Description

35kV Three Phase Oil Immersed Distribution Transformer

This image highlights the engineering core of the 35kV oil immersed transformer. The high-grade transformer insulating oil ensures fast and stable heat dissipation. It transfers heat away from windings and the magnetic core under heavy loads. This cooling performance supports continuous operation in demanding power systems. The oil also provides superior dielectric strength for internal insulation safety. It prevents electrical breakdown during voltage fluctuations or fault conditions. The insulation barrier protects coils, leads, tap switches, and core components. Moisture resistance further improves stability in humid or outdoor environments. Oxidation resistance keeps the oil clean and reduces long-term degradation.

These protections reduce thermal stress and extend the transformer’s operational lifespan. They also help maintain consistent transformer oil quality during long working cycles. The design improves reliability for three phase transformers in harsh conditions. It supports grid stability in urban and regional power networks. The system enables safe operation for substations and distribution transformer stations. Industrial users benefit from stable performance during high-demand production hours. Renewable energy facilities use this oil transformer for solar and wind integration. Heavy-duty applications rely on its mechanical strength and voltage endurance.

The enhanced cooling and insulation help control transformer oil temperature variations. This performance improves safety in HV transformer applications. It also minimizes maintenance costs for large-scale power users. As transformer oil price trends fluctuate, high-quality oil ensures long-term value. The overall design strengthens reliability for substation transformer installations. It offers strong durability for continuous operation in remote project sites. The optimized oil type transformer structure protects the entire electrical system. This makes it a preferred solution for utilities, factories, EPC projects, and energy developers.

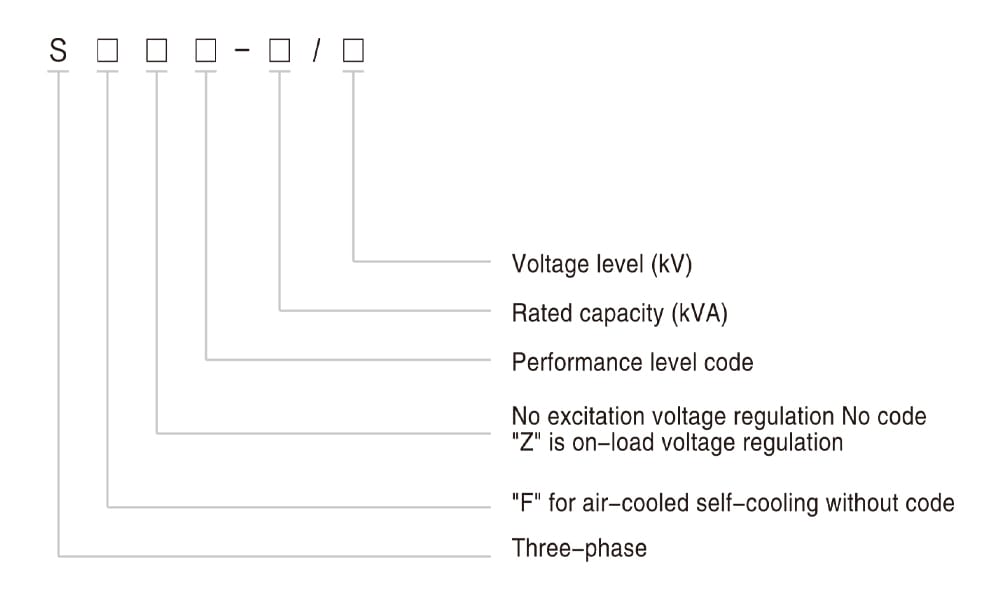

Model Meaning

This detailed model-meaning chart provides a complete breakdown of how a 35kV transformer’s model code is constructed, allowing engineers, procurement teams, and system designers to quickly interpret every technical parameter. Each section of the model represents a specific electrical or structural feature, ensuring that the chosen configuration aligns with project requirements, load characteristics, and local grid standards.

The voltage level (kV) indicates the transformer’s high-voltage rating and determines its suitability for medium- to high-voltage distribution networks. The rated capacity (kVA) defines how much power the transformer can handle continuously without overheating, making it essential for matching system load demands. The performance code reflects efficiency levels, loss standards, and design optimizations based on national or international regulations.

The chart also explains how cooling-method identifiers affect operating performance. The letter “F” marks air-cooling or air-natural/air-forced cooling modes, which influence heat dissipation efficiency and long-term stability. Meanwhile, “S” represents a three phase transformer, indicating compatibility with mainstream industrial and utility power systems.

