Table of Contents

- Introduction: Why EPC Contractor Transformer Selection Matters in Overseas Projects

- Understanding EPC Contractor Transformer Selection Project Requirements Before Selection

- International Standards and Compliance Requirements for EPC Contractor Transformer Selection

- Environmental and Site Conditions Impacting EPC Contractor Transformer Selection in Overseas Projects

- Transformer Types Commonly Selected by EPC Contractors for Transformer Selection

- Supplier Evaluation: What EPC Contractors Consider in Transformer Selection

- Cost vs Lifecycle Value in EPC Contractor Transformer Selection

- Common Mistakes EPC Contractors Make in Transformer Selection

- Best Practices from Experienced EPC Contractors for Transformer Selection

- Conclusion: Choosing the Right Partner for EPC Contractor Transformer Selection

- FAQ on EPC Contractor Transformer Selection

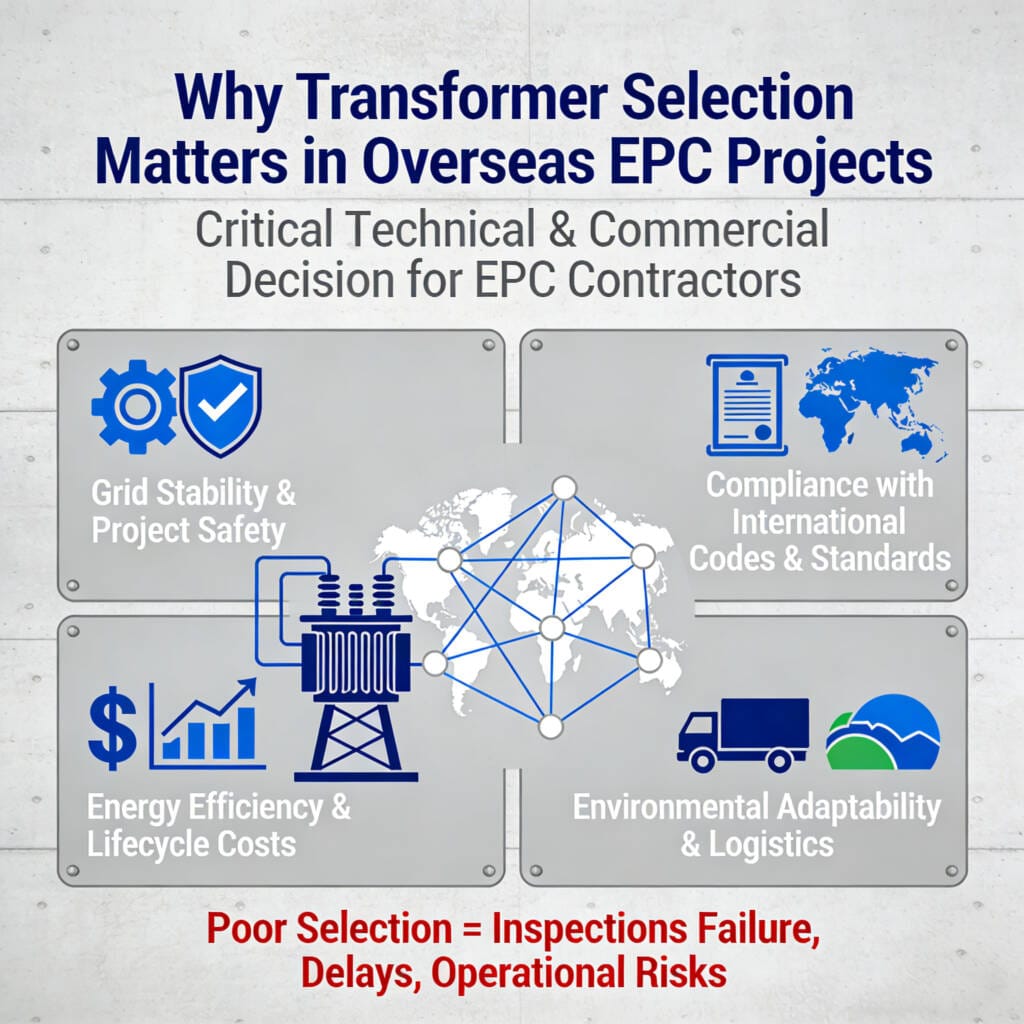

1. Introduction: Why Transformer Selection Matters in Overseas EPC Projects

In overseas power projects, EPC contractor transformer selection is one of the most critical technical and commercial decisions EPC contractors make. A transformer is not just an electrical component; it is a core asset that directly affects grid stability, project safety, energy efficiency, and long-term operating costs. For EPC contractors working on international power projects, selecting the right transformer determines whether a project progresses smoothly or faces costly delays and operational risks.

