Street lights, industrial motors, data centers, and sports stadiums—what do they all have in common? They require a constant and substantial supply of electricity to function effectively. However, accessing usable electricity isn’t as simple as connecting directly to high-voltage transmission lines, which operate at voltages far too high for everyday applications. This is precisely where the function of the transformer becomes crucial. The fundamental purpose of a transformer is to adjust voltage levels efficiently and safely. Before power can be distributed for daily use, it must be stepped down to a suitable, safer voltage through a transformer, making reliable and accessible electricity possible.

Transformers are crucial devices in the power distribution system, yet many people are unfamiliar with how they function. Whether you’re planning to purchase a transformer or simply want to understand the basics, this article explains what transformers are, why they’re essential, how they operate, and the key components inside.

What Is a Transformer?

A power transformer is a vital electrical device that keeps our electric power systems running safely and efficiently. Its function is simple yet incredibly important: it changes voltage levels between circuits so electricity can move where it’s needed. In high-voltage transmission lines, transformers work by increasing voltage to move power over long distances with minimal loss. Closer to homes, factories, and businesses, they reduce voltage to safer, usable levels. This ability to adapt voltage lies at the heart of transformer design, fulfilling its core purpose—to ensure electric power is delivered in the right form at the right place.

Without transformers, power grids could not operate reliably. Electricity must travel at high voltages for efficiency, but everyday equipment requires much lower voltages. The core purpose of a transformer is precisely to bridge this critical difference, enabling generators, transmission networks, and end-user systems to work together seamlessly. In this way, transformers fulfill their essential transformer purpose: they serve as the indispensable, quiet backbone of every modern power system, ensuring stable energy flow from power plants all the way to the devices people rely on daily.

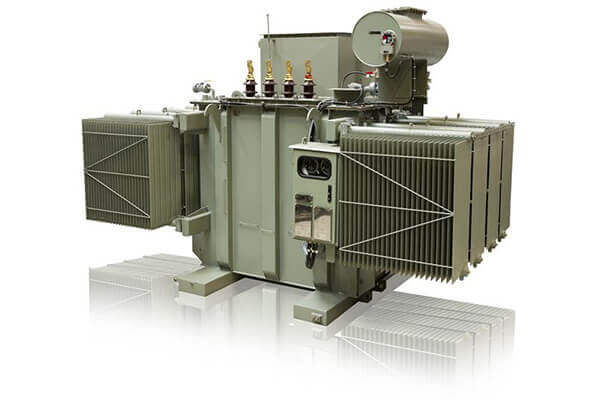

For many industrial and commercial sites, the 200KVA Oil Immersed Transformer provides dependable voltage conversion and consistent energy supply.

Whether used in substations, industrial facilities, or renewable-energy plants, the purpose of transformer technology remains the same: to protect equipment, improve efficiency, and maintain a steady and safe electricity supply.

Why Is Voltage Conversion Necessary?

Electricity consists of two fundamental properties:

- Current – the rate of electrical flow, measured in amps

- Voltage – the force pushing the electrical flow, measured in volts

To simplify, think of electricity like water in a pipe:

- Current is the amount of water flowing

- Voltage is the water pressure

Power plants transmit electricity at extremely high voltages—often exceeding 300,000 volts—to minimize energy loss over long distances. However, this “electrical pressure” is too intense for direct use in homes or commercial buildings. Just like high-pressure water mains need pressure regulators before water enters your home, high-voltage electricity must be transformed to lower voltages.

This is where step-down transformers come into play. They reduce high transmission voltages to safer, usable levels at the point of consumption. These range from:

- Substation transformers used by utilities

- Pad-mounted transformers outside commercial building

- Pole-mounted transformers installed on utility poles

While residential areas typically use single-phase transformers (for 120/240V supply), commercial and industrial facilities often rely on three-phase transformers delivering 208V or 480V power. In this article, we focus on three-phase distribution transformers.

How Do Transformers Work?

