Description

As a professional transformer supplier, we offer the SCB12 1000KVA Dry Transformer for global power distribution projects.

This product page presents a transaction-ready solution designed for buyers seeking a reliable cast resin dry type transformer for indoor applications. We design the SCB12 1000KVA dry-type transformer to deliver low loss, stable operation, and extended service life, making it well-suited for industrial facilities, commercial buildings, infrastructure systems, and renewable energy installations.

SCB12 1000KVA Dry Type Transformer

This image presents the SCB12-1000KVA dry-type transformer as a fully integrated power distribution solution.

Buyers typically seek a dry-type transformer when their project demands indoor installation, enhanced safety, and minimal maintenance. This model is precisely engineered to meet these requirements.

The cast resin insulation system shields the windings from moisture, dust, and contaminants. It lowers fire hazards and removes any concerns about oil leaks, making this transformer ideal for commercial buildings, industrial plants, hospitals, data centers, and renewable energy installations.

Its reliable performance ensures continuous operation under rated load. Stable functioning minimizes unplanned downtime and safeguards connected electrical equipment. An extended service life assists project owners in reducing overall lifecycle expenses and the need for frequent replacements.

Typical applications and buyer objectives addressed by this product:

Replacing oil-filled transformers with a safer, dry-type alternative.

Installing a medium-voltage transformer within indoor substations.

Decreasing maintenance efforts and mitigating environmental risks.

Guaranteeing consistent, long-term power supply for critical operations and facilities.

Common Application Scenarios

| Application Area | Why Dry Type Transformer Is Chosen |

|---|---|

| Commercial buildings | Fire safety and low noise |

| Industrial plants | Stable load handling and reliability |

| Hospitals & data centers | Clean, oil-free operation |

| Renewable energy systems | High efficiency and low losses |

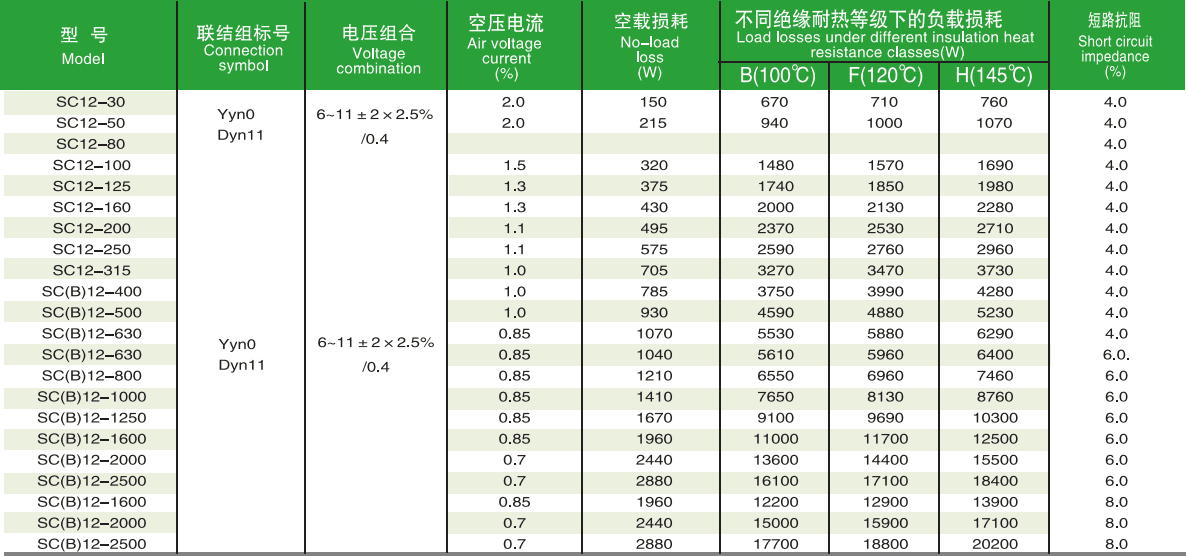

Technical Parameters Overview

This image provides a comprehensive overview of the core electrical performance data for the SCB12-1000KVA dry-type transformer. Engineers and technical buyers rely on these specifications to verify system compatibility, evaluate long-term operational costs, and ensure compliance with project requirements.

Key Performance Parameters Detailed:

Voltage Combination & Tapping Range: Enables adaptability to various grid standards and allows fine-tuning of output voltage under varying supply conditions (e.g., ±2×2.5% or custom tapping).

No-Load Current & No-Load Loss (Core Loss): Critical for evaluating energy efficiency during light-load or standby operation, directly impacting electricity costs over the transformer’s lifetime.

Load Loss (Copper Loss) at Rated Conditions: Reflects losses under full operational load, essential for calculating overall operating efficiency and thermal performance.

