Description

100KVA Dry Type Transformer

This powerful hero image showcases our flagship 100KVA Dry Type Transformer installed in a clean, operational setting. The frontal three-quarter view perfectly captures the unit’s robust, industrial-grade enclosure, finished in a standard RAL color to ensure it integrates seamlessly into any modern electrical room or facility.

Visual Highlights & Design Advantages:

Robust Enclosure & Professional Finish: The transformer features a durable, steel construction with a standard RAL color, designed for long-lasting performance and visual harmony in professional environments.

Optimized Thermal Management: The well-ventilated panel design is clearly visible, demonstrating its commitment to efficient heat dissipation and reliable, maintenance-free operation.

Safe & Simplified Handling: Key components like the sturdy lifting lugs and the secure, accessible terminal compartment door are highlighted, emphasizing ease of installation and operational safety.

This image is designed to immediately communicate the product’s core values of durability, safety, and advanced engineering, making it an ideal visual centerpiece for attracting potential customers and setting a benchmark for quality in the dry-type transformer market.

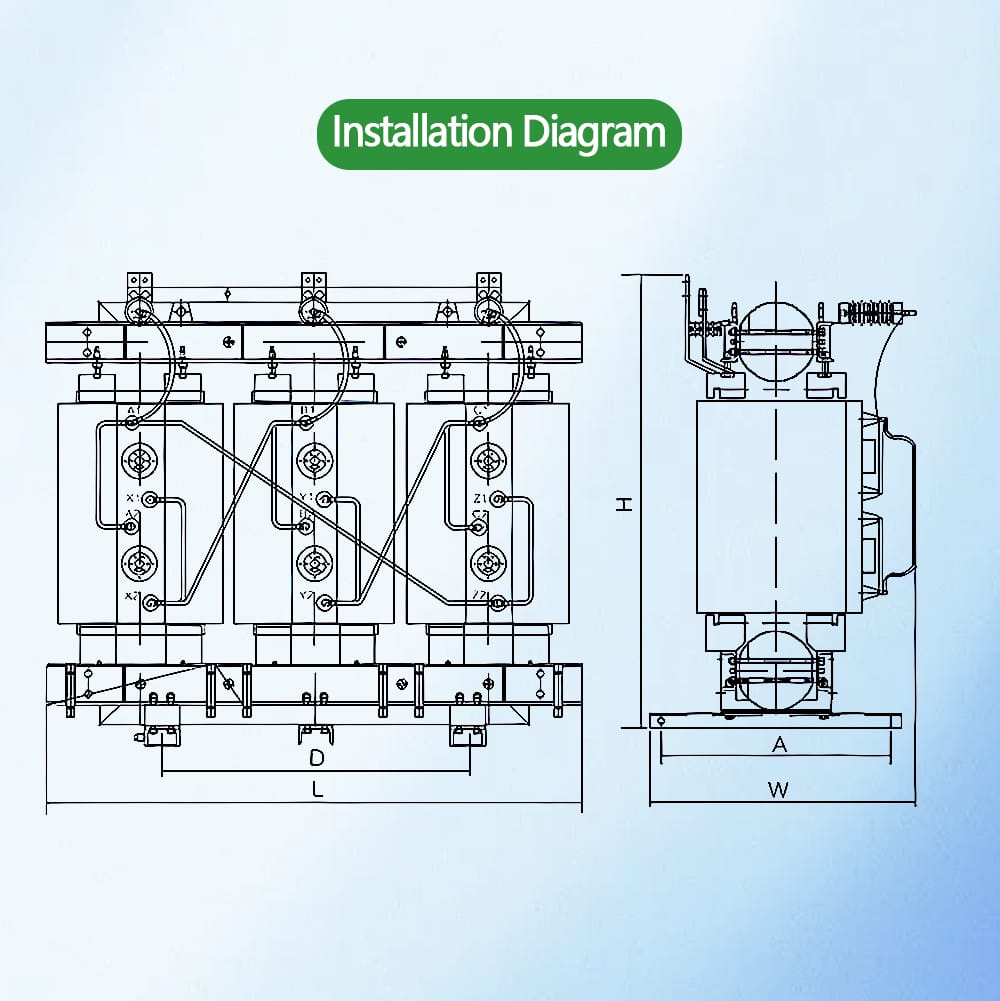

Installation Diagram

This detailed technical schematic offers a comprehensive reference for the seamless and compliant installation of the 100KVA Dry Type Transformer. Designed for engineers and project planners, the drawing clarifies all essential spatial and structural requirements to ensure a safe, efficient, and error-free setup.

