Description

GCK Low Voltage Switchgear is a modular low voltage power distribution solution designed for industrial, commercial, and infrastructure electrical systems. It controls, protects, and distributes electrical power to feeders, motors, and auxiliary equipment through a centralized cabinet structure. Engineers commonly select this switchgear for factories, power plants, water treatment facilities, and large buildings where stable operation and clear circuit management are required.

The system uses a withdrawable design and standardized cabinet configuration, which improves operational safety and simplifies installation and maintenance. By supporting power distribution cabinets, feeder cabinets, and MCC configurations, GCK Low Voltage Switchgear adapts easily to different project requirements and future expansion plans. Its structure, documentation, and certification support make it suitable for long-term operation in professional low voltage distribution systems.

GCK Low Voltage Switchgear Overview

Engineers design the GCK Low Voltage Switchgear as a reliable and customizable solution for low voltage power distribution in industrial and commercial electrical systems. Factories, utility systems, power plants, and large buildings use this switchgear where stable power control and continuous operation are critical.

The system supports flexible cabinet configurations to meet different project requirements. Engineers can configure it as a power distribution cabinet, a motor control center (MCC), or a feeder cabinet based on actual load conditions. This modular design allows users to expand or adjust the system without redesigning the entire electrical layout, reducing engineering effort and future upgrade costs.

GCK Low Voltage Switchgear centralizes power distribution while protecting downstream electrical equipment. It manages multiple outgoing circuits within one coordinated system, improving operational efficiency and simplifying control and maintenance. Clear circuit separation helps limit fault impact and supports safer operation in complex electrical environments.

Customers often search for low voltage switchgear when they need to distribute power safely, protect motors and feeders, and control multiple circuits in a centralized system. The GCK Switchgear meets these needs through a modular, expandable design that supports long-term operation, stable performance, and practical on-site maintenance.