Short-Circuit Impedance: Influences fault current levels, system stability, and protection coordination. Ensures the transformer can withstand and limit fault currents effectively.

Rated Capacity & Insulation Class: Defines continuous operational capability and thermal endurance under specified ambient conditions.

How This Data Supports Engineering Decisions:

Accurate Efficiency Evaluation: Allows for precise calculation of total ownership cost, including energy consumption across different load profiles.

Informed Protection & Coordination: Facilitates selection of appropriate protective devices (breakers, relays) and setting of trip thresholds based on impedance and loss data.

System Compatibility Assurance: Ensures seamless integration with upstream switchgear, downstream distribution equipment, and renewable energy interfaces.

Performance Transparency & Risk Mitigation: Verified test data from certified laboratories (e.g., compliant with IEC, IEEE, or GB standards) helps eliminate uncertainty regarding operational behavior and reliability.

By providing clear, tested electrical parameters, we empower engineers to design systems with confidence—optimizing for efficiency, safety, and durability while avoiding unforeseen operational risks.

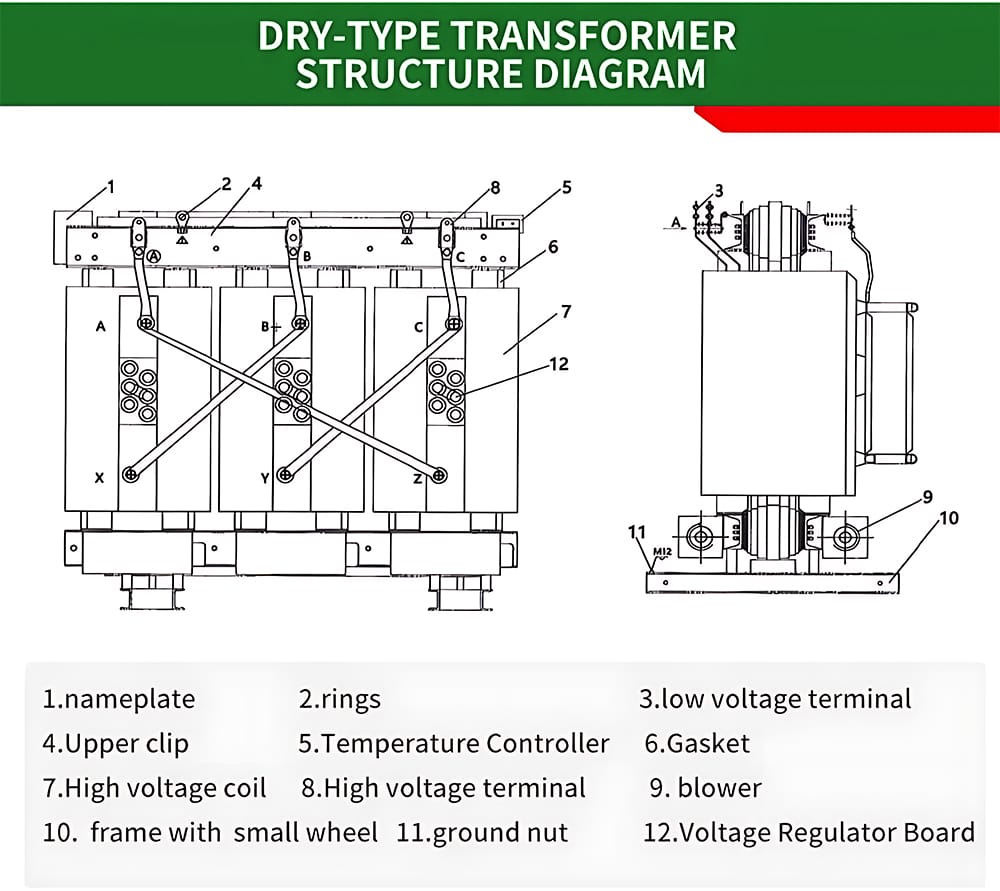

SCB12 1000KVA Dry Transformer Structure Diagram

This structural diagram illustrates the internal construction and design principles of the SCB12-1000KVA cast resin dry-type transformer. For engineers and EPC procurement professionals, a clear understanding of the internal layout is essential for evaluating key performance aspects such as safety, thermal management, and serviceability.

Each core component is engineered with a distinct, critical function:

High & Low Voltage Windings: Encapsulated in epoxy resin through a vacuum casting process, creating a solid insulation system with exceptional dielectric strength and resistance to environmental contaminants.

Intelligent Temperature Controller: Continuously monitors winding temperature via embedded sensors, providing real-time data, alarms, and trip signals to prevent overheating.

Cooling Fans/Axial Flow Blowers: Automatically activate during high-load operation to force air circulation, significantly improving heat dissipation and enabling sustainable performance at rated capacity.

