Introduction: Why Dry Type Distribution Transformer Matter Today

As global power infrastructure continues to evolve toward higher safety standards, Engineers and facility designers increasingly prefer dry type distribution transformer over traditional oil-filled designs for commercial buildings, hospitals, industrial plants, and renewable energy projects.

Unlike oil-immersed transformers, dry type transformers use air and solid insulation systems instead of liquid dielectric fluids. This fundamental design difference delivers clear advantages in safety, environmental protection, and maintenance—especially in indoor and high-risk environments.

We wrote this guide for engineers, EPC contractors, facility managers, procurement professionals, and project developers who want a clear, technically accurate, and experience-based understanding of dry type transformers. Drawing on our real-world manufacturing and project experience, we explain how dry type transformers work, why engineers and designers use them, and how to select the right solution for each application.

What Is a Dry Type Distribution Transformer?

A dry type transformer is an electrical transformer in which the core and windings are not immersed in insulating oil. Instead, the transformer relies on solid insulation materials and air cooling to manage heat and electrical isolation.

The term “dry type” refers to the absence of liquid cooling or insulation media. Common insulation materials include:

- Epoxy resin

- Fiberglass-reinforced insulation

- Nomex or high-temperature insulation paper

- Varnish or resin systems applied through vacuum processes

Engineers typically install dry type transformers indoors, close to the load, and design them to operate safely in environments where fire risk, environmental protection, or human safety is a primary concern.

How Does a Dry Type Distribution Transformer Work?

1 Basic Operating Principle

Like all transformers, dry type transformers operate based on electromagnetic induction:

- An alternating current flows through the primary winding.

- This current generates a magnetic field in the transformer core.

- The magnetic field induces voltage in the secondary winding.

- Electrical energy is transferred without direct electrical contact.

The voltage ratio depends on the turns ratio between the primary and secondary windings.

2 Cooling Mechanism

Because there is no oil to absorb and dissipate heat, cooling relies on air circulation:

- AN (Air Natural): Heat dissipates through natural air convection.

- AF (Air Forced): Fans enhance airflow, increasing cooling capacity and allowing higher short-term overloads.

Proper ventilation is essential to ensure stable temperature rise and long insulation life.

Main Types of Dry Type Distribution Transformer

Dry type transformers are not a single product category. They are available in different constructions depending on performance requirements, environmental conditions, and budget.

1 Cast Resin Dry Type Transformers

Cast resin transformers use epoxy resin to encapsulate the windings. This design provides:

- Excellent moisture resistance

- High mechanical strength

- Superior fire performance

- Strong resistance to dust and contaminants

They are widely used in hospitals, commercial buildings, metro stations, and renewable energy installations.

2 VPI (Vacuum Pressure Impregnated) Transformers

In VPI transformers, the windings are vacuum-treated and impregnated with varnish or resin, then cured under pressure.

Advantages include:

- Good thermal performance

- Lower cost compared to cast resin

- High efficiency

- Reduced partial discharge risk

VPI transformers are commonly used in industrial and commercial applications with controlled indoor environments.

3 Open-Wound Dry Type Transformers

These transformers use air as the primary insulation medium, with minimal resin coating.

They are suitable for:

- Clean, dry environments

- Electrical rooms with controlled conditions

- Cost-sensitive applications

However, they require stricter environmental control and regular inspection.

Key Advantages of Dry Type Distribution Transformer

1 Enhanced Fire Safety

One of the most important advantages of dry type transformers is fire safety.

- No flammable oil

- Self-extinguishing insulation materials

- Reduced explosion risk

- Compliance with strict fire regulations

This makes them ideal for installation in buildings where evacuation and fire containment are critical.

2 Environmentally Friendly Design

Dry type transformers eliminate the risk of oil leaks that can contaminate soil and groundwater. They support:

- Green building standards

- Environmental compliance

- Sustainable infrastructure development

In regions with strict environmental regulations, dry type transformers are often the only acceptable option.

3 Reduced Maintenance Requirements

Oil-filled transformers require periodic oil testing, filtering, and replacement. Dry type transformers eliminate these tasks.