Voltage regulation symbols further refine the model’s meaning. A model containing “Z” uses an on-load tap changer (OLTC), allowing voltage adjustments while the transformer remains energized—critical for power grids with fluctuating loads or renewable energy integration. When the model shows “no code”, it uses off-circuit tap regulation, which requires the transformer to be de-energized during adjustments, making it suitable for regions with stable voltage conditions.

By presenting these elements together, the chart helps eliminate guesswork and prevents costly specification errors. EPC contractors, utility planners, and engineering consultants can quickly identify the transformer’s functional capabilities—such as cooling class, tap-changer type, phase structure, and voltage rating—before finalizing technical drawings or procurement documents. This ensures the selected oil type transformer meets safety requirements, load profiles, installation environments, and local grid compliance standards.

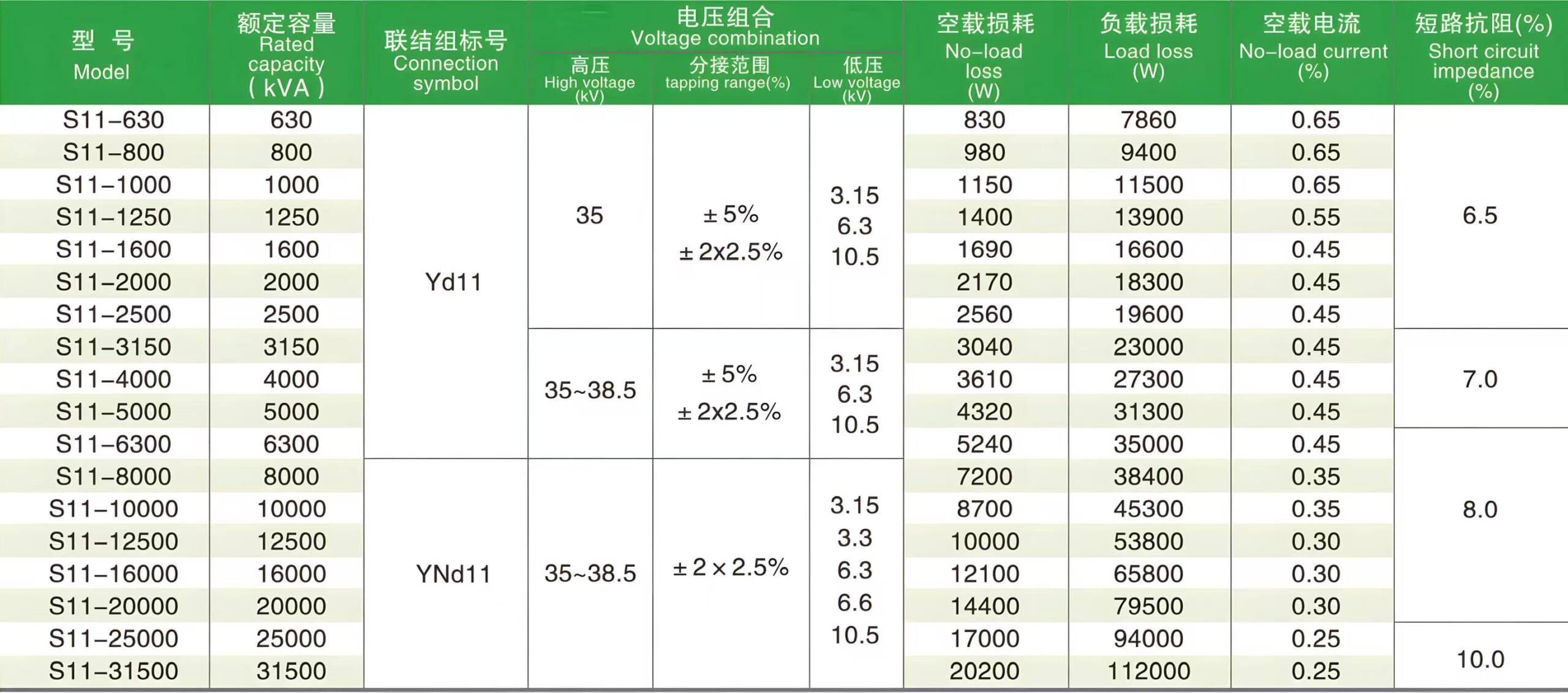

Parameters

This detailed dimension and parameter chart serves as a comprehensive technical reference for engineers evaluating the performance and suitability of a 35kV oil immersed transformer. Each data field included in the chart plays a critical role in determining how the transformer will operate under real-world electrical and environmental conditions.