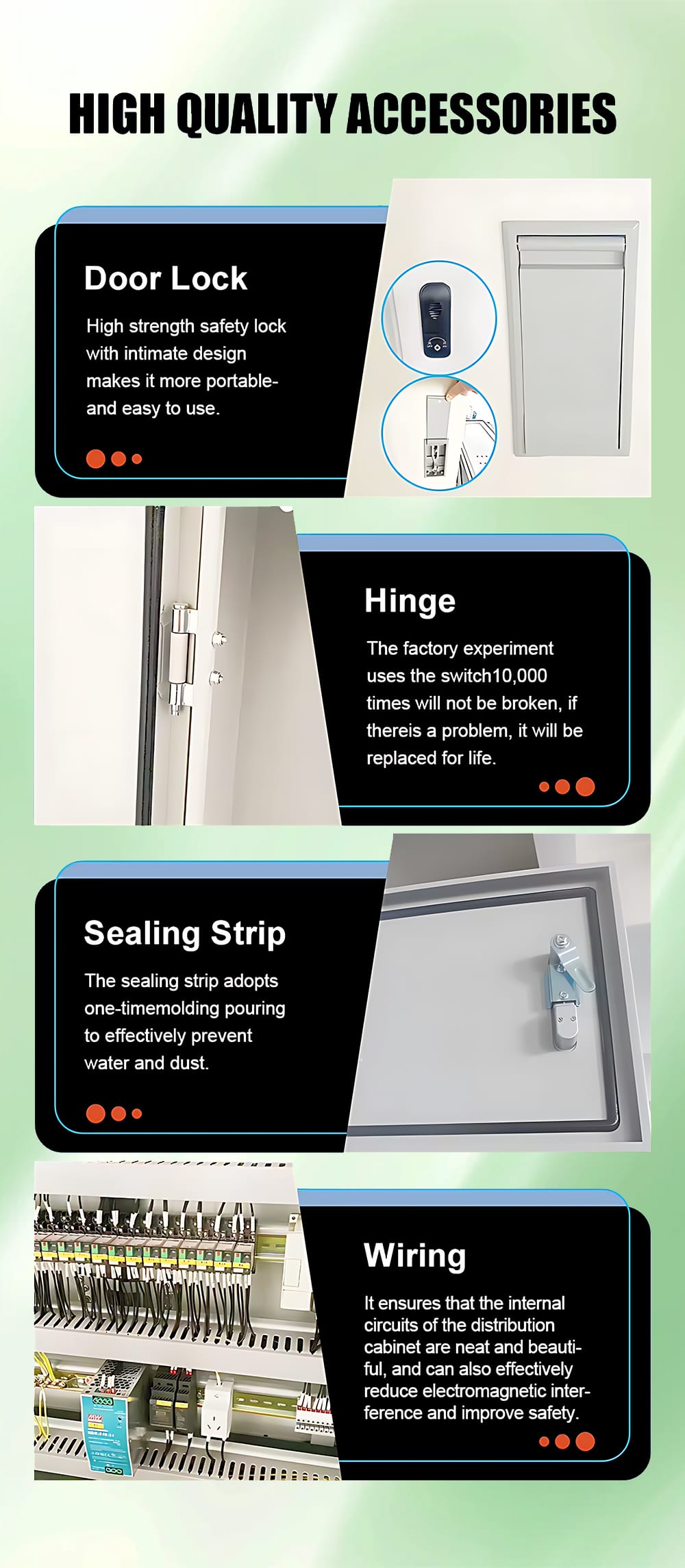

Structural Details for Safety, Durability, and Reliable Operation

This section presents the key structural details of the GCK Low Voltage Switchgear that directly influence safety, reliability, and long-term operation. The cabinet adopts a high-strength safety door lock that secures the enclosure during normal operation and maintenance activities. This design helps prevent accidental opening and protects operators working in electrical distribution rooms.

The cabinet door uses durable industrial hinges designed for frequent use. Factory testing confirms that the hinges withstand more than 10,000 opening and closing cycles without deformation or failure. This ensures stable door alignment and smooth operation throughout years of service in industrial and infrastructure environments.

To improve environmental protection, the cabinet applies a one-piece molded sealing strip around the door frame. This sealing structure limits the ingress of dust and moisture, supporting stable insulation performance in electrical rooms exposed to humidity, dust, or temperature variation. Such protection plays an important role in extending equipment service life.

Inside the cabinet, technicians route cables in an organized and clearly separated layout. Proper wiring arrangement improves heat dissipation, reduces electromagnetic interference, and supports easier inspection and troubleshooting. These structural details directly reduce maintenance workload and operational risk.

Buyers evaluating low voltage switchgear often focus on cabinet structure because it affects maintenance cost, operational safety, and long-term reliability. The GCK Switchgear addresses these concerns through practical design details that support stable performance over extended operating periods.

Key Structural Advantages

| Component | Design Feature | Practical Benefit |

|---|---|---|

| Door Lock | High-strength safety lock | Improved operational safety |

| Hinge | Tested over 10,000 cycles | Long service life |

| Sealing Strip | One-time molded sealing | Dust and water resistance |

| Internal Wiring | Organized and standardized layout | Reduced interference and higher reliability |

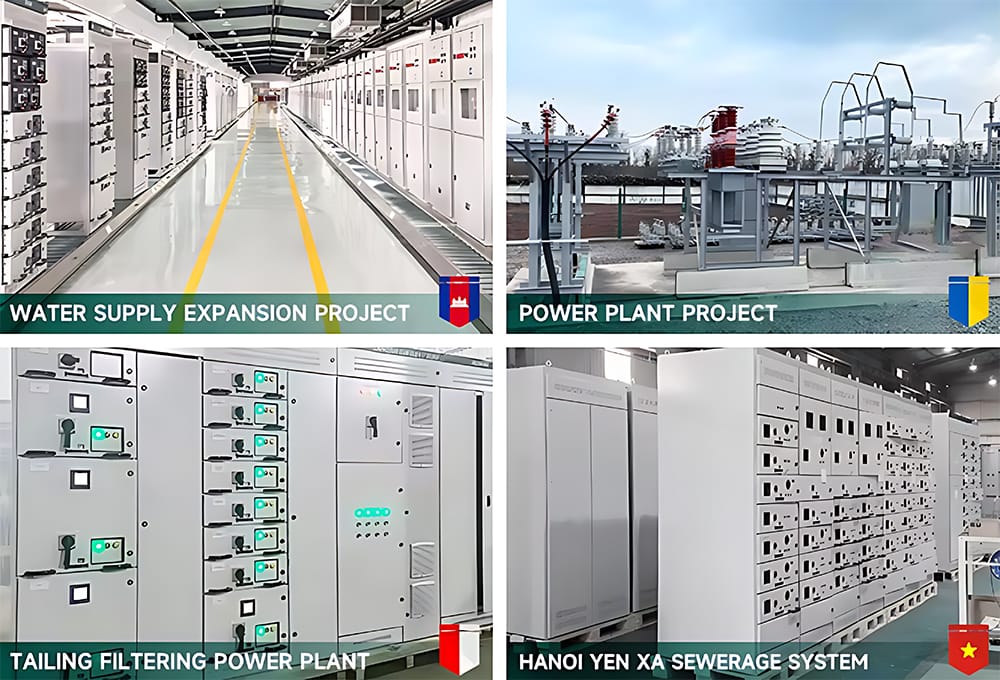

Typical Applications in Infrastructure and Industrial Power Systems

The GCK Low Voltage Switchgear serves infrastructure and industrial projects that require continuous and stable power supply. Engineers commonly apply it in water supply expansion systems, power plant auxiliary power distribution, sewage treatment facilities, and industrial processing plants where electrical reliability directly affects system operation.

