Description

1600KVA Dry Type Transformer

Our flagship 1600KVA Dry Type Transformer is presented here in its full operational readiness. This primary image is designed to instill confidence, showcasing the transformer’s professional, industrial-grade aesthetic.

The robust, low-profile enclosure is constructed from high-quality, corrosion-resistant materials, ensuring longevity even in demanding environments. The clearly marked and well-organized terminal panels for both high and low voltage demonstrate our commitment to safety and ease of installation and maintenance.

The monolithic design emphasizes structural integrity, minimizing vibration and noise—a key advantage over liquid-filled units. This 1600KVA model is the cornerstone of modern power distribution systems, providing a safe, reliable, and eco-friendly solution for data centers, hospitals, high-rise buildings, and industrial complexes where fire safety and minimal environmental impact are paramount.

Product Details

This detailed visualization delves into the engineering excellence that defines our 1600KVA Dry Type Transformer. At its heart lies the high-gauge, low-loss silicon steel sheet iron core, meticulously layered and annealed to create a highly efficient magnetic circuit, significantly reducing no-load losses and operational costs.

ال high-voltage and low-voltage windings are crafted from oxygen-free copper or electrical aluminum, chosen for superior conductivity, and are completely encapsulated in a vacuum-pressure-cast resin. This process makes the windings impervious to moisture, dust, and corrosive contaminants, guaranteeing exceptional dielectric strength and thermal stability.

Robust insulators and terminals provide secure, safe connections, while heavy-duty transformer clips and bracing ensure the core and coil assembly remains immovable under short-circuit stresses, guaranteeing mechanical robustness and a long service life. This attention to detail is what sets our dry-type transformers apart.

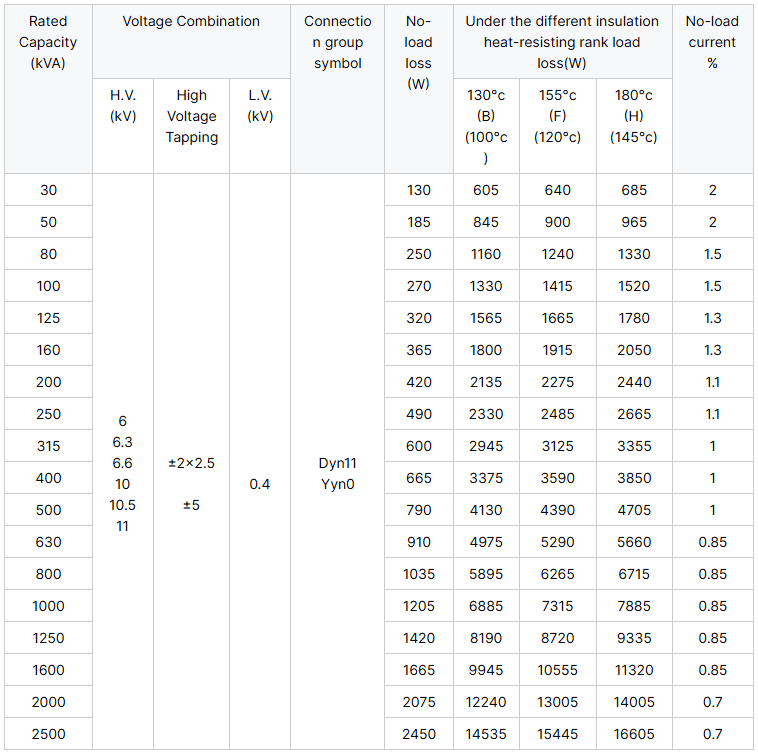

1600KVA Dry Type Transformer Parameters

Product Line

Quality is manufactured, not inspected. This collage offers a transparent look into our state-of-the-art production for the 1600KVA Dry Type Transformer.

Witness the stages of precision: from the automated, computer-controlled winding of coils to ensure consistency and eliminate human error; to the critical vacuum pressure gelation (VPG) process where coils are impregnated with resin under a perfect vacuum to eliminate any air pockets, ensuring partial discharge-free performance; to the computer-controlled curing ovens that solidify the resin with exact temperature profiles for ultimate mechanical and dielectric strength.

Finally, see the meticulous assembly where the core and coils are integrated into the enclosure by skilled technicians. This end-to-end control over manufacturing is what allows us to consistently deliver reliable and high-performance transformers.

Our Factory

Our manufacturing facility is the foundation of our product’s reliability. This panoramic showcase highlights the scale and capability behind every 1600KVA Dry Type Transformer we produce.

The images depict a clean, organized, and technologically advanced environment—a necessity for building high-voltage electrical equipment. You can see vast assembly bays with overhead cranes capable of handling large units, dedicated testing areas equipped with sophisticated diagnostic equipment (like impulse testers and power analyzers), and organized storage for raw materials.

We uphold a professional manufacturing ecosystem and apply strict 5S methodology, ensuring every transformer—from the smallest to our 1600KVA models—meets the same exacting standards of quality, safety, and performance.

Packaging & Shipping

We manage the journey of our 1600KVA Dry Type Transformer from factory to site with the same care as production. This image demonstrates our robust, export-ready packaging protocol.

We securely mount the transformer onto a heavy-duty, reinforced wooden skid base to ensure stable lifting and transport. We then enclose it in sturdy wooden crates to shield it from impacts and handling hazards. For international sea freight, we employ waterproof and moisture-proof wrapping materials, including desiccant bags inside the enclosure, to prevent corrosion from salty, humid air during transit.

We securely fasten all components to prevent any movement during transportation. This meticulous process guarantees that your investment arrives on-site in perfect, factory-fresh condition, ready for installation.

1600KVA Dry Type Transformer Certifications

Global Cooperation

التعليمات

Q1.Do you have MOQ?

The parties can reach the final agreement through negotiation, taking into account different perspectives. The larger the quantity is, the competitive the unit price will be.

Q2.Should the customer pay the delivery fee , How much is it?

We charge a delivery fee, or you provide your express account or cover the shipping cost. If you do not request, I will choose a cheap one in China.

Q3.How about the after sale service?

1)We always match the buyer’s sample quality and compensate if any quality issue occurs.

2)We will suggest our packing and take charge in our packing, we will keep the goods safe in the delivery.

3)We track goods from production to sale and resolve any issues customers face during the selling process.

Q4.When can I get a price?

We usually quote within 24 hours after we get your inquiry.

Q5: Are you a trade company or manufacturer?

We are a professional manufacturer with our own factory.

Reviews

There are no reviews yet.