Description

Solarasia is a professional manufacturer ل 50kVA oil immersed transformers for low and medium voltage power distribution systems.

Our 50kVA oil immersed distribution transformer is widely used in rural electrification, commercial buildings, small factories, and solar power projects. Designed according to IEC standards, it offers stable performance, low losses, and long service life.

We are a factory manufacturer of 50KVA Oil Immersed Transformers, offering direct supply at competitive prices. We provide flexible voltage customization, high-quality oil insulation, and export-ready packaging to support global power projects and EPC applications.

50kVA Oil Immersed Distribution Transformer Overview

For facility managers and project engineers, this 50KVA oil-immersed distribution transformer is engineered to directly reduce your long-term operational costs and risks. Its seamlessly welded tank with advanced anti-corrosion coating isn’t just robust—it eliminates the need for frequent touch-ups and protects against costly failures in humid, corrosive, or dusty environments.

The hermetically sealed conservator is a critical feature that minimizes oil degradation, ensuring stable insulating properties for over 25 years and drastically reducing the need for future oil filtration or replacement. Furthermore, the strategically placed, universally compatible HV/LV bushings are designed to save valuable installation time and labor costs, allowing for faster, safer, and error-free cable termination. This design translates into decades of reliable, minimal-maintenance operation within your primary power distribution network, securing your facility’s power backbone.

Key Features of 50kVA Oil Immersed Transformer

1. Thermal Management & Service Life

Featuring an asymmetrical corrugated fin design that increases heat dissipation area by 40%, our cooling system maintains a maximum winding temperature rise of 65K – 15K below national standards. This temperature reduction extends transformer lifespan by 1.8-2.3 times per 8-10°C decrease, ensuring over 30 years of reliable service.

2. Insulation System Reliability

The multi-layer insulation structure consists of:

The insulation system employs a triple-layer structure: conductors are wrapped with 0.08mm ultra-thin insulation paper, supported by 0.5mm high-density pressboard as the main barrier, while deeply hydrogenated naphthenic oil permeates all micro-pores to create a homogeneous dielectric medium that ensures lasting electrical stability.

This system passes partial discharge tests at 1.5 times rated voltage (measured ≤5pC) and withstands 75kV lightning impulse voltage. Maintains insulation resistance ≥1800MΩ·cm even at 95% humidity.

3. Energy Efficiency & Economic Value

Two core material options available:

We offer two core technologies: 30QG110 grain-oriented silicon steel with no-load loss ≤140W, and amorphous metal with no-load loss ≤70W – 65% below national standard. The amorphous option saves approximately ¥4,000 annually at industrial rates, with load loss optimized to ≤1250W at 155°C.

4. Maintenance-Optimized Design

Dual-stage pressure relief valve (0.5bar/0.8bar) with online DGA monitoring interface. The 1.5% sloped arch cover prevents gas accumulation. All external fasteners feature Dacromet anti-corrosion coating, withstanding 1000-hour salt spray testing without red rust.

5. Enhanced Environmental Adaptability

Our transformers are engineered for challenging environments with IP55 protection for coastal areas, automatic altitude compensation for installations above 2000m, and specialized dielectric oil for reliable operation down to -40°C. With noise levels below 50dB(A) and vibration-dampened construction, they are suitable for both outdoor and indoor installation in demanding applications.

