Description

Le 35KV European Box Substation is a prefabricated compact substation designed for medium voltage power distribution systems. It integrates transformers, medium voltage switchgear, protection devices, and auxiliary equipment into a single enclosure, reducing on-site construction work and installation time.

This solution is widely used by utilities, industrial facilities, and EPC contractors who need a safe, stable, and easy-to-deploy substation. With its European-style box structure, the system supports outdoor installation, flexible configuration, and long-term operation in various grid and environmental conditions.

Product Overview: 35kV European Box Type Substation

This 35KV European Box Type Substation is designed as a complete box-type power distribution system for medium and high voltage applications.

It integrates MV & HV transformers, switchgear, protection devices, and auxiliary systems into one compact enclosure.

The box-type design allows users to build, expand, and upgrade power distribution systems quickly, especially in projects with limited construction time or restricted site conditions. By integrating medium-voltage switchgear, transformers, and low-voltage distribution equipment into one prefabricated enclosure, the 35KV European Box Type Substation reduces on-site installation work and shortens commissioning schedules.

When load demand increases, users expand the system in a predictable and controlled manner by upgrading transformer capacity or adding feeder units. This flexible configuration supports long-term development plans and helps project owners avoid early system replacement.

The system delivers safe and reliable operation with stable electrical performance during continuous service. Engineers design the enclosure, insulation coordination, and internal layout to support long service life, reduce operational risk, and protect operating personnel.

Customers commonly choose this prefabricated box type substation when they need:

Medium-voltage power supply for factories, industrial parks, and manufacturing facilities, where stable power and minimal downtime directly affect productivity

Grid connection solutions for renewable energy projects, including solar power plants and wind farms that require reliable step-up or step-down substations

Compact substations for urban or space-limited sites, such as commercial developments, infrastructure projects, and public utilities

The system offers simple operation and low maintenance requirements, which helps utility companies and EPC contractors control lifecycle costs and improve operational safety. Project owners also benefit from the prefabricated design, which improves delivery certainty, reduces construction risk, and simplifies project coordination.

Internal Configuration of the 35kV Compact Substation System

This image shows the internal layout of the 35KV compact substation system, where engineers arrange all major electrical components in separated, clearly defined compartments. This layout improves operational safety, simplifies inspection, and helps maintenance teams identify equipment quickly during routine checks or fault handling.

The design physically separates medium-voltage, transformer, and low-voltage sections. This separation reduces the risk of electrical interference, enhances insulation coordination, and supports stable long-term operation under continuous load conditions.

The system supports multiple configuration options, including:

Medium-voltage switchgear for incoming and outgoing feeders, allowing flexible grid connection and feeder management

Oil immersed transformers for high-capacity applications and outdoor installations, where strong thermal performance and overload capability are required

Dry type transformers for projects that prioritize low fire risk, reduced oil use, and indoor-friendly operation, such as commercial or densely populated sites

Customers often search for a substation solution that allows flexible transformer selection without redesigning the entire system. This internal layout supports that requirement by accommodating different transformer types and ratings within a standardized enclosure.

Engineers commonly apply this design in industrial production lines, renewable energy power plants, and medium-voltage distribution substations, where safety, reliability, and ease of maintenance directly affect operating costs and system uptime. By combining modular configuration with clear internal zoning, the substation helps project owners balance performance, safety, and long-term operational efficiency.

Typical Internal Configuration Options

| Component Type | Common Selection Reason | Application Scenario |

|---|---|---|

| MV Switchgear | Reliable protection and switching | Utility grids, industrial feeders |

| Transformateur immergé d'huile | High efficiency and strong overload capacity | Outdoor substations, heavy industry |

| Dry Type Transformer | Low fire risk, low noise | Commercial zones, renewable projects |

This modular internal arrangement improves maintenance access and reduces downtime during inspections.

