Description

As a professional transformer manufacturer and supplier, we provide IEC-compliant 200kVA oil-immersed transformers designed for reliable medium-voltage power distribution in utility, industrial, and renewable energy projects. Our factory-direct supply ensures stable quality, flexible customization, and competitive pricing for global B2B buyers.

200KVA Oil Immersed Transformer

Built to serve as the resilient heart of your power distribution network, our 200kVA oil-immersed transformer is engineered for critical applications where downtime is not an option. It delivers tangible value through design choices that directly impact your operational bottom line.

Hermetically Sealed Tank: Eliminating a Major Failure Point

User Value: Drastically reduced maintenance and extended service life.

Technical Insight: The permanent seal prevents atmospheric moisture from degrading the insulating oil and cellulose paper—the two primary causes of aging in conventional transformers. This eliminates the need for periodic oil purification and associated testing, slashing long-term maintenance costs.

Cold-Rolled Steel Construction: Durability That Lowers Lifetime Cost

User Value: Superior protection against harsh environments, minimizing corrosion-related failures.

Technical Insight: The use of high-grade, cold-rolled steel with a multi-layer coating system provides exceptional resistance to industrial pollutants, salt spray, and UV radiation. This translates to a longer structural lifespan and a lower total cost of ownership, even in settings like mining or coastal plants.

Optimized Electrical Core: Consistent Performance Under Real-World Loads

User Value: Enhanced energy efficiency and stability for your entire facility.

Technical Insight: The core, built with low-loss, grain-oriented silicon steel, is precisely wound and balanced to minimize eddy current and hysteresis losses. This results in higher operational efficiency (reducing electricity costs) and superior voltage regulation, ensuring sensitive machinery in your plant operates without disruption from voltage sags or swells.

Definitive Applications

This transformer is the definitive choice for projects that cannot afford unexpected power interruptions, including:

Manufacturing Plants: Ensures consistent power for automated production lines.

Mining Operations: Withstands harsh conditions while powering heavy equipment.

Commercial Infrastructure: Provides the silent, reliable backbone for hospitals, data centers, and large complexes.

200KVA Oil Immersed Transformer Details

Durability Engineered, Component by Component

True reliability lies in the details. We invite you to explore the key features that ensure operational integrity and safety in our 200kVA Oil-Immersed Transformer—each part designed to deliver performance you can trust.

High-Visibility Oil Level Gauge – Clarity at a Glance

Engineered with a durable, high-transparency window, the oil level gauge allows quick visual inspection from a safe distance. No need for shutdowns or close-range checks. It enables early detection of fluid anomalies, helping prevent insulation issues before they impact performance.

High-Conductivity Tinned Copper Terminals – Efficient and Secure Connections

Featuring corrosion-resistant tinned copper construction, these terminals minimize contact resistance and reduce energy loss. Even under continuous load fluctuations and thermal stress, they maintain tight, reliable connections—extending service life and boosting energy efficiency.

Buchholz Relay – Your First Line of Defense

This precision gas detection relay monitors internal conditions in real time, responding instantly to arcs, overheating, or insulation breakdown. By triggering alarms or disconnecting the transformer at the earliest sign of fault, it prevents minor issues from becoming major failures.

Reinforced Oil Drain Valve – Simplified and Safe Maintenance

Built with anti-leak seals and a rugged, corrosion-resistant body, this valve ensures clean, controlled oil drainage and sampling. It streamlines routine checks and fluid replacement, reducing downtime and simplifying compliance with maintenance protocols.

Every component reflects a commitment not only to peak performance, but also to operational safety and service-friendly design. When you choose our 200kVA oil-immersed transformer, you’re choosing a system built to last—and engineered for ease.

