environments. Within a distribution layout, this flexibility shortens construction cycles and minimizes disruption to surrounding facilities.

Renewable Energy Power Distribution Layouts

In solar PV plants, wind farms, and hybrid energy systems, box-type substations are often deployed as modular distribution nodes. They collect power from multiple inverters or generators and interface with the grid. This decentralized distribution layout simplifies expansion and supports phased project development as capacity grows.

| Application Scenario | Power Distribution Layout Feature | Practical Benefit |

|---|---|---|

| Industrial Plant | Load-centered substation placement | Reduced voltage drop |

| Commercial Complex | Compact, enclosed layout | Space efficiency |

| Renewable Energy Plant | Modular distributed substations | Easy expansion |

Advantages of Box-Type Substations in Power Distribution Systems

In modern projects, the effectiveness of a power distribution layout is no longer judged solely by whether it delivers electricity, but by how efficiently, safely, and flexibly it supports long-term operation. Within this context, box-type substations offer clear advantages over traditional substation solutions.

One of the most significant advantages lies in layout efficiency. By integrating medium-voltage switchgear, transformers, and low-voltage distribution equipment into a single enclosure, box-type substations dramatically reduce the physical footprint required in a distribution layout. This compact design allows engineers to position substations closer to load centers, directly improving voltage stability and reducing cable-related losses.

Another key advantage is standardization. Factory-assembled box-type substations arrive on-site as tested and integrated units. From a distribution layout perspective, this minimizes on-site installation errors, shortens commissioning time, and ensures consistent quality across multiple substations in the same project.

Safety and environmental protection also play an essential role. The enclosed structure of a box-type substation isolates live components from external interference, enhancing personnel safety and reducing the risk of accidental contact. This is particularly valuable in urban, industrial, and renewable energy distribution layouts, where space constraints and environmental exposure are common challenges.

Finally, box-type substations support scalability. As load demand increases, additional substations can be seamlessly integrated into the existing power layout without major system restructuring. This modular characteristic makes them especially suitable for phased construction projects and long-term capacity expansion.

| Aspect | Traditional Substation | Box-Type Substation |

|---|---|---|

| Layout Footprint | Large civil works required | Compact, integrated design |

| Installation Time | Long on-site construction | Fast deployment |

| Safety Level | Open or semi-enclosed | Fully enclosed |

| Layout Flexibility | Limited | High |

| Scalability | Complex expansion | Modular expansion |

Key Design Considerations for Box-Type Substation Layouts

Designing an effective power layout using box-type substations requires more than equipment selection. It involves a systematic evaluation of electrical, environmental, and operational factors to ensure long-term reliability and compliance.

Capacity and Load Matching

Accurate load forecasting is the foundation of any distribution layout. Transformer capacity must be selected based on actual demand, future expansion, and load characteristics. Oversizing increases cost and losses, while undersizing limits system reliability.

Environmental and Site Conditions

Environmental factors such as ambient temperature, humidity, dust, and altitude directly affect substation performance. In outdoor or harsh environments, enclosure protection level, corrosion resistance, and ventilation design become critical elements of the power distribution layout.

Ventilation and Thermal Management

Proper heat dissipation ensures stable transformer operation. Layout designers must consider airflow paths, clearance distances, and cooling methods when integrating a box-type substation into the power distribution .

Accessibility and Maintenance

A well-planned power distribution allows safe access for inspection, operation, and maintenance. Door orientation, cable entry routes, and equipment spacing should support efficient maintenance without disrupting surrounding infrastructure.

Standards and Compliance

Box-type substations must comply with IEC standards and local grid regulations. Aligning the distribution layout with applicable standards ensures grid compatibility, operational safety, and long-term acceptance by utilities.

| Design Factor | Why It Matters in Power Distribution Layout |

|---|---|

| Transformer Capacity | Prevents overload and inefficiency |

| Ventilation Design | Ensures thermal stability |

| Protection Coordination | Limits fault impact |

| Accessibility | Simplifies maintenance |

| Standards Compliance | Ensures grid approval |

Common Mistakes in Power Distribution Layout Design and How to Avoid Them

Even with high-quality equipment, poor planning or execution can cause a power distribution layout to underperform. Engineers often create system failures and operational inefficiencies through avoidable layout-level design errors.

One common mistake is improper transformer sizing. In some projects, designers select transformer capacity based only on initial load demand, ignoring load growth and starting current characteristics. This leads to frequent overloads and reduced equipment lifespan within the distribution layout. A proper load assessment and allowance for future expansion are essential.

