Description

315kVA Dry Type Transformer (SCB11 Series) provide reliable and efficient power distribution for industrial and commercial projects. Our SCB11 dry-type transformers feature cast resin insulation, low-loss cores, and compact designs.

Factory-direct supply, flexible voltage options, and fast delivery make these transformers ideal for modern medium-voltage distribution systems. Request a quote today to get pricing and technical specifications for your project.

SCB11 315KVA Dry Type Transformer Overview

This main product image presents the SCB11 315KVA DRY type transformer, engineered with a modern high-reliability design to deliver superior electrical performance, enhanced safety, and long-term operational stability. Using advanced cast-resin insulation technology and high-quality low-loss silicon steel cores, this SCB11 315KVA DRY transformer achieves excellent energy-saving performance while significantly reducing no-load losses and minimizing operational noise, making it one of the most efficient units in the SCB11 dry type transformer series.

Built to support the increasing demands of today’s distribution networks, the 315KVA DRY transformer offers strong short-circuit resistance through reinforced coil structures, high mechanical strength, and precise resin encapsulation that protects the windings against moisture, dust, and environmental contaminants. This ensures stable operation even under harsh grid fluctuations or sudden overload conditions.

With its oil-free construction, the dry type transformer completely eliminates fire risks associated with traditional oil-immersed units, delivering zero oil leakage, higher environmental protection, and safer indoor installation. This makes it especially suitable for commercial complexes, data centers, substations, industrial facilities, residential high-rise buildings, hospitals, and clean-energy engineering projects where reliability and safety are critical.

As part of the high-efficiency SCB11 technology platform, this SCB11 315KVA DRY transformer provides:

Higher energy efficiency with optimized magnetic circuits

Improved heat dissipation for long service life

Low maintenance requirements thanks to a sealed and dust-resistant structure

Stable voltage regulation across a wide range of operating conditions

Environment-friendly and quiet operation suitable for populated areas

Overall, this product image clearly showcases a high-performance SCB11 315KVA dry type transformer, designed to deliver exceptional electrical distribution reliability while meeting modern standards for energy efficiency, environmental protection, and long-term operational stability.

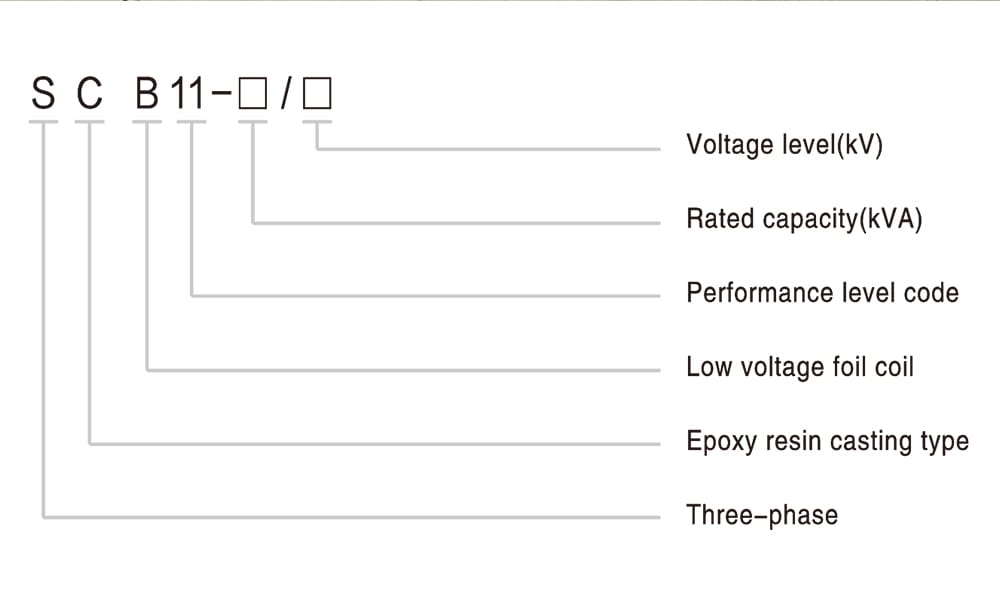

SCB11 Model Meaning & Transformer Ratings

This model meaning chart provides a clear and structured explanation of the designation system used across the SCB11 Series transformer family, enabling engineers, planners, and purchasers to accurately interpret each technical parameter. By breaking down every character in the code, the chart helps users quickly understand essential specifications of the SCB11 315KVA dry type transformer, ensuring precise model selection and smooth integration into industrial power distribution, commercial buildings, data centers, and substation environments.