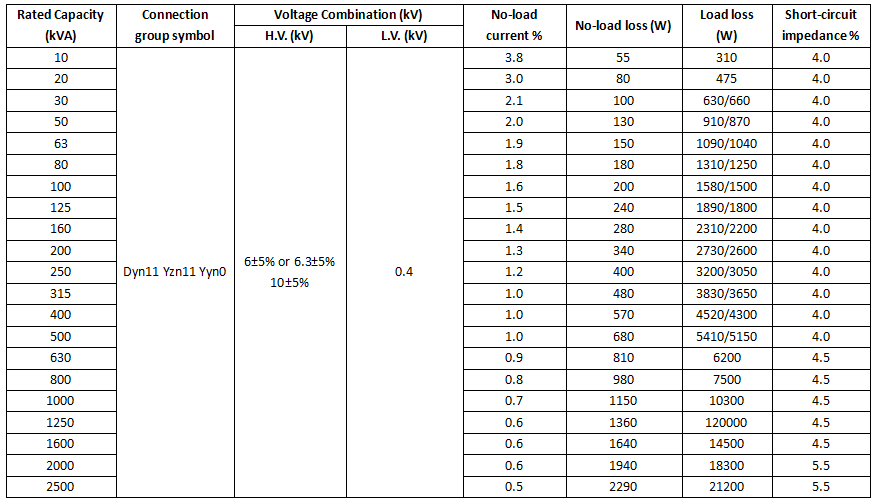

Technical Specifications of 200kVA Oil-Immersed Transformer

| Rated Capacity (kVA) | Connection group symbol | Voltage Combination (kV) | No-load current % | No-load loss (W) | Load loss (W) | Short-circuit impedance % | |

|---|---|---|---|---|---|---|---|

| H.V. (kV) | L.V. (kV) | ||||||

| 200 | Dyn11 Yzn11 Yyn0 | 6±5% or 6.3±5% 10±5% | 0.4 | 1.3 | 340 | 2730/2600 | 4.0 |

| 250 | 1.2 | 400 | 3200/3050 | 4.0 | |||

| 315 | 1.0 | 480 | 3830/3650 | 4.0 | |||

Precision engineering is defined by data. This detailed schematic provides the critical blueprint for integrating our Oil Immersed Transformer into your specific power system. It meticulously outlines key electrical parameters—such as the optimized voltage combinations, exceptionally low no-load losses (<1.2%), and precisely calibrated short-circuit impedance—that collectively ensure peak efficiency and stable grid performance.

The accompanying physical dimensions and weight specifications are crucial for planning seamless installation, ensuring proper clearances, and facilitating logistical handling. This transparency in technical data empowers you to make an informed decision, confirming that this oil immersed transformer is perfectly tailored to your operational and spatial requirements.

Why Choose Our 200kVA Oil-Immersed Transformer

This overview breaks down the six pillars of excellence that define our Oil Immersed Transformer, moving beyond basic specifications to highlight the tangible benefits you receive.

Superior Efficiency & Reduced Operating Cost

At the heart of our 200KVA oil immersed transformer is a core built from high-grade, cold-rolled, grain-oriented silicon steel. This advanced material, combined with precisely wound low-resistance copper conductors, minimizes energy loss. The result is significantly lower no-load and load losses, which translates directly into reduced electricity bills and a lower total cost of ownership over the decades-long lifespan of the unit.

Unmatched Durability for Harsh Environments

We construct the main tank of our 200KVA oil immersed transformer from reinforced steel plate, protected by a robust, multi-layer anti-corrosion coating. This defense system is engineered to resist rust and degradation caused by moisture, salt spray, and industrial pollutants, ensuring the transformer’s structural integrity and long service life even when installed in challenging outdoor or coastal environments.

Reliable Insulation & Efficient Cooling System

The combination of high-grade dielectric oil and a meticulously designed radiator bank creates a highly effective closed-loop system. This ensures optimal heat dissipation from the core and windings, maintaining stable operating temperatures under full load. This efficient thermal management prevents premature aging of the insulation, directly contributing to the exceptional reliability and extended operational life of the 200KVA oil immersed transformer.