Key Features & Installation Guidance:

Foundation & Mounting Specifications: Precise bolt positioning, sizing, and load-bearing details are provided to ensure a solid and stable base for the transformer, guaranteeing long-term operational integrity.

Dimensional Data & Safety Clearances: All critical external dimensions—including length, width, height, and total weight—are clearly annotated. The schematic emphasizes the minimum required clearances on all sides, which are vital for operational safety, effective heat dissipation, and ongoing maintenance access.

Cable Entry & Connection Points: The drawing accurately indicates cable entry locations, grounding terminal positions, and designated lifting points. This helps streamline the installation process, reduces wiring errors, and ensures compliance with electrical safety standards.

Compliance & Efficiency Benefits: By integrating these specifications early in the planning phase, installers can accelerate project timelines, minimize rework, and adhere to international operational guidelines—reducing both time and risk.

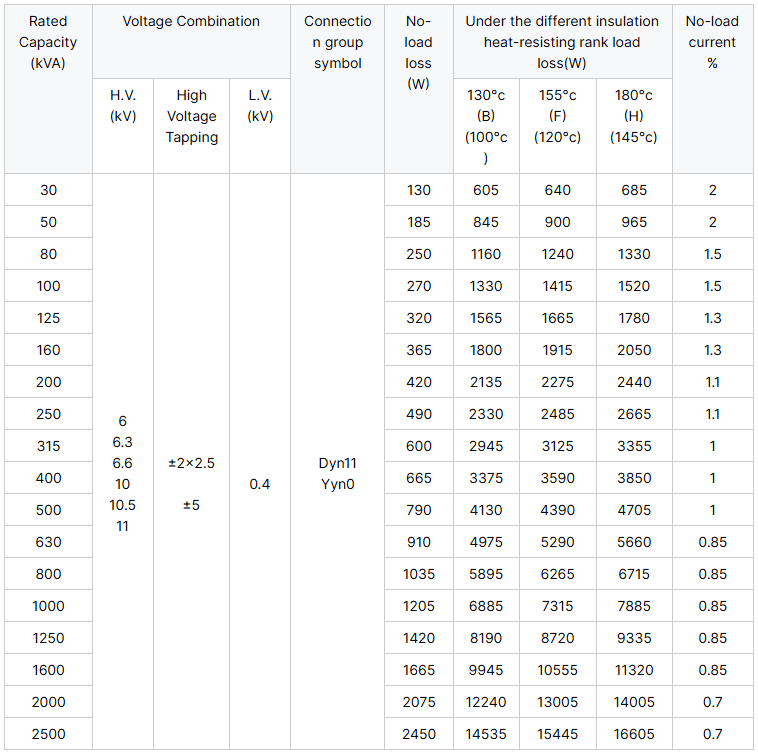

100KVA Dry Type Transformer Parameters

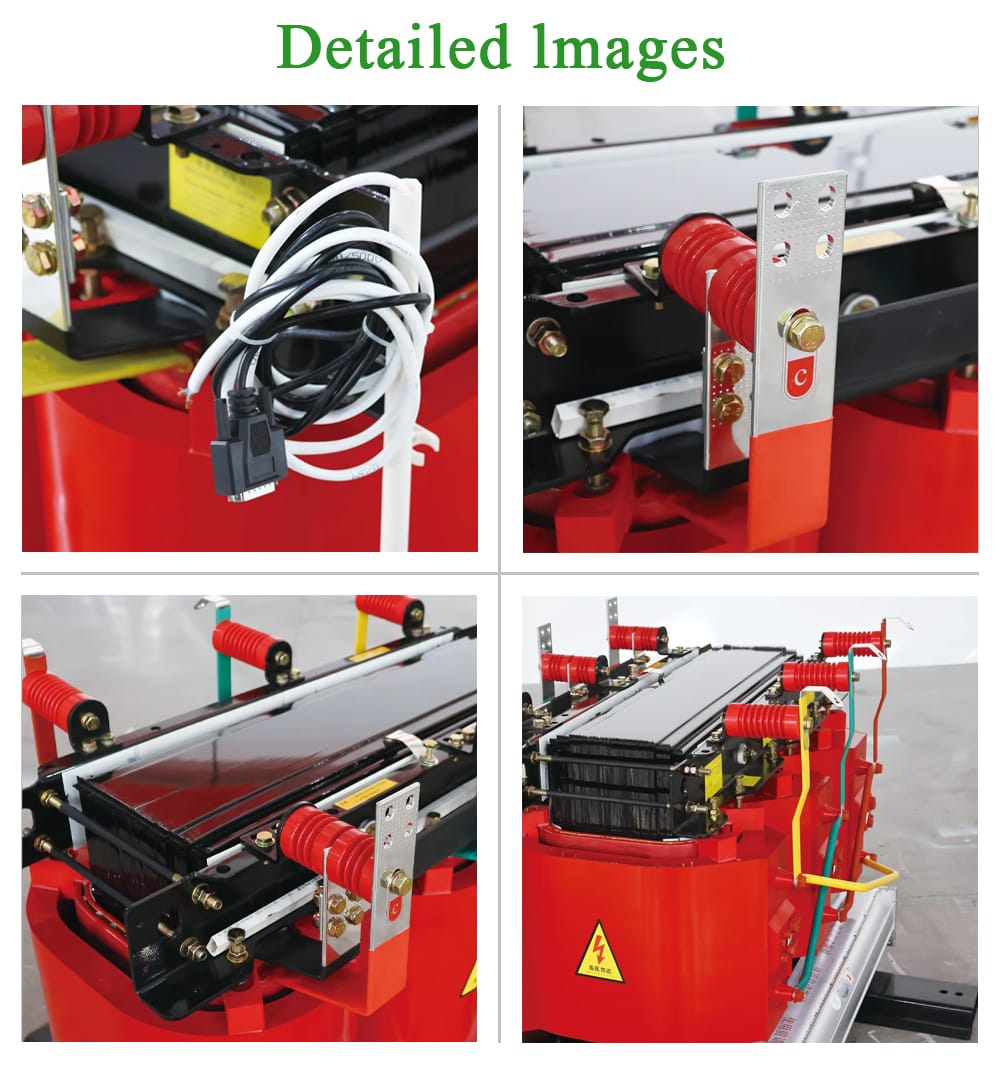

Detailed lmages

This detailed close-up highlights the four critical components of our Dry Type Transformer, showcasing its superior craftsmanship and performance:

Pure Copper Windings:

Constructed from high-conductivity oxygen-free copper, featuring a tight and uniform structure. Our transformer windings are insulated with cast epoxy resin. This is achieved via the Vacuum Pressure Impregnation (VPI) process. The result is exceptional resistance to moisture, dust, and corrosion. This ensures long-term operational stability and safety.

