Description

As a professional supplier and manufacturer, we offer the SCB13 Dry Type Transformer for industrial and commercial power distribution systems. This page is a product transaction page designed for buyers, engineers, and EPC contractors looking to source reliable cast resin dry type transformers.

Our SCB13 dry type transformer adopts epoxy resin casting technology, three-phase design, and low-loss core structure. It is suitable for indoor substations and projects requiring high safety, stable performance, and long service life. Technical support and customization are available directly from the factory.

SCB13 Dry Type Transformer

The SCB13 series is engineered for users who demand safe, efficient, and low-maintenance power distribution solutions. With a capacity range from 30 kVA to 2500 kVA, it is suitable for diverse applications, from small commercial installations to large-scale industrial projects.

As a cast resin dry-type transformer, it utilizes epoxy resin encapsulation instead of insulating oil. This design eliminates risks associated with oil leakage and fire, making it the preferred choice for indoor substations, commercial complexes, hospitals, data centers, and renewable energy systems.

For buyers seeking a reliable three-phase dry-type transformer, the SCB13 series delivers stable voltage performance, low operating losses, and extended service life. It is ideally selected for projects that prioritize electrical safety, environmental sustainability, and compliance with modern energy efficiency standards.

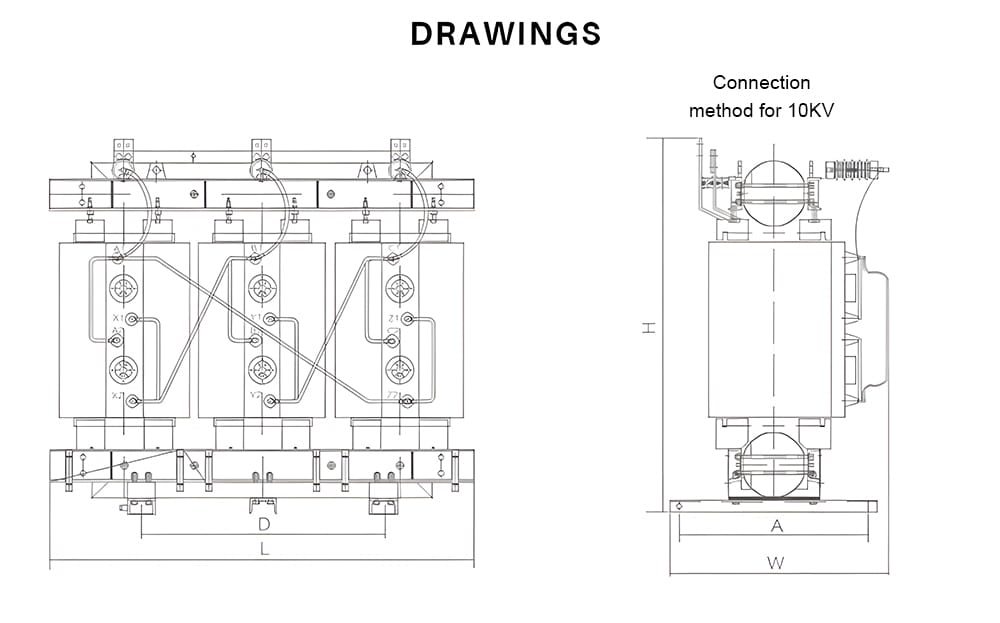

SCB13 Cast Resin Transformer Engineering Drawings and Structure Design

This image presents the engineering drawings of the SCB13 Cast Resin Dry-Type Transformer, which are essential for project planning, system integration, and installation preparation.

For engineers and EPC contractors, clear technical drawings are critical for verifying the dry-type structure, coil arrangement, insulation design, and layout compatibility with existing electrical rooms. They support precise foundation design, cable routing, ventilation planning, and maintenance access.

Beyond basic specifications, clients searching for dry-type transformer technical details often require confirmation that the unit will fit their substation space and meet their electrical system requirements. This drawing-based documentation reflects our engineering expertise and practical experience in delivering reliable dry-type transformers for real-world projects.

SCB13 Dry Type Transformer Manufacturing Process and Production Flow

This process flow image illustrates the complete manufacturing journey of every SCB13 dry-type transformer, from raw material management through to final delivery. Our standardized, fully-controlled production process ensures consistent quality, reliable performance, and long-term operational stability.

Many discerning clients and technical evaluators focus not only on product specifications, but also on the manufacturing process behind cast resin transformers. This emphasis is well-founded, as production quality directly influences critical performance indicators such as insulation integrity, partial discharge levels, thermal endurance, and overall service life.