Typical maintenance includes:

- Visual inspection

- Dust removal

- Connection tightening

- Fan inspection (if applicable)

This results in lower long-term operating costs.

4 Flexible Installation Options

Dry type transformers can be installed:

- Indoors near load centers

- In basements or technical rooms

- On upper floors of buildings

- In compact electrical spaces

Their compact footprint simplifies system design and reduces cable losses.

5 Long Service Life and Reliability

With high-quality insulation systems and proper cooling, dry type transformers can operate reliably for 25–30 years or more.

Advanced designs offer:

- High thermal class insulation (Class F or H)

- Low partial discharge levels

- Excellent short-circuit strength

Dry Type vs Oil-Filled Transformers

| Aspect | Dry Type Transformer | Oil-Filled Transformer |

|---|---|---|

| Cooling Medium | Air | Insulating oil |

| Fire Risk | Very low | Higher |

| Environmental Impact | Minimal | Oil leakage risk |

| Maintenance | Low | Moderate to high |

| Indoor Installation | Ideal | Limited |

| Initial Cost | Higher | Lower |

| High Capacity Use | Limited | Better suited |

The choice depends on application requirements rather than price alone.

A Practical Comparison

When manufactured in accordance with modern industry standards, medium-voltage dry-type transformers and pad-mounted transformers deliver comparable power efficiency and BIL performance at the same KVA rating. The practical differences between the two mainly arise from how and where they are installed and operated.

Utility providers commonly deploy pad-mounted transformers with liquid cooling in medium- and high-voltage systems, especially in outdoor environments such as substations. Engineers specifically design these transformers to withstand harsh weather conditions and deliver dependable electrical power. With proper protective housings, installers can also place these units in public outdoor areas. However, one notable drawback is the use of mineral oil as a cooling medium. Since the oil is combustible, internal faults caused by insulation breakdown, excessive heat, or lightning strikes may lead to fires or explosions. For this reason, liquid-filled pad-mounted transformers are generally unsuitable for indoor locations or areas where fire risks must be strictly controlled.

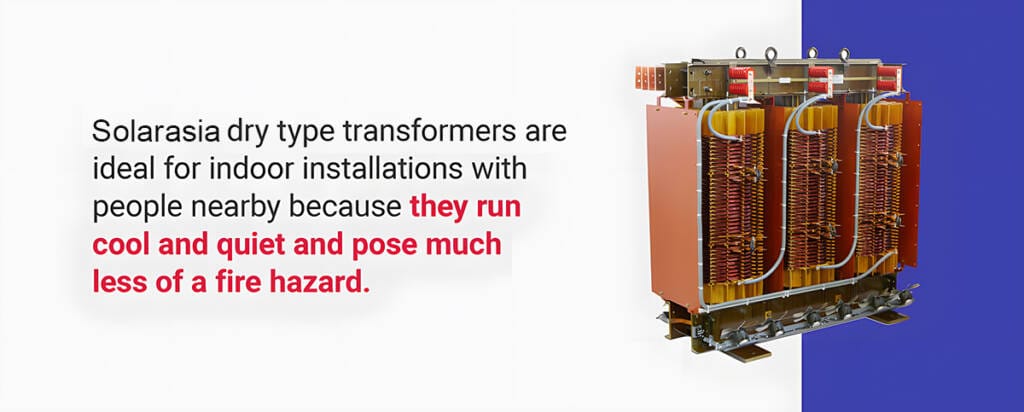

In contrast, dry-type transformers rely on natural or forced air for cooling and do not contain any liquid insulation. This design significantly reduces fire risk, making them well suited for indoor applications or environments with stringent safety requirements. Their low noise levels and efficient thermal performance make them a preferred choice for installations in commercial buildings, educational facilities, healthcare institutions, and clean manufacturing environments. In many cases, dry-type units can serve as a safe alternative to liquid-filled transformers in these settings.