Integrated Safety & Monitoring Features

Your peace of mind is engineered into our design. Critical accessories like the Buchholz Relay provide immediate detection of internal faults, while the Oil Level Indicator allows for easy visual monitoring. The Pressure Relief Device and Silica Gel Breather work in tandem to protect against over-pressure and maintain oil purity. These features make our 200KVA oil immersed transformer a safe and intelligent choice for your power network.

Globally Certified Quality & Performance

Every 200KVA oil immersed transformer we produce is manufactured under a stringent quality management system certified to ISO 9001 and is performance-tested in accordance with international standards such as IEC 60076. This certification backbone guarantees that the product you receive delivers consistent, reliable performance and adheres to the highest global benchmarks for safety and efficiency.

Streamlined Installation & Simplified Maintenance

We design with the end-user in mind. Features such as a sturdy lifting rigging, clearly marked terminals, and strategically located valves and gauges facilitate a faster, safer, and more cost-effective installation. The accessibility of key components also streamlines routine maintenance checks and any necessary servicing, reducing your operational downtime and long-term maintenance costs.

Related Products

While our reputation is firmly built on the reliability of our oil-immersed transformers, our engineering expertise powers a far more comprehensive portfolio of electrical solutions. This product family is engineered to meet the precise and varied demands of modern power systems, from dense urban centers to critical industrial facilities.

Dry-Type Transformers: Safety for Sensitive Environments

Core Technology: Utilize advanced vacuum pressure impregnation (VPI) or cast resin insulation systems, ensuring high dielectric strength and protection against moisture and contaminants.

Key Features:

Fire-Safe Operation: Completely free of flammable oils, making them ideal for indoor installations like high-rise buildings, hospitals, schools, and shopping malls.

Environmental Resilience: Class F or H insulation ensures stable performance in harsh conditions.

Low Maintenance: Eliminates the need for oil monitoring and testing, reducing lifetime costs.

Primary Applications: Indoor substations, marine applications, mining, and any location where fire safety is a paramount concern.

Pad-Mounted Transformers: Blending into the Community

Core Technology: Feature a completely enclosed, tamper-proof, and weatherproof steel cabinet with lockable doors.

Key Features:

Compact Footprint: Designed for space-constrained areas, preserving aesthetics and land use in suburban and urban neighborhoods.

Public Safety: Fully enclosed design prevents public access, meeting strict utility safety standards.

Durability: Corrosion-resistant coatings and robust construction withstand harsh environmental conditions.

Primary Applications: Underground distribution networks, residential subdivisions, parks, and commercial districts.

High Voltage Transformers: The Backbone of Power Transmission

Core Technology: Engineered with precision-wound cores and high-grade laminations, optimized for minimal loss at extra-high voltage levels.

Key Features:

Transmission Efficiency: Designed for the primary side of the grid (typically 69kV and above), ensuring efficient long-distance power transmission.

Superior Insulation: Advanced oil-paper insulation systems and bushings designed to withstand lightning and switching impulses.

Robust Construction: Built to deliver unwavering reliability in the demanding environment of generation stations and transmission substations.

Primary Applications: Power plant step-up units, transmission substations, and large industrial complexes with direct high-voltage connections.

Oil-Immersed Distribution Transformers: The Workhorse of the Grid

Core Technology: Leverage the excellent dielectric and cooling properties of insulating oil within a sealed tank.

Key Features:

Proven Reliability: A time-tested design known for its long service life and robust performance.

Optimal Thermal Management: The oil effectively dissipates heat generated by core and coil losses, allowing for consistent operation under load.

Economic Efficiency: Offers a cost-effective solution for a wide range of distribution capacities.

Versatility: Available in various configurations, including conventional, hermetically sealed, and conservator tank designs.

Primary Applications: Utility pole-top and ground-mounted distribution, industrial parks, renewable energy farms, and commercial power distribution.

