Description

SH15 M Series Oil lmmersed Transformer

This image presents a detailed view of the advanced SH15 M Series oil immersed transformer, designed to deliver exceptional efficiency and long-term reliability. The transformer features a high-performance amorphous alloy core, which significantly reduces no-load loss and enhances overall energy savings. Its fully sealed oil tank structure minimizes moisture intrusion, protects the transformer insulating oil, and ensures stable operation under varying environmental conditions.

The visual also highlights the transformer’s broad 30–2500kVA capacity range, compact footprint, and optimized heat-dissipation channels, making it well-suited for industrial, commercial, and utility-grade distribution networks. Clear labeling of external components helps users understand its Three Phase Transformer architecture and robust mechanical design.

By showcasing the product’s build quality, thermal stability, and low-maintenance configuration, this image effectively demonstrates why the SH15 M Series transformer is considered a high-efficiency oil type transformer. It provides buyers, engineers, and project developers with confidence in its durability, performance consistency, and long service life—while also supporting informed selection for modern power system upgrades and grid expansion projects.

Detail

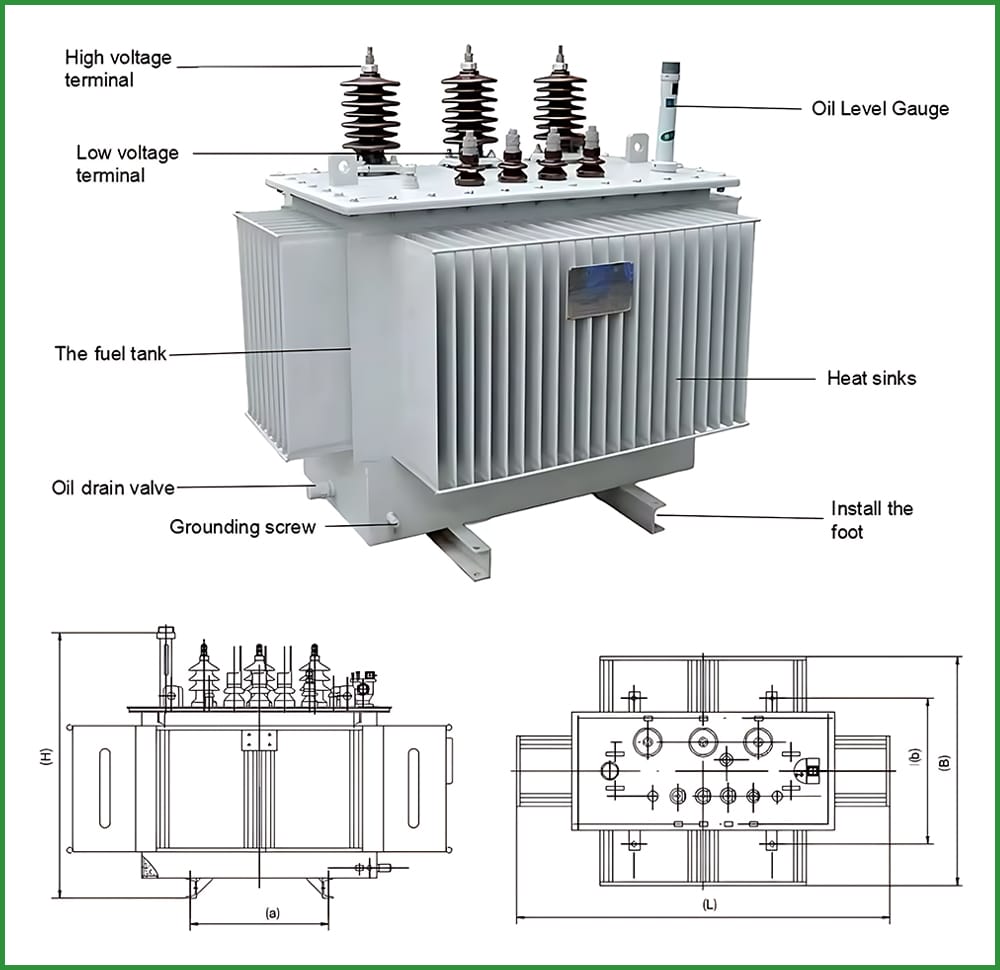

This detailed image showcases the core functional components of the SH15 M Series oil immersed transformer, providing a clear and professional breakdown of its structural design. Key elements such as the high-voltage terminal, low-voltage terminal, oil level gauge, fuel tank, oil drain valve, grounding screw, and heat sinks are prominently displayed, allowing users to understand how each part contributes to safe, stable, and efficient operation.

The visual emphasizes the transformer’s fully sealed construction, which protects the transformer insulating oil from contamination and ensures consistent thermal stability over long service periods. The heat sinks are shown in detail, demonstrating how the oil transformer manages heat through natural convection and optimized oil circulation pathways. This enhances cooling efficiency and prolongs the service life of critical components.

