Description

200KVA Dry Type Transformer

This commanding front-view image presents our flagship 200KVA Dry Type Transformer in a professional setting, immediately communicating robustness and reliability. The transformer’s enclosure, crafted from high-quality cold-rolled steel with a standardized RAL color coating, is designed for more than aesthetics; it provides an IP23 protection level, safeguarding critical internal components from dust, moisture, and accidental contact.

The ventilation grilles are strategically designed to facilitate optimal airflow, ensuring efficient cooling without compromising safety. As a dry-type model, it eliminates fire hazards associated with oil, making it the paramount choice for indoor installations in hospitals, high-rise buildings, and manufacturing plants where safety is non-negotiable. This image is engineered to build immediate trust and showcase the professional-grade quality of our power solutions.

Main Material

This detailed infographic deconstructs our 200KVA Dry Type Transformer to reveal the premium materials that constitute its superior performance and longevity:

High-Purity Copper Conductors: We utilize 100% electrolytic copper for all windings. This ensures exceptionally high conductivity, which translates to lower load losses (I²R losses), better energy efficiency, and superior resistance to thermal stress and short-circuit forces compared to aluminum alternatives.

New Silicon Steel Core: The core is assembled from advanced, grain-oriented silicon steel sheets. This material features low hysteresis loss and is laser-scribed to minimize eddy current loss. The result is a dramatic reduction in no-load loss, lower operating noise levels, and enhanced energy efficiency, contributing to a lower total cost of ownership.

Advanced Insulation System: The windings are vacuum-pressure impregnated with Class H or C insulation materials, such as high-temperature epoxy resin. This process creates a monolithic, moisture-proof, and corrosion-resistant insulation barrier that can easily withstand impulse tests of up to 3500V, ensuring dielectric strength and operational safety in humid or harsh environments.

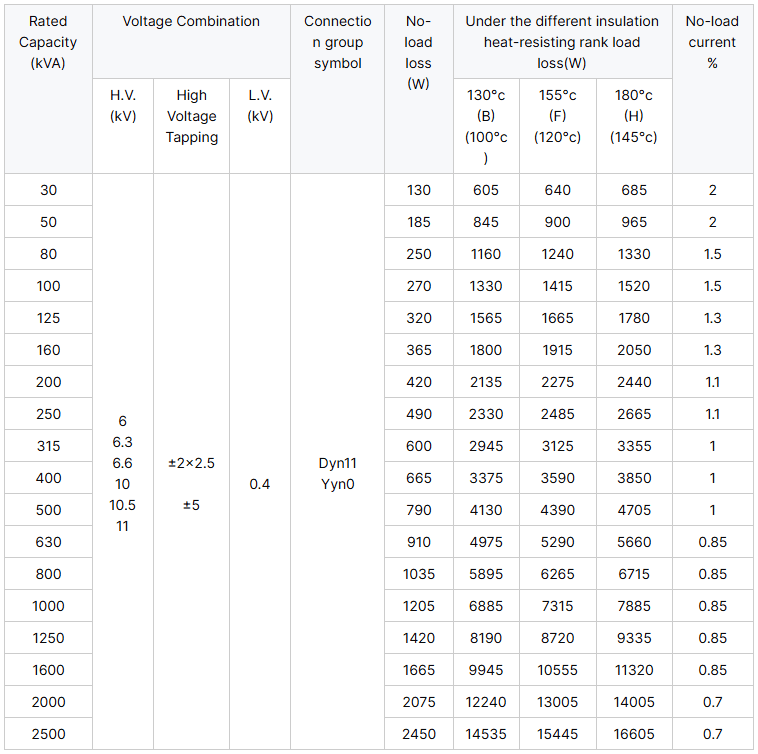

200KVA Dry Type Transformer Parameters

This comprehensive specification table provides unequivocal technical transparency for engineers and procurement specialists evaluating our 200KVA Dry Type Transformer. It is a critical tool for system design and compatibility verification. Key detailed parameters include:

Rated Capacity: Precisely 200KVA, defining its standard operational output.

Voltage Combination: Lists customizable High Voltage (e.g., 11kV) , showcasing its flexibility for various grid infrastructures.