In these projects, the switchgear must operate under long running hours, frequent load fluctuations, and complex control requirements. The GCK system maintains stable low voltage power distribution while clearly separating incoming, outgoing, and control circuits. This structure helps operators manage electrical loads efficiently and reduce operational risks.

The system supports pumps, motors, control panels, and auxiliary equipment that operate simultaneously within large-scale installations. Its modular cabinet design allows maintenance teams to isolate and service individual feeders without shutting down the entire power distribution system, which is critical for facilities that cannot afford unexpected downtime.

Buyers often search for low voltage switchgear when planning electrical systems for infrastructure upgrades or industrial expansion projects. They choose GCK Switchgear because it aligns with real operational demands, supports long-term system stability, and adapts to changing power distribution requirements throughout the project lifecycle.

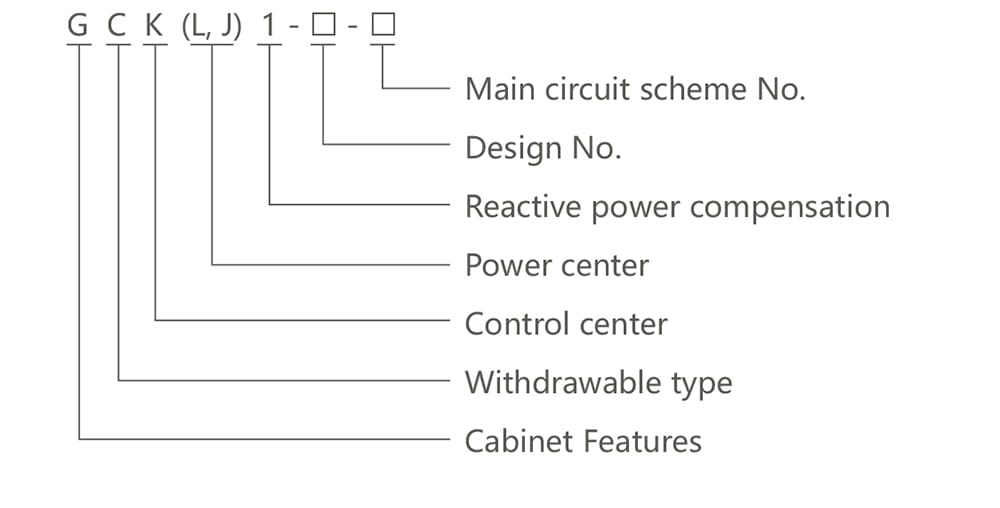

Understanding the GCK Switchgear Model Code and Configuration Logic

Understanding the model code helps engineers select the correct GCK Switchgear configuration. Each letter and number represents a specific functional meaning. The model code explains cabinet features, withdrawable structure, control center function, power center options, and reactive power compensation. It also defines the main circuit scheme and design version. This clear classification reduces selection errors and improves system compatibility during project design and procurement.

