In the petrochemical industry, ultra-high voltage (UHV) transformers serve as silent guardians. Though often overlooked, they are critical components that ensure the smooth operation of the entire supply chain. Imagine the chaos that would ensue in petrochemical operations without these powerful transformers!

Understanding Ultra-High Voltage Transformers

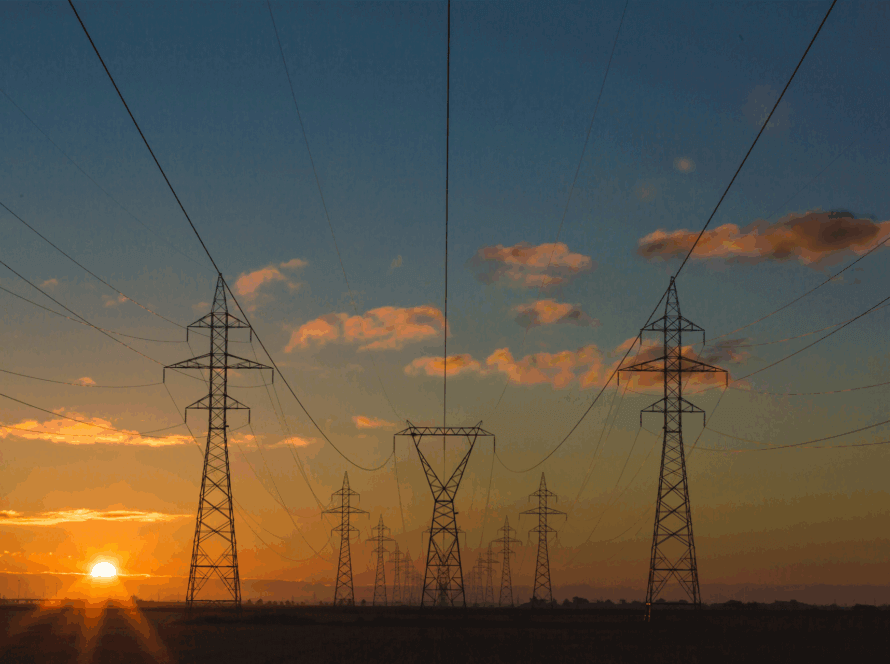

As the name suggests, ultra-high voltage transformers are designed to handle extremely high voltage levels. These devices are primarily used in power transmission systems to convert voltage from one level to another. In the petrochemical sector, their core function is to transform the high-voltage electricity generated by power plants into levels suitable for industrial equipment usage.

Why the Petrochemical Industry Needs UHV Transformers

First and foremost, petrochemical operations rely on a stable and uninterrupted power supply. Given the complexity of processes such as refining and chemical synthesis, even minor power fluctuations can lead to production halts or substantial financial losses. UHV transformers help ensure electrical stability—like providing calm waters for a smoothly sailing ship.

Secondly, UHV transformers significantly reduce energy losses during transmission. By stepping up the voltage to ultra-high levels, current intensity is lowered, thereby minimizing heat loss along transmission lines. This becomes especially crucial for long-distance power delivery—just like using a fine pipe to transport water efficiently without excessive waste due to friction.

Practical Applications of UHV Transformers

UHV transformers are widely used across the petrochemical industry. In refineries, for example, they supply power to large-scale equipment such as oil-gas separators and hydrocracking furnaces. Without them, these essential machines would be unable to operate, potentially paralyzing entire production lines.

Moreover, in chemical production processes, UHV transformers are also used to drive various motors and pumps. These components often require high power outputs to maintain safe and efficient operations—much like a high-performance race car depends on a powerful engine to fly down the track.

Maintenance and Management of UHV Transformers

Once installed, regular maintenance of UHV transformers is essential. Just as elite athletes must stay in peak condition, these transformers need periodic check-ups to prevent unexpected failures. Typical maintenance tasks include monitoring insulation oil quality, checking electrical connections, and inspecting internal components.

To ensure long-term reliability and safety, companies often implement multiple monitoring measures. For instance, online monitoring systems can track real-time operational data—like equipping a race car with panoramic cameras to monitor performance and ensure safe driving.

Conclusion

In summary, UHV transformers play a pivotal role in the petrochemical industry. They ensure stable power supply, reduce energy losses, and support the efficient operation of complex industrial systems. As technology advances and the industry continues to evolve, ultra-high voltage transformers are set to play an increasingly vital role in powering the future of petrochemicals.