Table of Contents (TOC)

- Introduction: Why Initial Price Is Not the Real Cost

- Understanding the Three Power Distribution Solutions

- 2.1 Oil-Immersed Transformers and Substations

- 2.2 Dry-Type Transformers

- 2.3 Pad-Mounted Substations

- How We Evaluate 10-Year Cost and Value

- Initial Capital Cost Comparison (Year 0)

- Operating Efficiency and Energy Loss Cost (Years 1–10)

- Maintenance, Inspection, and Labor Costs

- Safety, Environmental, and Compliance-Related Costs

- Downtime Risk and Reliability Impact

- 10-Year Total Cost of Ownership (TCO) Comparison

- Best-Fit Applications by Industry and Environment

- Practical Buying Advice to Avoid Long-Term Cost Mistakes

- Final Conclusion and Decision Guidance

1. Introduction: Why Initial Price Is Not the Real Cost

When selecting a transformer or substation solution, many buyers—especially in international tenders—focus almost exclusively on the initial purchase price. On paper, this approach seems logical. Procurement teams are often evaluated on how well they control upfront budgets, and bids are frequently awarded to the lowest-cost supplier.

However, in real-world power distribution projects, initial price represents only a fraction of the true cost.

Over a typical 10-year operating period, transformers and substations generate continuous expenses through energy losses, routine maintenance, inspections, downtime risks, and regulatory compliance. These ongoing costs often exceed the original equipment cost, especially in industrial, commercial, and utility-scale applications.

This is where many projects experience “hidden losses”:

- A transformer with a lower purchase price but higher energy losses

- A substation that requires frequent shutdowns for maintenance

- Equipment that meets basic standards but struggles with long-term reliability

From our experience working with EPC contractors, industrial plant owners, and overseas utility buyers, the most common regret we hear is:

“We should have evaluated the lifecycle cost, not just the quotation.”

In this article, we compare oil-immersed transformers, dry-type transformers, and pad-mounted substations through a 10-year cost-benefit lens. Rather than promoting a single “best” solution, our goal is to help you understand which option delivers the highest value for your specific application.

This analysis is especially relevant for:

- Industrial manufacturing facilities

- Commercial buildings and infrastructure projects

- Utility and distribution network upgrades

- Overseas EPC and renewable energy projects

2. Understanding the Three Power Distribution Solutions: A Substation Cost Comparison

Before comparing costs, it is essential to clearly understand what each solution is designed to do and where it is typically used. Many cost misunderstandings stem from comparing products that are not functionally equivalent.

Power Distribution Solutions Comparison

| Feature / Aspect | Oil-Immersed Transformer | Dry-Type Transformer | Pad-Mounted Substation |

|---|---|---|---|

| Insulation & Cooling | Mineral oil or ester fluid; oil circulation for cooling | Air-cooled; solid insulation (cast resin or VPI) | Integrated transformer + switchgear; can be oil-immersed or dry-type, enclosed |

| Typical Installation | Outdoor, utility or industrial substations | Indoor (commercial buildings, data centers, hospitals) | Outdoor, compact pad-mounted unit |

| Fire & Safety Risk | Higher; flammable oil, requires fire protection | Low; no flammable liquid | Low to medium; designed for public safety and secure enclosure |

| Initial Equipment Cost | Generally lower per kVA | Medium to high | High (integration includes transformer + switchgear + enclosure) |

| Maintenance Requirement | Medium to high; oil testing, cooling inspection | Low to medium; regular cleaning and ventilation check | Low; factory-tested, enclosed, minimal on-site maintenance |

| Energy Efficiency | High efficiency; good heat dissipation | Medium; sensitive to high ambient temperature | Medium to high; depends on integrated transformer type |

| Space Requirement | Larger footprint; outdoor space needed | Compact indoors | Compact; minimal civil works required |

| Application Fit | Power plants, heavy industry, utilities | Commercial buildings, indoor industrial facilities | Urban distribution, residential compounds, renewable energy projects |

| Reliability | Proven, but maintenance-dependent | Reliable indoors; sensitive to dust/temperature | High; integrated and factory-tested |

| Lifecycle Consideration | Oil degradation, potential fire hazard | Insulation aging, ventilation critical | Long-term stability, minimal field variability |

2.1 Oil-Immersed Transformers and Substations

Oil-immersed transformers use mineral oil or ester fluid as both an insulating medium and a cooling agent. Heat generated by the windings is transferred to the oil, which circulates naturally or through forced cooling systems.

