Description

1.5MVA Oil Immersed Transformer

Alright, let’s break down this 1.5MVA Oil Immersed Transformer. It’s built to be a set-and-forget workhorse—whether in a substation or out in the field. Most transformer failures come from moisture or contamination. That’s why we use a hermetically-sealed tank—simple but effective. It keeps the oil clean and the insulation dry, which means less maintenance and longer life. We learned this the hard way on an early coastal project where a faulty seal led to moisture ingress within a year.

Cooling is another area we don’t compromise on. After seeing some older units struggle in Middle Eastern heat, we oversized the radiators on this model. Now, even at full load, the tank stays cool to the touch—no hot spots, no insulation stress. We also stick to high-quality bushings from trusted suppliers. Once, a batch of cheaper bushings caused overheating and downtime on a mining site. Never again.

Built to IEC, ANSI, and GB/T standards, this 1.5 MVA power transformer handles harsh environments well—coastal air, industrial dust, you name it. It fits in substations, solar farms, data centers, and pairs easily with pad-mounted gear in distribution networks. A couple of practical notes: it’s heavy, so plan your lifting upfront. And though it’s sealed, don’t stuff it in a tight, unvented room—it still needs to breathe.

In short, this isn’t a flashy piece of gear. It’s just built to run quietly, efficiently, and reliably for years—so you can forget about it and focus on everything else. That’s the point.

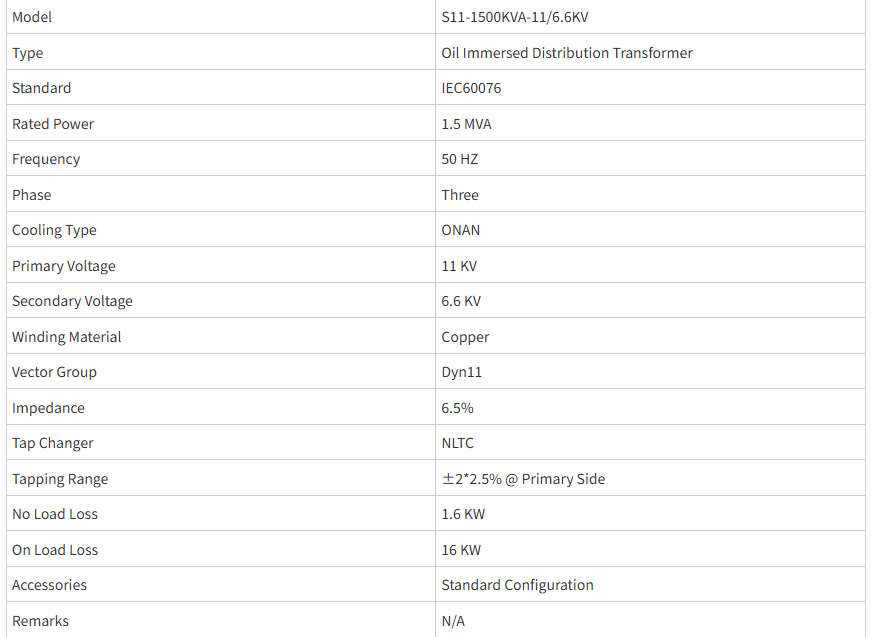

1.5MVA Oil Immersed Transformer Parameters

Highlights for Customers

Reliability comes from its oil. The fluid evenly distributes heat, giving you a buffer during load spikes that dry-types often lack. But—and this is key—that reliability depends entirely on keeping moisture out. We weld the tanks shut, but you should still run an occasional Dissolved Gas Analysis (DGA). Think of it as a routine blood test; it once helped a client spot a creeping fault two years before it could cause an outage.

Voltage control uses a standard No-Load Tap Changer (±2×2.5%). You have to power it down to adjust, so it’s not for fine-tuning day-to-day. But for most sites—like a wind farm with seasonal swings—you set it once at commissioning and forget it. It’s simpler, cheaper, and less fuss than an on-load system.

Efficiency is strong because we use good core steel and keep manufacturing tight. Just remember: even efficient transformers shed heat. You can’t tuck this 1.5 MVA power transformer into a cramped corner without airflow and expect peak performance.

Standards? We build to IEC 60076. But local utilities sometimes want extra tests—noise, temperature rise, partial discharge—before signing off. It’s not about the product; it’s about their local rules. Plan for it.

Where it fits: outdoors is its sweet spot—substations, solar farms, mines. Indoors, it needs a proper room. And it hums. Not loud, but noticeably. Don’t put it next to a quiet office wall.

In short: this transformer won’t impress you with features. It’s built to be ignored—to just work, year after year, with minimal drama. You install it, check the oil every so often, and move on with your day. That’s the point.

1.5MVA Oil Immersed Transformer Features

We’ve installed this 1.5MVA Oil Immersed Transformer in so many places—dusty factories, sun-baked solar fields, even quiet building basements. The oil really does handle erratic loads smoothly. I saw one in Vietnam stabilizing a wildly swinging load profile like it was nothing.

You’ll get all the paperwork—maybe too much, honestly. We can fully customize specs if you need. Our quality team does rigorous checks, though last year we caught a batch with under-torqued bushings during testing. It delayed a shipment, but now we verify every unit twice.

