Description

We are a professional supplier ل 160KVA European Box Substation. Our prefabricated substations integrate transformers, MV switchgear, and LV distribution panels. We provide factory-tested, customizable solutions for industrial, utility, and renewable energy projects. Each unit undergoes strict quality inspection to ensure safe and reliable operation. This page is a direct transaction page for buyers seeking European Box Substations for immediate project needs.

160KVA European Box Type Substation Overview

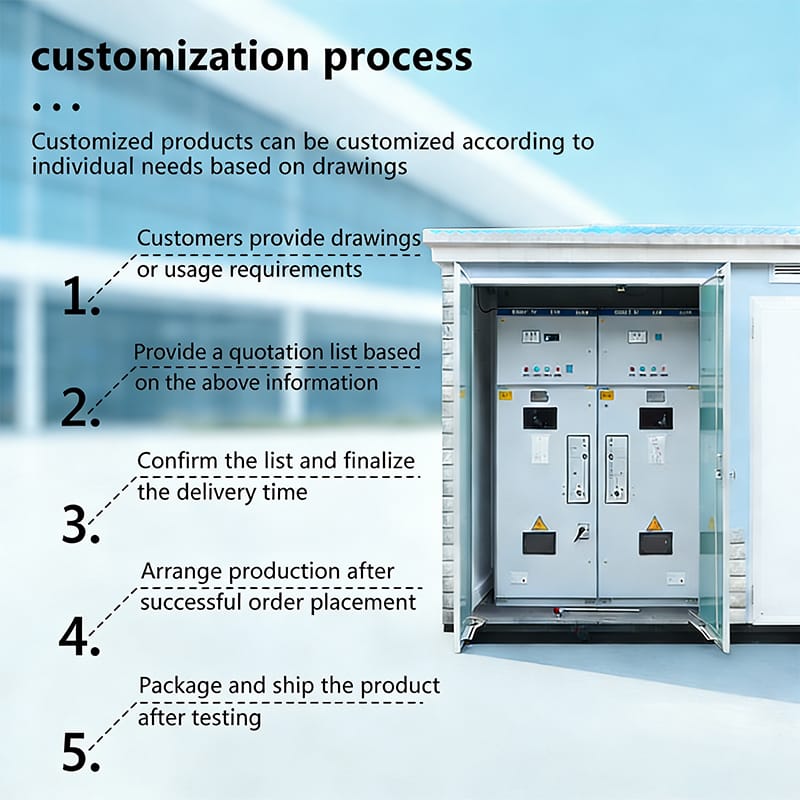

Customization Process of 160KVA European Box Type Substation

Every power project has unique technical and site-specific requirements. To accommodate this, the European Box Type Substation is designed with a clear and structured customization process.

Customers typically approach us with drawings, single-line diagrams, or application specifications. Using this information, our engineering team develops a detailed quotation and configuration proposal. Once the technical solution and delivery timeline are confirmed, we proceed with factory production. Each unit undergoes comprehensive testing before being packaged and shipped.

This tailored approach helps prevent specification mismatches and ensures the 160KVA European Box Type Substation meets local grid regulations, voltage parameters, and protection standards.

Customization Workflow Overview

| Step | Description |

|---|---|

| Requirement Input | Customer provides drawings or operating requirements |

| Technical Proposal | Configuration and solution are prepared |

| Quotation | Detailed quotation list is issued |

| Confirmation | Final specifications and delivery time confirmed |

| Production | Manufacturing arranged after order placement |

| Testing & Shipment | Factory testing, packaging, and delivery |

European Box Type Substation in Global Renewable Energy and Utility Projects

Real-world engineering applications clearly demonstrate the adaptability and performance of European Box Type Substations across diverse grid conditions. Documented project cases span photovoltaic power plants, onshore wind farms, and regional grid integration stations in various regions, including Europe and North America.

In renewable energy installations, the 160KVA European Box Type Substation frequently serves as a centralized unit for power collection, transformation, and safe grid interconnection. Its prefabricated, compact design enables project developers to accelerate commissioning timelines, significantly reduce on-site assembly work, and minimize coordination complexities during construction.

These practical cases confirm that the European Box Type Substation is engineered for reliable, long-term operation. It consistently meets performance requirements under a range of climatic conditions—from extreme temperatures to high humidity—and complies with varied regional grid codes and protection standards. The design ensures stability and durability, supporting continuous power distribution in demanding environments over its service life.

Typical Project Applications

| Project Type | Application Purpose |

|---|---|

| Photovoltaic Power Plant | Power collection and grid connection |

| Wind Power Project | Step-up and distribution for turbines |

| Utility Substation | Local power distribution support |

| Industrial Facility | Stable medium and low voltage supply |

Why Choose Us as Your European Box Type Substation Supplier

Choosing the right supplier directly impacts project safety, cost control, and long-term operation. We focus on delivering reliable European Box Type Substations for industrial and energy projects worldwide.