Oil-immersed transformers are widely used in:

- Power plants and substations

- Heavy industrial facilities

- Utility transmission and distribution networks

- Outdoor installations with sufficient space

Key characteristics:

- High efficiency and excellent heat dissipation

- Proven technology with decades of operational history

- Suitable for high-capacity and high-voltage applications

From a cost perspective, oil-immersed transformers often offer lower initial equipment cost per kVA, especially at medium and high ratings. However, they introduce additional considerations such as oil containment, fire protection, and environmental compliance.

In many projects, oil-immersed transformers are installed as part of a traditional outdoor substation, which includes foundations, oil pits, fencing, and fire safety systems.

2.2 Dry-Type Transformers

Dry-type transformers use air as the primary cooling medium and solid insulation systems such as cast resin or vacuum pressure impregnation (VPI). They do not contain flammable oil, which makes them particularly attractive for indoor and densely populated environments.

Typical applications include:

- Commercial buildings

- Hospitals and data centers

- Airports and transportation hubs

- Indoor industrial power rooms

Key characteristics:

- No oil leakage or fire risk from liquid insulation

- Lower environmental and regulatory burden

- Compact footprint for indoor installation

From an operational standpoint, dry-type transformers are often perceived as “low-maintenance” equipment. While this is generally true, they can be sensitive to dust, humidity, and ambient temperature, which directly affects long-term performance and cooling efficiency.

Initial purchase cost for dry-type transformers is usually higher than oil-immersed units of the same capacity, particularly for cast resin designs.

2.3 Pad-Mounted Substations

Pad-mounted substations are fully integrated power distribution units that typically include:

- A pad-mounted transformer

- Medium-voltage switchgear (RMU or load break switches)

- Low-voltage distribution panel

All components are enclosed in a weatherproof steel housing and installed on a concrete pad at ground level.

They are commonly used in:

- Urban distribution networks

- Residential and commercial developments

- Industrial parks

- Renewable energy projects

Key characteristics:

- Compact, integrated, and space-saving design

- Enhanced safety with dead-front construction

- Reduced on-site installation complexity

While pad-mounted substations often have a higher upfront cost, they can significantly reduce installation time, civil works, and coordination between multiple suppliers.

In many cases, buyers underestimate the cost savings from integration, focusing only on the equipment price rather than the total installed cost.

