Description

315KVA Oil Immersed Transformer

This image presents the core structure of the 315KVA oil immersed transformer, showcasing the integration of a low-loss silicon steel magnetic core and high-conductivity copper windings. The silicon steel core is engineered with precision-laminated sheets to minimize eddy current losses, reduce heat buildup, and enhance magnetic flux efficiency. The copper windings are tightly wound, insulated, and varnish-treated to ensure high dielectric strength and long-term thermal stability.

Together, these components create a durable three phase transformer capable of handling fluctuating loads while maintaining consistent voltage regulation. Filled with high-grade transformer insulating oil, the transformer achieves superior cooling, insulation, and extended operational lifespan, making it ideal for industrial, commercial, and utility-grade distribution systems.

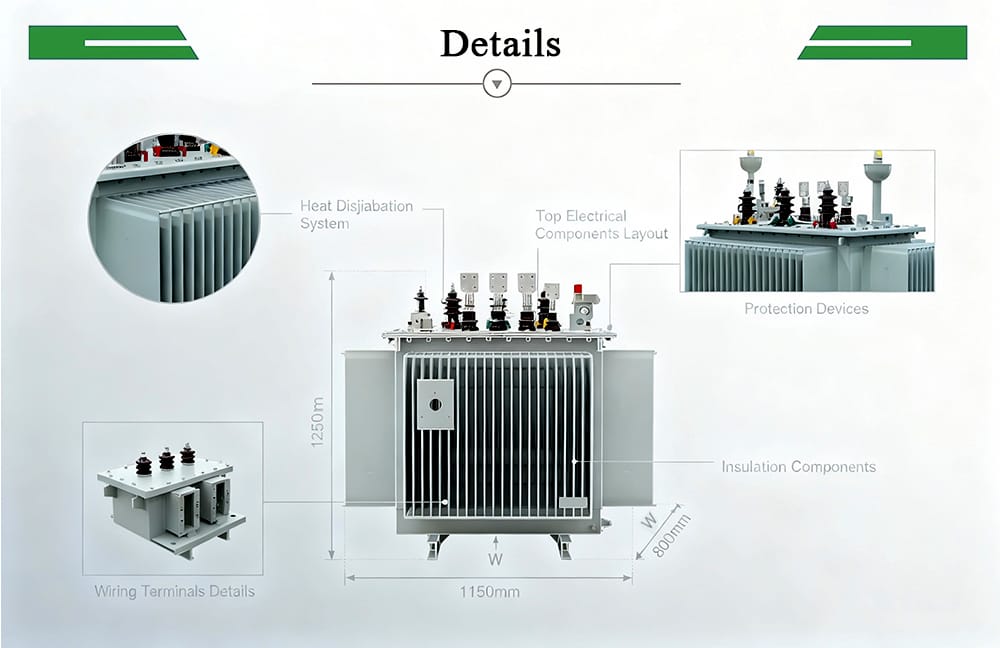

Details

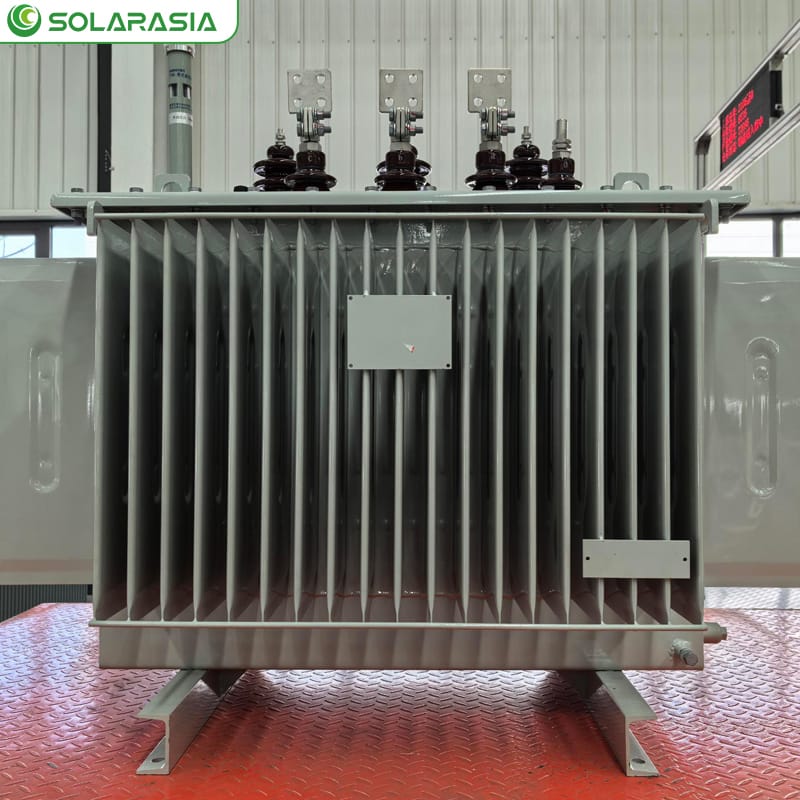

This detailed component image offers a close look at the internal and external build of the 315KVA oil immersed transformer, focusing on the heat dissipation system, upper electrical layout, wiring terminals, insulation parts, and integrated safety devices.

The radiator fins form an efficient ONAN natural air cooling system, allowing transformer insulating oil to circulate and release heat without mechanical assistance. The top-mounted electrical layout includes bushings, tap changers, and protective connections designed for stable grid performance.

Reinforced wiring terminals ensure secure electrical contact and minimized resistance losses. High-grade insulation materials—such as pressboard, epoxy-coated spacers, and cellulose components—provide dielectric strength under high temperature and voltage conditions. Built-in protection devices include pressure relief valves, oil-level indicators, thermometers, and grounding systems, ensuring safe, reliable operation throughout the transformer’s lifecycle.