Model Code Meaning

| Code Element | Meaning |

|---|---|

| G | Cabinet structural features |

| C | Withdrawable type design |

| K | Control center function |

| L / J | Power center configuration |

| 1 | Reactive power compensation option |

| Scheme No. | Main circuit configuration |

| Design No. | Design and version reference |

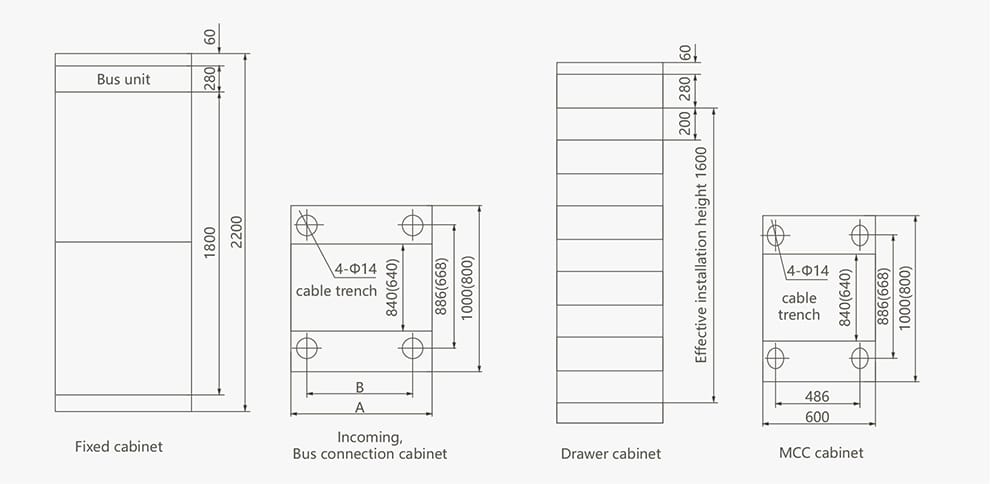

Modular Cabinet Structure of GCK Low Voltage Switchgear Systems

This sketch shows the overall system structure of the GCK Switchgear. The system can include incoming cabinets, bus connection cabinets, drawer cabinets, and MCC cabinets.

Such a structure allows the switchgear to handle different functions within one low voltage distribution system. Incoming cabinets manage main power input. Bus connection cabinets support internal power transfer. Drawer and MCC cabinets control motors and outgoing feeders.

Customers usually look for this type of system when they want centralized control with flexible expansion capability. The GCK system supports phased project expansion without major system modification.

Packaging and Transportation of GCK Low Voltage Switchgear Cabinets

Proper packaging plays a critical role in protecting large electrical equipment during transportation. For each GCK Low Voltage Switchgear cabinet, the manufacturer applies a structured packaging system that secures both the enclosure and internal components throughout the entire logistics process.

The packaging design minimizes vibration and impact that may occur during loading, unloading, and long-distance transportation. Reinforced external protection prevents cabinet deformation, while internal fixing methods keep busbars, breakers, and control units stable and aligned. This approach reduces the risk of mechanical damage before installation.

To address environmental risks, the packaging also limits exposure to moisture and dust during storage and shipping. Protective materials help maintain insulation performance and prevent corrosion, which is especially important for overseas delivery and extended transit times.

Reliable packaging ensures that the GCK Switchgear arrives at the project site in proper condition and ready for installation. Engineering contractors and industrial buyers often evaluate packaging quality when selecting a switchgear supplier, as it reflects manufacturing experience, export capability, and overall project reliability.

Quality Standards and Certifications for GCK Low Voltage Switchgear

The GCK Switchgear is manufactured in accordance with relevant quality and safety standards. Certification documents and test reports confirm compliance with electrical performance and safety requirements.

These certifications provide assurance for project owners, consultants, and inspectors. They help simplify approval processes during project execution and acceptance. Customers searching for certified low voltage switchgear often need documentation support for tenders, inspections, and audits.

The design and manufacturing of GCK Low Voltage Switchgear follow the requirements defined in the IEC 61439 low-voltage switchgear and controlgear standard for low voltage assemblies.

Real Project Experience with GCK Low Voltage Switchgear Customers

This image reflects real cooperation between the manufacturer and customers. Face-to-face communication helps clarify technical requirements and application details. Such cooperation ensures the delivered GCK Switchgear matches actual site conditions and operating needs. It also demonstrates long-term service capability beyond product delivery. For many buyers, supplier reliability and communication ability are as important as technical specifications.