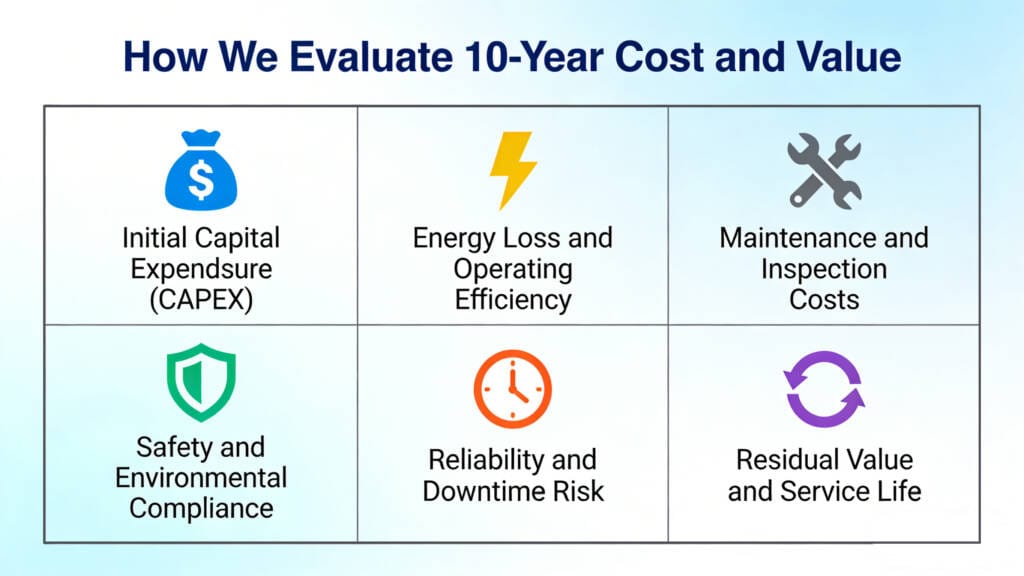

3. How We Evaluate 10-Year Cost and Value: A Substation Cost Comparison

To ensure a fair comparison, this analysis evaluates each solution across the same cost dimensions over a 10-year operating period, which is a standard planning horizon for industrial and utility assets.

Cost Evaluation Framework

We divide costs into six major categories:

- Initial Capital Expenditure (CAPEX)

- Equipment purchase price

- Transportation and import costs

- Installation and commissioning

- Energy Loss and Operating Efficiency

- No-load losses

- Load losses

- Impact on electricity bills

- Maintenance and Inspection Costs

- Routine servicing

- Testing and diagnostics

- Labor and spare parts

- Safety and Environmental Compliance

- Fire protection systems

- Environmental safeguards

- Regulatory inspections

- Reliability and Downtime Risk

- Failure probability

- Repair time

- Production or service interruption

- Residual Value and Service Life

- Expected lifespan beyond 10 years

- Refurbishment or replacement potential

By applying this framework, we avoid the common mistake of comparing equipment based solely on nameplate specifications or initial quotations.

4. Substation Cost Comparison: Initial Capital Cost (Year 0)

In Middle East projects, initial capital cost is often the most visible number during tender evaluation. However, what appears as a “lower price” at quotation stage can change significantly once installation conditions, climate adaptation, and regulatory requirements are fully considered.

4.1 Equipment Purchase Cost in Middle East Projects

For comparable capacity ratings (e.g., 1000 kVA to 2500 kVA at 11 kV or 33 kV), the general pricing trend in Middle East markets is:

- Oil-immersed transformers

Typically offer the lowest equipment price per kVA, especially for outdoor installations. Local utilities and EPCs are very familiar with oil-filled designs, which keeps acceptance barriers low. - Dry-type transformers

Usually 20–40% higher in initial unit price compared to oil-immersed transformers of the same rating. Cast resin designs further increase cost but are often specified for indoor commercial or infrastructure projects. - Pad-mounted substations

Appear more expensive at first glance because they combine multiple components into a single package. However, this comparison is misleading if evaluated only as “equipment cost.”

In Middle East tenders, we frequently observe that pad-mounted substations are compared against separately quoted transformers, RMUs, LV panels, foundations, and cabling, without accounting for the integration value.

4.2 Installation and Civil Works Cost

Installation costs in the Middle East are heavily influenced by labor availability, site conditions, and climate protection requirements.

Oil-Immersed Substations

Oil-immersed transformers typically require:

- Concrete foundations

- Oil containment pits or bund walls

- Fire protection clearances

- Fencing and restricted access

In hot desert environments, additional shading structures or cooling considerations may be required to prevent oil temperature from exceeding design limits.

While the transformer itself may be economical, civil works and fire safety systems can significantly increase total installed cost.

Dry-Type Transformers

Dry-type transformers are commonly installed indoors, which can reduce outdoor civil works. However, this shifts cost toward:

- Dedicated transformer rooms

- Ventilation or air-conditioning systems

- Dust protection measures

In Middle East climates, maintaining proper airflow and ambient temperature is critical. Poor ventilation can lead to derating, which effectively increases cost per usable kVA.