Proven Manufacturing Experience

We bring years of experience in manufacturing box-type transformers and prefabricated substations. Our production team follows standardized procedures to ensure stable and repeatable quality. Independent workshops allow strict control over materials, assembly, and delivery schedules.

Strong Engineering and Customization Capability

Our R&D engineers actively support technical design and solution optimization. We customize European Box Type Substations based on drawings and usage requirements. Engineering reviews help reduce mismatches between design and site conditions.

Quality Assurance and Compliance

We apply strict quality control throughout production and testing. Each substation undergoes factory testing before shipment. Qualification certifications support compliance with international standards and project approvals.

Professional After-Sales and Project Support

Our technical team supports installation and commissioning activities. We provide timely responses for operation and maintenance questions. Overseas project support helps customers reduce long-term operational risks.

Supplier Capability Overview

| Capability | Customer Benefit |

|---|---|

| Manufacturing Experience | Stable quality and proven designs |

| R&D Team | Technical support and solution optimization |

| Customization Service | Project-specific configurations |

| Independent Workshop | Quality control and delivery reliability |

| Certification | Compliance with international standards |

| After-Sales Support | Long-term operational assistance |

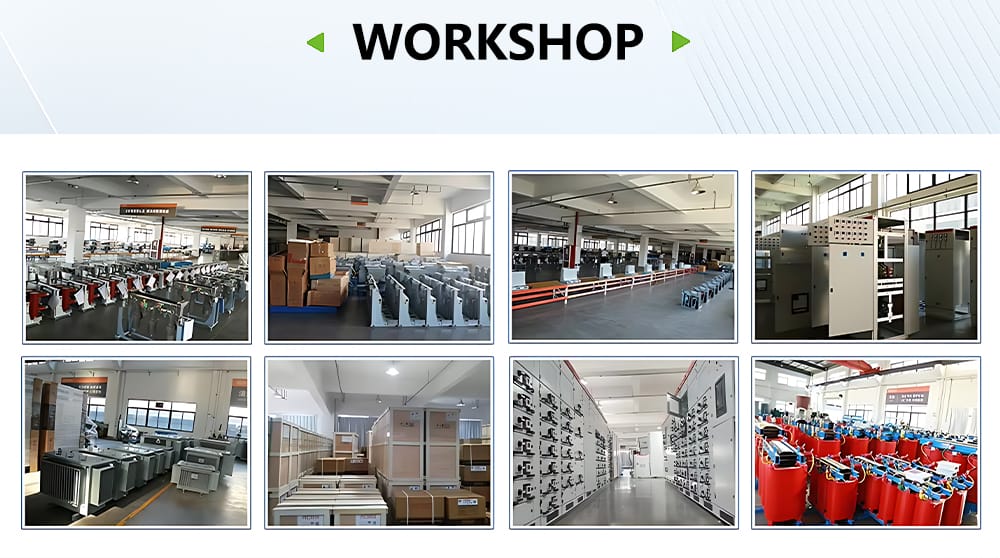

Manufacturing Quality of 160KVA European Box Type Substations

Manufacturing quality defines the performance of a European Box Type Substation.

Reliable production ensures stable operation in medium and low voltage distribution systems. We manufacture European Box Type Substations for industrial, utility, and renewable energy projects.

Dedicated Production Environment

This factory overview shows where European Box Type Substations are produced and assembled. We build box-type transformers and prefabricated substations in controlled production areas. Each production line supports accurate assembly of power distribution equipment.

Standardized Manufacturing Processes

Standardized processes improve consistency across European Box Type Substation production. Production teams follow defined procedures for assembly and wiring.

Process control reduces errors and improves electrical performance.

Quality Control and Internal Inspection

Quality teams perform inspections throughout the manufacturing process. Engineers verify key components used in box-type transformers. Internal checks confirm mechanical strength and insulation reliability.

Independent Workshops and Production Control

Independent workshops support flexible European Box Type Substation manufacturing. Teams manage component assembly, enclosure integration, and system wiring in-house. Close process control improves delivery accuracy and product stability.

Factory Testing and Performance Verification

Factory testing confirms European Box Type Substation operational performance. Testing verifies protection functions and electrical parameters. Verified substations reduce risks during installation and commissioning.

Long-Term Supplier Capability for Buyers

Factory capability indicates long-term European Box Type Substation supply reliability. Strong manufacturing supports repeat orders and project expansion needs.

Buyers prefer suppliers with proven prefabricated substation production capacity.

| Area | Purpose |

|---|---|

| Assembly Line | Accurate integration of MV, transformer, and LV systems |

| Quality Control | Inspection during each production stage |

| Testing Area | Electrical and functional verification |

| Packaging Area | Protection for long-distance transportation |

160KVA European Box Type Substation Project Cooperation with International Clients

This image reflects real cooperation between our team and international clients. Direct communication helps avoid misunderstandings and ensures technical requirements are clearly defined before production.

For buyers searching for a European Box Type Substation supplier, real cooperation experience indicates reliability and business transparency.