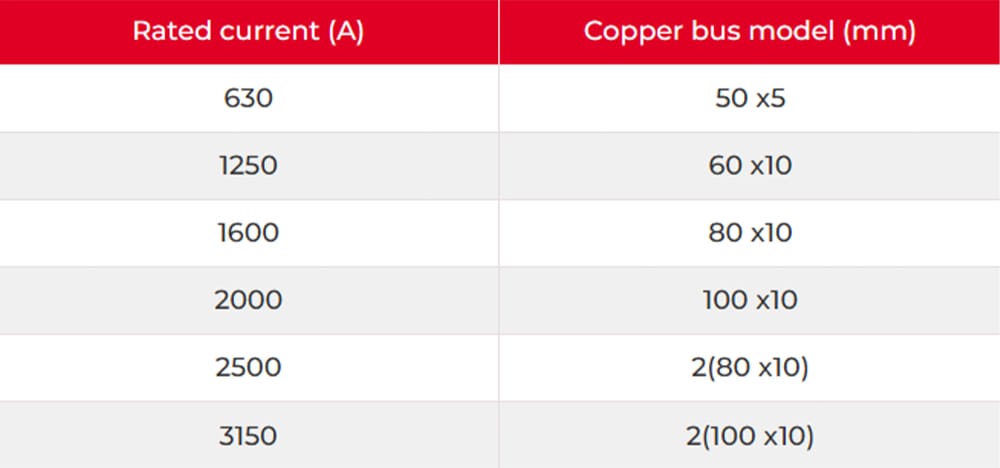

Rated Current Options of GCK Low Voltage Switchgear for Power Distribution

Copper Bus System Design in GCK LV Switchgear

The GCK Switchgear supports different rated current levels and bus configurations. Copper bus systems are selected based on load demand and system design. Proper bus selection improves current carrying capacity and reduces thermal stress. This directly affects system stability and service life. Customers usually evaluate rated current and bus design when selecting switchgear for high-load distribution systems.

