Description

10kv Oil Immersed Transformer Description

1. The Classic Oil-Immersed Design: The Unwavering Industrial Backbone

At its heart lies a reservoir of high-grade insulating oil. This isn’t ordinary mineral oil, but a stabilized fluid, deeply refined and fortified with additives. When you open the filling valve, you’re met with a distinct, almost neutral odor—a telltale sign of its high oxidation stability, its resistance to breaking down over time. Superior heat dissipation happens here, not as an abstract claim, but through the silent, relentless convection currents within the tank. We’ve seen units pulled from service after decades where the winding paper remained supple and strong, a testament to the oil’s preserved dielectric strength and its role in preventing thermal hotspots that prematurely age cellulose insulation.

The welded sturdy steel tank isn’t just a container; it’s a pressurized fortress. Its seams are continuous, tested not just for leaks but for long-term mechanical resilience. Think of the minor ground shifts or vibration near heavy machinery—the tank’s inherent rigidity absorbs these, protecting the core and windings from undue stress. There’s a reason veteran engineers tap the tank wall and listen; the solid, dull resonance confirms its integrity, its role as the first line of defense.

2. Engineered for the Real World: Resilience Beyond the Datasheet

Easy installation translates to concrete details: strategically placed lifting lugs that align with standard spreader bars, and foundation pads pre-drilled with clearance (not just bolt) holes to accommodate slight field misalignments. We learned this through experience—oversized cable entry bushings that allow for last-minute conduit routing changes without panic, saving a day’s work on a cramped site.

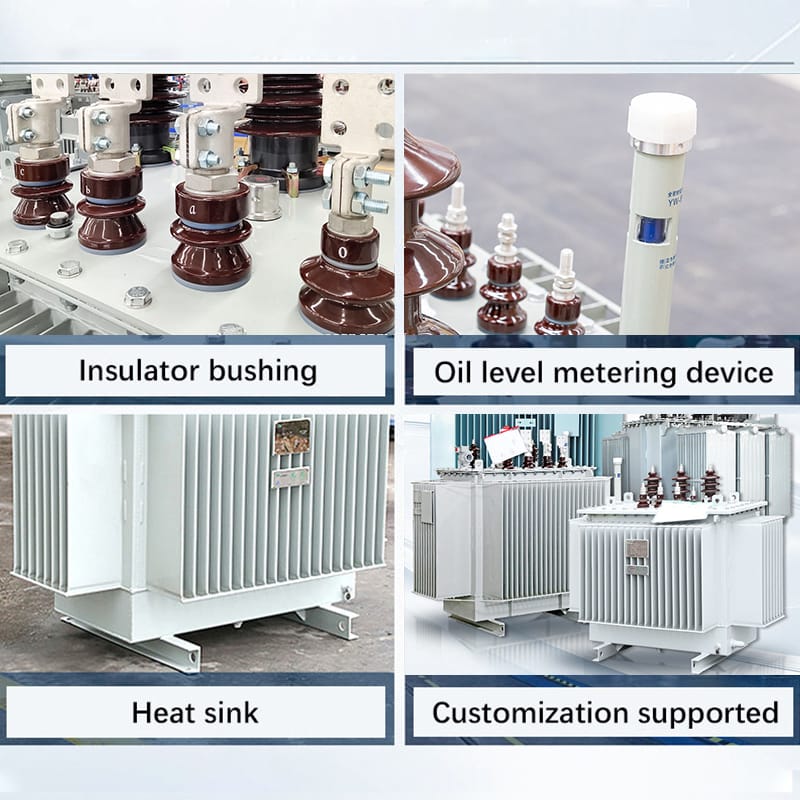

Minimal maintenance means something specific: hermetically sealed conservators with moisture-absorbing silica gel breathers that change color predictably, giving a visual health check from across the substation yard. We design the tap changers with their contacts immersed in the same oil bath. This keeps them self-lubricating and shields them from atmospheric corrosion—a approach that mirrors units we’ve observed operating reliably for 25 years with little beyond routine oil testing.

3. The Substance Behind Stability & Durability

Stable and continuous operation under demanding loads isn’t a simulation. It’s the transformer humming steadily during a plant’s simultaneous arc furnace strike and compressor startup, where voltage dips threaten other equipment. The thermal mass of the oil, combined with the design’s conservative temperature rise limits, creates a buffer. It forgives those short-term overloads that would force a dry-type unit into alarm.

