Description

This low voltage distribution switchgear is designed for safe and stable power distribution in industrial, commercial, and infrastructure projects. Operating at AC frequency 50Hz with a rated working voltage of 380V and current capacity up to 3150A, it supports flexible system configurations and reliable long-term operation. As a manufacturer and supplier, we provide standardized production, quality-certified assembly, and customized solutions for low-voltage power distribution systems.

Product Overview of Low Voltage Distribution Switchgear

This low voltage distribution switchgear is designed for customers who need stable and safe power distribution in industrial and commercial electrical systems. It operates at AC frequency 50Hz, with a rated working voltage of 380V and a rated working current of up to 3150A. These parameters meet the common requirements of low-voltage power distribution systems in factories, data centers, commercial buildings, and infrastructure projects.

Customers usually purchase this type of low voltage distribution switchgear to manage incoming power, distribute electricity to different loads, and protect downstream electrical equipment. It is commonly used together with transformers, generators, and motor control systems. The cabinet structure supports continuous operation and helps maintain stable power supply in daily production and facility operation.

This switchgear typically operates on the secondary side of a power transformer to distribute electricity to multiple circuits.

The electrical ratings follow common low voltage distribution practices defined in international standards such as IEC 61439 for low voltage switchgear assemblies.

Typical Applications

| Application Scenario | Purpose |

|---|---|

| Industrial factories | Main power distribution and load management |

| Commercial buildings | Stable electrical distribution for lighting and HVAC |

| Infrastructure projects | Centralized low-voltage power control |

| Power rooms | Connection between transformer and loads |

Structural Design and External Details

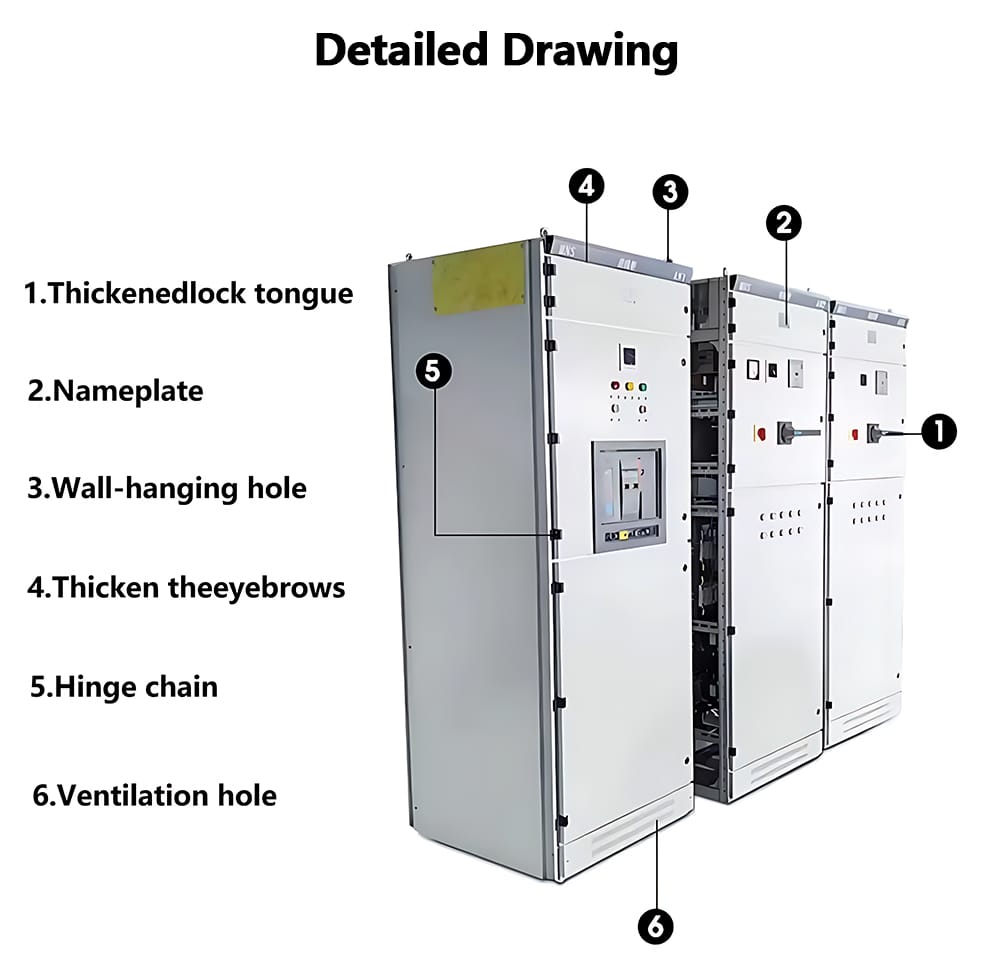

This image focuses on the external structural details of the low voltage distribution switchgear. Each design element serves a practical purpose during installation, operation, and maintenance. The thickened lock tongue improves door strength and cabinet sealing. The clear nameplate helps operators identify circuits quickly. Wall-hanging holes support stable installation and alignment.

The reinforced cabinet edges and hinge chain improve mechanical durability during long-term use. Ventilation holes are designed to support natural heat dissipation, helping the LV distribution cabinet maintain stable performance under continuous electrical load.

Customers searching for electrical distribution cabinets often care about safety, ease of maintenance, and long service life. These structural details directly support those needs and reduce daily operation risks.