Unlike domestic projects, overseas EPC power projects involve diverse grid codes, international standards, extreme environmental conditions, and complex logistics. EPC contractor transformer selection for overseas power projects must therefore balance technical compliance, environmental adaptability, delivery timelines, and lifecycle value. An incorrect decision may lead to failed inspections, rejected equipment, or unplanned derating after commissioning.

This article explains how EPC contractors approach EPC contractor transformer selection for power projects abroad. Based on real EPC workflows and international procurement practices, it outlines selection criteria, compliance requirements, transformer types, supplier evaluation methods, and common mistakes to avoid. The goal is to help EPC contractors, project engineers, and procurement teams reduce risk and select reliable transformers for overseas power projects.

2. Understanding EPC Contractor Transformer Selection Project Requirements Before Transformer Selection

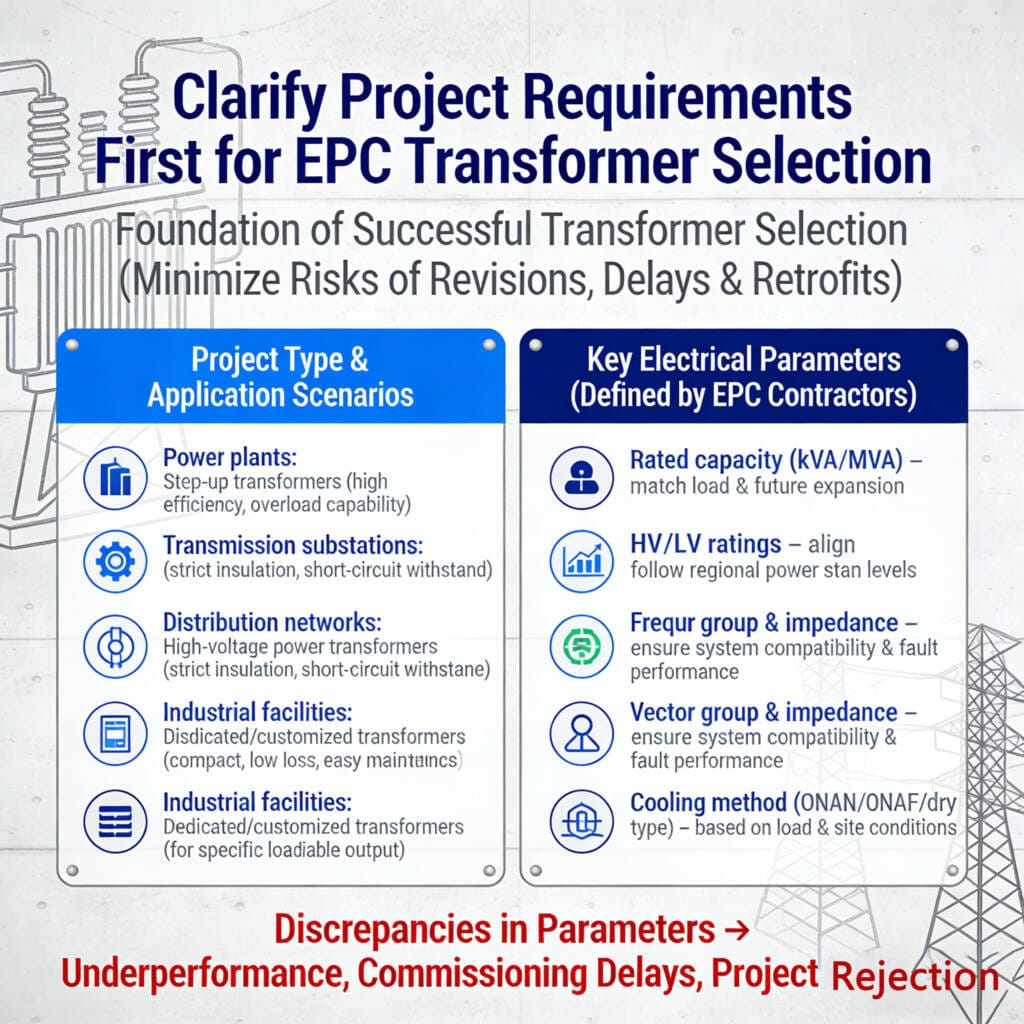

Successful transformer selection in EPC overseas power projects always begins with a thorough understanding of project requirements. Experienced EPC contractors clarify technical, environmental, and operational conditions at an early stage to minimize design revisions, procurement risks, and commissioning delays.