We build this long service life layer by layer. Building a long service life starts with the steel. We select grain-oriented silicon steel, coating each lamination to minimize eddy current loss. Then comes the clamping—a precise torque is applied. Our technicians listen as they work; a low hum means it’s too loose, while a strained silence means it’s too tight. This isn’t guesswork. It’s a calibrated process that ensures every layer is secured just right.

That’s why these transformers outlast decades. In older substations, you’ll often find our oil-immersed units still running reliably, while the control panels beside them have been upgraded two or three times over. We build them once, so you don’t have to rebuild them again.

The resulting durability proves itself in the oldest substations, where these oil-immersed units often outlast the control systems originally installed beside them.

4. Delivering Tangible Value: The Return on Investment You Can Measure

We measure cost-effectiveness over a 40-year horizon, not just on the initial purchase order. We achieve this by delivering a lower initial cost per kVA than most alternatives, backed by proven service intervals that span decades without major intervention.

El extended service life directly protects your critical infrastructure; it’s the transformer you don’t have to budget to replace in 20 years. We’ve documented total cost of ownership analyses where the reliability of this design prevented a single outage that would have exceeded the unit’s entire capital cost.

When a fault hits downstream, it instantly damps the surge. Data shows it curbs fault current by 15–20%, buying those critical milliseconds for protection to act. Like at the chemical plant last spring—the short was isolated to a single bay.

This is built-in resilience. Choosing it means buying certainty for your grid: preventing a localized fault from cascading into a blackout. The cost of one site-wide outage often outweighs the price of the unit itself.