The code illustrates several key attributes:

The voltage level expressed in kilovolts (kV)

The rated capacity measured in kilovolt-amperes (kVA)

The letter “B”, which indicates low-voltage foil coil construction—a structure known for improved heat dissipation and mechanical strength

The number “11”, representing an optimized performance level with reduced losses, enhanced efficiency, and lower operational noise

The letter “S”, designating a three-phase dry transformer configuration

The letter “C”, identifying epoxy resin cast insulation, a hallmark feature of resin cast transformers used in indoor, fire-safe, and maintenance-free applications

By presenting this information visually and systematically, the chart simplifies technical evaluation and ensures that buyers and engineers can confidently match transformer models with specific project requirements. It strengthens decision-making during system design, equipment specification, and upgrade planning while reinforcing the reliability, safety, and performance advantages of the SCB11 315KVA DRY transformer within modern electrical distribution networks.

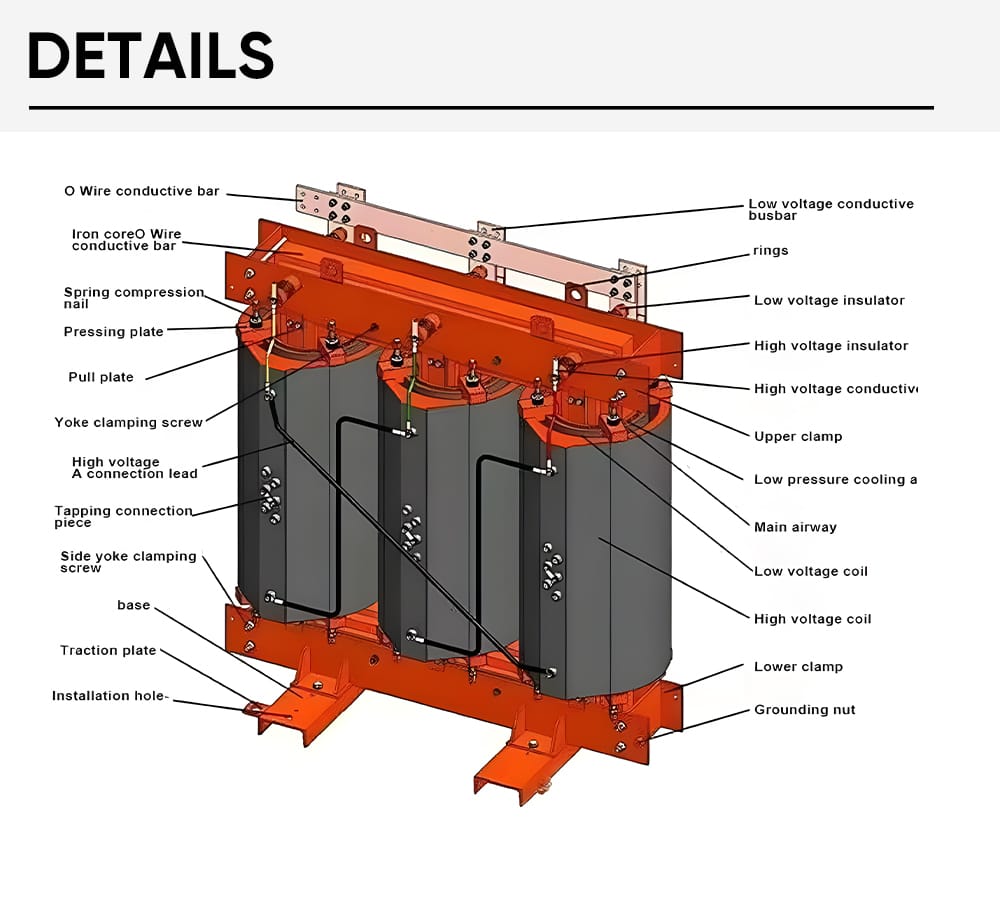

Transformer Structure & Key Component Diagram

Complete internal structure of the SCB11 315KVA cast resin dry-type transformer.