Our process integrates precision winding, vacuum casting, controlled curing, and rigorous testing at each stage, ensuring that every transformer meets stringent international standards and is ready for dependable, low-maintenance operation in demanding environments.

SCB13 Dry Type Transformer Production Process

| Production Stage | Purpose | Customer Value |

|---|---|---|

| Storage Warehouse | Controlled storage of core steel, copper, and insulation materials | Ensures material quality and traceability |

| Coil Winding Workshop | Precision winding of HV and LV coils | Improves electrical performance and reduces loss |

| Production Line | Epoxy resin casting and transformer assembly | Enhances insulation strength and mechanical stability |

| Deliver Goods | Final inspection, testing, and packaging | Guarantees safe transportation and on-site acceptance |

This transparent manufacturing flow builds trust for customers who need a reliable dry transformer supplier for long-term cooperation.

SCB13 Dry Type Transformer Applications in Industrial and Infrastructure Projects

Typical Application Scenarios

| Application Area | Why SCB13 Dry Transformer Is Used |

|---|---|

| Coal Mine | Oil-free design improves safety in enclosed spaces |

| Agriculture | Stable voltage supports irrigation and processing systems |

| State Grid Projects | Meets strict reliability and efficiency requirements |

| Dam & Infrastructure | Handles long-term continuous operation |

These cases demonstrate that the SCB13 dry type transformer is not only a standard product, but a proven power solution for demanding engineering projects.

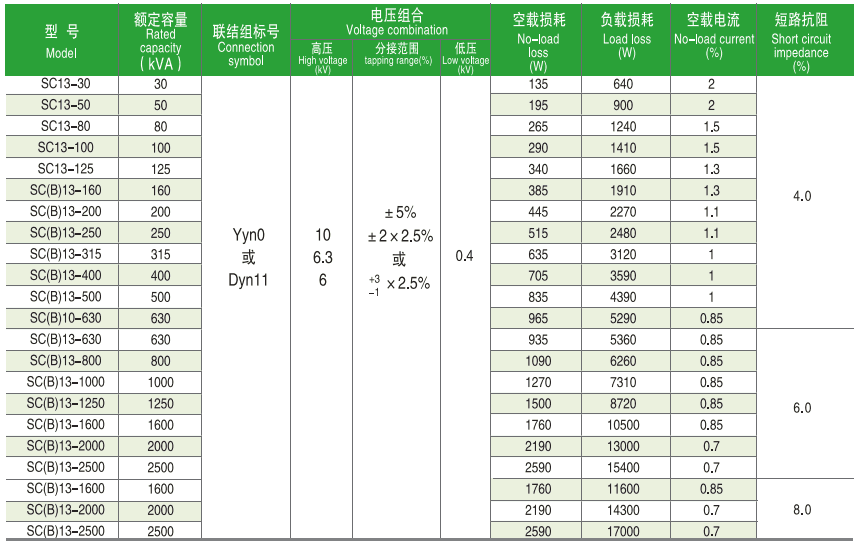

SCB13 Dry Type Transformer Technical Specifications and Performance Data

This technical specification image is designed to guide customers in selecting the correct SCB13 dry-type transformer model according to their specific electrical system requirements. It serves as a key reference for system design, project planning, and engineering validation.

Critical parameters such as rated capacity, voltage combination, connection group symbol, no-load loss, load loss, short-circuit impedance, and no-load current are essential for evaluating transformer performance and compatibility. Engineers rely on this data to calculate overall system efficiency, ensure stability under various load conditions, estimate operating costs, and validate compliance with energy efficiency standards.

Customers seeking detailed specifications for dry-type transformers are typically focused on ensuring seamless integration with their existing power network. This specification sheet supports precise matching of transformer characteristics to system demands — whether for new installations, capacity expansion, or system upgrades — thereby reducing the risk of improper selection, enhancing project safety, and optimizing long-term operational reliability.

This image shows the certifications and compliance documents related to the SCB13 dry type transformer. Certifications are a key trust factor for international buyers and project owners.

They confirm that the cast resin dry type transformer has been manufactured under controlled quality systems and meets safety and performance standards.

Certification Value for Customers

| Certification Aspect | Meaning for Buyers |

|---|---|

| Quality Management | Stable and repeatable product quality |

| Safety Compliance | Reduced operational and installation risk |

| Performance Testing | Verified electrical and thermal performance |

| Export Readiness | Suitable for international projects |

For customers sourcing a dry transformer for overseas projects, certifications reduce approval time and simplify procurement.