Pad-Mounted Substations

Pad-mounted substations are designed for outdoor installation, making them highly suitable for Middle East conditions.

Key installation advantages include:

- Minimal foundation requirements

- No oil pits (for dry-type pad-mounted designs)

- Reduced on-site wiring and commissioning time

For large-scale developments such as industrial parks or residential compounds, these advantages often translate into lower total installed cost, despite a higher equipment price.

5. Operating Efficiency and Energy Loss Cost (Years 1–10)

In Middle East countries, electricity tariffs for industrial users vary widely. Some regions benefit from subsidized rates, while others—especially private industrial zones—face rising energy costs.

Regardless of tariff structure, energy losses accumulate continuously over 10 years, making efficiency a critical cost factor.

5.1 Transformer Losses in High Ambient Temperature

High ambient temperatures directly affect transformer performance:

- Increased winding resistance

- Higher operating temperature

- Reduced cooling efficiency

Oil-immersed transformers generally perform well under high loads due to superior heat dissipation. However, prolonged exposure to extreme heat accelerates oil aging, which can indirectly increase long-term maintenance cost.

Dry-type transformers are more sensitive to ambient temperature. In Middle East conditions, it is common to see:

- Derating requirements of 5–15%

- Higher ventilation or cooling energy consumption

Pad-mounted substations, when properly designed with ventilation and sun-shielding, can maintain stable performance while minimizing auxiliary energy use.

5.2 Long-Term Energy Cost Impact

Even small differences in transformer losses can result in significant cost over 10 years.

For example, in a continuously loaded industrial facility:

- A slightly higher no-load loss may seem negligible

- Over 10 years, this loss translates into thousands of kilowatt-hours

- Which directly affects operating expenditure

In Middle East projects, where many facilities operate 24/7, loss optimization often delivers better ROI than initial cost savings.

6. Maintenance, Inspection, and Labor Costs

Maintenance practices in the Middle East vary depending on whether the asset is owned by:

- A utility company

- A private industrial operator

- An EPC under long-term service contract

6.1 Oil-Immersed Transformers

Oil-immersed transformers require periodic:

- Oil testing (dielectric strength, moisture content)

- Visual inspection for leaks

- Cooling system checks

In desert environments, dust accumulation on radiators and cooling fins is common, increasing cleaning frequency.

While these tasks are well understood, they introduce ongoing labor and downtime costs, especially in remote industrial locations.

6.2 Dry-Type Transformers

Dry-type transformers are often described as “low maintenance,” which is true in clean indoor environments.

However, in Middle East conditions:

- Dust and sand ingress can accumulate on windings

- High humidity near coastal areas can affect insulation

- Regular cleaning and inspection become essential

If neglected, these factors reduce cooling efficiency and increase failure risk.

6.3 Pad-Mounted Substations

Pad-mounted substations benefit from:

- Factory-tested integration

- Enclosed, weather-resistant design

- Simplified inspection routines

For utility-style networks and large developments, this often translates into lower maintenance labor per unit, which becomes a major advantage when managing dozens or hundreds of substations.

7. Safety, Environmental, and Compliance-Related Costs

Safety and compliance are especially critical in the Middle East due to:

- Dense urban developments

- High public safety expectations

- Strict utility and municipal regulations

7.1 Fire and Environmental Risk

Oil-immersed equipment introduces:

- Fire risk from flammable insulation

- Environmental liability in case of oil leakage

This often requires additional investment in fire barriers, drainage systems, and insurance coverage.

Dry-type transformers significantly reduce fire risk, making them preferred for indoor commercial projects.

Pad-mounted substations, particularly dry-type or ester-filled designs, offer a balanced solution—enhanced safety with outdoor flexibility.

7.2 Regulatory and Utility Approval

Many Middle East utilities maintain approved vendor lists and specific technical standards.

Pad-mounted substations are often favored because:

- They align with standardized utility designs

- Reduce variation in field installation

- Simplify inspection and approval processes

This indirect cost saving—faster approval and commissioning—is frequently overlooked but highly valuable in schedule-driven projects.