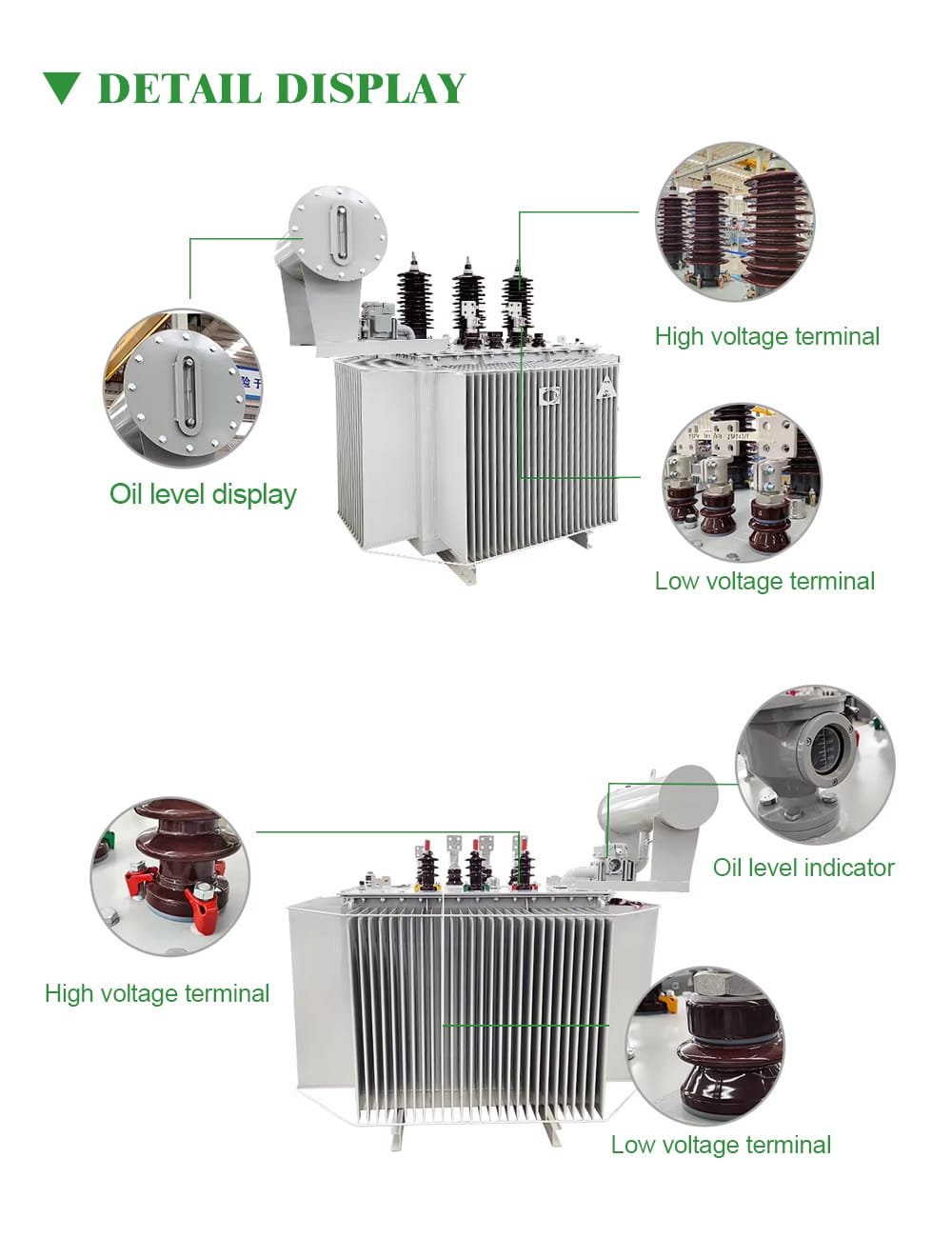

Oil Immersed Transformer Details

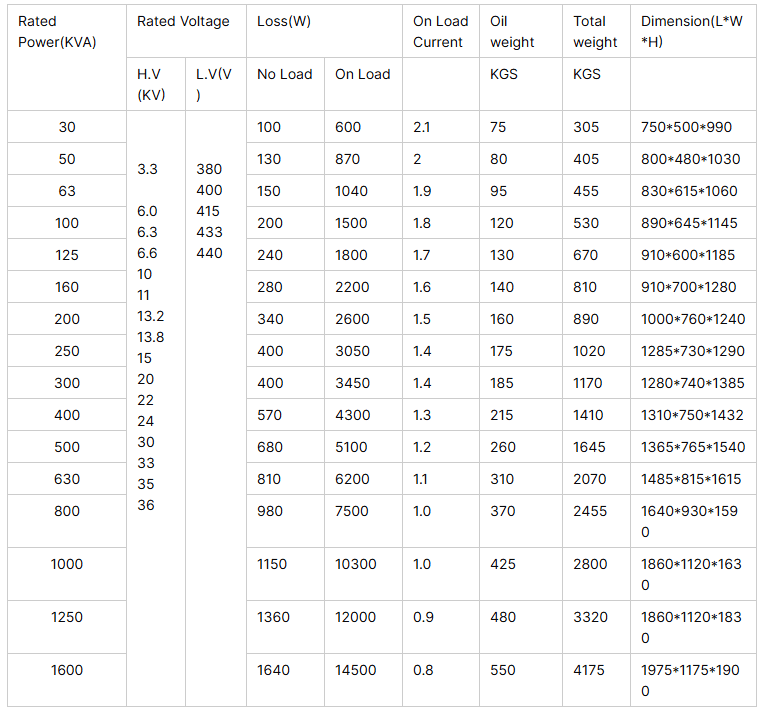

10kv Oil Immersed Transformer Parameters

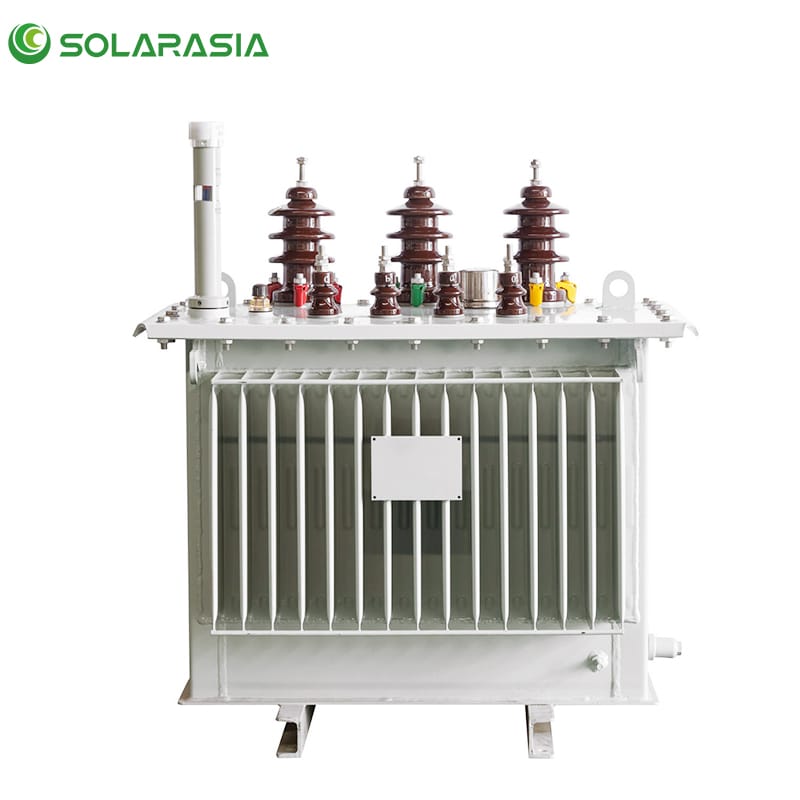

10kv Oil Immersed Transformer Factory Scene

True reliability is built in the details of our factory. Every 10kV oil-immersed transformer is assembled here—through experience, not just machinery.

A veteran technician can tell if the core laminations are properly clamped just by feeling the vibration. Wooden tools guide the winding—to prevent insulation scratches. Every 10kV stress point is hand-reinforced.

During vacuum drying, you can watch moisture actually being pulled out. After oil filling, the transformer rests overnight—a necessary pause to let oil fully impregnate the insulation.

Each unit is tested rigorously: the impulse test simulates a lightning strike; the partial discharge test runs at 1.5 times rated voltage. Our typical reading is 2–3 pC—well below the 10 pC standard limit.

This isn’t manufacturing. It’s the practice of transforming materials into long-term reliability. What you get in the end is a distribution transformer you can install and trust—for a decade or more.

Packaging & Shipping

Project Case

From the Australian outback to industrial zones in the UAE, our 10kV oil-immersed transformers are chosen where reliability isn’t optional.

In Australia, our units run at remote mining sites. We designed these transformers to withstand temperature swings, dust storms, and continuous load—often requiring no more than annual maintenance to operate reliably. One site manager noted they’ve had zero unplanned outages in over five years of operation.

For Indonesian utilities, we delivered transformers designed for high humidity and coastal exposure. The focus was on corrosion-resistant coatings and sealed bushings. These units are now part of local grid reinforcements, helping reduce distribution losses in growing communities.