The clearly designed terminals highlight strong electrical connection capability and simplified maintenance, making the SH15 M Series transformer reliable for installation in industrial facilities, commercial buildings, and utility distribution systems. By illustrating the internal build quality and reinforced protection structure, the image helps engineers, procurement teams, and EPC contractors evaluate durability, ease of servicing, and long-term performance under demanding operational conditions.

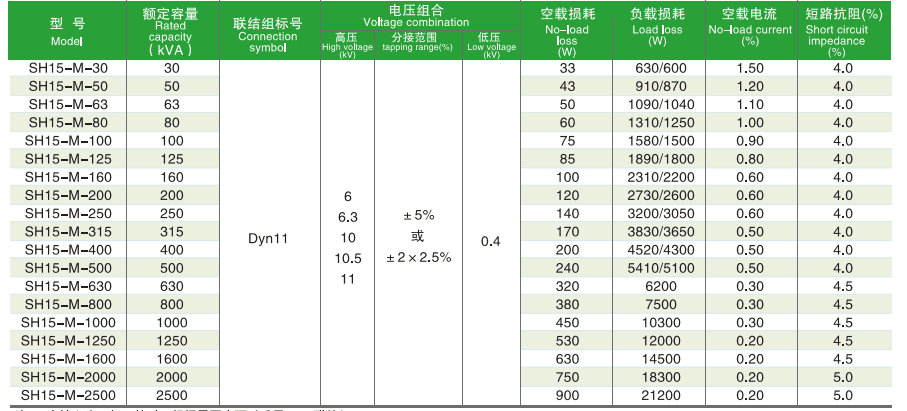

SH15 M Series Oil Immersed Transformer Parameters

This specification chart delivers a comprehensive technical overview of the SH15 M Series oil immersed transformer, presenting all essential performance parameters in a clear and organized format.

1. Key Electrical Specifications

The chart lists important data such as model number, rated capacity (kVA), connection symbol, and voltage combination, enabling engineers to evaluate transformer configuration and system compatibility. High-voltage tapping ranges and low-voltage settings are also included, helping users adjust the transformer to meet specific grid conditions or load requirements.

2. Performance Indicators

Critical operational metrics—such as no-load loss, load loss, no-load current, and short-circuit impedance—are displayed to illustrate the transformer’s energy efficiency and stability. These values highlight the advantages of the SH15 M Series, particularly its amorphous alloy core, reduced loss levels, and optimized thermal behavior.

3. Engineering and Procurement Benefits

By providing detailed and transparent data, the chart allows technical teams, EPC contractors, and procurement specialists to accurately assess installation suitability, expected operating cost, and system performance. This ensures the selected oil type transformer delivers high reliability, long service life, and consistent output under various industrial and utility applications.

4. Support for Decision-Making

Overall, the specification chart serves as a vital reference tool, helping buyers compare models, confirm compliance with project requirements, and determine lifecycle advantages—especially regarding transformer insulating oil performance and long-term operational efficiency.