Before comparing transformer models or suppliers, EPC teams first align transformer specifications with the project’s functional role in the power system. This early technical alignment ensures compliance with grid codes, optimizes lifecycle performance, and avoids costly retrofits after delivery.

2.1 Project Type and Application Scenarios

Different overseas power projects impose fundamentally different technical and operational demands on transformers. EPC contractors begin transformer selection by clearly identifying the project type and its application scenario, which directly determines transformer design, insulation level, cooling method, and protection requirements.

Typical overseas power project types and corresponding transformer applications include:

| Project Type | Transformer Application |

|---|---|

| Power plants | Step-up transformers for transmission |

| Transmission substations | High-voltage power transformers |

| Distribution networks | Distribution transformers |

| Industrial facilities | Dedicated power transformers |

| Renewable energy projects | Grid-connection transformers |

For power plants, transformers primarily function as step-up units, requiring high efficiency, strong overload capability, and long-term operational stability. Transmission substation transformers must handle high voltage levels and fluctuating loads while meeting strict insulation and short-circuit withstand requirements.

Distribution network projects typically focus on distribution transformers with compact designs, low losses, and simple maintenance. Industrial facilities often require customized transformers designed for specific loads, harmonics, or harsh operating conditions. Renewable energy projects, such as solar or wind power plants, demand grid-connection transformers that can accommodate variable power output and comply with local grid interconnection standards.

By clearly defining the application scenario, EPC contractors can quickly eliminate unsuitable transformer types and focus on technically appropriate solutions.

2.2 Electrical Parameters Defined by EPC Contractors

After clarifying the project type, EPC contractors define the core electrical parameters that form the technical foundation of transformer selection. These parameters must align with both the project’s design requirements and the local grid operator’s specifications.

Key electrical parameters typically include:

- Rated capacity (kVA or MVA) to match present load demand and future expansion

- High-voltage and low-voltage ratings based on grid connection levels

- Frequency (50Hz or 60Hz) according to regional power standards

- Vector group and impedance to ensure system compatibility and fault performance

- Cooling method such as ONAN, ONAF, or dry type, depending on load profile and site conditions

These parameters directly affect transformer efficiency, temperature rise, short-circuit performance, and parallel operation capability. EPC contractors pay particular attention to impedance and vector group selection, as improper configuration may cause circulating currents, voltage instability, or protection malfunctions.

Any discrepancy between the defined electrical parameters and actual grid requirements can lead to transformer underperformance, commissioning delays, or even project rejection by local utilities. Therefore, experienced EPC teams verify all electrical parameters early in the design stage to ensure smooth procurement, installation, and long-term operation.

3. International Standards and Compliance Requirements for EPC Contractor Transformer Selection

In overseas EPC power projects, compliance with international standards is not optional—it is a core technical and contractual requirement. EPC contractors treat transformer compliance as a critical approval checkpoint, as any deviation from required standards may lead to project approval delays, rework costs, or contractual penalties.

Before finalizing transformer selection, EPC teams verify whether the transformer design, testing scope, and documentation fully comply with applicable international standards and local grid regulations. Early compliance verification reduces technical risk and ensures smooth coordination with utilities, consultants, and regulatory authorities.

3.1 IEC, ANSI, and Local Grid Standards

Most overseas power projects adopt either IEC or ANSI/IEEE standards, depending on the project location and the requirements of the local utility or grid operator. EPC contractors identify the governing standard at the feasibility or basic design stage to avoid specification conflicts later in the project lifecycle.

| Standard | Common Regions | Key Focus |

|---|---|---|

| IEC 60076 | Europe, Middle East, Africa | Thermal performance, dielectric strength, testing methods |

| ANSI / IEEE | North America | Insulation systems, temperature rise limits |

| Local grid codes | Project-specific | Utility interconnection and operational compatibility |

IEC 60076 is widely applied in international power projects and defines comprehensive requirements for transformer design, testing, temperature rise, and insulation coordination. ANSI/IEEE standards are typically required for projects in North America and emphasize different design philosophies, especially regarding insulation levels and temperature classification.