Voltage Regulation Taps (Tap Changer Board): Allows for flexible adjustment of the output voltage within a specified range (e.g., ±2×2.5%), compensating for input voltage variations to maintain stable power supply.

Grounding Terminal & Reinforced Metal Frame: Provides a reliable, low-impedance path to earth for electrical safety, while the robust mechanical structure ensures physical stability and protection during handling and operation.

Design Advantages:

This optimized architecture is fundamental to the transformer’s stable electrical performance, operational durability, and long service life. It ensures reliable protection under continuous duty cycles and enhances overall system resilience.

Key Structural Components and Their Functions

| Component | Function in Operation |

|---|---|

| High voltage coil | Handles medium voltage input safely |

| Low voltage terminal | Delivers stable output power |

| Temperature controller | Prevents overheating |

| Cooling blower | Improves thermal performance |

| Grounding system | Enhances operational safety |

Buyers searching for “cast resin transformer structure” or “dry type transformer safety” usually want proof that the product is engineered, not assembled casually. This structure answers that concern directly.

Why Choose a 1000KVA Dry Transformer for Industrial Projects

This image demonstrates why customers select us as their preferred supplier for dry-type transformers – a choice based on our integrated capabilities, not just the product itself. For a growing number of clients, supplier reliability and comprehensive expertise are as critical as the technical specifications of the transformer.

1. Precision Engineering & Consistent Quality

Every stage of production – from core stacking and winding to vacuum resin casting and curing – is executed under strictly controlled and standardized procedures. This meticulous attention to detail ensures consistent, repeatable quality across every unit. We understand that even minor imperfections can impact performance over decades of continuous operation.

2. Efficient Production & Reliable Delivery

Our investment in smart, automated manufacturing equipment and lean production processes enables shorter lead times and greater production flexibility. This allows us to reliably meet urgent project schedules and accommodate time-sensitive delivery requirements without compromising on quality.

3. Value-Driven Cost Optimization

Through direct sourcing of high-grade raw materials and streamlined supply chain management, we effectively reduce intermediate costs. Our scientific operational and quality management systems further enhance efficiency, enabling us to deliver an outstanding cost-to-performance ratio without sacrificing long-term reliability or safety.

4. Tailored Solutions & Customized Service

We recognize that each project has unique requirements – whether in voltage levels, tapping ranges, protection schemes, enclosures, or special certifications. Our engineering team provides customized support from the initial design phase through final testing and commissioning to ensure the transformer perfectly adapts to your specific application and standards.

5. End-to-End Technical Support & Partnership

Our commitment extends beyond delivery. We offer comprehensive after-sales support, including installation guidance, operational training, and responsive maintenance assistance. By building long-term partnerships, we help clients optimize the lifecycle performance and total cost of ownership of their power infrastructure.

By choosing us, you are selecting a partner dedicated to quality, reliability, flexibility, and value – ensuring your project benefits from both an exceptional product and a seamless, professional collaboration.

International Installations of SCB12 1000KVA Cast Resin Dry Transformers

This project collage demonstrates the SCB12 1000KVA dry-type transformers in successful operation across diverse real-world installations, spanning regions such as Africa, Central Asia, Southeast Asia, and beyond.

Common questions from buyers include:

“Has this transformer model been deployed in countries with similar grid or environmental conditions?”

“Can it reliably adapt to varying grid voltages, frequent fluctuations, and harsh climatic challenges?”

These field installations showcase the transformer’s proven adaptability to demanding real-world conditions:

High Ambient Temperatures: Consistent performance in hot climates without derating, thanks to advanced thermal design and F-class or H-class insulation systems.

Unstable or Weak Grid Conditions: Robust design with wide input voltage tolerance and strong short-circuit withstand capability, ensuring stability in areas with inconsistent grid supply.

Harsh Industrial & Infrastructure Environments: Resilient against dust, moisture, and corrosive atmospheres, making it suitable for mining, factories, ports, and renewable energy sites.

Diverse Installation Scenarios: From indoor electrical rooms to outdoor protective enclosures, with options for customized protection ratings (IP ratings) and cooling configurations.

Every case shown is backed by documented operation history, not just laboratory certifications. This real-field evidence builds confidence for EPC contractors, project owners, and consulting engineers who require solutions that are not only compliant but also proven in conditions similar to their own projects.

Packaging and Transportation of SCB12 1000KVA Dry Transformer

This image details the specialized packaging and delivery preparation process for the SCB12-1000KVA dry-type transformer, addressing key concerns for buyers—especially those involved in international or long-distance logistics.

Key Buyer Concerns We Address:

Risk of damage during transit, including vibration, impact, or environmental exposure

Quality and durability of export-grade packaging

Reliability and safety over extended shipping distances

Our Packaging & Delivery Solution:

Reinforced Structural Protection

The transformer is secured within a custom-designed, steel-reinforced wooden crate. Internal bracing and anti-vibration mounts protect the core, windings, bushings, and control components from mechanical stress during handling and transit.

