Description

We are a professional manufacturer and supplier of 1250KVA Pad Mounted Substations. This product page introduces our three-phase, American style pad mounted substation designed for outdoor power distribution. The 1250KVA Pad Mounted Substation integrates transformer and switchgear into a compact, fully enclosed unit, suitable for utility, industrial, commercial, and renewable energy projects. This is a commercial product page for buyers seeking reliable supply, customization, and factory-direct pricing.

1250KVA Pad Mounted Substation Overview

This image illustrates the complete structure of a 1250kVA pad-mounted substation designed for three-phase power distribution. This fully enclosed, American-style design integrates the transformer, high-voltage switchgear, and low-voltage distribution components into a single compact unit.

The compact layout resembles a small, grounded enclosure often referred to as a “prefabricated” or “pad-mounted” substation. This all-in-one design eliminates the need for traditional brick-and-mortar switch rooms, allowing for quick installation and a significantly smaller footprint.

A key advantage of this design is its enhanced safety. The fully sealed enclosure effectively prevents accidental contact with live internal parts. It also provides protection against dust, moisture, and harsh outdoor weather conditions.

In practical applications, this type of substation is highly versatile. It is a common sight in urban distribution networks, frequently installed in residential communities, along streets, or in commercial districts. It is also widely used to supply power—whether temporary or permanent—to industrial parks and large construction sites. Furthermore, with the growth of renewable energy, it often serves as the grid connection point for solar farms or wind power plants, stepping up the generated clean electricity for grid integration.

In summary, this 1250kVA pad-mounted substation represents a complete, safe, and reliable outdoor power distribution solution that combines essential electrical equipment into one robust enclosure.

1250KVA Pad Mounted Substation Deatails

These detailed images clearly showcase the enclosure construction, internal layout, and component installation of the 1250kVA pad-mounted substation. The images reveal key manufacturing details. We can see the robust steel enclosure, which provides structural integrity and environmental protection. The internal arrangement logically groups components, ensuring clear and safe access. The images also demonstrate precise component installation, highlighting quality workmanship.

A standout feature is the clear physical separation between the high-voltage and low-voltage compartments. This design actively enhances operational safety by containing risks and prevents accidental contact. It also significantly improves maintenance convenience, allowing technicians to service one side without exposure to the other.

These specific, practical details confirm that this unit represents a finished, production-ready product. They reflect genuine manufacturing capability and rigorous quality control, moving beyond mere conceptual design to demonstrate a solution built for reliable, long-term field operation.

Key Features of 1250KVA Pad Mounted Substation

This 1250kVA Pad-Mounted Substation is designed around six core advantages that deliver reliable, adaptable, and efficient performance in medium-voltage power distribution.

1. COMBINATION IS CONVENIENT

The integrated, all-in-one design combines the transformer, high-voltage switchgear, and low-voltage distribution panel into a single compact enclosure. This prefabricated approach eliminates complex on-site assembly, reduces installation time, and simplifies project planning. It provides a true “plug-and-play” solution that arrives ready for connection.

2. STABILITY IS GOOD

Engineered for robust performance, the substation ensures exceptional operational stability. It maintains steady voltage output, handles load fluctuations reliably, and is built with high-quality components to withstand thermal and electrical stresses, ensuring long-term, trouble-free service.

3. NOVEL STRUCTURE

Featuring a modern, fully enclosed American-style design, its structure optimizes space, safety, and cooling. The layout strategically separates high and low-voltage compartments, enhances accessibility for maintenance, and utilizes durable, corrosion-resistant materials for extended outdoor life.

4. FLEXIBLE ELECTRICAL SCHEME

The substation supports a wide range of customizable electrical configurations. It can be adapted for various incoming supply arrangements (ring-main, radial feed) and outgoing distribution schemes to meet specific requirements of utilities, industrial parks, commercial complexes, or renewable energy plants.

5. HIGH BREAKING ABILITY

Equipped with advanced, internally mounted switchgear (such as vacuum interrupters or SF6 technology), the unit possesses a high short-circuit breaking capacity. This ensures it can safely and swiftly isolate fault currents, protecting both the substation itself and the broader electrical network from damage.

6. STRONG PRACTICABILITY

This substation excels in real-world application. Its compact footprint saves valuable space, the rugged enclosure requires minimal maintenance, and its proven design ensures compatibility with diverse grid environments—from dense urban areas to remote industrial or renewable project sites.

In summary, this substation successfully merges convenience, stability, and innovation with flexibility, protection, and rugged practicality, making it an outstanding solution for modern power distribution challenges.

Typical Application Scenarios

Utility Power Distribution Networks

Utility companies install 1250KVA Pad Mounted Substations in residential and urban distribution networks to step down medium voltage power safely and efficiently. The enclosed structure improves public safety and reduces maintenance requirements in populated areas.

Industrial Plants and Manufacturing Facilities

Factories and industrial plants use 1250KVA Pad Mounted Substations to supply stable three-phase power for heavy equipment, production lines, and motors. The high capacity supports continuous operation while the compact design saves valuable installation space inside or near industrial sites.

