Description

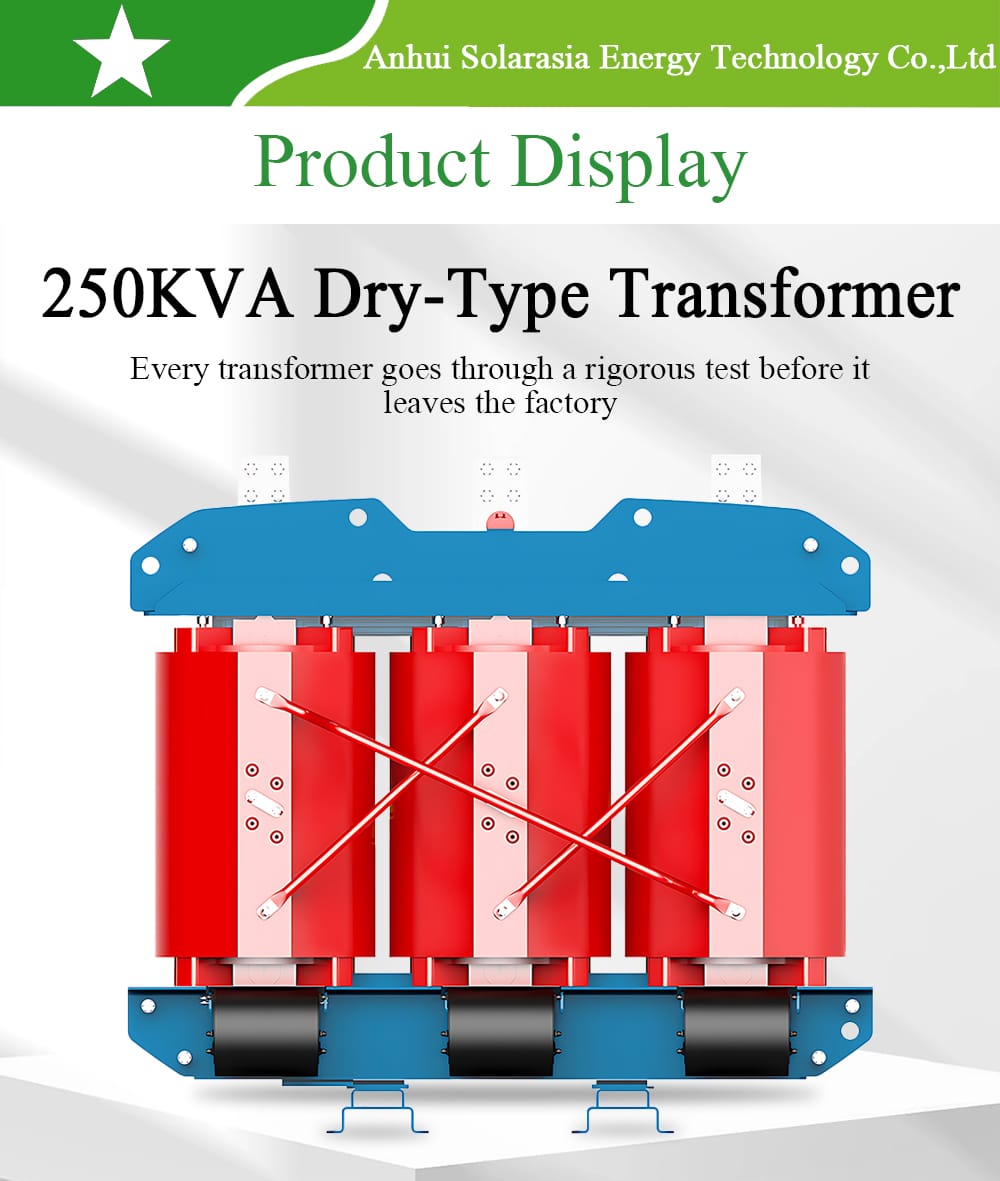

250KVA Dry Type Transformer

This striking front-view image showcases our flagship 250KVA Dry Type Transformer in all its professional glory. Photographed in a clean, well-lit environment, the transformer’s robust and modern design is immediately apparent.

The sleek, low-profile enclosure, typically finished in a standard RAL color, is not just for aesthetics; it provides crucial protection against dust, moisture, and mechanical intrusion, ensuring reliability in harsh industrial settings.

The absence of an oil tank eliminates the risk of fire, making this 250KVA transformer the ideal safe choice for indoor installations close to sensitive loads. Prominent terminals and clear labeling hint at the ease of connection and maintenance. This image is designed to instill confidence, communicating key messages of quality, safety, and advanced engineering inherent in our Dry Type Transformer product line.

Photos détaillées

This detailed cutaway or close-up image is an engineering deep dive into the heart of what makes our 250KVA Dry Type Transformer so exceptional. We focus on four critical components:

Epoxy Resin Insulation: The coil is meticulously cast in a vacuum environment with premium-grade epoxy resin. This process creates a solid, monolithic insulation system that is completely impervious to humidity, prevents partial discharges, and offers exceptional resistance to thermal cycling and short-circuit stresses.