The unit runs quiet, but you’ll notice a soft hum if installed near an office wall. Outdoor use is fine—just ensure a level foundation. We learned this after an installation crew in Indonesia nearly tipped one on an uneven pad.

Maintenance is simple: check oil levels, clean radiators, run a DGA test every few years. We recently replaced a 20-year-old unit in Thailand that was still running, just less efficiently. Choose this 1.5 MVA oil-filled transformer if you want reliability without fuss. It just works. And if it doesn’t perfectly fit your needs yet, we’ll adjust it until it does.

Application Scenarios

This 1.5MVA oil-immersed transformer isn’t a generic box—we’ve shaped it around real jobsites. In mines, it’s not just the constant load, but the harmonic spikes from crushers that kill transformers. The oil here acts like a thermal buffer, soaking up those surges. A client in Chile ran two units for five years straight on a grinding circuit—annual oil tests still came back clean.

At a cruise terminal in the Mediterranean, the challenge was salt air and voltage stability for shore power. We fitted one with a wider-ratio tap changer and corrosion-resistant bushings. Three years on, it’s still humming through peak season with only basic maintenance.

In automated factories, voltage dips can idle a whole robotic line. We tweak the impedance and balance the windings to stiffen the output. One German plant even used the monitoring points we added to trace a dip back to the grid—saved them weeks of troubleshooting.

For subway traction power, it’s about handling regenerative braking currents. We’ve used special ester-based oil in some underground projects for better fire safety. One unit in a Southeast Asian metro has seen daily rush-hour peaks for years without a hiccup.

So yeah, this 1.5MVA power transformer is less of an off-the-shelf product and more of a adaptable platform. It works where the air is dirty, the load is erratic, and downtime isn’t an option.

Factory Scene

People sometimes think a 1.5MVA Oil Immersed Transformer just rolls off an assembly line. It doesn’t. What you’re seeing here is our shop floor—loud, busy, and full of small decisions that end up inside your unit.

For instance, that’s Lin, our lead tech, hand-stacking core laminations. His team once missed a subtle gap spec. The unit passed all tests but had a faint hum. The customer noticed. Now they measure twice.

The loading photo is from last week’s Oman shipment. We used to use chains, but they scratched the tanks. Switched to nylon belts with protectors after a client complained. It’s the little things.

We have automated winders, but the settings are manual. A data center transformer gets wound differently than one for a steady factory load. Our operators know the difference from memory.

Every unit gets a final “sound check.” After the official tests, the plant manager walks by and listens. A clean hum is good. A buzz means something’s off. It’s not in the manual, but it works.

So, this 1.5 MVA oil-filled transformer isn’t just built. It’s tuned, checked, and sometimes corrected by people who’ve seen what happens when a detail gets missed. That’s what you’re really buying.

Certifications

Global Cooperation

A global network of partners builds our success through strong, collaborative relationships. This collage represents the trust that industry leaders place in us as their preferred transformer manufacturer and supplier. From multinational corporations to local utilities, we provide reliable 1.5MVA Oil Immersed Transformers that power their critical operations.

These partnerships reflect our product reliability, company integrity, and commitment to exceptional support and stable delivery. Join our growing list of satisfied clients and experience the difference quality makes.

FAQ

1. What makes the 1.5MVA oil-immersed transformer different from smaller units?

It handles much heavier loads, offers higher thermal stability, and is built for continuous operation in demanding industrial and utility environments.

2. How does the oil improve the transformer’s performance?

The insulating oil removes heat quickly and strengthens electrical insulation, keeping the transformer stable even during long hours of high-load operation.

3. Can this transformer handle frequent load changes?

Yes. Its core and windings are designed to stay stable under fluctuating or sudden load increases, making it suitable for factories, data centers, and renewable systems.

4. What type of cooling system does it use?

It mainly uses natural oil and natural air cooling. For harsher conditions, we can add forced-air cooling to increase heat dissipation capacity.

5. Is the transformer noisy during operation?

No. Its optimized core design keeps noise and vibration at low levels, making it suitable for both industrial and commercial environments.

6. How do you ensure long service life?

We use high-grade steel, durable tank coatings, dry-winding techniques, and stable insulating oil. These features slow down aging and extend lifespan.

7. Can it be customized for special installation sites?

Absolutely. We can adjust the voltage, bushings, tap changer type, cooling system, oil selection, and protection devices based on the project environment.

8. Is it suitable for outdoor installation?

Yes. The sealed tank protects the oil from moisture, dust, and oxidation, making the transformer reliable in rain, heat, snow, or coastal environments.

9. What protection features does it include?

Each transformer comes with essential protections such as temperature monitoring, oil level indicators, and pressure relief. Additional smart monitoring options can be added.

10. How often does it need maintenance?

Usually very little. Basic inspections for oil level, temperature, and external components are enough to keep it running smoothly for many years.

11. What industries typically use a 1.5MVA transformer?

It is commonly used in heavy manufacturing, large buildings, utility networks, renewable energy plants, and equipment that requires stable, high-capacity power.

12. Do you provide installation or technical guidance?

Yes. We can supply installation manuals, wiring diagrams, remote support, and onsite assistance if needed.

Reviews

There are no reviews yet.