In addition to international standards, EPC contractors must ensure compliance with local grid codes. These codes may specify parameters such as impedance tolerance, protection coordination, noise limits, or parallel operation conditions. Transformer selection for overseas power projects therefore requires alignment with both international standards and local utility-specific requirements.

To manage this complexity, EPC contractors often request a standard compliance matrix from transformer manufacturers. This matrix allows EPC teams to systematically verify conformity clause by clause before issuing purchase orders.

3.2 Certification and Documentation Requirements

Beyond design compliance, EPC contractors place strong emphasis on certification and technical documentation during transformer procurement. Complete and verifiable documentation is essential for project approval, site acceptance, and final handover.

Typical documentation required for overseas EPC projects includes:

- Type test reports demonstrating design compliance with IEC or ANSI standards

- Routine test reports for each manufactured transformer

- Factory acceptance test (FAT) procedures and records

- Third-party inspection certificates, when specified by contract or utility

These documents provide traceability from design to manufacturing and testing. During audits, inspections, or commissioning, missing or incomplete documentation can delay energization and impact overall project schedules.

Transformer compliance documentation therefore plays a decisive role not only in technical evaluation but also in contractual risk management. EPC contractors typically shortlist transformer suppliers who demonstrate proven experience in delivering fully compliant documentation for international power projects.

4. Environmental and Site Conditions Impacting EPC Contractor Transformer Selection in Overseas Projects

Environmental and site conditions play a decisive role in transformer selection for overseas EPC projects. Unlike domestic installations, international power projects often operate in extreme climates or challenging geographic locations. EPC contractors must evaluate these factors early in the design stage to ensure long-term transformer reliability, safety, and lifecycle performance.

Ignoring environmental constraints may lead to accelerated insulation aging, reduced cooling efficiency, or frequent maintenance issues. Therefore, experienced EPC teams integrate site condition analysis directly into the transformer selection criteria rather than treating it as a secondary consideration.

4.1 Climate and Geographic Challenges

Overseas power projects are frequently exposed to harsh environmental conditions that directly affect transformer operation and service life. Common challenges include:

- High ambient temperatures, which increase winding temperature rise and accelerate insulation degradation

- High humidity or salt mist, typical in coastal and offshore regions, leading to corrosion and insulation surface tracking

- Desert dust or sandstorms, which block cooling ducts and reduce heat dissipation efficiency

- High-altitude conditions, where reduced air density negatively impacts cooling performance

These environmental factors significantly influence insulation systems, cooling methods, and material selection. As a result, environmental considerations in transformer selection must include thermal, dielectric, and mechanical derating to ensure compliance with design standards under actual site conditions.

For EPC contractors, accurately assessing climate and geography is essential to avoid transformer overheating, premature failure, or non-compliance with project performance guarantees.

4.2 Design Adaptations for Site Conditions

To address environmental challenges, EPC contractors collaborate closely with transformer manufacturers to implement site-specific design adaptations. These adaptations allow transformers to operate reliably under local conditions without compromising safety or efficiency.

| Environmental Factor | Design Adaptation |

|---|---|

| High temperature | Enhanced cooling systems or upgraded cooling class |

| Coastal or marine areas | Anti-corrosion coatings and moisture-resistant materials |

| High altitude | Insulation and cooling derating adjustments |

| Dusty or desert regions | Sealed enclosures and improved filtration |

Such measures are essential components of customized transformer solutions for overseas power projects. In many cases, standard transformer designs cannot meet the combined requirements of climate, altitude, and environmental exposure.

By integrating site condition–based transformer design adaptations, EPC contractors reduce operational risks, extend transformer service life, and ensure stable performance throughout the project lifecycle.

5. Transformer Types Commonly Selected by EPC Contractors for Transformer Selection

Selecting the correct transformer type for EPC power projects is a crucial step that directly affects operational efficiency, project cost, and long-term reliability. Experienced EPC contractors evaluate the project’s electrical requirements, site conditions, and compliance constraints before determining the most suitable transformer solution.