The chart begins with model specifications and rated capacity (kVA), which define the transformer’s operational power range and determine whether it can support peak and continuous load demands within industrial plants, substations, utility grids, and renewable-energy systems. The connection symbol provides clarity on the winding configuration—such as Dyn11 or Yyn0—which affects phase shift, fault behavior, and compatibility with upstream and downstream network equipment.

The voltage combination and high/low-voltage tapping range help engineering teams understand how the transformer adapts to regional grid fluctuations. These values indicate whether the transformer can compensate for voltage drops, harmonics, or unstable feeder lines through on-load or off-circuit voltage adjustments. They also play a vital role in maintaining system stability, equipment life, and power quality.

Performance indicators such as no-load loss and load loss reveal how efficiently the transformer converts electrical energy. No-load loss reflects magnetic-core behavior when energized without load, while load loss illustrates winding performance under full or partial loading conditions. Lower losses translate directly into reduced operating costs, improved sustainability, and compliance with modern high-efficiency energy standards.

The chart also includes no-load current, a parameter that influences magnetizing performance, harmonic generation, and reactive power consumption. The short-circuit impedance percentage indicates how the transformer responds to fault currents, influences voltage regulation, and determines the distribution of fault levels across the system. This metric directly impacts protection coordination, safety margins, and the design of upstream circuit breakers and switchgear.

This dimension and parameter chart is therefore indispensable for precise system planning, equipment selection, electrical design, and compliance verification in utilities, industrial complexes, infrastructure networks, and renewable-energy projects. It enables engineering teams, EPC contractors, and procurement specialists to make informed decisions that ensure operational safety, high efficiency, long-term stability, and cost-effective performance across the entire power distribution system.

Factory

This collage demonstrates the full production capability of the manufacturer, showcasing a well-equipped facility capable of producing oil type transformers across various capacities and voltage levels. The “Owned Factory” section reinforces vertical supply chain control, reducing production lead time and ensuring consistency in quality. “Complete Specifications” reflects the wide product range—from compact distribution transformers to large substation transformers. “Worth Choosing” and “Prompt Delivery” highlight operational efficiency and customer satisfaction.

The images also illustrate field plant readiness, on-site support capability, and strict adherence to material selection standards. Together, these visuals position the manufacturer as a reliable global supplier of 35KV transformers for utilities, EPC contractors, and industrial end users.