Engineers can also install dry-type transformers outdoors under certain conditions, provided the climate remains relatively moderate in terms of temperature and humidity. In such cases, installers typically use a NEMA 3-rated enclosure to ensure adequate protection from environmental exposure.

Common Applications of Dry Type Distribution Transformer

1 Commercial Buildings

- Office towers

- Shopping malls

- Hotels

- Mixed-use developments

Dry type transformers are preferred due to safety, low noise, and minimal maintenance.

2 Healthcare and Educational Facilities

- Hospitals

- Universities

- Research centers

These facilities require uninterrupted power and maximum fire safety.

3 Industrial Facilities

- Manufacturing plants

- Automation lines

- Food processing factories

- Clean production environments

Forced-air cooling options allow dry type transformers to handle industrial loads reliably.

4 Renewable Energy Systems

- Solar power plants

- Wind farms

- Energy storage systems

Dry type transformers support clean energy goals and simplify environmental compliance.

5 Infrastructure and Transportation

- Airports

- Metro stations

- Data centers

- Tunnels and underground facilities

Key Technical Parameters to Consider

1 Rated Power and Voltage

Correct sizing ensures:

- Stable operation

- Future load expansion

- Optimal efficiency

2 Insulation Class

Common insulation classes include:

- Class F (155°C)

- Class H (180°C)

Higher classes allow greater thermal margin and longer service life.

3 Temperature Rise

Lower temperature rise improves insulation longevity and reliability.

4 Noise Level

Dry type transformers are often installed close to occupied areas, making low-noise design important.

5 Protection Degree

IP-rated enclosures (e.g., IP23, IP44, IP54) protect against dust, moisture, and accidental contact.

Installation Best Practices

The following guidelines are specifically for indoor installations of Solarasia dry type transformers, which fall under NEC Article 450.21-28. Outdoor installations are regulated by NEC 450.41-48. Here are key considerations to prepare for a safe and efficient indoor setup.

Handling on Delivery

Transformers can be moved using hand trucks or forklifts if the forks are long enough to support the entire base. Because many units have a high center of gravity, extra caution is necessary during lifting or relocation. Larger transformers typically require a crane and rigging team. If the unit needs to be moved outdoors in adverse weather, ensure it is fully protected from moisture.

Storage

Storage areas should be clean, dry, and maintain stable temperatures. Technicians should keep protective coverings intact until they place the transformer in its final location. If technicians store transformers in damp or dusty conditions, they must dry and clean them before installation and energization.

Choosing the Installation Location

When selecting an indoor location for a dry type transformer, consider:

- Accessibility for installation and maintenance

- Adequate ventilation for cooling

- Environmental conditions such as humidity and temperature

- Noise levels and proximity to occupied spaces

Additional recommendations include:

- The area should be free from dust, excessive moisture, chemicals, fertilizers, corrosive fumes, and flammable materials, following NEC 450.21.

- Ensure sufficient clearance along access routes to move the transformer; avoid stairs and elevators when possible.

- The floor should be level, smooth, and capable of supporting the transformer’s weight (preferably reinforced concrete).

- Transformers must be installed upright with proper air circulation. Minimum clearance from nearby equipment or walls should follow NFPA 60 (NEC 450.21). Engineers strongly recommend installing the unit within a NEMA enclosure in a locked room for safety and security.

- Avoid areas prone to flooding, excessive moisture, or temperatures above 30°C.

- Technicians must not position the transformer under wet fire suppression sprinklers; if fire protection is required, they must use dry or foam systems instead.

Room Requirements for Indoor Installations

Indoor installations of Solarasia dry type transformers must follow the requirements outlined in NEC Article 450.21. Rooms housing multiple transformers should be spacious enough to maintain adequate clearance between units, ensuring proper air circulation as specified by NEC 450.21. Sufficient space should also be available around each transformer to allow personnel to perform routine inspections and maintenance safely.