Commercial and Infrastructure Projects

Commercial complexes, data centers, transportation facilities, and public infrastructure projects choose 1250KVA Pad Mounted Substations for reliable outdoor power distribution. The low-profile design integrates easily into urban environments without affecting site planning.

Renewable Energy Projects

Solar and wind power projects use 1250KVA Pad Mounted Substations to step down generated power and connect to distribution grids. The flexible electrical scheme supports varying voltage levels and ensures stable operation under fluctuating loads.

Mining, Oil & Gas, and Remote Areas

In mining sites, oil & gas facilities, and remote areas, engineers install 1250KVA Pad Mounted Substations for their robust structure and outdoor durability. The pad mounted design allows fast deployment and reliable operation in harsh environments.

Temporary or Expanding Power Systems

Projects with phased construction or future expansion select 1250KVA Pad Mounted Substations because the integrated structure simplifies relocation, upgrade, or system expansion when power demand increases.

| Application Area | Why Use 1250KVA Pad Mounted Substation |

|---|---|

| Utility Distribution | Safe outdoor installation with compact footprint |

| Industrial Plants | Stable three-phase power for heavy loads |

| Renewable Energy | Suitable for solar and wind power step-down |

| Commercial Zones | Low noise and enclosed safety design |

| Urban Infrastructure | Minimal space requirement |

Why Choose Us as Your Supplier

This image demonstrates why we are your trusted partner for Pad-Mounted Substations. Each technical advantage is backed by our comprehensive supply chain and service commitment, forged through extensive experience in global power projects.

1. COMBINATION IS CONVENIENT – Supported by Honest Descriptions & Fast Delivery

Our fully integrated, combined structure offers ultimate convenience. We provide clear, accurate product specifications—what you see is precisely what you get. This transparency, combined with our streamlined original factory production, enables fast and reliable delivery of a complete, ready-to-install solution, reducing your project timeline and complexity.

2. STABILITY IS GOOD – Backed by Original Factory Quality & Experience

The operational stability of our substation is a direct result of in-house manufacturing control and long-term global project experience. We oversee every production stage, using proven designs and premium materials to ensure a product that delivers consistent, reliable performance in diverse environments for years to come.

3. NOVEL STRUCTURE – Engineered with Professional Technical Support

Our innovative, fully enclosed structure optimizes safety and service life. Our team of engineering experts provides professional technical support to tailor this modern design to your specific site conditions and standards, ensuring optimal layout, ventilation, and accessibility.

4. FLEXIBLE ELECTRICAL SCHEME – Customized through Professional Collaboration

We offer flexible electrical schemes because we understand that every project is unique. Our professional technical support team works closely with you from the design phase to customize the high-voltage switching and low-voltage distribution layout, ensuring the perfect fit for your application, whether utility, industrial, or renewable energy.

5. HIGH BREAKING ABILITY – Assured by Original Factory Integrity

The high breaking capacity of our switchgear is guaranteed through strict original factory manufacturing and testing. We use certified, high-performance components and adhere to rigorous quality protocols. Our honest product descriptions accurately report these performance ratings, giving you absolute confidence in the equipment’s protective capabilities.

6. STRONG PRACTICABILITY – Proven by Global Project Experience

The strong practicality of our substation—its durability, low maintenance, and space efficiency—is not just a claim. It is proven and refined through our long-term experience supplying equipment for global projects. We have validated its performance across different climates and grid demands, ensuring a solution that works reliably in the real world.

In essence, when you choose us, you select more than just a product with superior features. You gain a reliable partner who ensures these features are delivered through honest communication, controlled manufacturing, expert customization, and proven global expertise—all dedicated to the success of your project.

Global Cooperation

This image shows real communication between our team and overseas clients. It represents actual cooperation on pad mounted substation projects rather than marketing material. Such experience helps us understand different technical standards, project requirements, and delivery expectations.

Certifications and Standards

The certification image demonstrates that our 1250KVA Pad Mounted Substation complies with relevant industry standards. Certifications support safe operation, quality control, and acceptance in international power distribution projects.

Factory Production Capability

This image offers a direct view into our in-house production and assembly facilities for pad-mounted substations. It captures more than just a manufacturing process; it showcases the core of our commitment to quality, reliability, and partnership.

1. End-to-End Quality Control

Unlike outsourced assembly, our controlled, in-house manufacturing allows us to oversee every critical stage—from material inspection and precision fabrication to electrical assembly and comprehensive testing. This vertical integration is the foundation of our stable, consistent product quality. We ensure that every component and every weld meets our stringent standards before it leaves our factory floor.

2. Engineered for Flexibility & Customization

Our production line is designed for adaptability. The image illustrates how we can efficiently tailor designs to meet specific project requirements, whether adjusting busbar layouts, integrating unique switchgear, or accommodating special safety features. Flexible customization is not an exception here; it is a standard part of our process, enabling us to deliver solutions that fit your exact technical and site specifications.