8. Reliability, Downtime Risk, and Operational Impact

In Middle East industrial and infrastructure projects, reliability is not a technical preference—it is a financial necessity.

Many facilities operate under one or more of the following conditions:

- Continuous or near-continuous operation (24/7)

- High cost of production interruption

- Remote locations with limited maintenance access

- Contractual penalties for power outages

Under these conditions, even short periods of downtime can result in significant financial losses.

8.1 Oil-Immersed Transformers: Proven but Maintenance-Dependent

Oil-immersed transformers have a long operational history and are generally considered reliable when properly maintained. However, reliability in Middle East environments is highly dependent on maintenance discipline.

Common reliability-related challenges include:

- Oil degradation accelerated by high ambient temperatures

- Cooling efficiency reduction due to dust accumulation

- Increased failure risk if oil testing intervals are extended

In utility-managed substations, these risks are usually well controlled.

In privately operated industrial facilities, however, maintenance gaps are a frequent cause of unexpected failures.

Downtime impact in such cases includes:

- Long repair or replacement lead times

- Environmental cleanup requirements

- Utility re-approval before re-energization

8.2 Dry-Type Transformers: Stable Indoors, Sensitive to Environment

Dry-type transformers perform very reliably when installed in clean, well-ventilated indoor environments.

In Middle East projects, reliability issues often arise when:

- Indoor ventilation is insufficient

- Dust control measures are underestimated

- Transformers operate close to thermal limits due to derating

When properly specified and installed, dry-type transformers can deliver excellent long-term stability. When environmental control is poor, however, failures tend to occur suddenly rather than gradually, leaving limited warning time.

8.3 Pad-Mounted Substations: Reliability Through Integration

Pad-mounted substations are designed to reduce field variability, which is one of the primary causes of reliability problems in power distribution systems.

Key reliability advantages include:

- Factory-assembled and factory-tested systems

- Consistent protection coordination

- Reduced on-site wiring errors

For Middle East EPC projects with tight schedules and multiple subcontractors, this integrated approach often results in lower commissioning risk and fewer early-life failures.

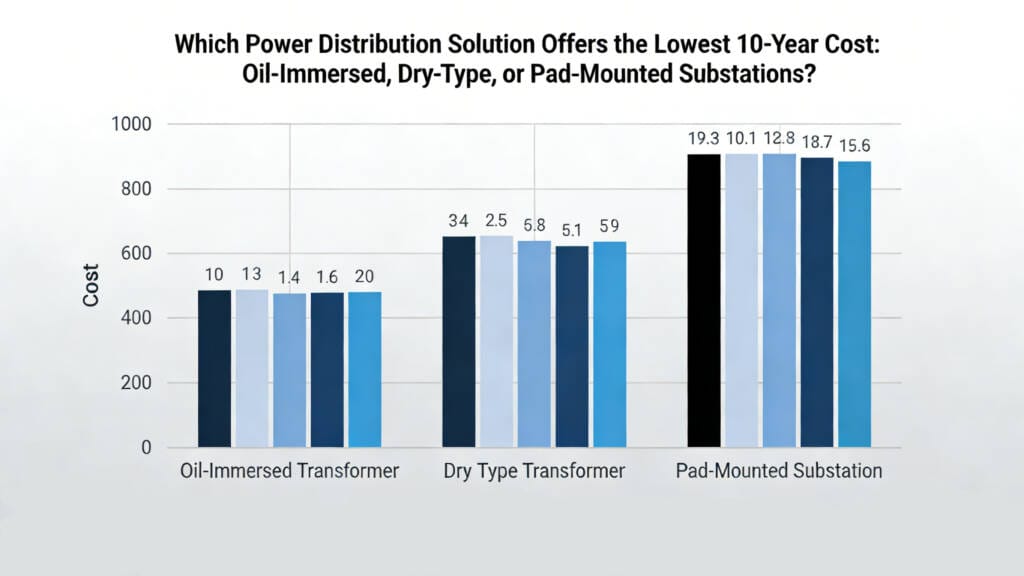

9. Substation Cost Comparison: 10-Year Total Cost of Ownership

When all cost components are combined, the picture becomes much clearer.