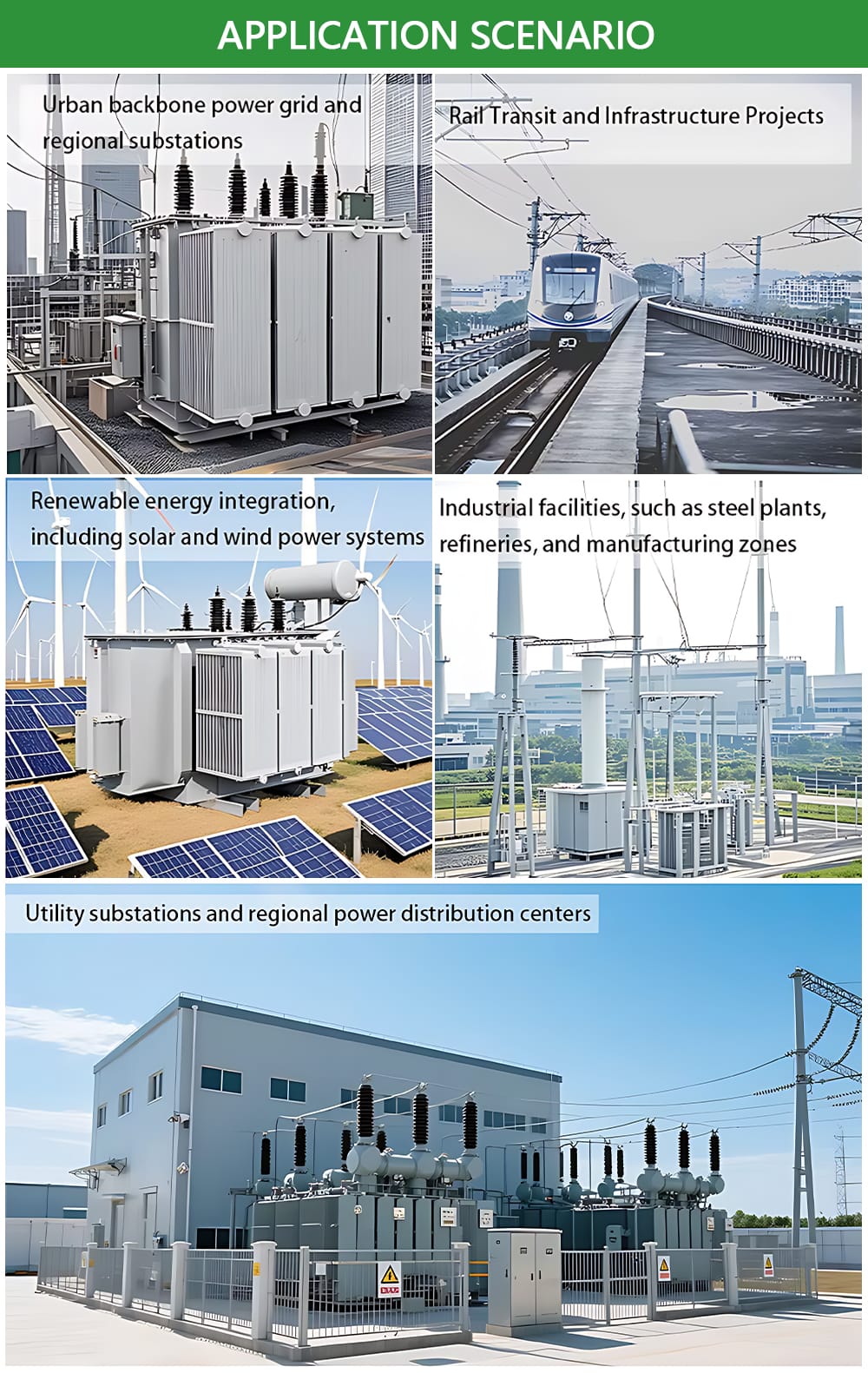

Application Scenarios

This application collage highlights the extensive versatility of the 35KV oil immersed transformer, showing its core role in multiple sectors. Across urban backbone power grids, the transformer stabilizes energy flow and maintains voltage quality. Rail transit and major infrastructure networks rely on it to deliver continuous, stable power for stations, signaling systems, and traction substations.

When used in renewable energy projects, the transformer links solar farms, wind turbines, and hybrid clean-energy systems to the grid with reliable efficiency. Industrial facilities such as steel plants, refineries, and manufacturing hubs rely on the transformer’s durability for heavy electrical loads and demanding production cycles. Utility substations and regional power centers use the transformer to step down high-voltage electricity for safe regional distribution. This wide adaptability underscores the unit’s reliability, efficiency, and long-term cost savings.

Packaging & Transportation

This collage demonstrates the comprehensive packaging and logistics solutions designed to protect 35KV oil immersed transformers during long-distance international shipping. Each unit undergoes careful preparation, including moisture-proof sealing, vibration-resistant reinforcement, and polyurethane cushioning to protect internal components. Heavy-duty wooden crates and steel frames secure the transformer tank, bushings, and accessories during handling.

The manufacturer uses reliable logistics channels for moving large electrical equipment safely. These channels support delivery to ports, project sites, and remote industrial areas. This system protects the oil transformer throughout transport and keeps each unit in optimal condition. It helps prevent shocks or impacts that may harm internal insulation or oil quality. It also avoids damage to external structures that could affect long-term performance.

35KV oil immersed transformer Certifications

Global Cooperation

This image captures a successful meeting between company leaders, engineering specialists, and international business partners. It shows the manufacturer’s ability to provide full technical support for transformers and high-voltage equipment. The photo conveys trust and professionalism built through long-term cooperation with global clients. It demonstrates a team skilled in project execution, export documentation, and multi-country compliance. It also highlights the company’s commitment to clear communication, flexible customization, and reliable delivery valued by global partners.

FAQ

1. What applications are suitable for this oil transformer?

It is ideal for utilities, industrial plants, infrastructure projects, and renewable energy systems.

2. How is the transformer protected during transportation?

It is secured with shock-proof packing, moisture control, and reinforced steel framing.

3. Can the transformer be customized?

Yes, we offer customizable voltage, capacity, tap settings, cooling methods, and terminal configurations.

4. What standards does the product meet?

It complies with IEC, ANSI, IEEE, and regional grid standards based on customer requirements.

5. How long is the production and delivery time?

Production typically takes 4–8 weeks depending on specifications and order quantity.

Reviews

There are no reviews yet.