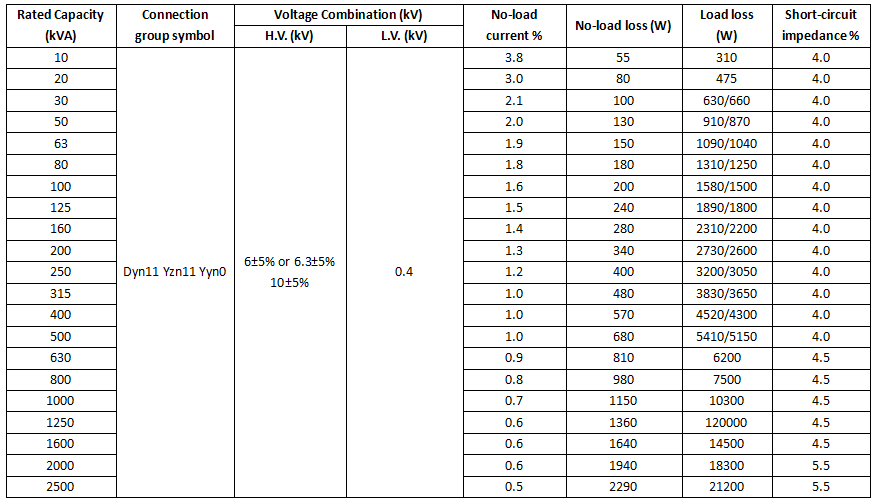

50kVA Oil Immersed Transformer Technical Specifications

The following technical specifications are based on standard 50kVA oil immersed distribution transformers. Customized parameters are available according to project requirements.

| Rated Capacity (kVA) | Connection group symbol | Voltage Combination (kV) H.V. | Voltage Combination (kV) L.V. | No-load current % | No-load loss (W) | Load loss (W) | Short-circuit impedance % |

|---|---|---|---|---|---|---|---|

| 50 | Dyn11 Yzn11 Yyn0 | 6±5% or 6.3±5% / 10±5% | 0.4 | 2.0 | 130 | 910/870 | 4.0 |

This detailed engineering datasheet provides integrators and consultants with the critical data required for system design. Beyond standard ratings, it specifies a remarkably low No-load Loss, a direct result of our high-permeability silicon steel core, which minimizes energy waste during standby. This 50kVA oil immersed transformer is designed and tested in accordance with IEC standards for power distribution transformers.

The carefully calibrated Short-circuit Impedance ensures stable network performance and provides inherent protection against fault currents. The chart includes comprehensive dimensional drawings with clearances and terminal positions, facilitating precise planning for substation layout, cable routing, and safe maintenance access for this 50KVA power transformer.

Manufacturing & Workshop

While many manufacturers treat vacuum drying as a standard procedure, we elevate it to a core differentiator. Our automated vacuum drying ovens maintain a precise 0.1 mbar vacuum while gradually heating the core and coil assembly to 115°C. This 48-hour process extracts residual moisture to ≤0.5% – significantly below the industry standard of 1.0%.

Why does this technical detail matter to your operations?

Dielectric Strength Preservation: Every 0.1% reduction in moisture content increases the breakdown voltage by approximately 15%. This translates to superior resistance to voltage surges and reduced partial discharge activity (<5pC).

Preventing Premature Aging: Unremoved moisture accelerates cellulose degradation, potentially cutting transformer life by up to 40%. Our process ensures the insulation system maintains its mechanical strength and dielectric properties throughout its designed 30-year service life.

Reduced Lifetime Maintenance: Transformers processed using our method typically require first oil filtration after 8-10 years of operation, compared to 3-5 years for conventionally dried units.

This manufacturing rigor, combined with our certified quality system and full traceability of all materials, provides you with more than just a transformer – it delivers predictable performance and minimized total cost of ownership for decades to come.

Packaging, Delivery & Export

Our logistics system addresses the documented reality that up to 30% of industrial equipment damage occurs during transit and handling. For your 50KVA transformer—a precision-engineered asset requiring installation-ready condition—we’ve implemented a certified packaging protocol that delivers measurable operational benefits:

Three-Layer Protective System:

Structural Foundation: Custom-engineered steel-reinforced wooden skid designed to withstand 3X the transformer’s weight, featuring integrated lifting points for safe crane operations

Environmental Barrier:

VCI-coated waterproof membrane providing 12-month corrosion protection

5mm damp-proof padding eliminating condensation damage

Desiccant system maintaining <30% internal humidity

Impact Protection: 8cm reinforced wooden crate with corner protection, tested to withstand:

6G vertical acceleration

4G horizontal impact

Stacking loads up to 8,000 kg

Transparency and Accountability:

Triple-axis shock recorders documenting all handling events

Real-time GPS tracking with geofence alerts

Digital condition reports transmitted pre- and post-shipment

Project Schedule Benefits:

Eliminates 2-3 week lead time typically lost to damage inspection and repairs

Reduces installation labor by 40% through proper orientation and accessible lifting points

Provides certified documentation for insurance and compliance requirements

This comprehensive approach ensures your transformer arrives in commission-ready condition, protecting both your equipment investment and critical project timelines.