Model Code Meaning

This diagram explains the full model configuration of the 315KVA oil type transformer, helping buyers and engineers easily interpret the unit’s specifications. The voltage level (kV) indicates the intended grid connection class, while the rated capacity (kVA) defines the actual load-handling capability under normal operating conditions.

The letter “M” denotes a fully sealed structure, preventing transformer oil oxidation and moisture ingress. The number “11” represents the performance level code, indicating loss standards and efficiency classification.

The letter “S” identifies the device as a three-phase transformer, suitable for medium-voltage distribution networks. By visualizing these elements, the diagram helps purchasers correctly select the model that aligns with system requirements, operating environments, and long-term performance expectations.

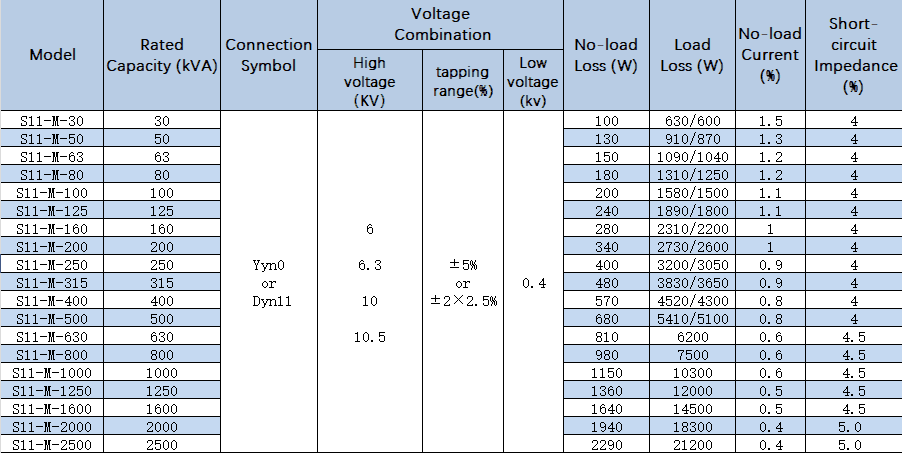

315KVA Oil Immersed Transformer Parameters

This technical drawing provides a complete overview of the mechanical dimensions and electrical parameters for the 315KVA three phase transformer, enabling engineers to evaluate installation, load characteristics, and compatibility with existing systems.

Specifications include detailed model identification, rated capacity (kVA), and connection groups for HV/LV windings. The voltage combination outlines standard primary and secondary voltage levels, while the HV tapping range indicates the adjustable percentages available for voltage fine-tuning.

Performance metrics include no-load loss, load loss, no-load current, and short-circuit impedance, all of which directly influence transformer efficiency, heat generation, and voltage regulation behavior. These parameters are essential for calculating lifecycle cost, selecting appropriate protection equipment, and ensuring compliance with local grid standards.

