Description

A 33KV European Box Type Substation is a prefabricated power distribution solution designed for medium-voltage networks. It integrates MV switchgear, transformer, and LV distribution equipment into one compact enclosure, enabling fast deployment and safe operation in outdoor environments.

This type of prefabricated box type substation is widely used in utility grids, industrial facilities, and renewable energy projects where reliability, space efficiency, and installation speed are critical. The European-style enclosed design reduces on-site construction work while supporting long-term, stable power distribution.

What Is a 33KV European Box Type Substation?

When buyers search for a 33KV European Box Type Substation, they are usually facing one of three situations:

a new power project, a grid upgrade, or a capacity expansion.

This product is designed to solve a common problem in medium-voltage power distribution:

how to deliver reliable 33KV power without building a traditional substation from the ground up.

This type of substation follows widely recognized IEC standards for power substations, which define safety, insulation, and operational requirements for medium-voltage systems.

The European box-type design integrates the MV transformer, switching equipment, and protection system into a single prefabricated enclosure. This reduces:

Civil construction complexity

On-site wiring work

Installation time and coordination risk

From an operational view, the substation supports stable performance under continuous load. From a project view, it offers predictable delivery and installation schedules.

Many customers choose this solution because it provides a balance between:

Compact footprint

Operational safety

Long service life

Scalable power capacity

This makes the 33KV European Box Type Substation suitable for industrial facilities, renewable energy projects, and urban power distribution where space and time are limited.

Key Structural Components of a 33kv Prefabricated Box Type Substation

The internal structure of a 33KV European Box Type Substation is not only about layout. It is about risk control during long-term operation.

In daily use, most incidents in substations are related to:

Incorrect operation

Poor separation of voltage levels

Difficult maintenance access

This box-type substation addresses these risks through a strictly separated chamber design.

Internal Chamber Roles and Buyer Benefits

| Internal Area | Engineering Purpose | Practical Benefit |

|---|---|---|

| High-Pressure Chamber | MV switching and protection | Limits fault impact and improves grid safety |

| Transformer Room | Voltage conversion and heat dissipation | Supports stable 33KV operation |

| Low-Pressure Chamber | Power distribution and control | Enables safe downstream power supply |

Each chamber can be accessed independently. This allows maintenance work without shutting down the entire system, which is critical for factories and infrastructure that require continuous power supply.

For buyers, this structure means lower operational risk and easier maintenance planning.

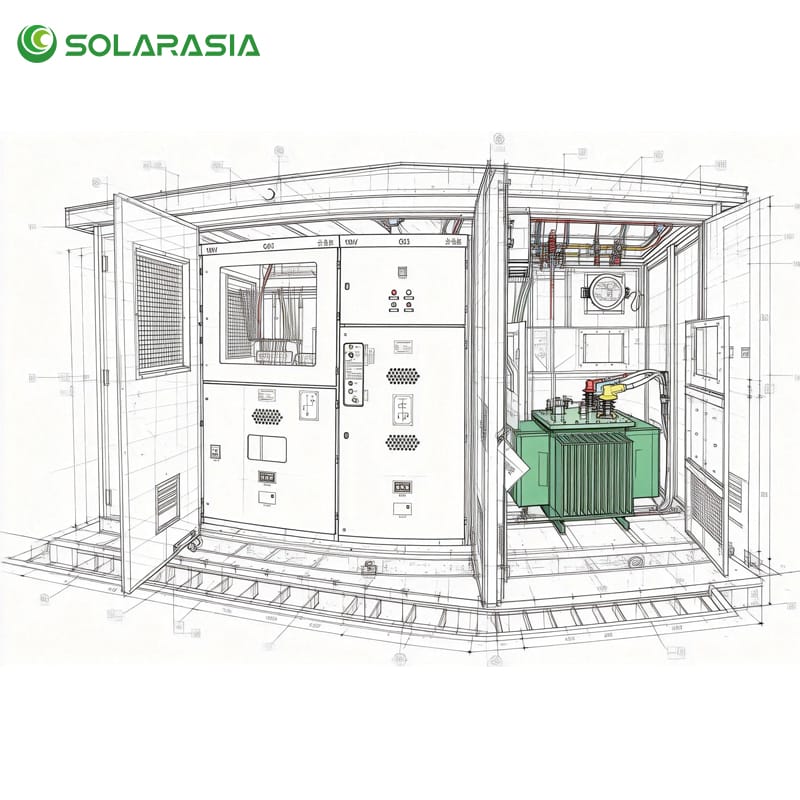

Internal Layout and Design Concept of European Box Substations

Before placing an order, engineers and EPC teams often ask for technical drawings, not brochures. The technical sketch of the 33KV prefabricated box type substation plays a key role in early project decisions.