9.1 Summary of Cost Drivers Over 10 Years

| Cost Category | Oil-Immersed | Dry-Type | Pad-Mounted Substation |

|---|---|---|---|

| Initial Equipment Cost | Low | Medium–High | High |

| Installation & Civil Works | High | Medium | Low |

| Energy Loss Cost | Low–Medium | Medium | Low |

| Maintenance Cost | Medium–High | Low–Medium | Low |

| Safety & Compliance Cost | High | Low | Low |

| Downtime Risk Cost | Medium | Medium | Low |

9.2 Interpreting the Results

- Oil-immersed solutions often show the lowest initial price but accumulate higher costs through maintenance, safety systems, and downtime risk.

- Dry-type transformers balance safety and maintenance advantages but may incur higher operating costs if environmental control is inadequate.

- Pad-mounted substations typically have the highest upfront investment but deliver the lowest and most predictable 10-year TCO in many Middle East outdoor and utility-style applications.

The key takeaway is simple:

The most economical solution over 10 years is rarely the one with the lowest quotation.

10. Best-Fit Applications in the Middle East

Rather than recommending a single solution, experienced buyers match technology to application.

10.1 Oil & Gas and Heavy Industry

Best fit:

- Oil-immersed substations

- Pad-mounted substations (utility-grade)

Why:

- High load demand

- Outdoor installation

- Strong maintenance capability

10.2 Commercial Buildings and Infrastructure

Best fit:

- Dry-type transformers

- Indoor substations

Why:

- Fire safety priority

- Indoor installation

- Lower environmental risk

10.3 Urban Distribution and Residential Developments

Best fit:

- Pad-mounted substations

Why:

- Compact footprint

- Public safety

- Fast deployment and approval

10.4 Renewable Energy Projects (Solar & Storage)

Best fit:

- Pad-mounted substations

- Oil-immersed transformers with compact outdoor enclosures

Why:

- Remote locations

- Standardized layouts

- Scalability

11. Substation Cost Comparison: Practical Buying Advice to Avoid Long-Term Cost Mistakes

Based on real Middle East projects, here are the most important lessons buyers learn—often too late.

11.1 Do Not Compare Equipment in Isolation

Always evaluate:

- Installation requirements

- Environmental adaptation

- Utility approval timelines

A lower-priced transformer can easily become the most expensive solution after installation.

11.2 Ask Suppliers Lifecycle Questions, Not Just Technical Ones

Key questions to ask:

- What maintenance is required in desert conditions?

- How does the design handle high ambient temperatures?

- What failures are most common after 5–7 years?

Suppliers with real regional experience will answer confidently and specifically.

11.3 Prioritize Standardization for Large Projects

For projects involving multiple substations:

- Standardized pad-mounted designs

- Unified protection schemes

- Consistent spare parts

These choices dramatically reduce long-term operational complexity and cost.

12. Final Conclusion and Decision Guidance on Substation Cost Comparison

Choosing between oil-immersed transformers, dry-type transformers, and pad-mounted substations is not a matter of technology preference—it is a matter of lifecycle value.

In Middle East environments, where heat, dust, safety, and project timelines all play critical roles, decisions based solely on initial price almost always lead to higher long-term costs.

A well-informed decision considers:

- Total cost of ownership over 10 years

- Environmental and safety risks

- Reliability and downtime impact

- Approval and commissioning efficiency

For many modern Middle East projects, pad-mounted substations and properly specified dry-type solutions increasingly outperform traditional approaches when evaluated holistically.

- Evaluate the best-fit solution for your application

- Optimize for high ambient temperature environments

- Reduce long-term operational and maintenance risk

👉 Request a customized cost-benefit analysis for your project