This comprehensive component diagram provides a clear and detailed overview of the internal structure and mechanical design of the SCB11 315KVA dry type transformer. It highlights major elements such as precision-stacked iron core laminations, resin-cast high- and low-voltage coils, compression springs, reinforced clamping plates, conductive copper bars, multi-channel ventilation ducts, LV and HV busbars, tapping connectors, epoxy-insulated brackets, grounding terminals, and vibration-damping installation frames.

Each labeled part demonstrates the advanced engineering of the SCB11 Series dry transformer, reflecting its strong mechanical durability, excellent thermal stability, and high dielectric performance. The SCB11 315KVA DRY transformer applies class-F or class-H insulation, moisture-resistant epoxy resin, and optimized magnetic circuits to reduce core losses, enhance efficiency, and maintain stable output under variable load and grid conditions.

The diagram also shows how the 315KVA dry type transformer achieves high safety and reliability through reinforced short-circuit resistance, uniform heat dissipation via axial and radial cooling channels, low partial discharge levels, and long-term resistance to dust, humidity, and corrosive environments. These features make it suitable for commercial complexes, substations, industrial distribution, hospitals, data centers, and transportation facilities.

For engineers and installers, the diagram serves as a valuable technical reference that clarifies how each component contributes to structural strength, operational efficiency, and long service life. For buyers, it reinforces confidence in the transformer’s manufacturing quality, material selection, and precision assembly. Overall, the illustration shows that the SCB11 315KVA dry type transformer is engineered for dependable performance and long-term stability in demanding electrical applications.