High-Performance Core:

Built from high-quality Cold Rolled Grain-Oriented (CRGO) silicon steel laminations. We precisely cut and stack the core laminations. We then arrange them in a step-lap configuration. This design minimizes magnetic resistance and energy loss. The result is low no-load loss and exceptionally quiet operation.

Efficient Cooling Ducts:

The windings incorporate scientifically designed vertical and horizontal cooling ducts. The internal components and louvered vents work in concert. Together, they form an efficient natural convection cooling system. This system effectively dissipates operational heat. It maintains a stable temperature rise under rated load, thereby extending service life.

Robust Protective Structure & Terminals:

The image reveals the transformer’s sturdy metal frame, clamping fixtures, and base, which offer excellent mechanical support and seismic resistance. The design features clearly visible copper wiring terminals that simplify on-site installation and maintenance through easy, reliable connections.

Factory Show

This collage reveals our advanced facility’s dry type transformer production process.

It captures key stages: Precision Winding, where skilled technicians wind copper coils with accuracy;

Vacuum Pressure Encapsulation (VPE) resin-encases coils under controlled conditions to eliminate voids and ensure perfect insulation.;

The process includes core assembly with precision silicon steel stacking and final testing with rigorous impulse and partial discharge diagnostics.

This image builds trust by demonstrating our advanced production capabilities, strict quality control processes, and the expertise of our workforce.