This drawing helps project teams confirm:

Whether the substation fits the available site space

How cables enter and exit the enclosure

How different voltage levels are physically separated

How ventilation and inspection access are arranged

From an engineering workflow perspective, these drawings support:

Grid connection approval

Safety assessment

Construction planning

They also reduce late-stage design changes, which can cause delays and cost overruns.

For buyers managing complex power projects, a clear and complete technical sketch signals that the supplier understands engineering reality, not just product sales.

33KV Box Type Substation Project Applications and Case Scenarios

Buyers searching for a 33KV box type substation usually have a clear purpose. They are not looking for a generic product; they are looking for a solution to a specific power problem.

This European-style box substation is commonly selected in scenarios where:

Space is limited and traditional substations are impractical

Construction schedules are tight

Power demand is expected to grow over time

On-site maintenance resources are limited

Typical Buyer Scenarios and Decision Logic

| Buyer Situation | Why This Substation Is Chosen |

|---|---|

| New residential or commercial development | Compact design reduces land use |

| Urban grid renovation | Fast replacement with minimal disruption |

| Industrial parks | Reliable medium-voltage supply for heavy loads |

| Temporary or emergency power | Rapid deployment and relocation capability |

These scenarios explain why the prefabricated box type substation is often preferred by developers, utilities, and industrial operators who need predictable performance with lower project risk.

Typical Application Scenarios for 33KV European Box Type Substations

In photovoltaic power projects, the role of the substation is critical. It connects generation units to the grid and ensures stable energy transmission. Our 33KV European Box Type Substation balances compactness, outdoor durability, and electrical stability, making it widely used in PV projects. Many renewable energy and grid connection projects reference renewable energy grid integration guidelines published by international energy organizations.

Solar project owners typically focus on:

Grid connection reliability

Continuous operation under changing weather conditions

Compatibility with inverters and energy storage systems

Reduced on-site installation complexity

This type of substation has been applied in:

Utility-scale ground-mounted solar plants

Distributed rooftop PV systems

Industrial and commercial solar installations

Agricultural and remote-area photovoltaic projects

Medium-voltage substations also play a key role in power infrastructure development for urban and industrial distribution networks.

In renewable energy systems, downtime directly affects energy output. The proven use of this substation in solar applications helps buyers reduce operational uncertainty and meet grid compliance requirements.

Why Choose Us for 33KV Box Type Substation Projects

You are not only selecting a 33KV European Box Type Substation, but also a partner who understands medium-voltage power projects.

Our team focuses on prefabricated box type substations for utility, industrial, and renewable energy applications. From technical configuration to manufacturing and export coordination, we support projects that require reliability, compliance, and clear communication.

Key reasons project owners and EPC contractors work with us include:

Experience in medium-voltage substation manufacturing

Clear technical documentation and configuration support

Compliance with international electrical and safety standards

Stable production capacity and export-ready packaging

This approach helps reduce project risks and ensures smoother execution from design to installation.

Professional Team Support for International Substation Projects

When purchasing a 33KV European Box Type Substation, buyers are not only evaluating technical specifications. They are also evaluating the supplier’s experience and communication ability.

This image represents real project discussions between engineers, management, and international customers. Such direct communication helps:

Clarify technical requirements early

Align product configuration with site conditions

Reduce misunderstandings during manufacturing

Improve overall project coordination

For buyers managing complex power projects, working with a supplier who understands both technical details and project execution significantly reduces risk and improves long-term cooperation.

Compliance, Certification, and Quality Standards

For many buyers, certification is not optional—it is a project requirement. We manufacture and test the 33KV European Box Type Substation according to applicable international standards to support global deployment.

From a procurement perspective, certification helps buyers:

Pass grid operator inspections

Meet regulatory and safety requirements

Reduce legal and compliance risk

Simplify project documentation

Quality management and manufacturing processes align with ISO quality management standards commonly adopted in electrical equipment production.

For EPC contractors and utility companies, certified equipment shortens approval cycles and avoids redesign or replacement later in the project. This is especially important for public infrastructure, renewable energy projects, and cross-border power investments.

Export Packaging and Transportation for 33KV Box Type Substations

A common concern among buyers is whether large electrical equipment will arrive on site in good condition. We integrate transportation protection into the 33KV prefabricated box type substation as an essential component of the product, not as an afterthought.

Packaging and logistics design focus on:

Structural reinforcement during lifting and loading

Protection against vibration during long-distance transport

Shielding from moisture, dust, and environmental exposure

Proper packaging reduces:

On-site repair work

Installation delays

Risk of hidden damage affecting performance

For international buyers and EPC projects, reliable transportation preparation ensures that the substation is ready for installation immediately after delivery.