Key Structural Features

| Feature | Function |

|---|---|

| Thickened lock tongue | Improves door strength and safety |

| Nameplate | Easy circuit identification |

| Hinge chain | Stable door operation |

| Ventilation holes | Heat dissipation and airflow |

| Wall-hanging holes | Convenient installation |

Internal Assembly and Electrical Components

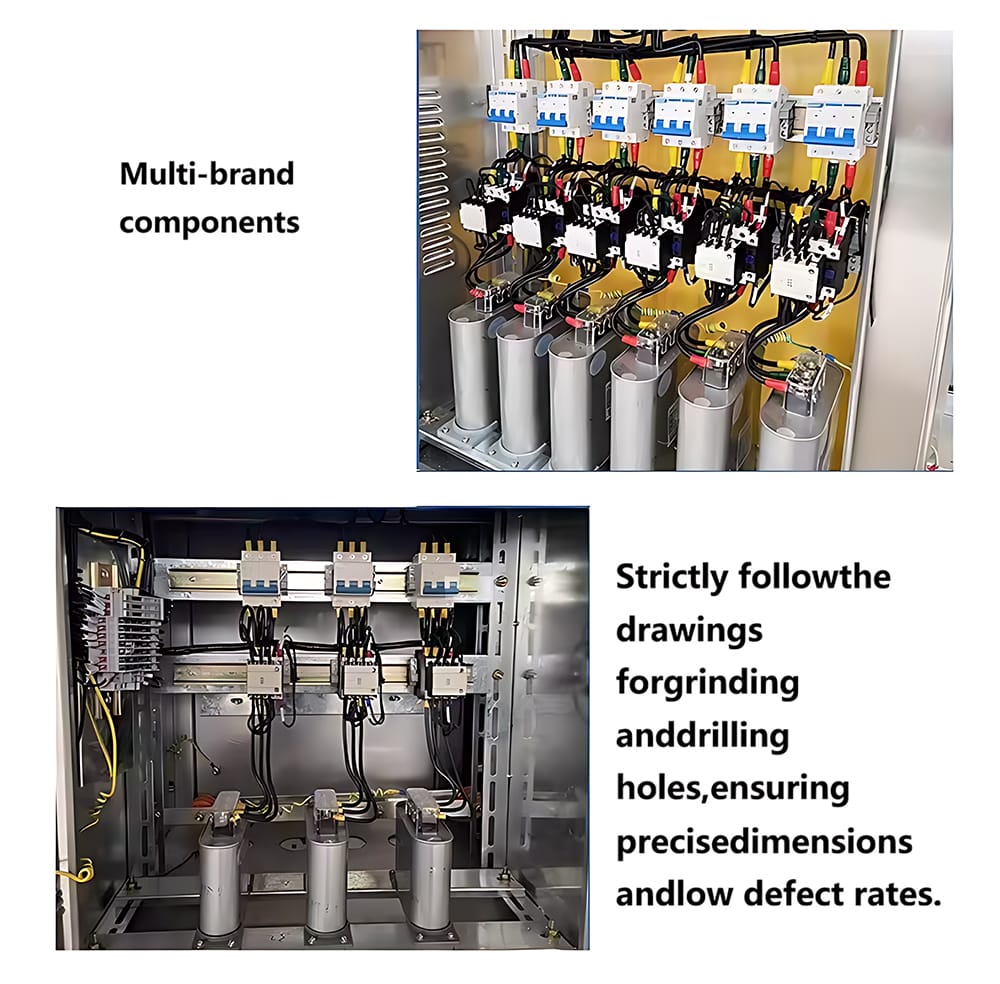

The internal structure of the low voltage distribution switchgear shows a clean and well-organized electrical layout. Multi-brand electrical components are used to meet different customer preferences and project specifications. Busbars, terminals, and internal wiring are arranged to support stable current flow and easy inspection.

All grinding and drilling processes strictly follow engineering drawings. Hole positions and dimensions are controlled with precision. This reduces assembly errors and lowers defect rates. For customers, this means more consistent quality and fewer issues during commissioning.

Many buyers search for low voltage distribution switchgear suppliers who can ensure reliable internal assembly. This manufacturing approach reflects real production experience and engineering expertise.

Many low voltage switchgear assemblies use circuit breakers and control components that comply with internationally recognized electrical component standards.

