Description

11KV Dry Type Transformer

This powerful front-view image presents our flagship 11KV Dry Type Transformer in an operational environment, showcasing its professional industrial design. The transformer features a rugged enclosure constructed from cold-rolled steel with a corrosion-resistant RAL code powder coating, providing IP23 protection that safeguards against dust ingress and water splashes.

The strategically designed ventilation system ensures optimal thermal management through natural air convection, maintaining operating temperatures within safe limits. As a dry-type design, it completely eliminates fire hazards associated with liquid-filled transformers, making it perfectly suited for installation in hospitals, high-rise buildings, shopping malls, and industrial plants where fire safety is paramount.

The clean, modern appearance with clearly labeled terminals and accessories demonstrates our commitment to both functionality and aesthetic excellence in electrical power equipment.

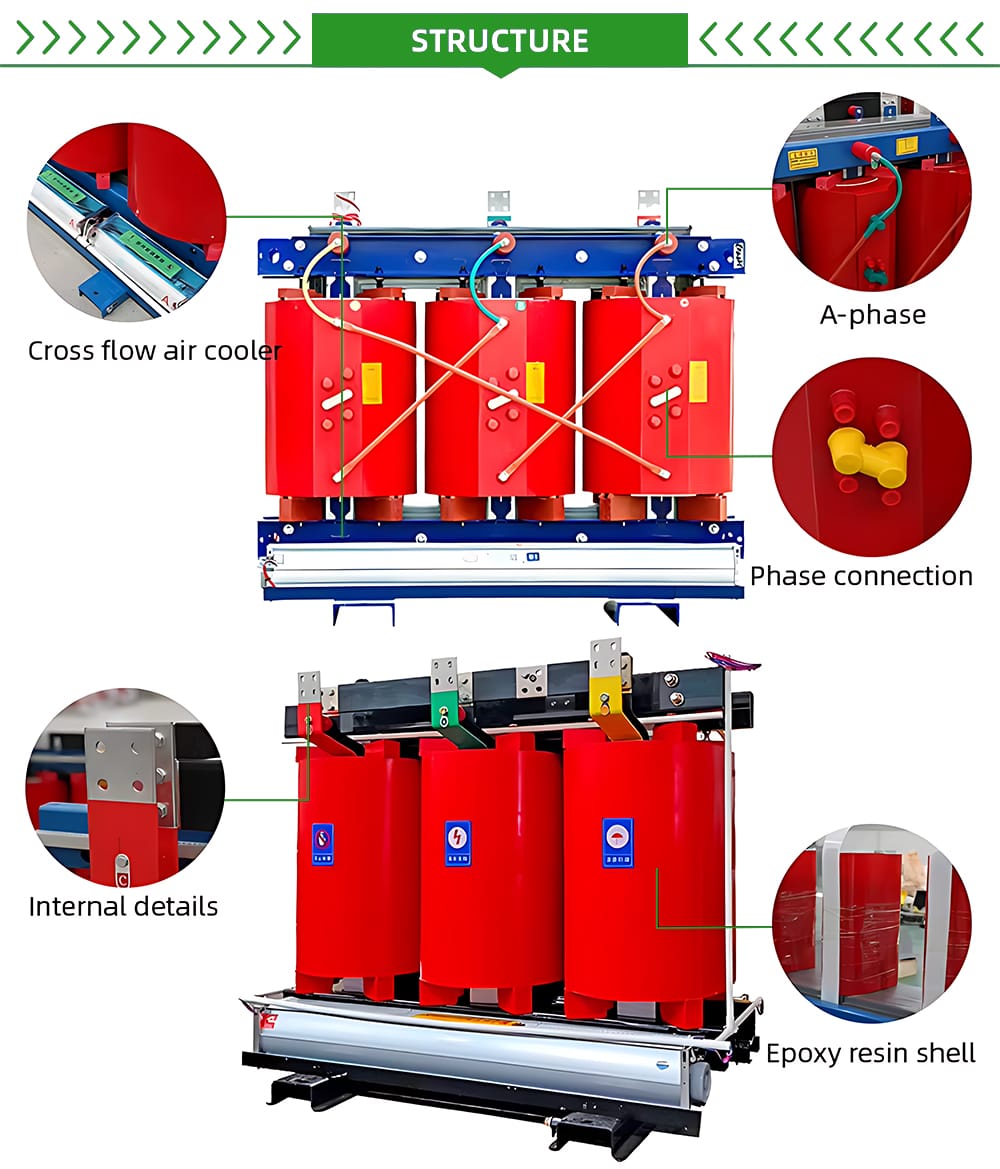

STRUCTURE

This detailed cross-sectional diagram provides an engineering-level view of the advanced internal architecture of our 11KV Dry Type Transformer. The illustration clearly shows the innovative cross-flow air cooling system that ensures efficient heat dissipation through strategically placed ventilation channels.

The internal details reveal the precision-engineered A-phase configuration with perfectly aligned magnetic circuits, while the phase connection system demonstrates the robust busbar arrangement that ensures minimal electrical losses.