This diverse portfolio demonstrates a fundamental truth: when you choose our products, you are investing in more than just a component. You are leveraging deep, specialized knowledge across the entire field of electrical transformation technology, ensuring the right solution for every challenge.

Applications of 200KVA Oil Immersed Transformer

Our oil-immersed transformers are engineered for reliability; however, the true test happens in the field. As concrete evidence, the following project snapshots demonstrate how we deliver stable power in diverse, demanding environments across the globe.

Ensuring Uninterrupted Production for an Agricultural Processing Plant

The Challenge: A new processing facility required a power solution that could handle high humidity, dust, and continuous 24/7 operation without failure. Any voltage instability would risk spoiling perishable goods and halting production lines.

Our Solution: Installation of a dedicated oil-immersed transformer, chosen for its robust thermal management and proven tolerance to harsh conditions.

The Outcome: The client achieved stable, uninterrupted power for critical refrigeration and processing units, safeguarding product quality and maximizing operational uptime during peak harvest seasons.

Supporting Essential Services for a Municipal Water Treatment Plant

The Challenge: A city’s water treatment plant needed to upgrade its electrical infrastructure with a transformer that offered extreme long-term reliability and corrosion resistance, as any power failure would directly impact public health and safety.

Our Solution: Deployment of a corrosion-resistant, hermetically sealed oil-immersed transformer designed for decades of silent, maintenance-efficient service.

The Outcome: The municipality gained a highly reliable component of its critical infrastructure, ensuring continuous water purification and distribution for the community while minimizing lifetime maintenance costs.

Delivering Power in Extreme Climates for a Remote Mining Operation

The Challenge: A mining operation in a region with extreme temperature swings—from scorching days to freezing nights—needed a power transformer that could maintain performance and mechanical integrity under constant thermal stress.

Our Solution: Supply of specially calibrated oil-immersed transformers with optimized cooling systems and materials tested for performance across a wide temperature range.

The Outcome: The mine secured a dependable power source that operates consistently in a challenging climate, supporting heavy equipment and on-site processing without weather-related disruptions, thereby protecting their investment and schedule.

Why These Cases Matter to You:

These projects are not isolated cases; they actively demonstrate how our product is built to perform under pressure. In fact, whether your priority is continuous uptime, corrosion resistance, or climatic resilience, real-world conditions consistently validate our solutions.

Ultimately, by choosing our transformers, you are not just buying a component—you are investing in a platform of proven reliability that powers progress and economic growth across industries worldwide.

Packaging & Shipping of 200KVA Oil Immersed Transformer

We know that the reliability of a precision-engineered transformer is built long before it is energized on-site. For this reason, we implement a comprehensive, end-to-end delivery process, meticulously controlling every step to ensure your oil-immersed transformer arrives in perfect condition anywhere in the world, ready for immediate installation.

Custom-Engineered, Weatherproof Packaging

Superior engineering demands superior protection from the start.

- Heavy-Duty Crating: Each unit is secured within a custom-built, steel-reinforced wooden crate, constructed from treated timber to resist moisture and pests. Moreover, the design is calculated to absorb shocks and prevent any movement during transit.

- Component-Specific Protection: We shield critical and vulnerable components—including bushings, conservators, and gauges—with high-density, form-fitting foam molds and protective caps to prevent damage from vibration and impact.

- Complete Environmental Sealing: We wrap the entire transformer in multi-layer, waterproof, and anti-condensation VCI film, and place desiccant bags strategically inside to control humidity and prevent corrosion during ocean transit.

Expert Loading and Secure Transit Procedures

After we securely package each unit, our team then handles it with precision.

Specialized Loading Equipment: We utilize self-propelled modular trailers (SPMTs), hydraulic jacking systems, and custom-built ramps to ensure a smooth and controlled loading process onto shipping containers or flatbed trucks.