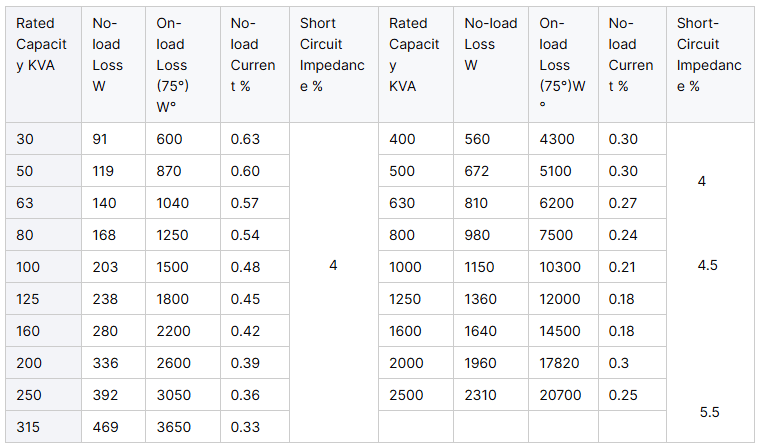

Key Performance Parameters of the 33KV Box Type Substation

| Rated Capacity (kVA) | No-load Loss (W) | On-load Loss (75°C) (W) | No-load Current (%) | Short Circuit Impedance (%) | Rated Capacity (kVA) | No-load Loss (W) | On-load Loss (75°C) (W) | No-load Current (%) | Short Circuit Impedance (%) |

|---|---|---|---|---|---|---|---|---|---|

| 30 | 91 | 600 | 0.63 | 4 | 400 | 560 | 4300 | 0.30 | 4 |

| 50 | 119 | 870 | 0.60 | 500 | 672 | 5100 | 0.30 | ||

| 63 | 140 | 1040 | 0.57 | 630 | 810 | 6200 | 0.27 | ||

| 80 | 168 | 1250 | 0.54 | 800 | 980 | 7500 | 0.24 | 4.5 | |

| 100 | 203 | 1500 | 0.48 | 1000 | 1150 | 10300 | 0.21 | ||

| 125 | 238 | 1800 | 0.45 | 1250 | 1360 | 12000 | 0.18 | ||

| 160 | 280 | 2200 | 0.42 | 1600 | 1640 | 14500 | 0.18 | ||

| 200 | 336 | 2600 | 0.39 | 2000 | 1960 | 17820 | 0.3 | 5.5 | |

| 250 | 392 | 3050 | 0.36 | 2500 | 2310 | 20700 | 0.25 | ||

| 315 | 469 | 3650 | 0.33 | – | – | – | – |

When buyers evaluate a 33KV European Box Type Substation, electrical performance is often more important than appearance or footprint. Performance directly affects operating cost, grid stability, and equipment lifespan.

We designed this substation to maintain stable voltage behavior under fluctuating load conditions. In real projects, load variation is common—especially in industrial parks, solar plants, and mixed commercial developments.

Key performance concerns from buyers usually include:

Whether no-load and on-load losses remain controlled over time

Whether current behavior stays stable during peak demand

Whether short-circuit impedance aligns with grid protection coordination

Whether performance remains consistent in outdoor environments

From a system perspective, stable electrical behavior reduces:

Unplanned shutdowns

Excessive heat generation

Long-term energy waste

For customers operating production lines or renewable energy systems, performance stability directly impacts revenue and operational continuity. This is why many buyers prioritize proven electrical behavior over low initial cost.

FAQ

1. What does a 33KV European Box Type Substation do?

A 33KV European Box Type Substation distributes medium-voltage power in utility grids, industrial facilities, and renewable energy projects. It combines MV switchgear, a transformer, and LV distribution equipment into one prefabricated enclosure.

2. How does a European box type substation differ from a traditional substation?

A European box type substation uses a prefabricated and enclosed design to reduce on-site civil work and installation time. Traditional substations usually require open structures, longer construction periods, and more commissioning work.

3. Can this 33KV box type substation operate outdoors?

Yes. The enclosed housing protects internal equipment from weather, dust, and environmental exposure. This design supports stable, long-term outdoor operation in medium-voltage power systems.

4. Can you customize the substation for specific project requirements?

Yes. We adjust the 33KV prefabricated box type substation configuration based on transformer capacity, protection schemes, switchgear layout, and site conditions to match different project needs.

5. Which standards does the 33KV European Box Type Substation meet?

The substation meets applicable international electrical and safety standards. These standards ensure operational safety, system reliability, and smoother approval for overseas power projects.

6. How quickly can teams install a prefabricated box type substation?

Factory assembly and testing allow installation teams to complete on-site work much faster than with traditional substations. This approach helps projects meet tight construction schedules.

7. What information should buyers provide to start a quotation or technical review?

Buyers can start the process by providing voltage level, transformer capacity, application type, and installation environment. This information allows engineers to prepare technical recommendations efficiently.

Request Technical Support for Your 33KV Substation Project

If you are planning a 33KV power distribution project, our engineering team supports you with configuration advice, technical drawings, and project-specific recommendations.

📩 Send your project details today, and we will review your requirements and respond with clear technical guidance.

Reviews

There are no reviews yet.