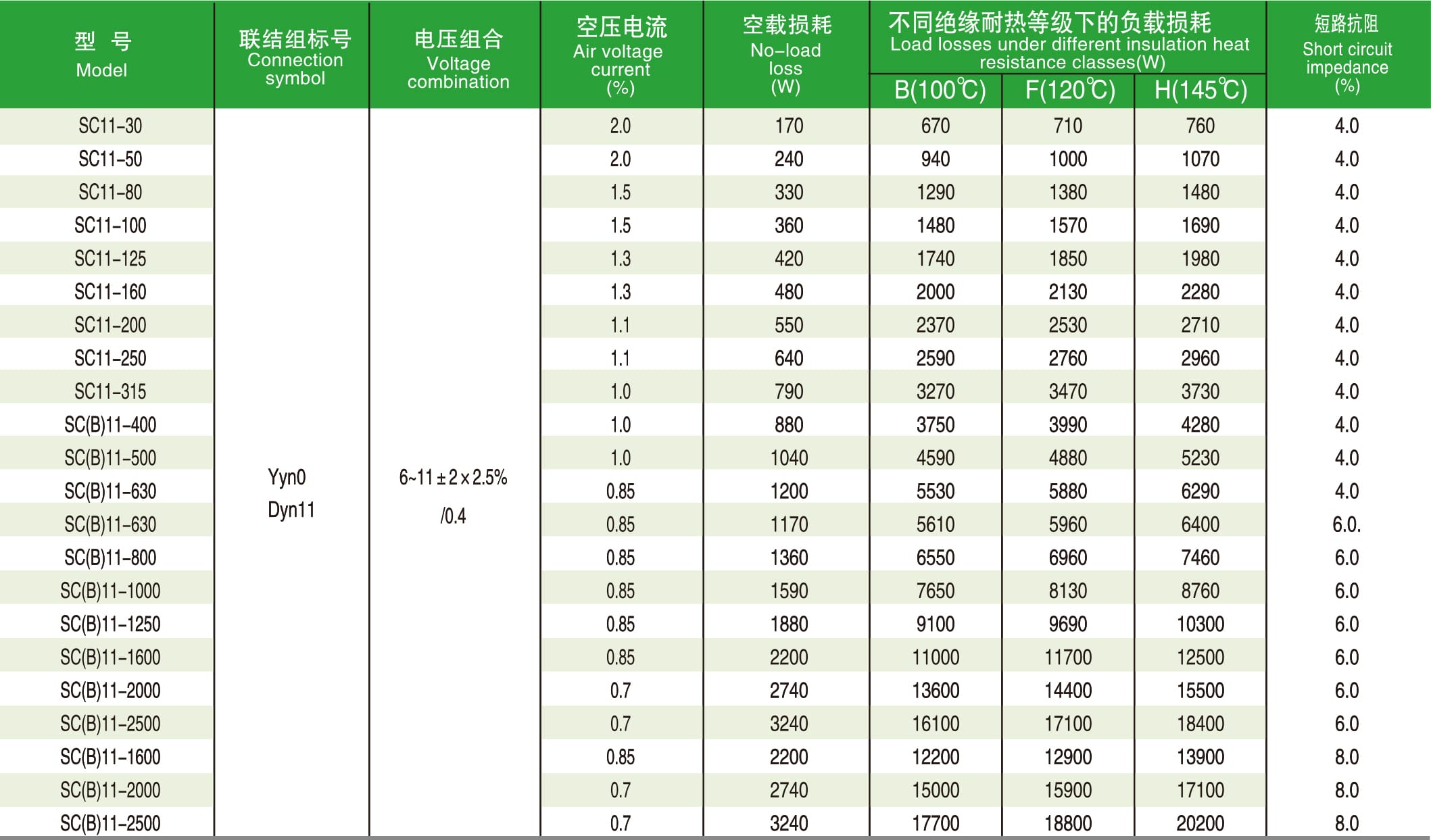

Dimensions and Technical Specifications

| Model | Air voltage current (%) | No-load loss (W) | Load losses B(100℃) (W) | Load losses F(120℃) (W) | Load losses H(145℃) (W) | Short circuit impedance (%) |

|---|---|---|---|---|---|---|

| SC11-315 | 1.0 | 790 | 3270 | 3470 | 3730 | 4.0 |

This technical specification chart delivers a comprehensive overview of the SCB11 315KVA dry type transformer, outlining its key electrical and mechanical parameters to support precise installation planning and system compatibility assessment. By presenting detailed performance metrics, the chart enables engineers, project designers, and maintenance teams to accurately evaluate how this resin cast transformer integrates into industrial power distribution, commercial buildings, substations, data centers, and other critical infrastructure environments.

The chart highlights essential specifications such as the voltage combination, winding connection symbol, no-load loss, air voltage current, and short-circuit impedance, all of which define the operational behavior and efficiency level of the SCB11 315KVA DRY transformer. It also includes load-loss values under different insulation heat resistance classes—B, F, and H—allowing engineers to analyze thermal endurance, cooling performance, and long-term stability. These measurements are crucial for ensuring that a Three Phase Dry Type Transformer operates safely under fluctuating load conditions and meets energy-efficiency expectations in demanding applications.

By offering complete and precise transformer data, this specification chart enhances decision-making, simplifies model comparison, and reinforces the reliability and high-efficiency characteristics that define the SCB11 Series transformer and its suitability for indoor, low-noise, maintenance-free, and high-safety power distribution systems.