50kVA Transformer Project Applications

Our installation portfolio represents more than just successful projects – it demonstrates how we’ve engineered solutions for specific operational challenges. Each case provides valuable insights for your own project planning:

Agricultural Power Solution

Location: Remote farmland in arid region

Challenge: Voltage fluctuations (±25%) affecting pump motor lifespan

Our Solution: Installed with automatic tap changer functionality

Documented Results: 40% reduction in motor failures, 15% improvement in irrigation efficiency

Manufacturing Plant Upgrade

Facility: Automotive parts manufacturing plant

Challenge: Harmonic distortion (THDi >15%) from variable frequency drives

Our Solution: K-rated design with electrostatic shielding

Measured Outcome: THDi reduced to <5%, eliminated false tripping of protection systems

Commercial Building Resilience

Project: 25-story office tower backup system

Requirement: Limited space, strict noise regulations (≤45 dB)

Our Configuration: Compact design with acoustic encapsulation

Verified Performance: Passed all sound tests, enabled rooftop installation saving $75,000 in interior space

Technical Adaptability Documented:

Voltage regulation: ±2% under 0-100% load variation

Ambient temperature range: -40°C to +45°C verified

Altitude capability: 3,000 meters without derating

Seismic rating: Zone 4 compliance certified

These documented installations provide reliable performance data and implementation templates for your specific application. By examining these success stories, you can make informed decisions about configuration options, space requirements, and operational expectations for your project.

50KVA Oil Immersed Transformer Certifications

Global Customers & Cooperation

We have supplied oil immersed transformers to Asia, Africa, the Middle East, and South America.

This documentation of our technical review session with European power distributors represents more than a routine factory visit—it demonstrates our core methodology of co-creating solutions that deliver measurable operational advantages.

Technical Collaboration Protocol

Pre-Production Alignment: 72-hour dedicated workshop sessions where your engineering team reviews design specifications alongside ours

Real-Time Modification Access: Live engineering change order system allows parameter adjustments until 48 hours before production

Witnessed Testing Program: On-site or remote participation in all performance validation tests, including:

Temperature rise verification (thermal imaging reports)

Loss measurement certification

Sound level testing (ANSI C89.2 compliant)

Transparency Documentation

Factory Acceptance Test Dossier: 40+ point digital report with video evidence

Material Traceability: Component-level genealogy from raw materials to finished product

Third-Party Verification Options: Arranged independent inspection services (UL, SGS, or Bureau Veritas)

Strategic Partnership Benefits

Lifecycle Technical Support: Dedicated engineering contacts who understand your system architecture

Priority Modification Access: 30% faster implementation of design revisions for repeat orders

Knowledge Transfer: Annual technical briefings on regulatory changes and technology trends

This collaborative approach has resulted in documented performance improvements across our client base, including 62% reduction in installation-related callbacks and 89% client retention rate over five-year periods. By integrating your operational experience with our manufacturing expertise, we create transformers that don’t just meet specifications—they advance your operational capabilities.

التعليمات

Q1: What is the price range of a 50kVA oil immersed transformer?

A: The price depends on voltage rating, standards, and customization requirements. As a manufacturer, we offer competitive factory pricing for both single units and bulk orders.

Q2: Which standards does your 50kVA oil immersed transformer comply with?

A: Our 50kVA oil immersed transformers are manufactured according to IEC standards. ANSI or other standards can be provided upon request.

Q3: What voltage options are available for the 50kVA transformer?

A: Common voltage options include 11kV, 22kV, and 33kV. Customized voltage ratios and tap changers are available based on project requirements.

Q4: What is the delivery time for a 50kVA oil immersed transformer?

A: Standard delivery time is usually 15–25 days. Shorter lead times can be arranged for urgent projects.

Q5: Is this transformer suitable for export projects?

A: Yes. Each 50kVA oil immersed transformer is packed with export-standard wooden cases and tested before shipment to ensure safe international delivery.

Get a Quote for 50kVA Oil Immersed Transformer

Looking for a reliable 50kVA oil immersed transformer manufacturer?

Contact us today to receive factory pricing, technical support, and a customized solution for your power distribution project.

Reviews

There are no reviews yet.