Sea-Worthy & Road-Worthy Securement: Our logistics team actively secures the crated transformers inside containers or on flatbeds, utilizing heavy-duty chains, twist locks, and reinforced blocking and bracing. As a result, every shipment consistently complies with the strictest international shipping standards.

Real-Time Monitoring (Optional): For critical projects, we offer the option of integrated shock and tilt recorders. This provides you with verifiable data and a GPS-tracked log of the entire journey, ensuring full transparency and accountability.

Global Logistics Expertise and On-Site Delivery

Our capability extends seamlessly from our factory to your foundation.

Multi-Modal Flexibility: We manage complex logistics through a network of trusted partners, expertly coordinating seamless overland, rail, and ocean freight (both Ro-Ro and containerized) to any global port.

Final-Mile Precision: Our responsibility includes comprehensive on-site delivery guidance. We provide detailed manuals for safe unloading, positioning, and initial checks, ensuring a smooth transition from transporter to foundation.

Our Commitment to You:

When you choose our transformer, you receive more than a product; you gain a seamless, worry-free delivery experience. Our dedicated project management team actively oversees every step. As a result, we consistently preserve the quality built into our transformers until they are successfully powering your project.

Certifications of 200kVA Oil-Immersed Transformer

Global Cooperation

Behind every Oil Immersed Transformer is a story of collaboration and trust. This photograph captures our technical team with valued international clients, directly reflecting the global partnerships we build.

More importantly, it underscores our commitment to providing not just a product, but comprehensive support—from pre-sales technical consulting and customized solution design to after-sales service.

We engage directly with our clients to understand their unique challenges. Therefore, the oil-immersed transformer they receive is not just a standard unit, but rather an integral part of their success.

FAQ

Q1: What is a 200kVA Oil-Immersed Transformer?

A1: A 200kVA Oil-Immersed Transformer is a three-phase transformer designed for industrial and commercial power distribution. As a trusted 200kVA oil-immersed transformer manufacturer, SolarasiaPV ensures high-efficiency and low-maintenance performance.

Q2: Can I buy 200kVA Oil-Immersed Transformers directly from SolarasiaPV?

A2: Yes, you can buy 200kVA oil-immersed transformers for industrial use directly from the manufacturer. We provide fast delivery, competitive pricing, and expert support worldwide.

Q3: What makes your transformers different from other suppliers?

A3: Our low-maintenance 200kVA oil-immersed transformer supplier services ensure strict quality control and reliable performance for industrial power distribution projects.

Q4: How do I request a quote or place an order?

A4: Simply click the “Request a Quote” button or contact us via email or phone. Our team will help you purchase 200kVA oil-immersed transformers for industrial use quickly and securely.

Q5: What are the primary loss standards for your 200kVA oil-immersed transformer?

A5: Our 200kVA units are engineered to meet or exceed IEC 60076 standards. We utilize high-permeability silicon steel to ensure ultra-low No-load loss (approx. 340W) and Load loss (approx. 2600W/2730W). This high-efficiency design directly reduces operational costs for industrial and commercial power distribution systems.

Q6: Can I customize the voltage ratio (e.g., 11kV to 400V) and connection group?

A6: Absolutely. While our standard configuration is 10kV to 0.4kV with Dyn11 connection, we provide full customization services. We can adjust the primary/secondary voltage, tap changer range, and vector groups (such as Yzn11 or Yyn0) to satisfy the specific grid requirements of different regions like Southeast Asia, Africa, or the Middle East.

Q7: How can I get a formal price quote for a 200kVA oil transformer today?

A7: Because material costs for copper and oil fluctuate, we provide real-time quotes valid for 15-30 days. Simply click the “Inquiry Now” button or contact our sales team via WhatsApp with your required quantity and destination port. We typically return a detailed technical proposal and FOB/CIF price within 2 hours.

Get Your 200KVA Oil Immersed Transformer Today

Need a reliable 200KVA Oil Immersed Transformer for your project? Request a quote today or contact our engineers for expert guidance.

Reviews

There are no reviews yet.