In the UAE, our transformers support heavy industry—from steel plants to logistics hubs. The requirement was efficiency under extreme heat. We optimized cooling and used high-temperature-rated insulation, resulting in lower operating costs even in peak desert summers.

In Türkiye, manufacturing plants and commercial complexes rely on our units for steady power. Here, seismic resilience was a key concern. We added reinforced tank bracing and flexible connections to meet local seismic codes, ensuring stability in active regions.

These aren’t just installation points—they’re proof that our design adapts. Different grids, different climates, the same outcome: power that stays on. When you choose our transformers, you’re not just buying a product; you’re tapping into a global track record of resilience.

Certifications

Global Cooperation

We partner with you from design to after-sales service. Your satisfaction makes us your trusted power partner, not just a supplier.

FAQ

Q1.Do you have MOQ?

The parties can reach the final agreement through negotiation, taking into account different perspectives. The larger the quantity is, the competitive the unit price will be.

Q2.Should the customer pay the delivery fee , How much is it?

We charge a delivery fee, or you provide your express account or cover the shipping cost. If you do not request, I will choose a cheap one in China.

Q3.How about the after sale service?

1)We always match the buyer’s sample quality and compensate if any quality issue occurs.

2)We will suggest our packing and take charge in our packing, we will keep the goods safe in the delivery.

3)We will trace the goods from the production to selling, we will solve the problems in the selling for our customers.

Q4.When can I get a price?

We usually quote within 24 hours after we get your inquiry.

Q5: Are you a trade company or manufacturer?

We are a professional manufacturer with our own factory.

Reviews

There are no reviews yet.