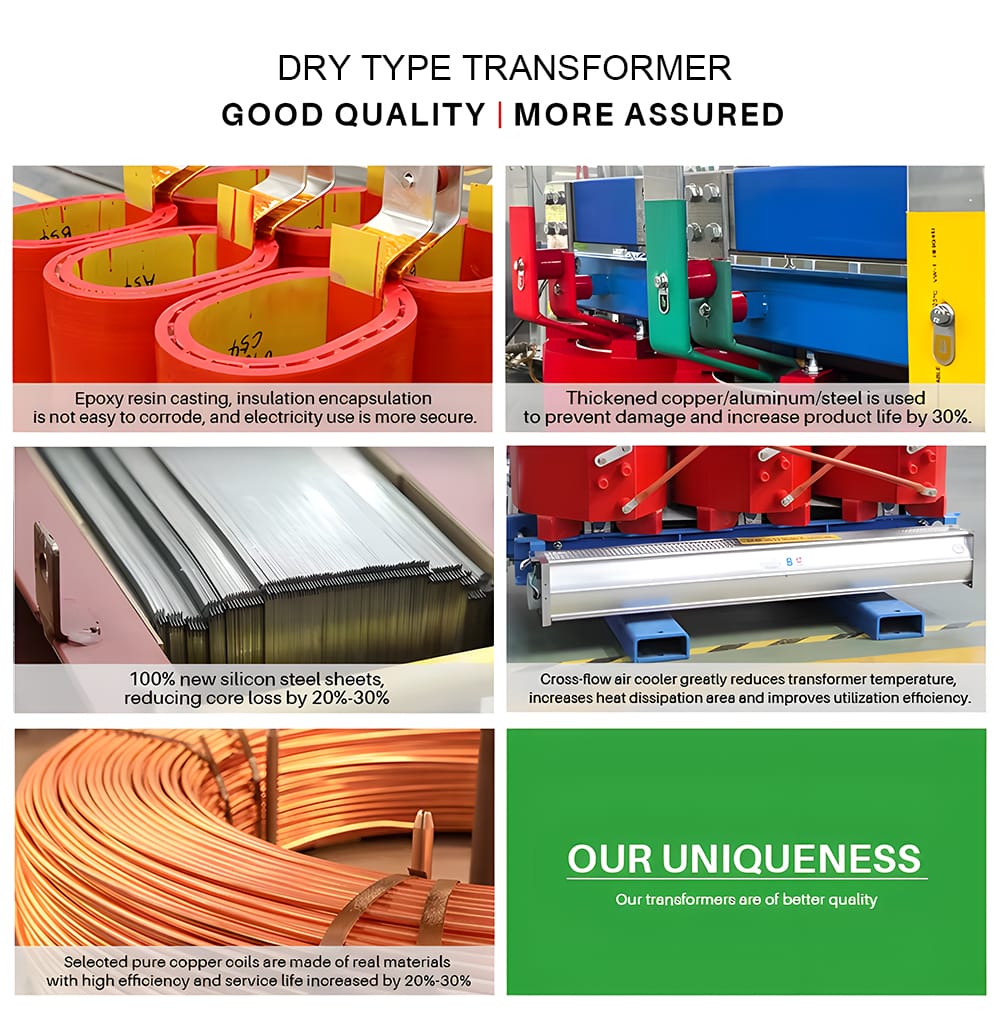

SCB13 Cast Resin Transformer Design Advantages and Quality Features

This image details why the SCB13 dry-type transformer consistently outperforms conventional dry-type transformers in long-term operation. Its engineering philosophy emphasizes three core objectives essential for continuous-use applications: operational efficiency, structural durability, and system safety.

1. Advanced Material Selection

Epoxy Resin Casting: Ensures superior insulation strength while providing moisture and corrosion resistance.

High-Purity Copper Coils: Deliver higher conductivity, minimizing energy loss under load.

Advanced Silicon Steel Core: Reduces no-load loss and lowers operating temperature.

2. Optimized Thermal Management

Cross-Flow Air Cooling Design: Promotes uniform heat dissipation, maintains stable operating temperatures, and prevents thermal stress concentration.

3. Robust Structural Engineering

Thickened Conductors: Enhance mechanical strength and vibration resistance, extending service life under demanding conditions.

Integrated Casting Technology: Creates a solid, maintenance-free structure resistant to environmental and electrical stresses.

4. Long-Term Operational Value

The combined effect of these design features results in:

Lower total cost of ownership through reduced energy consumption

Extended service life with minimal performance degradation

Enhanced reliability in continuous or cyclical loading scenarios

Reduced maintenance requirements and operational downtime

These engineering advantages make the SCB13 series particularly suitable for applications where operational continuity, energy efficiency, and long-term reliability are critical considerations. The transformer maintains consistent performance throughout its lifecycle while delivering measurable economic benefits through reduced operating expenses.