3. Guaranteed Reliability for Project Planning

For large-scale rollouts or urgent project timelines, control over production is paramount. This internal capability gives us direct command over our production schedule. We can allocate resources, prioritize workflows, and expedite without relying on external suppliers, allowing us to provide reliable, predictable lead times you can confidently build your project schedule around.

4. The Tangible Outcome: A Superior Product

The result of this controlled environment is a substation built with integrity. It translates to robust construction, precise internal layout, and reliable long-term performance. What you see in this image is the assurance that your equipment is crafted with expertise, traceability, and a singular focus on durability and safety.

In summary, this factory scene represents our core promise: complete control over the entire build process to deliver a product of uncompromising quality, tailored to your needs, and delivered on a schedule you can trust. This is how we transform standard components into reliable power distribution solutions for critical infrastructure projects worldwide.

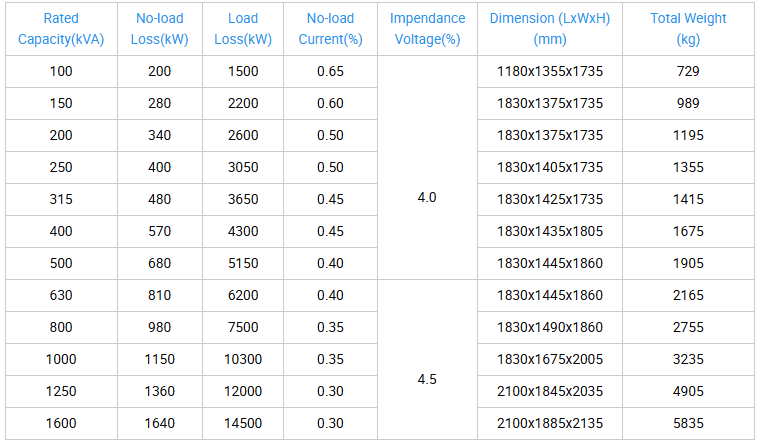

Technical Specifications

This image clearly presents the key technical parameters essential for system evaluation and procurement. It serves as a critical reference point, providing engineers and buyers with the objective data needed to make confident, informed decisions.

1. Foundation for System Compatibility Assessment

The detailed specifications—such as rated power (1250kVA), voltage levels (HV/LV), impedance, frequency, and insulation class—enable precise technical vetting. Engineers can systematically verify grid compatibility, load-matching, protective device coordination, and compliance with local standards, ensuring seamless integration into the existing electrical network.

2. Enabling Accurate Comparative Analysis

Transparent, standardized technical data allows for a fair and objective comparison between different suppliers or models. Key performance indicators like loss values (no-load/load loss), sound level, temperature rise limits, and short-circuit withstand capacity can be directly evaluated, moving the selection process beyond marketing claims to a fact-based assessment of efficiency, reliability, and total cost of ownership.

3. Reducing Project Risk and Streamlining Procurement

By providing complete and accessible technical information upfront, we help eliminate uncertainties that can lead to costly design revisions, installation delays, or performance shortfalls. This transparency builds trust, accelerates the approval and tendering processes, and empowers procurement teams to justify their selection with clear, auditable data.

4. Supporting Long-Term Operational Planning

Beyond initial compatibility, these parameters are vital for lifecycle planning. Data on dimensions, weight, cooling requirements, and maintenance clearances assists in planning site preparation and future service needs. Electrical characteristics inform long-term system stability, loss evaluation, and upgrade potential.

التعليمات

Q1: Where do customers typically use a 1250KVA Pad Mounted Substation?

A: Customers use the 1250KVA Pad Mounted Substation in outdoor power distribution systems such as utility networks, industrial plants, commercial zones, and renewable energy projects. The compact and fully enclosed design allows safe installation close to load centers.

Q2: Can you customize the 1250KVA Pad Mounted Substation for my project?

A: Yes. We customize voltage levels, enclosure structure, protection schemes, and applicable standards based on your project requirements. As a manufacturer, we design and produce the pad mounted substation according to your electrical drawings and site conditions.

Q3: Are you the manufacturer of the 1250KVA Pad Mounted Substation?

A: Yes. We manufacture 1250KVA Pad Mounted Substations in our own factory. We control material selection, assembly, testing, and delivery to ensure stable quality and consistent performance.

Q4: Can this pad mounted substation operate safely outdoors?

A: Yes. We design the 1250KVA Pad Mounted Substation specifically for outdoor installation. The fully enclosed and insulated structure protects internal components from weather, dust, and unauthorized access.

Q5: Which standards can this pad mounted substation comply with?

A: We manufacture the 1250KVA Pad Mounted Substation according to IEC or ANSI standards, depending on project needs. We also support certification and documentation required for international projects.

Q6: How does a 1250KVA pad mounted substation help reduce installation space?

A: The integrated American style design combines transformer and switchgear into one compact unit. This structure significantly reduces footprint compared to traditional substations and simplifies site installation.

Looking for a reliable 1250KVA Pad Mounted Substation supplier?

Contact us today to get technical support, drawings, and a factory-direct quotation for your project.

Reviews

There are no reviews yet.