Rated Current & Bus Options

| System Type | Rated Current Range | Bus Material |

|---|---|---|

| Power Distribution Cabinet | According to design | Copper bus |

| Feeder Cabinet | According to load | Copper bus |

| Bus Connection Cabinet | System dependent | Copper bus |

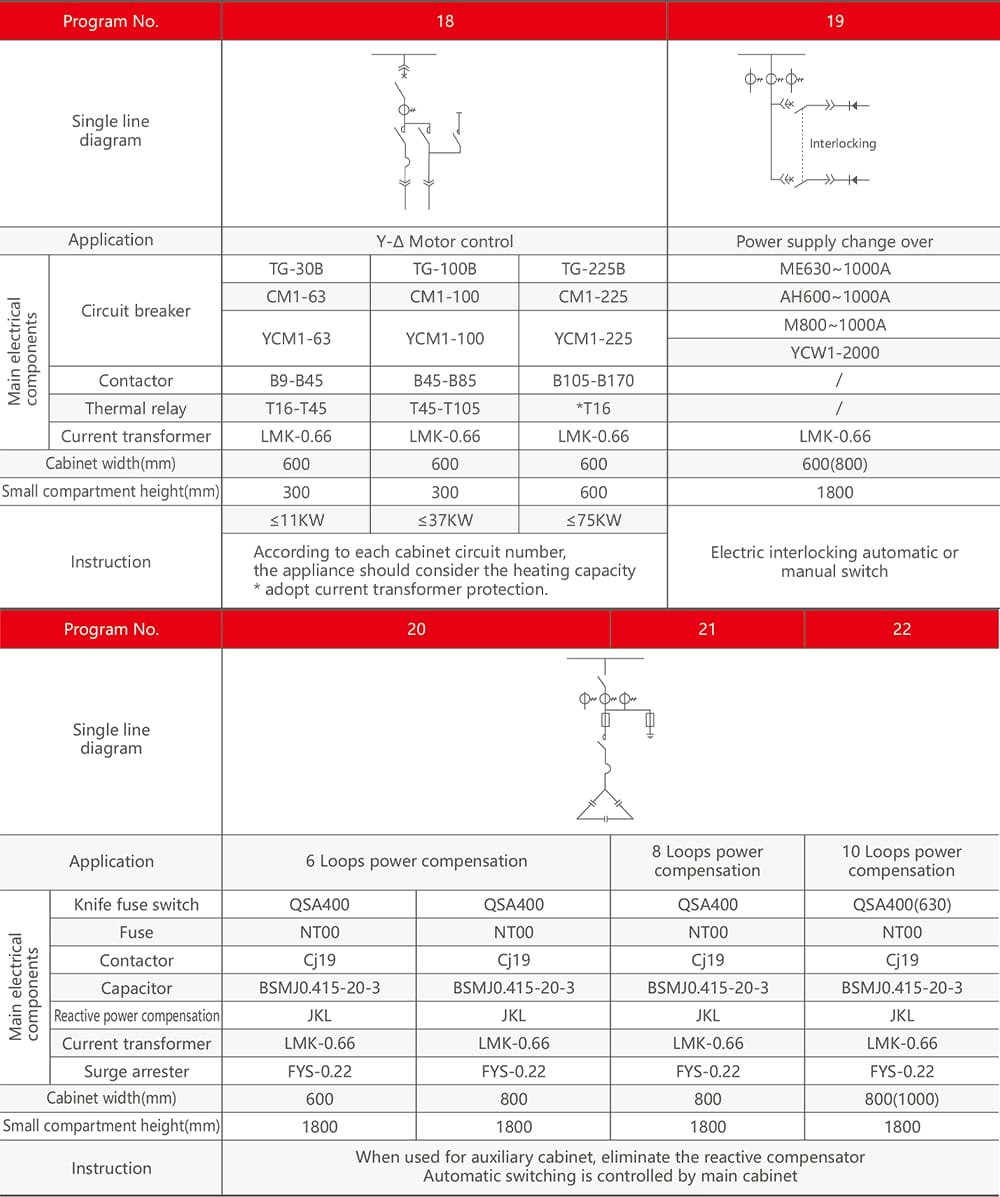

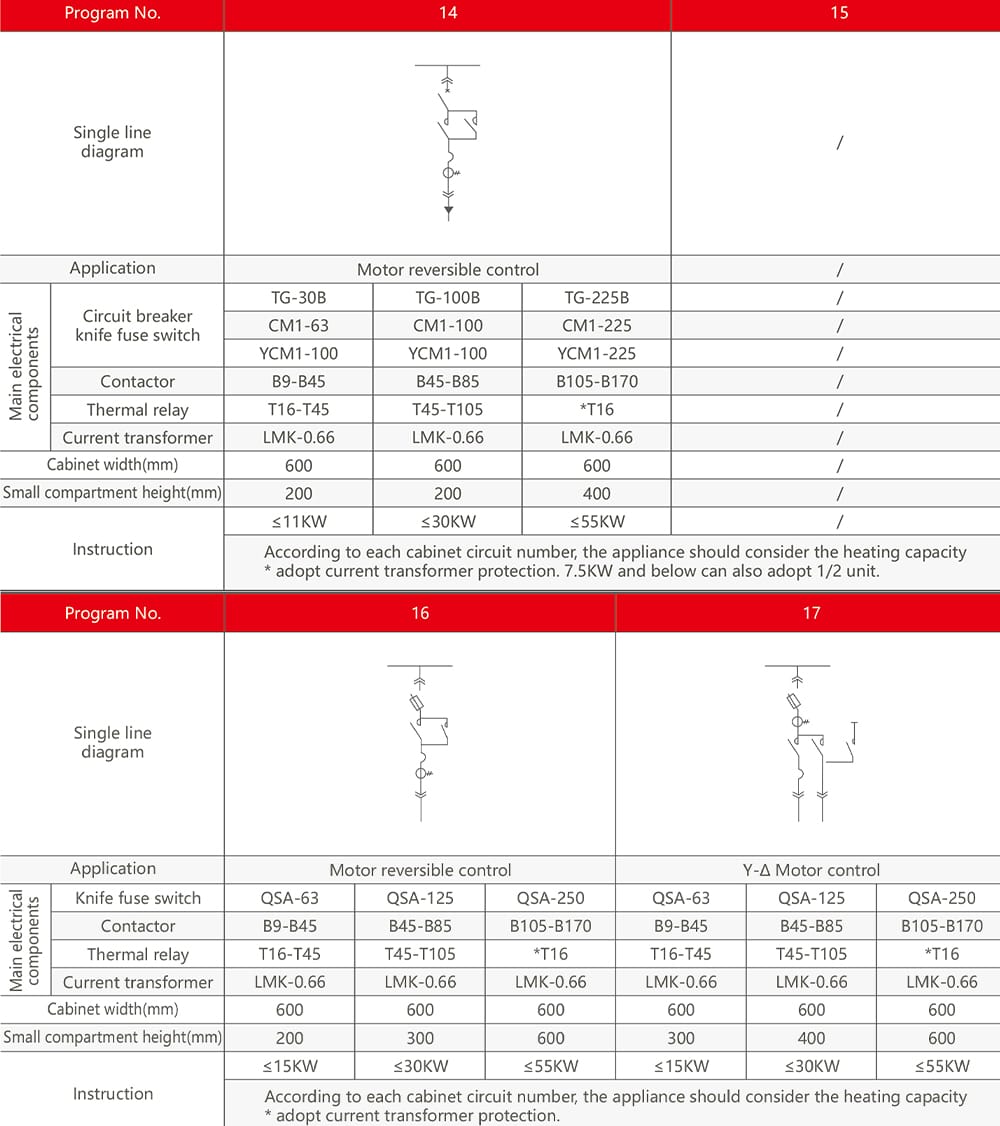

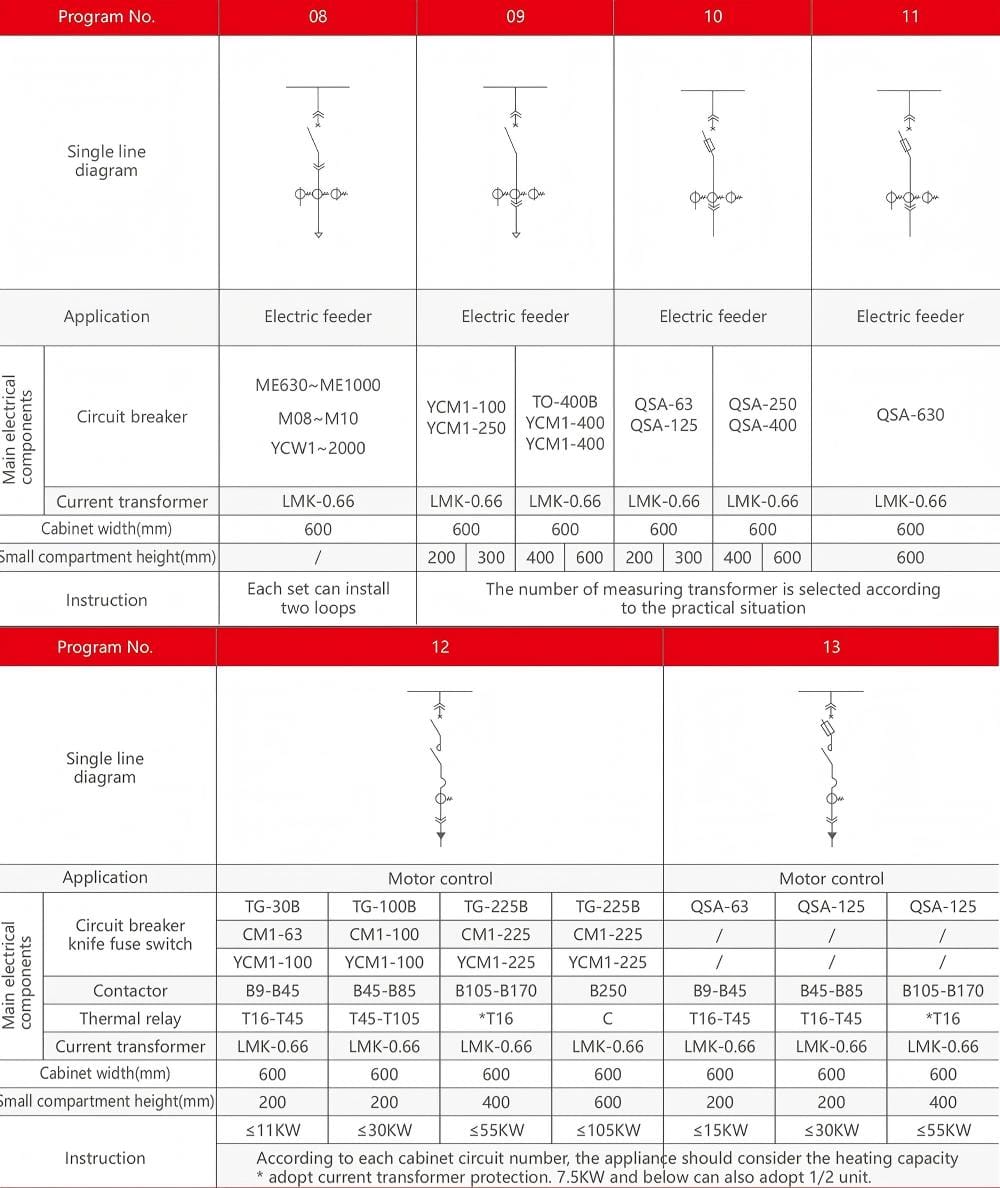

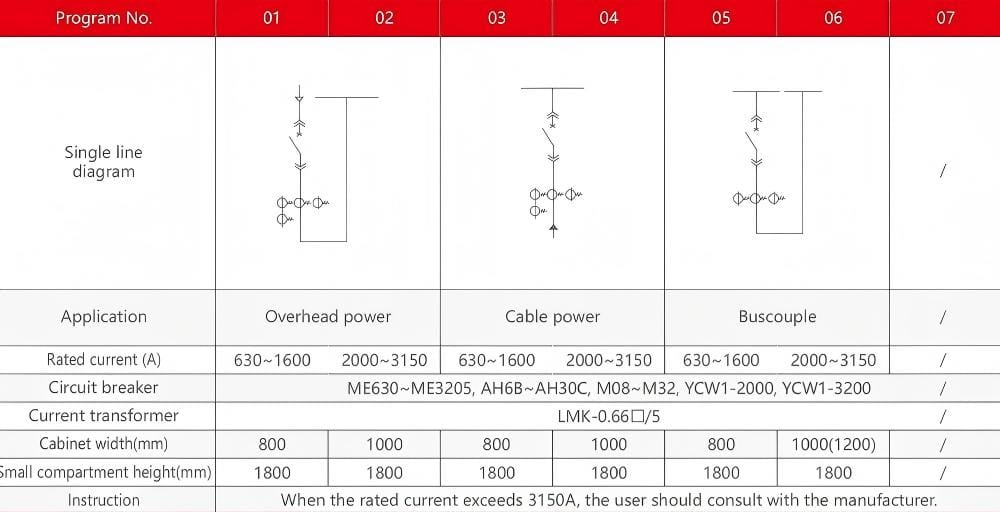

Electrical Program Design of GCK LV Switchgear Systems

These specification diagrams provide detailed technical information for the GCK Switchgear. They include program numbers, single-line diagrams, application types, rated current, circuit breaker options, and current transformer configurations. Such information supports accurate system design and equipment matching. Engineers use these details to ensure protection coordination and operational safety.

Customers searching for detailed switchgear specifications are usually in the decision or procurement stage. Clear and structured technical data helps speed up evaluation and approval. GCK LV Switchgear belongs to the category of low voltage switchgear assemblies, which are widely used for power distribution and control in industrial electrical systems.

Key Electrical Configuration Items

| Article | Description |

|---|---|

| Program Number | Electrical scheme reference |

| Single Line Diagram | System structure overview |

| Application | Power distribution or motor control |

| Circuit Breaker | Protection and switching device |

| Current Transformer | Measurement and protection support |

| Cabinet Structure | Standardized modular configuration |

FAQ

What is GCK Low Voltage Switchgear used for?