This image outlines the key reasons why customers consistently choose us as their preferred supplier for SCB13 Cast Resin Transformers. We understand that selecting a transformer supplier involves more than just product specifications—it requires confidence in quality, support, value, and proven experience. Our commitment in these areas directly addresses the core concerns of project managers, engineers, and procurement specialists.

1. Rigorous Quality Assurance

What It Means for You:

Risk Reduction: Every transformer undergoes stringent factory testing—including routine, type, and special tests—ensuring compliance with IEC, IEEE, and customer-specific standards.

Consistent Performance: Advanced manufacturing processes and automated quality control minimize defects, preventing costly on-site rework or operational downtime.

Long-Term Reliability: Our transformers are designed and built to perform reliably over a 30+ year lifespan, even in demanding environments.

2. Responsive Technical & Service Support

What It Means for You:

Quick Response: Dedicated technical support is available within 2–4 hours for urgent inquiries, with on-call engineers for critical project phases.

Pre- & Post-Sales Collaboration: From specification review to installation guidance, we work closely with your team to ensure seamless integration.

Local Service Network: Supported by service partners in key regions to provide timely maintenance, troubleshooting, and spare parts supply.

3. Competitive Factory-Direct Pricing

What It Means for You:

Cost Transparency: Eliminating intermediary margins allows us to offer true value-engineering solutions without compromising quality.

Budget Certainty: Stable pricing and clear contractual terms help you maintain financial control throughout the project lifecycle.

Customized Solutions: We optimize designs and configurations to match your exact requirements, avoiding over-specification and unnecessary costs.

4. Proven Experience Across Markets

What It Means for You:

Global Reference Portfolio: Successful deliveries to industrial plants, data centers, hospitals, renewable energy projects, and commercial complexes across Asia, Europe, the Middle East, and the Americas.

Regulatory Familiarity: Deep understanding of regional standards and certification requirements (CE, UL, CSA, GCC, etc.), streamlining compliance and approval processes.

Application Expertise: Ability to recommend and adapt solutions based on real-world experience in diverse environmental and operational conditions.

5. Project-Driven Partnership Approach

Beyond these advantages, we operate as an extension of your project team, providing:

Flexible Logistics & Scheduling: Just-in-time delivery and customized packaging to suit site constraints.

Documentation & Compliance Support: Complete set of manuals, test reports, drawings, and certification packages.

Lifecycle Value Focus: Emphasis on total cost of ownership—not just initial purchase price—through energy efficiency, durability, and serviceability.

By choosing us as your SCB13 transformer supplier, you gain more than a product—you secure a reliable partner committed to your project’s success, timeline, and long-term operational performance.

SCB13 Dry Type Transformer Supplier Team and Global Project Cooperation

This image reflects the real people behind the SCB13 dry type transformer. It shows company management, technical engineers, and international customers discussing successful cooperation.

For many buyers, choosing a transformer supplier is not only about the product, but also about communication, technical support, and long-term reliability. This image demonstrates real business interaction and project experience rather than marketing claims.

Customers looking for a trusted dry type transformer manufacturer often value proven cooperation and responsive support.

FAQ

What is the working principle of an SCB13 dry type transformer?

An SCB13 dry type transformer transfers electrical energy through electromagnetic induction. The primary winding creates a magnetic field in the silicon steel core, and the secondary winding converts it into the required voltage level. Epoxy resin casting insulates the windings without using oil.

How do operators clean a dry type transformer?

Operators disconnect the power supply before cleaning. They remove dust from windings and ventilation channels using dry air or a vacuum device. Regular cleaning helps maintain cooling efficiency and stable insulation performance.

Where do engineers commonly use SCB13 dry type transformers?

Engineers install SCB13 dry type transformers in indoor substations, commercial buildings, factories, hospitals, data centers, and renewable energy systems where fire safety and low maintenance are critical.

What advantages does the SCB13 series offer compared to standard dry transformers?

The SCB13 series reduces no-load loss and operating noise. It also improves energy efficiency and thermal performance, making it suitable for long-term continuous operation.

Can customers customize an SCB13 dry type transformer?

Customers can customize rated capacity, voltage combination, connection group, protection level, and branding based on project requirements. The factory supports both OEM and project-specific configurations.

How long does an SCB13 dry type transformer usually operate?

With proper installation and routine maintenance, an SCB13 dry type transformer operates reliably for many years. High-quality epoxy resin insulation and optimized core design help extend service life.

Ready to Source SCB13 Dry Type Transformer?

Looking for a reliable SCB13 Dry Type Transformer for your project?

Contact us today to receive technical support, model selection advice, and a competitive factory price from an experienced dry type transformer supplier.

Reviews

There are no reviews yet.