Internal Assembly Advantages

| Aspect | Benefit |

|---|---|

| Multi-brand components | Flexible project compatibility |

| Precise drilling | Accurate installation and alignment |

| Standardized layout | Easier inspection and maintenance |

| Controlled defect rate | Improved operational reliability |

Dimensions, Functional Units, and Configuration Options

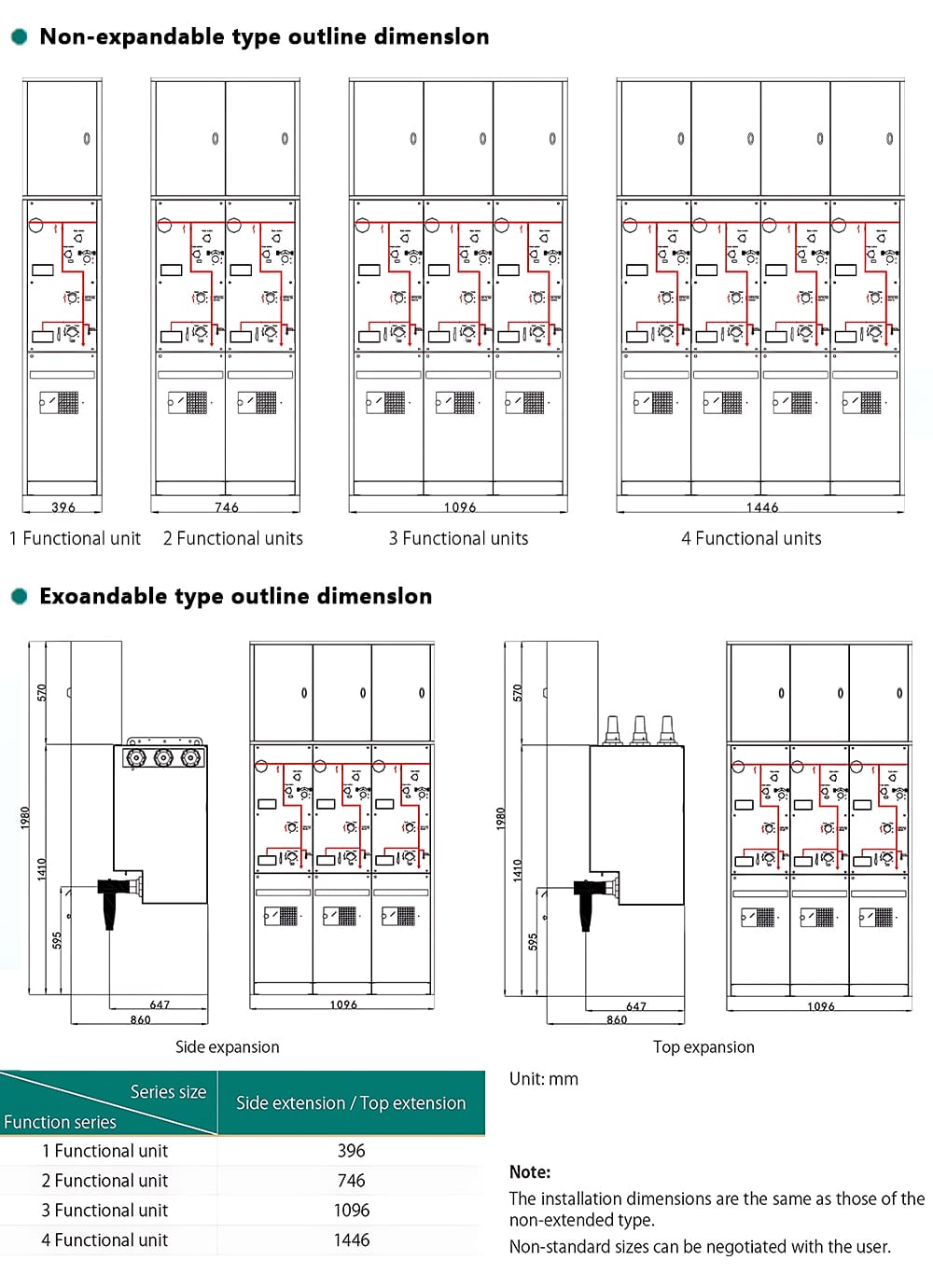

This drawing explains how the low voltage distribution switchgear is configured in real power distribution systems. It shows the relationship between cabinet size, functional units, and system expansion options. Each functional unit is designed to handle specific electrical tasks such as incoming power, outgoing feeders, protection circuits, and control functions.

Customers usually check this drawing when they plan a power room or distribution system layout. The ability to combine multiple functional units allows the switchgear to adapt to different load requirements. Side extension and top extension options make future system expansion easier without changing the original installation position.

The installation dimensions remain the same as the non-extended type. This reduces engineering work on site and avoids redesign during later capacity upgrades. For projects with special space limitations or system requirements, non-standard configurations can be discussed and customized. This flexibility is especially important for industrial power distribution systems where layouts vary from project to project.

Key Advantages and Service Capability

This section focuses on the real reasons customers choose this low voltage distribution switchgear instead of a generic electrical cabinet. In power distribution projects, buyers care about more than price. They care about product stability, delivery reliability, and long-term service support.

Excellent quality ensures stable operation under continuous electrical load. On-time delivery helps customers keep construction and commissioning schedules under control. Various cabinet sizes and configurations allow the switchgear to match different transformer capacities and power distribution schemes. One-stop service reduces communication costs when customers purchase switchgear together with related electrical equipment.