Choosing the wrong transformer type may lead to underperformance, maintenance challenges, or regulatory non-compliance in overseas installations. Therefore, transformer type selection in overseas EPC projects must consider load capacity, cooling efficiency, fire safety, and adaptability to site-specific conditions.

5.1 Oil Immersed Transformers for Power Projects

Oil immersed transformers remain the most widely applied solution in overseas power projects, particularly for high-capacity transmission and distribution networks. Their combination of high load capacity and robust thermal performance makes them ideal for projects requiring long-term reliability.

Key advantages include:

- High load capacity suitable for power plants and substations

- Excellent thermal performance with effective oil circulation and cooling

- Long service life due to well-established design and maintenance practices

- Flexibility to accommodate customized voltage and capacity requirements

Oil filled transformers are typically preferred where space constraints are minimal and fire safety regulations allow liquid-insulated equipment. EPC contractors often evaluate oil quality, conservator design, and cooling class (ONAN, ONAF) to ensure transformers meet the operational conditions of overseas installations.

5.2 Dry Type Transformers in Overseas Projects

Dry type transformers are increasingly selected in EPC overseas projects that require enhanced fire safety, low maintenance, and installation in confined spaces. These transformers eliminate the risk of oil leakage and are ideal for urban, industrial, or underground installations, making the 11KV Dry Type Transformer a reliable medium-voltage solution for commercial and industrial power distribution systems.

Typical applications include:

- Commercial buildings with strict fire safety regulations

- Underground substations where oil-free design prevents contamination and leakage

- Industrial facilities that require maintenance-friendly transformers

Key selection considerations for dry type transformers in overseas projects include:

- Insulation class to withstand thermal and environmental stresses

- Ventilation design to maintain efficient cooling under variable load conditions

- Enclosure protection rating for dust, humidity, and corrosive environments

By factoring in these elements, EPC contractors ensure that dry type transformers provide stable and safe operation throughout the project lifecycle.

5.3 Special Transformers for EPC Projects

Certain overseas EPC projects require specialized transformer solutions to optimize space, reduce installation time, or integrate with renewable energy systems.

| Transformer Type | Typical Application |

|---|---|

| Compact substation transformer | Urban distribution networks with limited space |

| Pad-mounted transformer | Utility networks requiring surface-mounted installations |

| Renewable energy transformer | Solar and wind farms with variable load and grid integration needs |

These special transformer solutions for overseas power projects allow EPC contractors to meet specific project requirements while maintaining compliance with local regulations. Customization often includes modular design, optimized cooling, and integration with control or monitoring systems.

Selecting the right transformer type—whether oil immersed, dry type, or specialized—ensures reliable, efficient, and code-compliant performance in overseas EPC power projects.

6. Supplier Evaluation: What EPC Contractors Consider in Transformer Selection

Transformer selection for EPC projects goes beyond technical specifications. Even the best transformer design cannot ensure project success without a reliable and experienced supplier. EPC contractors carefully evaluate manufacturers to minimize procurement risks, ensure on-time delivery, and guarantee long-term operational reliability.

A thorough transformer supplier evaluation for overseas EPC projects includes manufacturing capability, engineering support, logistics, and after-sales services.

6.1 Manufacturing Capability and Experience

EPC contractors prioritize transformer manufacturers with proven experience in overseas power projects. Critical evaluation factors include:

- Production capacity to handle high-volume or large-capacity transformers

- Export experience with knowledge of international shipping regulations and customs

- Reference projects demonstrating successful EPC project delivery under similar conditions

Selecting a manufacturer with strong overseas project experience reduces procurement risk, avoids delays, and ensures transformers meet quality and compliance requirements. EPC contractors often request project reference lists and factory audit reports before issuing purchase orders.

6.2 Engineering Support and Customization

Effective engineering support from transformer suppliers is a key factor in EPC project execution. Contractors favor suppliers who provide:

- Technical clarification responses to address specification or design queries promptly

- Drawing reviews to ensure compatibility with site layouts and civil works

- Custom design optimization for load, site conditions, and local grid compliance

Strong engineering collaboration ensures that customized transformer solutions for overseas EPC projects are technically feasible and integrate smoothly into the overall project. It also reduces design revisions, accelerates approval cycles, and improves overall project efficiency.