The epoxy resin shell encapsulation is shown protecting the high-voltage windings, creating a monolithic insulation system that is impervious to moisture, chemicals, and environmental contaminants. This construction ensures exceptional dielectric strength, thermal stability, and resistance to short-circuit forces, providing reliable performance in the most demanding applications.

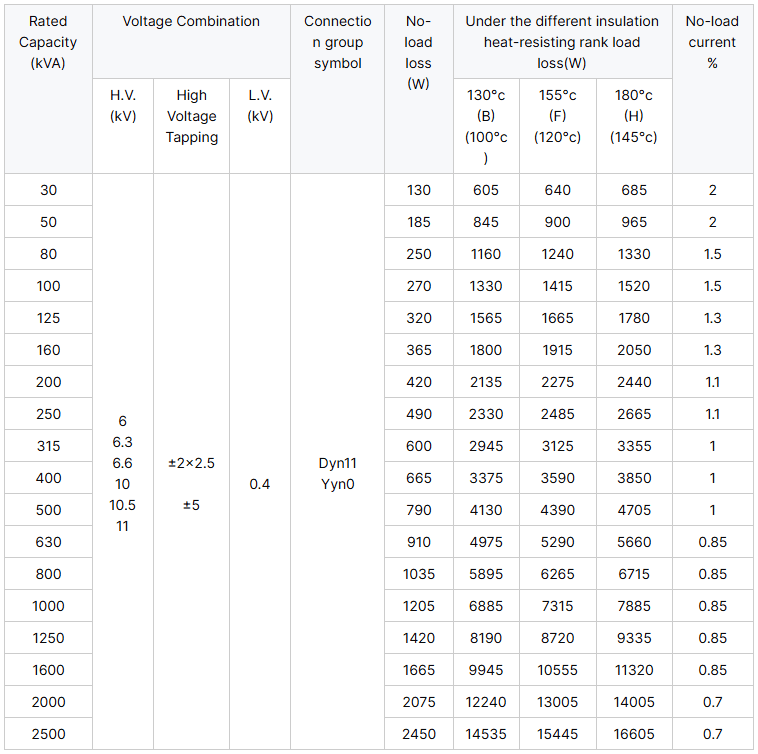

11KV Dry Type Transformer Parameters

This comprehensive technical specification table provides essential engineering data for our 11KV Dry Type Transformer, serving as a crucial reference for electrical engineers and project planners.

The table includes Rated Capacity options ranging from 100KVA to 2500KVA to meet various load requirements. Voltage Combination details show flexibility in both High Voltage (11KV, 6.6KV) and Low Voltage configurations.

The Connection group symbol indicates available vector groups including Dyn11, Yyn0, and others to match specific system requirements.

No-load loss and load loss values are meticulously measured under different insulation classes (F, H, C), demonstrating exceptional energy efficiency that meets and exceeds international standards. The No-Load current specification, reflects the high quality of our magnetic core materials and manufacturing precision.

Product Details

Packaging & Shipping

Our sophisticated packaging system ensures that every 11KV Dry Type Transformer arrives at its destination in perfect condition. The transformer is first mounted on a heavy-duty wooden skid with reinforced steel brackets, then wrapped in multiple layers of protective materials including waterproof plastic sheeting, moisture-resistant barrier paper, and shock-absorbing foam padding.

The entire unit is then enclosed in a custom-built wooden crate with reinforced corners and lifting points for safe handling. Each package includes desiccant bags to control humidity and impact indicators to monitor any rough handling during transit. Our logistics team coordinates with certified carriers experienced in handling heavy electrical equipment, ensuring smooth transportation by sea, land, or air to any global destination.

11KV Dry Type Transformer Certifications

Global Cooperation

This collaborative collage showcases the human element behind our 11KV Dry Type Transformer success story. It features our experienced engineering team with over 100 years of combined expertise in transformer design and manufacturing. The production specialists demonstrate their craftsmanship in precision winding and quality assembly processes.

Our quality assurance team is shown conducting rigorous tests including impulse voltage tests, temperature rise tests, and partial discharge measurements. International partners from Europe, North America, and Asia are featured during factory inspections and technical meetings, highlighting our global collaboration network. The leadership team showcases their strategic vision in driving innovation and excellence in power transformation technology. This human-centric approach ensures that every transformer delivers exceptional performance and reliability.

FAQ

Q1.Do you have MOQ?

The parties can reach the final agreement through negotiation, taking into account different perspectives. The larger the quantity is, the competitive the unit price will be.

Q2.Should the customer pay the delivery fee , How much is it?

We charge a delivery fee, or you provide your express account or cover the shipping cost. If you do not request, I will choose a cheap one in China.

Q3.How about the after sale service?

1)We always match the buyer’s sample quality and compensate if any quality issue occurs.

2)We will suggest our packing and take charge in our packing, we will keep the goods safe in the delivery.

3)We track goods from production to sale and resolve any issues customers face during the selling process.

Q4.When can I get a price?

We usually quote within 24 hours after we get your inquiry.

Q5: Are you a trade company or manufacturer?

We are a professional manufacturer with our own factory.

Reviews

There are no reviews yet.