Many customers search for a low voltage distribution switchgear supplier who can support the whole project lifecycle, not just deliver a cabinet. This combination of product quality and service capability helps reduce project risk and improves overall efficiency.

Customer Value Summary

| Customer Concern | How This Switchgear Helps |

|---|---|

| System stability | Reliable structure and electrical design |

| Project schedule | On-time production and delivery |

| Layout flexibility | Multiple sizes and configurations |

| Procurement efficiency | One-stop service support |

Packaging, Transportation, and Delivery Protection

This image shows how the low voltage switchgear is prepared for transportation. Packaging is designed to protect the cabinet structure, internal components, and surface finish during handling and long-distance shipping. Reinforced materials help prevent deformation, vibration damage, and moisture impact.

Customers often purchase low voltage distribution switchgear for projects located far from the manufacturing site. Transportation damage can cause installation delays and additional costs. Proper packaging reduces these risks and ensures the switchgear arrives on site in good condition.

The goal of this packaging method is not only safe delivery, but also on-site readiness. After unpacking, the electrical distribution cabinet can be installed and commissioned without additional repair work, which is critical for tight project schedules.

Certifications and Compliance Standards

This image presents the certifications related to the low voltage switchgear. Certification is a key requirement in many industrial, commercial, and infrastructure projects. It shows that the product meets recognized quality management and electrical safety standards.

Customers searching for low voltage switchgear often need equipment that can pass inspections and meet project specifications. Certified products reduce approval risks during bidding, installation, and final acceptance. They also help contractors and system integrators meet regulatory requirements.

Compliance is not only about documents. It reflects standardized manufacturing processes, controlled quality inspection, and consistent product performance. This gives customers confidence when selecting electrical distribution equipment for long-term operation.

Compliance with low voltage switchgear standards supports safe installation inspection and acceptance during project execution.