| Parameter | SCB10 | SCB11 |

|---|---|---|

| Core Material | Standard | High-grade, low-loss |

| No-load Loss | Higher | Lower by 10–20% |

| Temperature Rise | Higher | Lower |

| Efficiency | Standard | High-efficiency level |

| Noise Level | Moderate | Low noise |

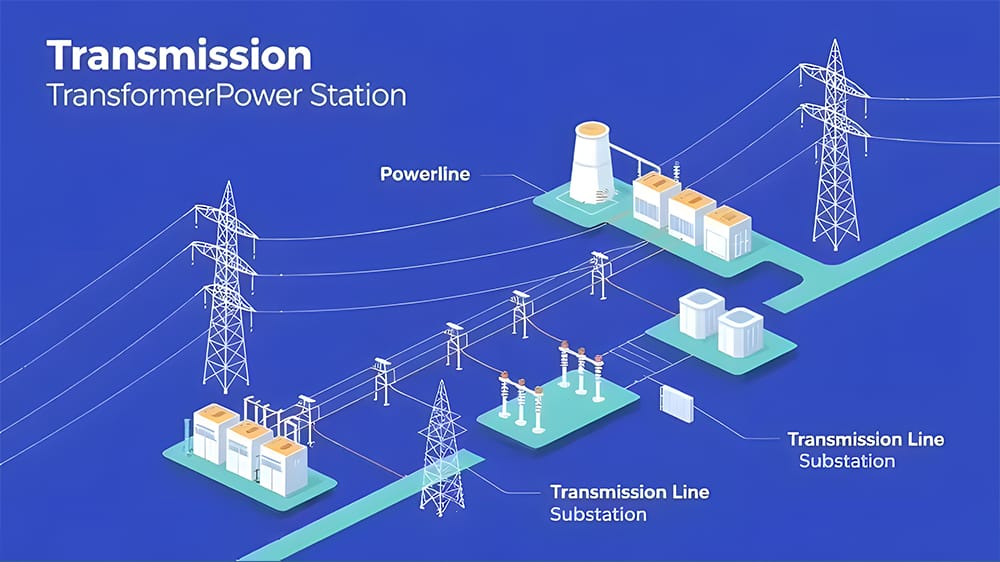

Working Principle of SCB11 Dry Type Transformers

This principle diagram clearly illustrates the essential role that the SCB11 Series three-phase transformer plays within the modern electrical power transmission and distribution network. The visual layout actively traces the complete journey of electrical energy—beginning from long-distance high-voltage transmission lines, passing through major step-down stations, and finally entering local power distribution systems where voltage levels are adjusted for safe and reliable use.

The diagram first highlights how electricity travels across vast distances through ultra-high-voltage transmission lines. These lines operate at extremely high voltage to reduce energy loss during transportation. As the power approaches regional substations, specialized step-down transformers reduce the voltage to a more manageable level. At this stage, the SCB11 315KVA dry type transformer becomes a critical component. It further steps down and stabilizes the electrical output, ensuring controlled voltage levels that can safely feed commercial buildings, industrial plants, residential areas, and public infrastructure.

By clearly illustrating each stage—from power generation to final load distribution—the diagram emphasizes how dry-type transformers such as the SCB11 315KVA DRY transformer support grid reliability and energy efficiency. With resin-cast insulation, strong short-circuit resistance, and excellent thermal performance, this Three Phase Transformer maintains stable voltage, reduces risk of fire, and operates without oil leakage, making it ideal for indoor and safety-critical environments.

This visual explanation helps non-technical buyers, project planners, and engineers understand exactly how a dry transformer integrates into a larger electrical system. It also reinforces the value of the SCB11 Series transformer in modern infrastructure projects—demonstrating its contribution to voltage transformation, system stability, and efficient energy distribution across the grid.

Packaging, Packaging & Transportation

This packaging and logistics collage demonstrates how the SCB11 315KVA dry-type transformer is securely prepared for domestic and international shipping. It shows heavy-duty wooden crates, reinforced pallets, anti-vibration cushioning, moisture-proof wrapping, and professional loading procedures.

These protective measures ensure that each transformer is delivered safely, minimizing the risk of damage during handling or marine transport.

The image emphasizes the company’s commitment to safe delivery, export-grade packaging standards, and reliability throughout the supply chain, making the SCB11 Series transformer suitable for global engineering projects.

Factory Production Process & Quality Assurance

This factory collage presents a visual overview of the advanced production environment where SCB11 Series dry-type transformers are manufactured. It highlights key workshops such as core processing, coil winding, epoxy resin vacuum casting, automated assembly, and full-process testing and inspection.

The images emphasize modern manufacturing technology, highly skilled technicians, and strict process control, all of which ensure consistent quality and reliability in every SCB11 315KVA unit.

This collage also reflects the company’s large-scale production capacity, making it capable of supporting bulk orders, fast delivery timelines, and customized transformer solutions for global clients.

Applications of SCB11 315KVA Dry Type Transformers

SCB11 315KVA dry type transformers are widely used in industrial, commercial, and municipal power distribution systems. They step down medium-voltage electricity to the levels required for factories, office buildings, shopping centers, and residential complexes, providing safe and reliable power supply.

These transformers are suitable for indoor and outdoor installations, and their cast-resin insulation ensures excellent fire safety and low maintenance, making them ideal for schools, hospitals, and data centers where continuous power is critical.

They also support renewable energy integration, including solar and wind projects, by adapting to specific voltage and protection requirements. Their compact design allows installation in limited spaces, such as auxiliary power rooms or urban substations.

For projects requiring medium-voltage power distribution, SCB11 315KVA dry type transformers comply with IEC 60076 standards to guarantee quality and reliability. You can also explore our dry type transformer selection guide to see which model fits your application best.