Proper ventilation is critical to maintaining optimal transformer temperatures. The room’s airflow functions as part of the transformer’s cooling system, helping to prevent the unit from exceeding its nameplate temperature rating. Ideally, the air should be clean and dry. Using filtered air at or above atmospheric pressure can reduce maintenance needs in environments where dust or other contaminants are present. The required size and placement of ventilator openings depend on the room height, opening locations, and the transformer’s maximum load. A qualified HVAC technician should assess the airflow to ensure compliance with NFPA 90A (sections 4.1–4.3) and IEEE C57.12.01–2020.

In rooms or confined spaces, ventilation must be sufficient to dissipate the transformer’s full-load heat loss without causing the temperature to exceed the nameplate rating. Engineers should install forced-air ventilation if natural airflow is insufficient to maintain safe operating temperatures.

Maintenance and Operational Guidelines

The following information summarizes key maintenance points for Solarasia medium-voltage dry type transformers and is not exhaustive. Full compliance with NEC Article 450, Chapter 21.3 and IEEE Std. 57.12.91 is required for proper testing and maintenance procedures.

1. Maintain a Temperature Log

Regularly monitor and record transformer temperatures under normal load conditions, comparing them with previous log entries. All three-phase coils should show similar readings; significant differences or rising temperatures under constant load may indicate issues with the air cooling system or the transformer itself.

2. Perform Maintenance Only on De-Energized Units

Technicians must conduct all inspections, cleaning, servicing, and tests with the transformer fully de-energized, with both primary and secondary circuits disconnected and all terminals grounded. When de-energizing the unit, technicians must wear appropriate safety gear such as an Arc Flash suit. Technicians no longer need full Arc Flash protection once they de-energize, lock out, tag out, and ground the transformer.

2.1 Visual Inspection

Technicians only need to perform visual checks and should minimize physical contact. The frequency of inspections depends on operational load—continuous 24/7 operation requires more frequent checks than standard 8-hour daily loads. Conduct inspections during scheduled shutdowns and maintain a log of all findings and maintenance activities.

- Ensure adequate ventilation space and remove any obstructions.

- Check for dust accumulation on surfaces and clean while de-energized. Dusty environments may require inspections every 3–6 months.

- Look for winding discoloration, which may indicate overheating, and document any findings with photos.

2.2 Cleaning the Unit

Avoid direct contact with components. Use a vacuum and compressed dry air (20–25 psi) to remove dust from windings and cooling fans. Do not use chemical cleaners. Inspect de-energized electrical connections, tighten hardware, and replace damaged insulation or components to prevent operational issues.

2.3 Detecting Potential Problems

During cleaning, inspect for:

- Rust on clamps and core steel

- Carbonization, tracking, or discoloration on windings and insulation

- Cracked, discolored, or loose insulators

- Loose, corroded, or discolored electrical connections

Tighten or replace hardware as needed, or consult a qualified professional. Inspect auxiliary devices such as fans and motors for proper operation. Document all abnormalities and report them to the plant engineer or facilities manager before re-energizing.

3. Routine Maintenance Testing

If visual inspection reveals discoloration, carbonization, or other signs of overheating, qualified engineers must perform additional tests on fully de-energized units using proper protective equipment and test instruments.

3.1 Transformer Turns Ratio (TTR)

Verifies that the voltage ratio between primary and secondary windings matches the nameplate or certified values within ±0.5% (NEC 450.11.2 & IEEE 57.12.91).

3.2 Insulation Resistance Test (IR)

Measures insulation integrity between coil conductors. Resistance below the required Mega-Ohm threshold indicates degradation and potential failure (NEC 450.11.11.3).

3.3 Winding Resistance Test (WR)

Ensures coil winding resistance matches factory values or previous test results within 1% tolerance (NEC 450/11.11.7).

Transformer-specific insulation and winding resistance data for Solarasia units are available in the supplied documentation or by contacting Solarasia with the serial number.

3.4 Additional Tests

Some diagnostic procedures require specialized equipment and should only be performed by experienced professionals. All new Solarasia transformers undergo certification testing, with results documented in the accompanying certificate. For questions regarding testing or additional diagnostics, contact Solarasia technical support to consult with transformer engineers.