Connection Group: Standardly Dyn11, providing a neutral point for earthing and superior harmonic handling.

Losses: Guaranteed values for No-Load Loss (core loss) and Load Loss (copper loss at specific insulation classes like F or H), which are paramount for calculating energy efficiency and operating costs over the transformer’s lifespan.

No-Load Current: A low percentage value , indicating the high quality of the magnetic core material and precise manufacturing, leading to reduced reactive power consumption.

FACTORY SCENE

This dynamic collage pulls back the curtain on our state-of-the-art manufacturing hub, where precision engineering meets scale. It visually narrates the journey of a 200KVA Dry Type Transformer from raw materials to a tested finished product. The images likely depict:

Automated Core Cutting Lines: Precision machinery cuts the laminations to exacting tolerances to minimize core loss.

Computer-Numeric-Controlled (CNC) Winding Machines: Creating perfectly tensioned and layered copper coils for consistent performance.

Vacuum Pressure Impregnation (VPI) Tanks: We seal the windings in insulation, guaranteeing protection against environmental contaminants.

Rigorous Testing Bays: Showcasing final products undergoing routine tests, including induced voltage and partial discharge tests, to validate every performance claim before shipment. This demonstrates our unwavering commitment to quality control and investment in modern manufacturing technology.

OUR PROJECTS

This graphic powerfully validates the reliability and prestige of our 200KVA Dry Type Transformer by associating it with world-renowned infrastructure projects. It demonstrates proven performance in the most demanding applications:

Beijing South Railway Station: Demands transformers with utmost reliability for passenger safety and uninterrupted operation. Our units provide clean, stable power for signaling, lighting, and critical systems.

Hangzhou Bay Bridge: Exposed to corrosive, salty air, requiring transformers with exceptional environmental protection (like our IP23 enclosure and epoxy insulation) to ensure long-term durability.

Beijing Airport Expressway: Relies on our transformers for tunnel lighting, ventilation, and tolling systems, where failure is not an option.

Indonesian Soma (Project): Illustates our global reach and capability to supply products that meet diverse international standards and climatic conditions. This portfolio serves as a testament to the trust placed in our products by major engineering firms worldwide.

PACKAGING & SHIPPING

This image details our meticulous, export-ready packaging process, a critical final step in our quality assurance chain. We know a product is only as good as its condition upon arrival. Our team securely mounts the Dry Type Transformer onto a heavy-duty wooden skid base. Finally, we protect it with a robust, weather-proof plastic sheet during transit.

We fully enclose it in a custom-built, reinforced wooden crate designed to absorb shocks and impacts during transport. This meticulous process ensures your investment arrives on-site in pristine, factory-fresh condition, ready for immediate installation and commissioning.

200KVA Dry Type Transformer Certifications

Coopération mondiale

This human-centric collage tells the story behind the technology, highlighting our greatest asset: our people. It features a blend of our visionary leadership setting strategic direction, our deeply skilled and dedicated engineers and technicians who breathe life into every Dry Type Transformer, and our successful collaborations with international clients and partners.

Images of joint meetings, factory inspections, and signed contracts build a narrative of trust, global partnership, and shared success. It reassures potential customers that they are not just purchasing a piece of equipment but are entering a long-term partnership with a credible, experienced, and globally-minded team committed to their success.

FAQ

Q1.Do you have MOQ?

The parties can reach the final agreement through negotiation, taking into account different perspectives. The larger the quantity is, the competitive the unit price will be.

Q2.Should the customer pay the delivery fee , How much is it?

We charge a delivery fee, or you provide your express account or cover the shipping cost. If you do not request, I will choose a cheap one in China.

Q3.How about the after sale service?

1)We always match the buyer’s sample quality and compensate if any quality issue occurs.

2)We will suggest our packing and take charge in our packing, we will keep the goods safe in the delivery.

3)We track goods from production to sale and resolve any issues customers face during the selling process.

Q4.When can I get a price?

We usually quote within 24 hours after we get your inquiry.

Q5: Are you a trade company or manufacturer?

We are a professional manufacturer with our own factory.

Critiques

Il n'y a pas encore de critiques.