Advantages

This image highlights the core advantages of the SH15 M Series oil immersed transformer, showcasing its advanced engineering, long-term reliability, and industry-leading efficiency.

1. Ultra-Low Loss Amorphous Alloy Core

The visual emphasizes the use of high-grade amorphous alloy materials, which significantly reduce magnetic losses compared to traditional silicon-steel cores. This ultra-low-loss design helps lower overall energy consumption, reduce heat generation, and enhance system-level efficiency—making it highly beneficial for modern, energy-conscious power networks.

2. Quiet and Stable Operation

The optimized magnetic circuit and precise coil winding process contribute to exceptionally quiet operation, minimizing vibration and noise. This stability ensures consistent performance in residential, commercial, and industrial environments where low noise levels are essential.

3. Enhanced Safety and Reliability

The SH15 M Series incorporates upgraded insulation systems, a fully sealed oil tank, and eco-friendly transformer insulating oil to ensure long-term protection against moisture, contamination, and thermal stress. These features improve dielectric strength, reduce maintenance needs, and extend service life under demanding grid conditions.

4. Superior Energy-Saving Performance

The layout illustrates how reduced no-load and load losses contribute to lower operating costs and improved lifecycle value. Its Three Phase Transformer structure supports efficient voltage regulation and reliable overload capacity, ensuring continuous, stable output in fluctuating load environments.

5. Strong Economic and Application Benefits

With its high reliability, durable construction, and competitive transformer oil price, this oil type transformer stands out as a cost-effective solution for utilities, industrial facilities, and distributed energy systems. The image reinforces its suitability for long-term deployment in substations, distribution grids, and large-scale infrastructure projects.

Factory

This collage provides an in-depth overview of the SH15 M Series transformer manufacturing facility, presenting every key stage of production with clarity and professionalism. It visually guides viewers through the factory’s core lamination workshops, precision coil winding lines, oil tank fabrication areas, assembly stations, quality inspection zones, and final packaging procedures. Each segment reflects a highly integrated workflow designed for accuracy, efficiency, and long-term product reliability.

1. Advanced Manufacturing Capabilities

The image highlights the use of CNC core-cutting machinery, automated winding equipment, and environmentally controlled assembly environments. These technologies ensure precise dimensions, uniform coil tension, and stable transformer performance across all production batches.

2. Strict Quality Control Standards

From raw material inspection to loss testing, oil treatment, partial discharge checks, and final routine tests, the collage demonstrates the company’s commitment to rigorous evaluation standards. Each SH15 M Series transformer undergoes multiple verification steps to ensure electrical safety, mechanical strength, and compliance with international requirements.

3. Professional Engineering and Skilled Workforce

The image emphasizes the presence of trained technicians and experienced engineering teams overseeing every detail. Their expertise ensures that each oil transformer is manufactured to deliver high reliability, low noise, and long service life—aligned with customer expectations for premium energy-saving transformers.

4. Stable Production Output and Batch Consistency

The collage communicates the factory’s capability to handle large-scale manufacturing while maintaining uniform quality. This reliability supports timely delivery for utility projects, industrial installations, and commercial distribution networks.

5. Transparency and Customer Confidence

By showcasing real manufacturing scenes, the collage reinforces trust and demonstrates the company’s industrial capability, technological strength, and commitment to providing cost-effective products with a competitive transformer oil price.

Application

This visual highlights a wide range of real-world application scenarios where the SH15 M Series oil immersed transformer operates reliably and efficiently. It demonstrates the transformer’s versatility across multiple sectors and its ability to maintain stable performance in demanding electrical environments.

1. Urban and Municipal Distribution Networks

The image illustrates how the transformer supports city grids, residential communities, and commercial districts. Its low-loss amorphous alloy core and fully sealed oil tank provide stable voltage delivery, reduced energy waste, and long maintenance intervals—ideal for continuous urban power supply.