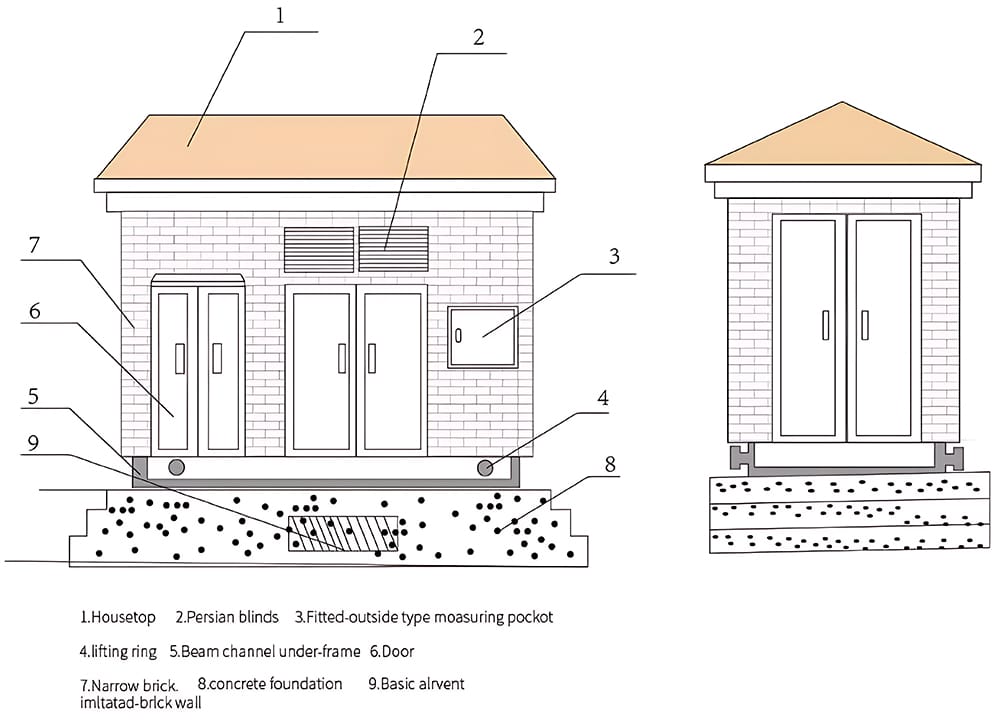

Structural Design of the 35KV European Box Substation

The structural design of the 35KV European Box Type Substation prioritizes durability and outdoor adaptability for long-term field operation. Engineers reinforce the housetop, integrate ventilation blinds, install certified lifting rings, and design a rigid under-frame beam channel to withstand transportation stress, outdoor exposure, and repeated lifting during installation.

The system uses a concrete foundation combined with ventilated brick walls to improve airflow and maintain thermal stability around key electrical components. This structural approach reduces internal heat accumulation and helps the substation operate reliably under continuous load and varying ambient temperatures.

External measuring pockets and full-access doors allow technicians to perform inspection, monitoring, and routine operation without dismantling major structural elements. This feature shortens maintenance time, improves operator safety, and minimizes service interruptions during the substation’s lifecycle.

This structural configuration particularly suits customers who:

Install substations in outdoor or semi-outdoor environments, such as industrial zones and utility networks

Require fast civil works through prefabricated solutions, especially in EPC or fast-track projects

Operate equipment in harsh climates, including high temperatures, humidity, dust, or remote locations

The prefabricated structure reduces on-site construction time, lowers installation risk, and improves overall project delivery efficiency, making it a practical choice for utilities, industrial users, and infrastructure developers seeking reliable medium-voltage substation solutions.

Global Projects Using the 35KV European Box Substation

This image presents real engineering cases of compact substation transformers delivered and commissioned in multiple regions worldwide. These installations show how the 35KV European Box Type Substation operates under different grid conditions, climates, and regulatory environments.

Representative projects include:

33kV distribution transformer projects in Kenya, supporting local utility and regional power distribution networks

113 units of compact substations equipped with GIS medium-voltage switchgear in West Africa, designed for standardized and high-density deployment

S10-20000-35KV transformer projects, serving high-capacity power transmission and industrial supply requirements

3000kVA compact substation installations in Kyrgyzstan, operating in regions with temperature variation and challenging site conditions

These projects clearly demonstrate that the 35KV European Box Type Substation represents a proven engineering solution, not a conceptual or experimental design. Utilities and project owners have already integrated this system into real power networks with continuous operation requirements.

When customers search for a box type substation supplier, they often look for confirmation that:

The system operates reliably in environments similar to their own projects

The design supports long-term grid operation and stable power delivery

The supplier understands international standards, logistics, and project coordination requirements

Global deployment experience builds confidence in system reliability, engineering capability, and delivery consistency. By supporting projects across Africa, Central Asia, and other regions, this substation solution demonstrates adaptability, proven performance, and readiness for international power infrastructure applications.

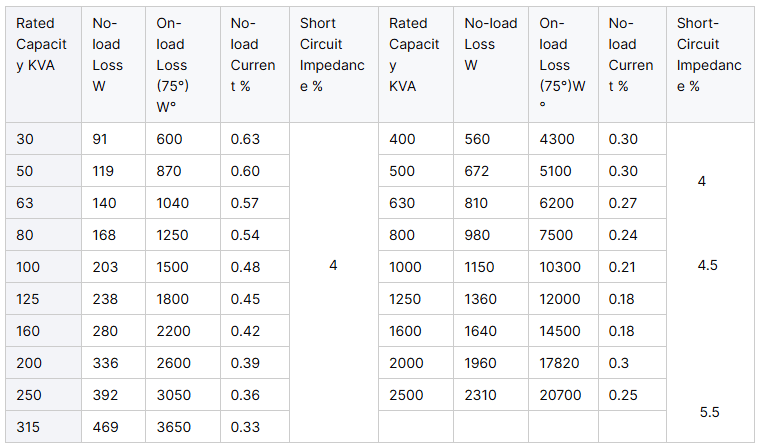

Electrical Performance of the 35KV European Box Substation

This section focuses on the electrical performance parameters of the 35KV box type substation system.