Packaging and Delivery of European Box Type Substations

Packaging and delivery are critical for heavy electrical equipment like European Box Type Substations. Safe and reliable shipment ensures the substation arrives ready for installation. Proper packaging protects transformers, medium voltage switchgear, and low voltage panels.

Comprehensive Quality Inspection

Each 160KVA European Box Type Substation undergoes 100% factory inspection before packaging. Engineers check electrical performance, insulation resistance, and mechanical integrity. We confirm all components meet design specifications and safety standards. Only verified units proceed to packaging, ensuring minimal risk during transport.

Protective Packaging Methods

We apply customized protective packaging for prefabricated substations and box-type transformers. Protective measures include shockproof padding, moisture-proof wrapping, and secure fixture. Packaging prevents vibrations, impacts, and environmental exposure during long-distance transportation. Special attention is given to outdoor enclosures and sensitive electrical components.

Efficient Logistics Planning

Our logistics team plans shipment according to substation weight, size, and destination. Transport methods include container shipment, flatbed trucks, or specialized carriers. We schedule delivery to align with project installation timelines. Tracking and coordination ensure European Box Type Substations reach sites on time.

Overseas and Industrial Project Support

For international clients, we manage customs documentation and export compliance. We provide guidance for safe unloading and handling at project locations.

Our team coordinates with site engineers to reduce installation delays and minimize risks. Reliable delivery ensures industrial, renewable energy, and utility projects start on schedule.

Supplier Reliability and Buyer Confidence

Buyers rely on suppliers who control both packaging and delivery. Well-managed shipment reduces potential damage, project delays, and operational risks. Our structured process demonstrates professionalism and long-term capability. Choosing a supplier with proven packaging and delivery expertise ensures project success.

Delivery Process Overview

| Stage | Description |

|---|---|

| Inquiry | Customer sends project request |

| Contact | Technical and commercial communication |

| Production | Manufacturing based on confirmed specs |

| Quality Inspection | 100% factory testing |

| Packaging | Protective packing for transport |

| Delivery | Shipment to customer site |

Certified European Box Type Substation

Certifications are essential for European Box Type Substations used in utility, industrial, and renewable energy projects. Certification confirms that the product meets safety, quality, and regulatory requirements.

Certified substations reduce approval risks and simplify project acceptance. For EPC contractors and project owners, certification is often a mandatory requirement when selecting a transformer or prefabricated substation.

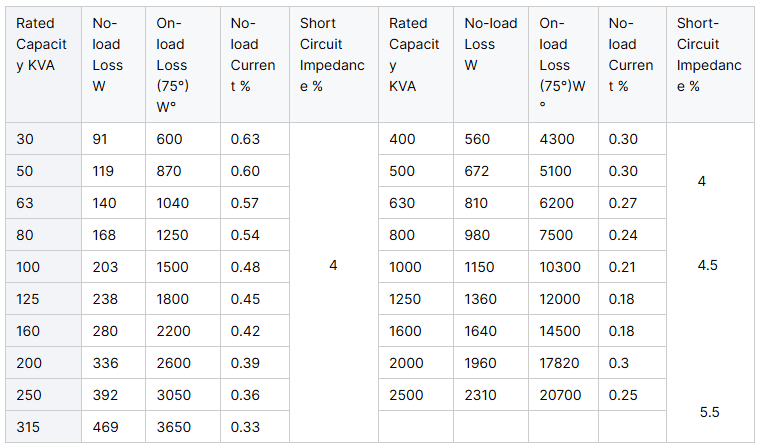

Technical Specifications of 160KVA European Box Type Substation

This 160KVA European Box Type Substation provides stable medium and low voltage power. Rated capacity ensures reliable supply for industrial, commercial, and renewable energy projects. No-load loss and on-load loss indicate high energy efficiency during operation. No-load current is low, reducing unnecessary energy consumption and maintaining stability. Short-circuit impedance ensures proper coordination with protective devices and safe operation. These specifications help engineers and project owners plan installation and evaluate performance.

التعليمات

Q1: What applications suit the 160KVA European Box Substation?

A1: It suits industrial facilities, renewable energy plants, commercial buildings, and utility distribution networks.

Q2: Can you customize the substation according to project requirements?

A2: Yes. We provide customization based on drawings, voltage levels, and protection schemes.

Q3: How do you ensure quality and reliability?

A3: Each substation undergoes 100% factory testing, quality inspections, and compliance with international certifications.

Q4: Do you support overseas delivery and installation?

A4: Yes. We manage logistics, packaging, and provide guidance for safe shipment and installation at project sites.

Q5: What is the lead time for a 160KVA European Box Substation?

A5: Typical delivery time depends on customization, usually within 6–10 weeks after order confirmation.

Get Your 160KVA European Box Substation Today

Contact our engineering team to discuss specifications, request a quotation, or arrange a factory inspection.

We provide professional solutions and fast delivery for industrial and renewable energy projects worldwide.

Reviews

There are no reviews yet.