Why Certification Matters

| Project Stage | Customer Benefit |

|---|---|

| Tendering | Meets technical requirements |

| Installation | Easier inspection approval |

| Operation | Improved safety and reliability |

| Long-term use | Reduced compliance risk |

Real Customer Cooperation and Project Experience

This image shows real interaction between the company and customers. Direct communication helps clarify technical details such as system configuration, load requirements, and installation conditions. These discussions improve product matching and reduce misunderstandings during project execution.

For many buyers, choosing a low voltage switchgear supplier is not only about the product. It is about trust and experience. Real project cooperation shows that the supplier understands how customers use the switchgear in actual power distribution systems.

This experience helps support customers during design, production, delivery, and after-sales service. It also reflects long-term cooperation capability, which is important for customers planning multiple projects or system upgrades.

FAQ

What is a low voltage distribution switchgear used for?

Low voltage distribution switchgear receives electrical power from a transformer and distributes it safely to different loads. It controls circuits protects equipment and isolates faults within a low voltage power distribution system. Engineers install it in factories commercial buildings infrastructure projects and electrical rooms to ensure stable power distribution.

Where do engineers usually install low voltage distribution switchgear?

Engineers usually install low voltage distribution switchgear in electrical rooms power distribution rooms or control rooms. It connects to the secondary side of the transformer and distributes electricity to lighting systems motor loads HVAC equipment and auxiliary power circuits.

What electrical ratings does this low voltage distribution switchgear support?

This low voltage distribution switchgear operates at AC frequency 50Hz with a rated working voltage of 380V. It supports rated working current up to 3150A. These electrical ratings meet the standard requirements of most industrial and commercial low voltage distribution systems.

Can customers customize this low voltage distribution switchgear for different projects?

Yes customers can customize this low voltage distribution switchgear based on project requirements. The cabinet supports different functional unit combinations and allows side extension and top extension. The manufacturer can also negotiate non standard sizes to match site layout space limitations and system design needs.

What components are installed inside the low voltage distribution switchgear?

The low voltage distribution switchgear uses electrical components from multiple well known brands according to customer specifications. Technicians install all components strictly according to engineering drawings. This process ensures accurate hole positioning reliable assembly and low defect rates during production.

How does this low voltage distribution switchgear improve operational safety?

This low voltage distribution switchgear improves safety through a reinforced cabinet structure reliable locking design clear nameplate identification and effective ventilation. These features protect operators reduce electrical risks and support long term stable operation in low voltage electrical distribution systems.

Is this low voltage distribution switchgear suitable for industrial environments?

Yes this low voltage distribution switchgear suits industrial environments that require continuous operation and high load stability. Many customers use it in manufacturing plants processing facilities power stations and infrastructure projects where reliable electrical distribution is critical.

How does the manufacturer package the low voltage distribution switchgear for transportation?

The manufacturer packages each low voltage distribution switchgear with reinforced protective materials. The packaging prevents deformation surface damage and vibration during lifting loading and long distance transportation. This ensures the electrical distribution cabinet arrives on site in good condition and ready for installation.

Does this low voltage distribution switchgear meet certification and compliance requirements?

Yes the low voltage distribution switchgear complies with relevant electrical safety standards and quality management requirements. Certification supports project approval factory inspection and site acceptance. This helps customers meet regulatory and tender requirements in different markets.

What types of projects commonly use this low voltage distribution switchgear?

Customers commonly use this low voltage distribution switchgear in industrial factories commercial buildings data centers energy projects and infrastructure facilities. It works well for new power distribution installations and system upgrades where engineers need reliable low voltage electrical control and protection.

Why should buyers choose an experienced supplier for low voltage distribution switchgear?

An experienced supplier understands system design manufacturing processes and project execution. Professional suppliers provide stable product quality technical support and delivery reliability. This reduces installation risks improves system performance and helps customers complete projects on schedule.

Engineering Support for Global Power Distribution Projects

If you are planning a low voltage power distribution project or upgrading an existing electrical system, this low voltage distribution switchgear provides a reliable and flexible solution. Our engineering team supports project evaluation technical configuration and production coordination.

Send us your project requirements drawings or electrical parameters. We will review your application and recommend a suitable switchgear configuration for your system.

Contact us to discuss your project and get technical support from an experienced low voltage switchgear manufacturer.

Reviews

There are no reviews yet.