Another frequent issue is poor ventilation planning. In compact installations, insufficient clearance and blocked airflow paths can cause excessive heat accumulation inside the box-type substation. Thermal stress not only affects transformer performance but also accelerates insulation aging, undermining the reliability of the entire distribution layout.

Cable routing is also often overlooked. Excessive cable length, tight bending radius, or unorganized cable entry points increase losses and complicate maintenance. A well-organized distribution layout should optimize cable paths while ensuring accessibility for inspection and replacement.

Finally, many layouts fail to account for future scalability. When designers reserve no physical space or electrical margin for expansion, upgrades become costly and disruptive. Designing a distribution layout with modular expansion in mind significantly reduces long-term project risk.

| Common Mistake | Impact on Power Distribution Layout | Recommended Solution |

|---|

| Undersized transformer | Overload and downtime | Perform load forecasting |

| Poor ventilation | Overheating and aging | Ensure airflow clearance |

| Inefficient cable routing | High losses, hard maintenance | Optimize routing paths |

| No expansion planning | Costly future upgrades | Design modular layout |

How to Select the Right Box-Type Substation for Your Project

Selecting the right equipment is essential for building a reliable distribution layout.

Engineers should select a box-type substation as part of an integrated distribution system, not as isolated equipment.

The selection process starts by defining voltage levels and transformer capacity based on actual load demand. Designers should include reasonable capacity margins to support future expansion without unnecessary oversizing. This approach helps the distribution layout operate efficiently and remain flexible over time.

Next, engineers must evaluate installation conditions such as temperature, humidity, and available space. Outdoor installations require higher enclosure protection, corrosion resistance, and thermal adaptability. In urban or confined environments, compact dimensions and low operational noise become critical considerations.

Engineers should then compare standard and customized box-type substations. Standard units offer cost and delivery advantages for conventional distribution layouts. Customized solutions better support complex layouts, special protection schemes, or unique grid requirements.

Finally, supplier capability plays a decisive role in long-term system performance. Experienced suppliers provide layout optimization, technical drawings, and reliable after-sales support. Strong supplier collaboration improves lifecycle reliability and overall distribution layout performance.

| Selection Factor | Impact on Power Distribution Layout |

|---|---|

| Voltage Level | Determines grid compatibility |

| Transformer Capacity | Affects load stability |

| Installation Environment | Influences enclosure design |

| Customization Level | Supports layout complexity |

| Supplier Support | Ensures long-term reliability |

Conclusion: Optimizing Power Distribution Systems with Box-Type Substations

With years of experience supplying box-type substations for industrial and renewable energy projects, we support EPC contractors across multiple regions. A well-engineered distribution layout is the backbone of a reliable and efficient electrical system. Throughout this article, we have explored how box-type substations integrate seamlessly into modern distribution networks, offering a compact, safe, and scalable solution for a wide range of applications.

By combining medium-voltage protection, voltage transformation, and low-voltage distribution within a single enclosure, box-type substations simplify layout planning while enhancing system reliability. Their modular nature allows engineers to optimize power flow, reduce losses, and adapt layouts to changing load demands without extensive reconstruction.

From industrial facilities and commercial complexes to renewable energy projects, a thoughtfully designed distribution layout using box-type substations delivers long-term operational benefits. When engineers properly address capacity planning, environmental conditions, ventilation, and compliance, these systems provide a future-ready foundation for sustainable power distribution.

Ready to Optimize Your Power Distribution Layout?

If you are planning a new project or upgrading an existing power distribution system, our engineering team can support you with box-type substation selection, layout optimization, and technical documentation.

Contact us to discuss your application requirements, request layout drawings, or receive a customized solution tailored to your distribution layout.

Frequently Asked Questions (FAQ)

Q1: What role does a box-type substation play in a power distribution layout?

A box-type substation connects medium-voltage supply to low-voltage loads within the power distribution layout.

Q2: How does a box-type substation improve power distribution layout efficiency?

It shortens cable length, reduces voltage drop, and simplifies the overall power distribution layout.

Q3: Can box-type substations operate outdoors in power distribution layouts?

Yes, box-type substations support outdoor installation in industrial, urban, and renewable power distribution layouts.

Q4: Can engineers expand a power distribution layout using box-type substations later?

Engineers can easily expand the power distribution layout by adding modular box-type substations.

Q5: Which standards should box-type substations follow in power distribution layouts?

Box-type substations typically comply with IEC standards and local grid requirements.