6.3 Logistics and After-Sales Support

Overseas transformer projects often involve complex logistics and challenging installation conditions. EPC contractors carefully assess supplier capabilities in:

- Packing and transportation solutions to protect transformers during long-distance shipping

- Installation guidance and supervision to ensure correct setup and safe energization

- Spare parts availability and after-sales support for long-term operational reliability

Comprehensive after-sales support for transformers in EPC projects ensures that any operational issues are quickly addressed, minimizing downtime and protecting project performance guarantees. Contractors often evaluate supplier responsiveness, technical support networks, and warranty terms as part of the selection process.

By combining manufacturing capability, engineering support, and robust logistics, EPC contractors can secure a transformer supplier that delivers both quality and reliability for overseas power projects.

7. Cost vs Lifecycle Value in EPC Contractor Transformer Selection

For transformer selection in EPC projects, price alone should never dictate the decision. Experienced EPC contractors evaluate the total lifecycle value of transformers, balancing initial investment with long-term operational costs, reliability, and energy efficiency.

Focusing solely on upfront cost may lead to higher expenses over the transformer’s service life, operational disruptions, or premature replacement. A holistic lifecycle cost analysis for transformers ensures EPC projects achieve both financial efficiency and technical performance.

7.1 Initial Cost vs Operating Cost

While a lower purchase price may seem attractive, operating costs and maintenance expenses often outweigh short-term savings. EPC contractors consider multiple cost components in transformer evaluation:

| Cost Component | Impact |

|---|---|

| Purchase price | Initial capital investment and procurement budget |

| Energy losses | Long-term operational cost due to transformer inefficiency |

| Maintenance | Ongoing operational reliability and repair expenses |

By analyzing these components, EPC contractors determine the transformer lifecycle cost, which includes purchase price, energy losses, maintenance, and potential downtime. This approach enables more informed investment decisions, reducing total cost of ownership while maintaining high system reliability.

7.2 Energy Efficiency and Reliability

High-efficiency transformers play a crucial role in reducing energy losses and improving overall system stability. EPC contractors increasingly prioritize energy-efficient transformer designs for overseas power projects, especially in regions where electricity costs are high or grid stability is critical.

Key considerations include:

- Transformer efficiency class according to IEC or ANSI standards

- Loss reduction technologies such as amorphous cores or optimized winding designs

- Reliability under varying load conditions to minimize unscheduled downtime

By focusing on energy efficiency and operational reliability, EPC contractors ensure that transformer selection aligns with both financial objectives and long-term project sustainability. This strategic approach helps prevent costly operational inefficiencies while supporting environmental and regulatory compliance goals.

8. Common Mistakes EPC Contractors Make in Transformer Selection

Even experienced EPC contractors occasionally encounter challenges during transformer selection for overseas power projects. Oversights at any stage—from design specification to supplier selection—can lead to project delays, increased costs, safety risks, and operational inefficiencies. Understanding the most common transformer selection mistakes helps EPC teams implement better procurement strategies, reduce risk, and ensure long-term project reliability.

8.1 Ignoring Environmental Derating

A frequent mistake is ignoring environmental derating requirements. Transformers installed in extreme conditions—such as high ambient temperature zones, coastal areas with high humidity and salt exposure, high-altitude sites, or dusty deserts—can suffer from accelerated insulation aging, higher operating temperatures, and reduced load capacity if derating factors are not applied.

Key considerations include:

- Temperature rise and cooling performance: Select transformers with suitable cooling class (ONAN, ONAF, or dry type) for the local climate.

- Insulation class: Ensure insulation can withstand thermal stresses caused by high ambient temperature or altitude.

- Material protection: Apply anti-corrosion coatings, sealed enclosures, and dust-proof ventilation where necessary.

Performing an environmental derating analysis for transformers ensures reliable operation under actual site conditions, reduces maintenance frequency, and extends the transformer’s service life.

8.2 Overlooking Local Grid Requirements

Another common error is overlooking local grid codes and utility standards. Even a transformer compliant with IEC or ANSI may fail to meet regional utility regulations.

Important aspects EPC contractors check include:

- Vector group and impedance compatibility with the local power network to prevent circulating currents and voltage imbalances.

- Short-circuit withstand capacity for protection coordination with breakers and fuses.

- Harmonic and load considerations to ensure proper operation in industrial or renewable energy projects.

Neglecting grid compliance review for transformers may result in delayed approvals, costly modifications, or rejection by local utilities. Early verification with the grid operator and inclusion of grid code compliance in procurement documents is crucial.