New Silicon Steel Core: The core is constructed from high-grain-oriented, low-loss silicon steel. This material, combined with advanced step-lap design, significantly reduces no-load losses and exciting current, directly contributing to the high energy efficiency of the 250KVA transformer.

100% Copper Windings: Unlike aluminum or copper-clad alternatives, we use 100% electrolytic copper for all windings. Copper provides higher conductivity, better mechanical strength, superior thermal performance, and ultimately, a longer operational lifespan under heavy loading conditions.

Solid Heel Block & Insulation: The solid heel blocks and robust insulation system secure the windings, preventing movement and damage from electromagnetic forces during short-circuit events. This attention to mechanical detail ensures the structural integrity and long-term reliability of the Dry Type Transformer.

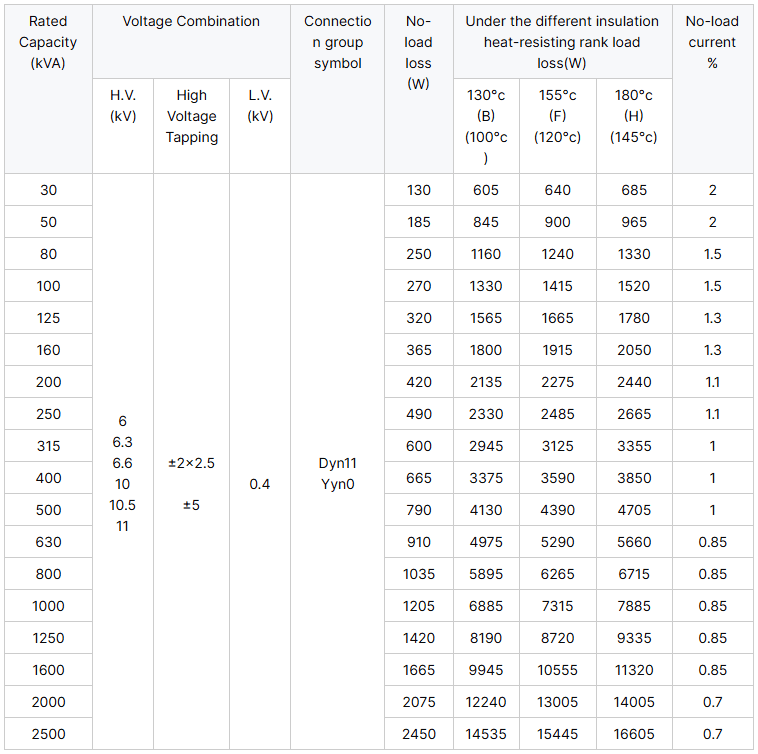

250KVA Dry Type Transformer Parameters

This comprehensive and clearly formatted data table provides all the essential engineering specifications required to evaluate and select our 250KVA Dry Type Transformer. It serves as a critical technical reference for consultants, engineers, and procurement specialists. Key parameters detailed include:

Rated Capacity: Confirmed at 250KVA, defining its standard output.

Voltage Combinations: Lists various standard High Voltage (HV) and Low Voltage (LV) options (e.g., 11kV/0.415kV, 22kV/0.415kV), demonstrating its flexibility for different grid connections.

Connection Group: Typically Dyn11, which is standard for distribution transformers, providing a neutral point for grounding and handling unbalanced loads.

Losses: Clearly states the guaranteed No-Load Loss and Load Loss (at specific insulation classes like F or H), which are vital for calculating the transformer’s lifetime operating cost and efficiency.

No-Load Current: A low percentage value indicating the high quality of the magnetic core and the resulting energy efficiency.

This transparency in data allows for precise system modeling and confirms that this 250KVA Transformer meets the exact requirements of your project.

Factory Show

This dynamic collage offers a behind-the-scenes look at the scale, technology, and meticulous processes within our state-of-the-art manufacturing facility. It’s where our 250KVA Dry Type Transformers are born. The images might showcase:

Automated Production Lines: Advanced machinery for precise winding and core cutting, ensuring consistency and quality in every unit.

Clean-Room Casting Rooms: Where the epoxy resin impregnation and curing process takes place under strictly controlled temperature and humidity conditions.

Organized Assembly Floor: Rows of transformers in various stages of completion, demonstrating our high production capacity and organized workflow.

Quality Control Stations: Technicians conducting rigorous tests like impulse voltage tests and routine tests, highlighting our unwavering commitment to quality.

This image builds trust by proving our manufacturing capability, technological investment, and commitment to producing reliable Dry Type Transformers on a large scale.