Common Questions About Dry Type Distribution Transformer

Are dry type transformers suitable for outdoor use?

They can be used outdoors only with properly designed enclosures and weather protection.

Are dry type transformers more expensive?

Initial cost is higher, but total lifecycle cost is often lower due to reduced maintenance and safety infrastructure.

How long do dry type transformers last?

With proper design and operation, 25–30 years or longer.

Why Choose Dry Type Distribution Transformer for Modern Projects?

When deciding between a dry-type transformer and a liquid-cooled transformer, the installation environment plays a decisive role.

- Several key questions should be evaluated in advance:

- Will the transformer be installed indoors or outdoors?

- Is fire safety a critical concern for this application?

- Is it necessary to eliminate the risk of oil or fluid leakage?

- Will personnel frequently be present near the installation area?

- How much physical space is available at the site?

- Can the floor structure support the transformer’s weight?

- Is the installation area dry, properly ventilated, and free from dust, chemicals, or corrosive substances?

Solarasia dry-type transformers are especially well suited for indoor environments where people are nearby. Their air-cooled design allows them to operate at lower temperatures and with reduced noise levels, while significantly lowering fire risk. Facility engineers can position these transformers close to the electrical load, which often provides advantages in industrial and commercial settings. In certain outdoor applications with mild climate conditions, engineers can also install them within a NEMA Type 3 enclosure, although the overall reliability depends largely on the enclosure’s quality and protection level.

To ensure proper performance, dry-type transformers require sufficient clearance around the unit for effective air circulation and routine maintenance, in accordance with NEC 450.21. Installation planning should consider the transformer’s overall dimensions, weight, and connection points, which can be provided by Solarasia and evaluated against the available site conditions.

Common indoor applications for air-cooled transformers include hospitals, universities, shopping centers, office buildings, and residential facilities.

Additional suitable use cases include:

- Environmentally sensitive locations,

- Areas with elevated fire safety requirements,

- Auditoriums and conference venues,

- Oil, chemical, and gas facilities,

- Renewable energy generation sites.

If the intended installation area meets the following conditions, a dry-type transformer becomes an optimal solution, allowing its full range of benefits to be realized:

- The transformer is installed indoors,

- Electrical connections are overhead or side-mounted,

- Ambient temperature and humidity remain moderate year-round,

- Clean air is maintained through HVAC systems,

- Access is restricted or the unit is housed in a dedicated room,

- Operation occurs close to occupied areas,

- Low noise levels are required,

- Fire risk must be kept to a minimum.

Why Choose Solarasia for Dry Type Distribution Transformer

At Solarasia, we serve clients across a wide range of industries, providing high-quality transformers backed by decades of experience. Many members of our expert team have over 22 years of industry experience and are available to answer any questions regarding transformer selection, installation, or operation.

Leveraging this expertise, our team delivers industry-leading solutions tailored to customer needs. We also provide expedited shipping, with select dry type and oil-filled padmount transformers ready to leave our facility within 24 to 48 hours.

We are proud of our long-standing reputation for reliability in designing, manufacturing, and delivering dry type transformers without any warranty issues related to design, materials, or workmanship. Our team remains committed to maintaining this standard on every order.

To further support our customers, all new indoor dry type transformers come with an extended five-year warranty, exceeding the standard one-year coverage and reflecting our confidence in product quality and performance.

Conclusion

Dry type transformers are no longer a niche solution. They represent a mature, reliable, and forward-looking technology for modern power distribution systems. Whether for commercial buildings, industrial facilities, or renewable energy projects, dry type transformers provide a balance of safety, performance, and environmental responsibility.

Choosing the right transformer requires technical understanding, real-world experience, and a reliable manufacturing partner. When selected and installed correctly, dry type transformers deliver decades of dependable service.

Request a Quote on New Dry Type Transformers

Solarasia has been dedicated to repairing and rebuilding transformers from other manufacturers for over a century. Our team brings decades of hands-on experience in restoring failed transformers to full functionality. In addition to dry type transformers, we also provide padmount transformers and pre-owned transformer solutions.