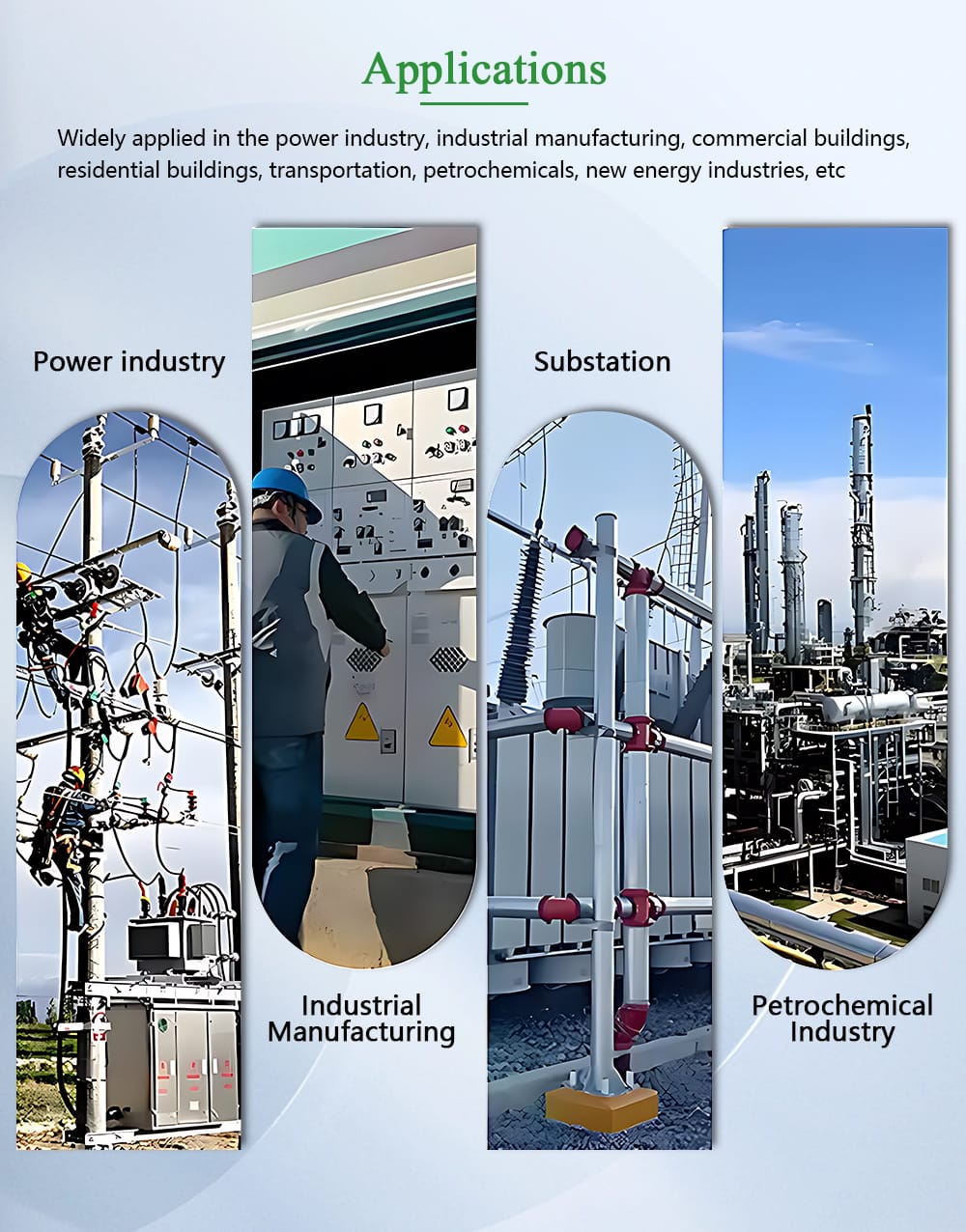

Applications

This illustrative infographic charts the diverse and critical applications of our Dry Type Transformer across global industries. It visually connects the product to four key sectors:

Power Industry (shown within a distribution substation, stepping down voltage for local grids);

Industrial Manufacturing (powering machinery, CNC systems, and production lines in factories due to its reliability and safety);

Commercial & Public Substations (located in basements of hospitals, airports, data centers, and high-rise buildings because of its fire-safe, dry-type design);

Petrochemical Industry (operating in harsh, corrosive environments where its robust construction and minimal maintenance are essential). This demonstrates the transformer’s versatility and critical role in infrastructure.

100KVA Dry Type Transformer Certifications

Global Cooperation

Reviews

There are no reviews yet.