Climate-Resistant & Secure Sealing

The packaging is lined with moisture-resistant barriers (such as desiccant and waterproof film) to prevent corrosion and insulation degradation. All openings are sealed to guard against dust, salt spray, and humidity—particularly critical for sea freight and outdoor storage.

Labeled for Safe Handling & Customs Clarity

Each package includes clear lifting guides, center-of-gravity indicators, and “fragile” warnings to ensure proper handling. Commercial invoices, packing lists, and harmonized system (HS) codes are enclosed to facilitate smooth customs clearance.

Logistics Tailored to Project Needs

We coordinate with certified freight partners to arrange optimal transport—whether by container, flat rack, or open-top—ensuring the transformer arrives at the project site intact and ready for installation, even in remote or challenging locations.

Certifications and Compliance

This certification image confirms that the SCB12 1000KVA cast resin transformer complies with recognized international standards.

For buyers, certifications answer key questions:

Is the product safe to install?

Does it meet export and project requirements?

Is the manufacturer reliable?

Certified dry type transformers are easier to approve in:

EPC bidding processes

Government or utility projects

International tenders

Certification demonstrates controlled manufacturing, verified testing, and consistent quality.

Real Business Cooperation and Team Experience

From a buyer’s perspective, this image reflects several important assurances:

The supplier has proven experience working with overseas customers

Key technical discussions are conducted face-to-face

Projects are carried out through collaborative partnership, not just anonymous transactions

This builds Experience and Trust, which is especially valuable for buyers sourcing transformers for long-term projects or repeat orders.

Contact Us Today to Order Your SCB13 1000KVA Dry Transformer or Request a Customized Solution.

FAQ

1. What is the SCB12 1000KVA dry type transformer mainly used for?

Buyers primarily use the SCB12 1000KVA dry-type transformer in indoor power distribution systems across applications such as factories, commercial buildings, hospitals, data centers, and renewable energy projects, particularly when they require enhanced safety, stable operation, and low maintenance.

The cast resin insulation makes it suitable for long-term indoor operation without oil leakage risk.

2. Why choose a dry type transformer instead of an oil immersed transformer?

Many buyers search this question when planning indoor substations.

A dry type transformer does not use insulating oil.

This reduces fire risk, environmental impact, and routine maintenance work.

Compared with oil immersed transformers, dry transformers are safer for enclosed spaces and populated areas.

3. Is the SCB12 1000KVA cast resin transformer suitable for indoor installation?

Yes, we have specifically designed it for indoor installation.

The cast resin insulation system provides high electrical strength and moisture resistance.

It allows stable operation in electrical rooms, basements, and indoor substations.

This makes the SCB12 1000KVA dry type transformer suitable for projects with strict safety requirements.

4. What voltage levels and configurations are available for the SCB12 1000KVA transformer?

The SCB12 1000KVA dry transformer supports multiple voltage combinations.

High voltage, low voltage, and tapping ranges can be customized according to local grid standards.

This helps engineers match the transformer with different power systems and load conditions.

5. How efficient is a 1000KVA dry type transformer in daily operation?

Efficiency is important for buyers who focus on long-term energy cost.

The SCB12 1000KVA dry type transformer uses an optimized magnetic core and winding design.

This reduces no-load loss and load loss during continuous operation.

Lower losses help reduce electricity waste and operating expenses over time.

6. Can the SCB12 1000KVA dry transformer operate in high temperature environments?

Yes, it can operate under high ambient temperatures.

The cast resin insulation and cooling system provide strong thermal performance.

A temperature controller and cooling blower help protect the transformer under heavy load.

This makes it suitable for industrial and tropical environments.

7. What certifications does the SCB12 1000KVA cast resin transformer have?

The SCB12 1000KVA cast resin transformer is manufactured under strict quality control systems.

It complies with relevant international safety and performance standards.

Certifications help buyers meet EPC, utility, and project approval requirements.

8. Can the 1000KVA dry type transformer be customized for specific projects?

Yes, customization is available.

Buyers can request changes in voltage level, tapping range, protection class, or installation structure.

Customization helps ensure the transformer fits specific project and grid requirements.

9. How long is the delivery time for a SCB12 1000KVA dry type transformer?

Delivery time depends on configuration and order quantity.

Standard models usually have shorter production cycles.

Customized transformers may require additional design and testing time.

Efficient production capacity helps support project schedules.

10. How is the SCB12 1000KVA dry transformer packaged for international shipping?

We package the transformer with reinforced protection to ensure its safety during international transportation.

Packaging protects coils, terminals, and control components during loading and shipping.

This ensures the transformer arrives safely and ready for installation.

Reviews

There are no reviews yet.