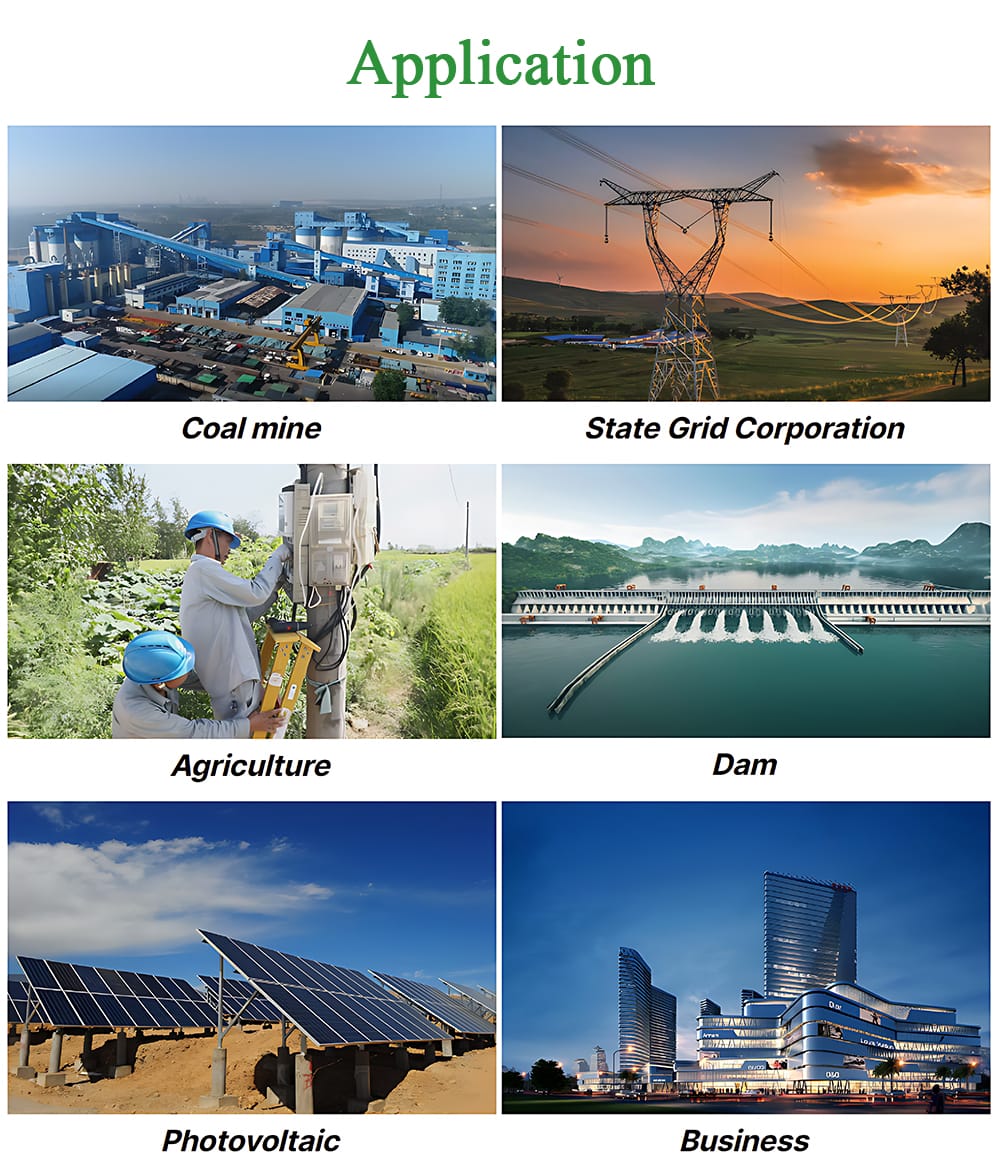

Application

This graphic communicates the versatility of our 250KVA Dry Type Transformer. It shows its ruggedness by placing it in real-world context. It is engineered to perform reliably in a vast array of critical and demanding sectors:

Photovoltaic (PV) Solar Farms: Serving as a key step-down unit in inverter stations, handling variable loads from solar arrays with high efficiency.

State Grid Corporation & Power Distribution: Acting of a reliable node in the power distribution network, providing stable electricity to urban and rural communities.

Coal Mines & Heavy Industry: Its flame-retardant, self-extinguishing properties make it the safest choice for hazardous environments with strict fire safety regulations.

Dam & Water Treatment Plants: Resisting humid and corrosive atmospheres thanks to its sealed, epoxy-protected construction.

Agriculture & Irrigation: Powering large-scale farming operations and irrigation systems reliably.

Commercial Buildings (Shopping Malls, Hospitals, Airports): Providing clean, safe, and quiet power deep within buildings, close to the electrical load.

This wide applicability underscores the product’s robustness and adaptability.

250KVA Dry Type Transformer Certifications

Coopération mondiale

This human-centric collage tells the story of the people behind the product—our greatest asset. Our experienced leadership sets the vision and direction. Our skilled technicians and engineers build and test every 250KVA Dry Type Transformer. Smiling international partners and clients join us during factory visits and project milestones.

This image highlights our expertise through focused technicians. It shows trust and global reach in international collaborations. It reassures customers of a committed partnership with our professional, globally-minded team.

Critiques

Il n'y a pas encore de critiques.