8.3 Incomplete Technical Documentation

Incomplete or missing documentation is another frequent cause of project risk. EPC contractors rely heavily on complete records to verify quality, performance, and compliance.

Critical documents include:

- Type test reports demonstrating compliance with IEC/ANSI standards

- Routine test reports for each manufactured unit

- Factory Acceptance Test (FAT) reports to ensure transformers meet contractual specifications

- Third-party inspection certificates required by utilities or contracts

Ensuring complete transformer documentation for EPC projects avoids delays during project audits, commissioning, and handover, while also providing traceability for future maintenance and warranty claims.

8.4 Selecting Suppliers Based on Price Alone

Many EPC contractors make the mistake of choosing suppliers based solely on low purchase price, ignoring factors that affect total lifecycle value.

Risks include:

- Poor manufacturing quality leading to early failures

- Insufficient engineering support for custom designs or site-specific adaptations

- Limited logistics experience, resulting in shipping delays or transformer damage

- Weak after-sales service, causing longer downtime during maintenance or repairs

Evaluating supplier experience, manufacturing capacity, technical support, logistics, and after-sales service ensures the selected supplier can deliver reliable, compliant, and efficient transformers for the entire project lifecycle. Focusing on total lifecycle value versus price in transformer procurement helps EPC contractors avoid cost overruns and operational inefficiencies.

8.5 Lack of Integrated Project Approach

A subtler but impactful mistake is treating transformer selection as an isolated decision. EPC contractors sometimes overlook how transformers interact with other systems, including:

- Substation layout and civil works

- Protection and control systems

- Parallel operation with other transformers or generators

Failing to consider these interactions can lead to installation challenges, commissioning delays, or operational instability. Adopting an integrated project approach for transformer selection ensures transformers are fully compatible with site-specific technical, environmental, and operational requirements.

By understanding and proactively addressing these common mistakes, EPC contractors can achieve efficient, reliable, and compliant transformer selection for overseas power projects, reducing operational risks, maintenance costs, and lifecycle expenses.

9. Best Practices from Experienced EPC Contractors for Transformer Selection

Successful EPC contractors follow structured transformer selection processes that integrate technical performance, compliance, cost efficiency, and project execution timelines. Over the years, top EPC teams have developed a series of best practices for transformer selection in overseas power projects to mitigate risk, reduce delays, and ensure long-term operational reliability.

Adopting these practices helps EPC contractors make informed procurement decisions, select the optimal transformer type, coordinate with suppliers, and comply with local grid regulations while ensuring lifecycle value.

9.1 Early Supplier Engagement

Engaging transformer suppliers early in the project lifecycle is a critical success factor. Early supplier engagement in transformer selection allows EPC contractors to:

- Verify supplier capabilities for manufacturing high-capacity or specialized transformers for overseas projects.

- Clarify design adaptations for environmental factors such as high temperature, high humidity, coastal salt exposure, high altitude, or dusty conditions.

- Plan logistics and delivery schedules in advance, including sea freight, customs clearance, and on-site handling.

- Coordinate preliminary engineering reviews, ensuring transformer dimensions, weight, and installation requirements fit the substation layout.

Early collaboration also allows suppliers to provide recommendations on transformer optimization, such as improved insulation class, cooling systems, or fire-safe designs, which may reduce operational risks and lifecycle costs.

9.2 Clear Technical Specifications

Providing clear, detailed technical specifications for EPC transformers ensures that procurement, manufacturing, and site installation proceed without misunderstandings. Experienced contractors include:

- Electrical parameters: Rated capacity, high/low voltage, frequency, vector group, and impedance.

- Environmental parameters: Temperature limits, humidity, altitude, dust, or corrosive conditions.

- Compliance requirements: IEC, ANSI/IEEE, and local grid codes.

- Documentation requirements: Type tests, routine tests, FAT reports, and third-party certifications.

Clear specifications reduce the risk of manufacturing errors, simplify supplier evaluation, and ensure transformers meet operational and safety requirements from day one.

9.3 Standardized Evaluation Criteria

Using standardized evaluation criteria for transformers ensures transparent and objective supplier comparisons. EPC contractors typically assess:

- Technical compliance with specifications, environmental conditions, and international standards.

- Supplier capabilities, including production capacity, engineering support, after-sales service, and prior overseas project experience.