Rated capacity, no-load loss, load loss, no-load current, and short-circuit impedance are key factors in system design.

These parameters directly affect:

Energy efficiency of the power distribution system

Heat generation during operation

Grid compatibility and protection coordination

Customers typically review this information when:

Selecting transformers for utility or industrial projects

Comparing energy losses between different suppliers

Designing protection schemes for medium voltage systems

Clear and transparent technical data helps engineers make accurate design decisions.

Certifications and Standards for the 35KV European Box Substation

We manufacture this 35KV European Box Type Substation in accordance with relevant international standards and industry norms.

Certification confirms that the product meets safety, quality, and performance requirements.

Certified box type substations are often required in:

Government and utility projects

Export-oriented EPC contracts

Renewable energy grid-connection projects

Compliance with recognized standards improves project approval efficiency and reduces regulatory risk for buyers.

Packaging and Transportation of the 35KV European Box Substation

This image shows how our logistics team packages and prepares the prefabricated box type substation for transportation. The team applies reinforced protective structures, shock-resistant supports, and secure fixing methods to protect key equipment during long-distance and overseas shipping.

For international customers, transportation safety directly affects project schedules and total cost. This packaging process reduces the risk of mechanical damage, moisture exposure, and vibration during loading, sea transport, and inland delivery. As a result, the substation arrives on site in installation-ready condition, which helps customers avoid rework, delays, and unexpected expenses.

This logistics process supports:

Export projects to overseas markets, including Africa, Central Asia, and other international regions

Delivery to remote or infrastructure-limited sites, where replacement or on-site repair is difficult

Large-scale batch shipments, ensuring consistent protection across multiple units

Reliable delivery capability forms an essential part of the complete 35KV European Box Type Substation solution. By combining engineered packaging with experienced export handling, the supplier helps customers reduce logistics risk and improve overall project execution efficiency.

Engineering Experience Behind the 35KV European Box Substation

This image shows the company team communicating with overseas clients during project discussions. Technical exchange and face-to-face cooperation reflect practical experience in substation engineering projects.

For customers, this indicates:

Clear communication during design and procurement

Technical support before and after delivery

Understanding of international project workflows

Strong cooperation capability builds trust beyond the product itself and supports long-term partnerships.

FAQ

What is a 35KV European Box Substation used for?

A 35KV European Box Substation is used for medium voltage power distribution.

Engineers commonly apply it in utility networks, industrial plants, renewable energy projects, and infrastructure developments, where the compact design and fast installation meet project requirements.

What equipment is integrated inside the box substation?

The substation typically integrates medium voltage switchgear, transformers (oil immersed or dry type), low voltage distribution equipment, and protection systems.

Our engineering team customizes the internal configuration according to project requirements and grid standards.

Is the 35KV European Box Substation suitable for outdoor installation?

Yes.

Our design team intends the enclosure and structural layout for outdoor use. The engineers design the ventilation, protection, and foundation interfaces to ensure stable operation under different climate and environmental conditions.

Can the transformer type and capacity be customized?

Yes.

Customers can select oil immersed or dry type transformers with different rated capacities based on load demand, installation environment, and safety requirements. This flexibility is one of the key advantages of a prefabricated box type substation.

What standards and certifications does the substation comply with?

Our manufacturing team produces the 35KV European Box Substation in accordance with relevant international and regional standards.

Certification and compliance documents can be provided to support utility projects, EPC contracts, and export requirements.

How is the substation transported and installed on site?

Our team delivers the substation as a prefabricated unit with secure packaging for long-distance transportation.

After delivery, installation mainly involves foundation preparation, positioning, cable connection, and commissioning, which significantly reduces on-site work time.

What type of customers usually choose this solution?

Utility companies, industrial users, EPC contractors, and renewable energy developers often choose this solution for its reliable medium voltage substation performance and predictable delivery schedules.

If you are planning a medium voltage power distribution project and need a reliable 35KV European Box Substation, our technical team can support you with system configuration, transformer selection, and project documentation.

Contact us to discuss your application, technical requirements, and project timeline.

We provide professional support from design to delivery for utility, industrial, and energy projects.

Critiques

Il n'y a pas encore de critiques.