GCK Low Voltage Switchgear distributes and controls low voltage power in industrial, commercial, and infrastructure systems. It supplies power to feeders, motors, and auxiliary equipment while providing protection and centralized control. Engineers commonly install this switchgear in factories, power plants, water treatment facilities, and large electrical rooms.

Why do engineers choose GCK Low Voltage Switchgear for power distribution systems?

Engineers choose GCK Low Voltage Switchgear because it provides a modular cabinet structure and a withdrawable design. This structure improves operational safety and simplifies maintenance. The system also supports standardized components and organized wiring, which reduces installation errors and long-term operating risks.

Can GCK Low Voltage Switchgear be configured as an MCC system?

GCK Low Voltage Switchgear supports motor control center configurations. Users combine incoming cabinets, feeder cabinets, and MCC drawers to control motors and outgoing circuits within one low voltage distribution system. This configuration helps manage motor loads efficiently and supports future system expansion.

What types of projects commonly use GCK Low Voltage Switchgear?

Industrial plants, infrastructure systems, utility facilities, and commercial buildings commonly use GCK Low Voltage Switchgear. Project teams select this switchgear when they require stable long-term operation, clear circuit management, and reliable low voltage power distribution.

How does GCK Low Voltage Switchgear improve operational safety?

GCK Low Voltage Switchgear improves safety through a withdrawable unit design and a robust cabinet structure. The system separates live parts clearly and reduces exposure during maintenance. Neat internal wiring also lowers the risk of short circuits and electromagnetic interference.

Can users customize the cabinet configuration of GCK Low Voltage Switchgear?