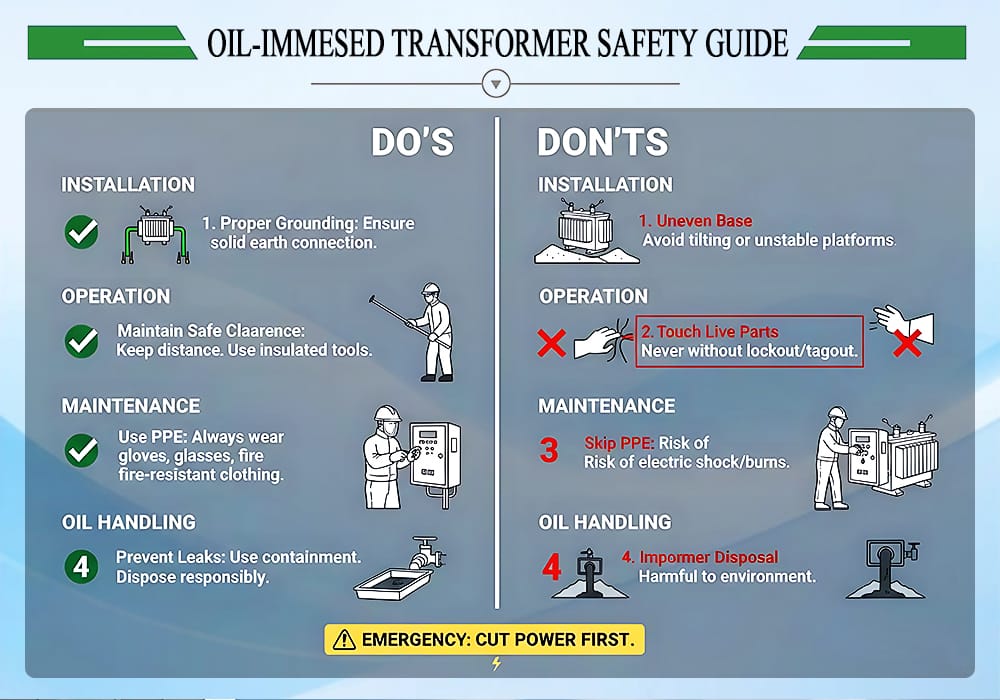

Oil Immersed Transformer Safety Guide

The safety guide image presents clear, practical instructions for the proper installation, operation, maintenance, and oil handling of the 315KVA oil transformer. The DO’s emphasize correct grounding, stable installation surfaces, maintaining clearance distances, and using insulated tools during energized work. Maintenance best practices include mandatory use of PPE such as gloves, safety glasses, and flame-resistant clothing.

The oil handling guidelines stress the importance of leak prevention, proper containment, and environmentally responsible disposal of used transformer oil. The DON’Ts highlight critical safety violations—such as installing the transformer on uneven bases, touching live components without lockout/tagout procedures, skipping protective equipment, or improperly discarding oil, which may cause severe environmental harm. The emergency reminder to cut power first underscores the importance of isolating the transformer before performing any corrective actions.

Our Projects

This engineering application collage highlights real-world installation scenes where the 315KVA oil type transformer operates within industrial facilities, solar farms, and electrical substations.

The transformer plays a crucial role in stabilizing medium-voltage distribution, supporting renewable energy integration, and powering large industrial equipment. Its sealed tank structure and optimized ONAN cooling allow it to withstand outdoor environments such as desert heat, heavy rain, or high humidity.

The transformer’s stable performance, low loss levels, and long-life transformer oil enable reliable energy transfer, reduced operating costs, and minimal maintenance downtime. These application examples demonstrate the product’s adaptability across diverse industries and global infrastructure projects.

Package and Shipping

This montage shows secure packaging for the 315 kVA transformer. It highlights a safe export process for global shipments. Protective materials keep the transformer stable in transit.

The transformer is wrapped with moisture-proof protective film to guard against humidity and condensation. Foam padding and reinforced wooden or steel pallets stabilize the product during long-distance transport. Heavy-duty straps prevent shifting, while corner protectors and vibration-absorbing materials reduce mechanical impact during handling. The packaging meets strict sea and land transport requirements. It also satisfies container loading safety standards. These measures ensure reliable delivery in tough conditions.

315KVA Oil Immersed Transformer Certifications

Coopération mondiale

This image shows a successful business meeting. Company leaders and engineers discuss project requirements. International partners review transformer solutions together. The scene reflects trust and professional cooperation.

The scene reflects professionalism, mutual trust, and a strong commitment to global cooperation in power distribution projects. Discussions often include specification customization, pricing for transformer oil and core materials, engineering support, after-sales service, and long-term supply agreements.

The image highlights the company’s global service capability. We supply three phase transformers for worldwide projects. Our 315KVA oil immersed transformers meet strict standards. We support clients with diverse technical requirements.

Critiques

Il n'y a pas encore de critiques.