SCB11 315KVA dry transformer Certifications

Global Cooperation

This group photo features the company’s leadership team, employees, and international customers after a successful business negotiation involving the SCB11 Series transformer. The image represents strong cooperation, trust, and long-term partnerships with overseas clients.

It highlights the company’s professional service attitude, international business capability, and commitment to offering high-quality dry-type transformer solutions worldwide.

Such photos help build credibility, showcasing real interactions and face-to-face cooperation with global buyers, EPC companies, and engineering project managers.

FAQ: Common Questions about SCB11 Dry Type Transformers

1. What is an SCB11 315KVA Dry Type Transformer?

The SCB11 315KVA dry type transformer is a three-phase, cast-resin distribution transformer designed for indoor power systems. It features low losses, low noise, strong short-circuit resistance, and high safety due to its oil-free structure. It is widely used in commercial buildings, factories, substations, and utility distribution networks.

2. What are the main advantages of the SCB11 Series dry-type transformer?

Key advantages include:

Low losses & high efficiency

Low noise operation

No oil leakage & fire-safe epoxy resin design

Strong mechanical strength & short-circuit resistance

Low maintenance requirements

Environmentally friendly & suitable for indoor installation

These benefits make SCB11 Series transformers ideal for modern distribution systems.

3. Where is the SCB11 315KVA dry-type transformer typically used?

It is suitable for:

Industrial plants

Commercial complexes

High-rise buildings

Hospitals & schools

Data centers

Substations & distribution rooms

Airports & public infrastructure

Its fire-safe, oil-free design makes it ideal for indoor or safety-sensitive environments.

4. What is the difference between a dry-type transformer and an oil-immersed transformer?

Dry-type: Uses epoxy resin for insulation, no oil, fire-safe, low maintenance, ideal for indoor settings.

Oil-immersed: Uses transformer oil for cooling, requires more maintenance and oil monitoring, often installed outdoors.

The SCB11 315KVA is a dry-type (cast resin) transformer designed for clean, safe indoor applications.

5. Does the SCB11 315KVA transformer support customization?

Yes. We offer customization for:

Voltage levels (6kV, 10kV, 11kV, etc.)

Tapping range

Capacity (50kVA–3150kVA)

Installation method

Protection enclosure (IP20 / IP23 / IP30)

Cooling options

Our engineering team can provide tailored solutions based on project requirements.

6. What certifications does this transformer have?

The SCB11 Series dry-type transformer typically includes:

ISO 9001 Quality Management

ISO 14001 Environmental Management

ISO 45001 Occupational Safety

CE Certification

Type Test & Routine Test Reports

These ensure compliance with international electrical and safety standards.

7. How long is the lifetime of an SCB11 dry-type transformer?

Under proper operating conditions, the expected service life is 20–30 years or more. The epoxy resin insulation, advanced cooling channels, and robust core materials ensure long-term stability and reliability.

8. What maintenance is required for dry-type transformers?

Dry-type transformers require minimal maintenance. Routine checks include:

Visual inspection

Cleaning surface dust

Checking ventilation airflow

Monitoring temperature rise

Tightening cable connections

No oil testing or oil replacement is needed, reducing long-term maintenance costs.

9. How is the SCB11 315KVA dry transformer packaged for shipping?

We use export-grade packaging:

Heavy-duty wooden crates

Anti-vibration shock-proof padding

Moisture-proof wrapping

Reinforced pallet base

Secure forklift-friendly design

This ensures safe transport by sea, land, or air, even for long-distance international shipments.

10. What is the typical lead time for production and delivery?

Normal lead time: 15–25 days depending on order quantity and customization.

Urgent orders can be prioritized based on production schedule.

11. Can this transformer be used in hot or cold environments?

Yes. SCB11 dry-type transformers operate reliably in:

High-altitude areas

High-humidity environments

Cold regions

High-temperature industrial rooms

Optional H-class insulation enhances thermal resistance up to 145°C.

12. Do you offer installation guidance or technical support?

Yes. We provide:

Installation manuals

Wiring diagrams

Online technical support

On-site engineer service (for large projects)

Our engineering team ensures smooth and safe installation.

Request a Quote for SCB11 315kVA Dry Type Transformers

Contact us for pricing, specifications, and delivery details for your industrial or commercial power project.

Reviews

There are no reviews yet.