2. Industrial Facilities and Manufacturing Plants

Applications in factories, processing centers, and large industrial workshops show the transformer’s strong overload capacity and robust structure. Its efficient heat dissipation and durable transformer oil ensure reliable operation under heavy and fluctuating load conditions.

3. Renewable Energy and Distributed Generation Systems

The visual includes scenarios such as solar farms, wind power stations, and hybrid microgrids. The transformer’s high efficiency supports reliable integration with renewable power sources. Its low no-load loss improves overall power generation and distribution performance.

4. Commercial Buildings and Infrastructure Projects

Usage in malls, office complexes, and data centers shows its stable power delivery capability. The transformer also supports hospitals that require precision, high reliability, and continuous uptime.

5. Remote and Rural Power Stations

The collage also highlights installations in remote villages, agricultural areas, and off-grid sites. Its fully sealed design prevents moisture ingress, ensuring long-term durability even in harsh climates.

6. Consistent Reliability Across All Applications

Across all scenarios, the transformer demonstrates strong environmental adaptability, efficient heat management, and long-lasting transformer oil performance. These features make the SH15 M Series suitable for indoor and outdoor installations. They ensure dependable operation and help reduce the transformer’s overall lifecycle cost.

SH15 M Series Oil Immersed Transformer Certifications

Global Cooperation

A successful meeting between company leaders, engineers, and international clients is shown in this image. The conversation demonstrates global confidence in the SH15 M Series oil immersed transformer. Professional interaction highlights the company’s strong export capability and international project experience. Technical discussions reveal deep product expertise and reliable engineering support.

Clients express trust in the transformer’s stable performance and long service life. The scene also reflects appreciation for the company’s competitive transformer oil price. Strong teamwork illustrates a customer-first philosophy and responsive communication. This positive atmosphere reinforces brand credibility and long-term cooperation potential. Global buyers gain confidence in the company’s oil type transformer solutions. The image ultimately shows commitment to quality, transparency, and dependable after-sales service.

FAQ

1. What is the SH15 M Series oil immersed transformer?

The SH15 M Series is a fully sealed oil immersed transformer with an amorphous alloy core designed for ultra-low loss, high efficiency, and long service life. It is ideal for industrial, commercial, and utility distribution systems.

2. What are the main advantages of the SH15 M Series transformer?

Key benefits include reduced no-load loss, quiet operation, improved insulation reliability, strong overload capability, and enhanced energy savings thanks to the amorphous alloy magnetic core.

3. What capacity range is available for this transformer?

The SH15 M Series covers a wide rating range from 30 kVA to 2500 kVA, suitable for small distribution projects to large utility applications.

4. What type of insulating oil does this transformer use?

It uses premium transformer insulating oil designed for stable heat dissipation, long-term dielectric strength, and extended service life. Low-maintenance, sealed designs minimize oil contamination.

5. Is the SH15 M Series suitable for outdoor installation?

Yes. The fully sealed structure protects against moisture, dust, and environmental factors, making it reliable for indoor and outdoor installations.

6. Does the transformer support renewable energy applications?

Absolutely. Its high efficiency and low-loss design make it ideal for solar farms, wind projects, and hybrid microgrids, improving overall system performance.

7. What standards does the SH15 M Series comply with?

It can be manufactured according to IEC, ANSI, GB, and customer-specific standards to meet global grid requirements.

8. What is the expected service life of this transformer?

With proper installation and maintenance, the SH15 M Series typically provides 20–30+ years of stable operation, depending on load conditions and environment.

9. Can I customize voltage, connection group, or accessories?

Yes. Options include customized HV/LV voltage combinations, tap changers, protection devices, terminal interfaces, and monitoring components.

10. Is after-sales technical support available?

We offer full technical consultation, installation guidance, operation training, and long-term after-sales support for global customers.

Reviews

There are no reviews yet.