- Lifecycle value, considering initial cost, operating efficiency, maintenance, and expected service life.

- Project references, verifying successful delivery of similar EPC projects in comparable environments.

A structured scoring system or matrix allows contractors to rank suppliers consistently and minimize subjective decision-making, ensuring both reliability and cost efficiency.

9.4 Integrated Project Management Approach

Top EPC contractors apply an integrated project management approach for transformer selection, which considers interactions with other substation or plant systems:

- Substation layout and civil works: Ensures transformers fit physically and allow proper clearances for maintenance and safety.

- Protection and control systems: Confirms compatibility with relays, SCADA, and automation systems.

- Parallel operation or renewable energy integration: Evaluates transformer performance in grid-connected solar, wind, or hybrid systems.

- Logistics and installation planning: Coordinates shipment, site handling, crane requirements, and assembly sequence.

This integrated approach reduces commissioning delays, prevents operational conflicts, and improves long-term reliability of the transformer in overseas power projects.

9.5 Continuous Learning and Feedback

Experienced EPC contractors also incorporate a continuous learning loop into their transformer selection process:

- Collect feedback from installed transformers regarding operational efficiency, downtime, and maintenance requirements.

- Update selection criteria and supplier evaluation templates based on lessons learned.

- Implement best practices across future projects, improving overall procurement efficiency and reducing risks in similar environments.

By systematically applying these practices, EPC contractors achieve efficient, reliable, and compliant transformer selection for overseas projects, ensuring that each project benefits from prior experience while mitigating technical, environmental, and operational risks.

10. Conclusion: Choosing the Right Partner for EPC Contractor Transformer Selection

Transformer selection for overseas power projects is a multifaceted process that goes far beyond simply choosing equipment based on specifications or price. Successful EPC contractors understand that optimal transformer performance depends on technical expertise, compliance awareness, site-specific adaptations, and strategic supplier evaluation.

By adopting a holistic approach to transformer selection, EPC teams achieve:

- Enhanced reliability through careful evaluation of transformer types, environmental derating, and grid compliance.

- Lower total lifecycle costs by considering energy efficiency, maintenance, and operational longevity rather than upfront price alone.

- Smoother project execution thanks to early supplier engagement, clear technical specifications, and standardized evaluation processes.

10.1 Strategic Supplier Partnership

Choosing the right transformer partner is not just about equipment quality; it is also about engineering support, compliance capability, and long-term collaboration.

Key considerations include:

- Supplier technical expertise to provide engineering guidance, custom design adaptations, and site-specific recommendations.

- Regulatory and standards compliance capability, ensuring that transformers meet IEC, ANSI/IEEE, and local utility requirements.

- After-sales and lifecycle support, including spare parts availability, maintenance guidance, and operational troubleshooting.

- Proven track record in overseas EPC projects, demonstrating the ability to deliver on time and handle complex logistics.

By partnering with a reliable transformer supplier, EPC contractors can mitigate project risks, optimize transformer performance, and ensure sustainable, high-performance power delivery for the lifetime of the installation.

10.2 The Holistic EPC Approach

Ultimately, the key to success lies in a holistic EPC approach to transformer selection, which integrates:

- Technical specification alignment with project requirements

- Compliance with international and local standards

- Environmental and site condition adaptation

- Supplier evaluation and lifecycle value analysis

This integrated strategy allows EPC contractors to select transformers that not only meet immediate project needs but also support long-term operational efficiency, cost savings, and reliability in overseas installations.

By combining technical rigor, compliance awareness, and strategic supplier partnerships, EPC contractors can ensure that transformer selection for overseas power projects delivers optimal value, mitigates risk, and enhances project success from design to commissioning and beyond.

11. FAQ on EPC Contractor Transformer Selection

Q1: What is the most important factor in transformer selection for EPC projects?

A: Compliance with project specifications, international standards, and site conditions is the most critical factor.

Q2: Are dry type transformers suitable for overseas power projects?

A: Yes, especially for applications requiring fire safety and low maintenance.

Q3: How can EPC contractors reduce transformer procurement risks?

A: By engaging experienced manufacturers early and conducting thorough technical evaluations.

Call to Action

If you are an EPC contractor planning an overseas power project, selecting the right transformer partner is essential. Contact our engineering team to discuss customized transformer solutions that meet international standards, site conditions, and project timelines.

1 Comment