Users can customize the cabinet layout, functional units, and electrical configuration of GCK Low Voltage Switchgear. This flexibility allows the system to meet different power distribution requirements without redesigning the entire electrical system.

What protection components does GCK Low Voltage Switchgear support?

GCK Low Voltage Switchgear supports various circuit breakers and current transformers. These components provide overload protection, short-circuit protection, and accurate current measurement. Engineers select protection devices based on application requirements and rated current.

How do engineers select the rated current for GCK Low Voltage Switchgear?

Engineers select the rated current according to system load and application conditions. They consider feeder capacity, motor power, and future expansion. Correct rated current selection ensures stable operation and extends equipment service life.

Is GCK Low Voltage Switchgear suitable for continuous operation?

GCK Switchgear supports continuous operation in demanding industrial environments. Its cabinet structure, bus system, and electrical components are designed for long-term power distribution and control.

What documentation is provided with GCK Low Voltage Switchgear?

Manufacturers provide technical drawings, electrical schematics, operation manuals, and test reports with GCK Switchgear. Certification documents support project approval, inspection, and system commissioning.

How does GCK Low Voltage Switchgear support installation and maintenance?

GCK Switchgear uses a modular and standardized design that simplifies installation and commissioning. Withdrawable units allow technicians to perform maintenance or replacement work efficiently without shutting down the entire system.

Critiques

Il n'y a pas encore de critiques.