Transformers operate on the principle of electromagnetic induction, a concept first discovered by Michael Faraday. When alternating current flows through the primary winding, it creates a changing magnetic field. This magnetic field then induces a voltage in the secondary winding, allowing electric power to move from one circuit to another without direct electrical contact. This simple but powerful mechanism is what enables transformers work in practice. Whether in a large power transformer or a compact distribution unit, this principle lies at the heart of all transformer design and explains what transformers do at their core.

Instead of producing electricity, a transformer adjusts voltage levels so power can be moved efficiently and safely through the grid. High voltages are essential for long-distance transmission because they reduce energy losses. Once electricity reaches factories, commercial buildings, or homes, the transformer lowers the voltage to levels that equipment and appliances can safely use. This illustrates the essential function of the transformer—and, indeed, the purpose of a transformer: to ensure electricity is delivered at the appropriate voltage for every stage of the power network, enabling both efficient transport and safe end-use.

In practical terms, transformers ensure that power plants, transmission lines, and end-use systems all work together smoothly. By controlling voltage levels and improving energy efficiency, transformers play an essential role in keeping modern electrical infrastructure stable, safe, and reliable.

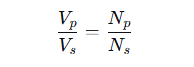

The Principle of Electromagnetic Induction

Transformers operate on Faraday’s law of electromagnetic induction, which explains how a changing magnetic field can induce voltage in a conductor. This principle enables efficient AC voltage adjustment.

Here’s the basic process:

- Magnetic Field Generation: Alternating current in the primary winding produces a varying magnetic field.

- Magnetic Coupling: The core, typically made of laminated silicon steel, efficiently transfers this field to the secondary winding.

- Voltage Induction: The changing magnetic field induces an AC voltage in the secondary winding. The voltage level depends on the turns ratio of the coils.

The turns ratio determines the voltage transformation:

Where:

- Vp = primary voltage

- Vs = secondary voltage

- Np = number of turns in the primary coil

- Ns = number of turns in the secondary coil

A higher turns ratio in the primary coil steps down the voltage, while a higher ratio in the secondary coil steps it up.

Practical Example:

A transformer with a 25:1 turns ratio converts an input of 12,000 V to an output of 480 V. This step-down process enables efficient transmission and safe usage in industrial and commercial applications.

In summary, transformers use electromagnetic induction to enable high-voltage, low-loss power transmission over long distances, followed by safe voltage reduction for practical applications.

Transformer Coil Configurations

Transformers achieve voltage conversion through precisely arranged coil systems designed for both efficiency and operational reliability. A basic transformer includes two windings:

- Primary Coil: Draws electrical energy from the input source.

- Secondary Coil: Supplies the converted voltage to the connected load.

These windings are commonly constructed from copper or aluminum and are wound around a laminated iron core. The core guides magnetic flux to enhance energy transfer between coils while reducing losses. As the core repeatedly magnetizes and demagnetizes with AC current, it undergoes subtle physical vibrations—resulting in the characteristic hum of operating transformers.

Materials and Winding Design

- Copper Windings: Preferred for demanding applications due to superior conductivity, efficiency, and mechanical resilience.

- Aluminum Windings: Offer a balance of performance and economy, suitable where weight and cost are constraints.

- Winding Geometry: Layouts such as layered, disc-type, or helical are selected based on voltage rating, isolation needs, and thermal behavior.

Three-Phase Winding Arrangements

For high-power distribution, three-phase transformers employ specific interconnection strategies to maintain system balance:

- Delta (Δ) Connection: Windings are joined sequentially to form a closed circuit. This setup supports robust performance under high loads, tolerates phase faults, and is widely adopted in industrial settings.

- Wye (Y) Connection: One terminal of each coil connects to a shared neutral, enabling dual voltage outputs (line and phase). This versatility makes it well-suited for distribution grids requiring multiple service voltages.

Main Components of a Transformer

While there are many types—such as pad-mounted, pole-mounted, substation, and dry-type transformers—they share common structural elements. Here’s an overview of the major parts found in an oil-filled pad-mounted transformer:

1. Core

The transformer core, made of thin laminated silicon steel sheets, provides a highly effective magnetic path linking the primary and secondary windings. This laminated structure reduces eddy current and hysteresis losses, resulting in smoother magnetic coupling and significantly higher energy transfer efficiency.

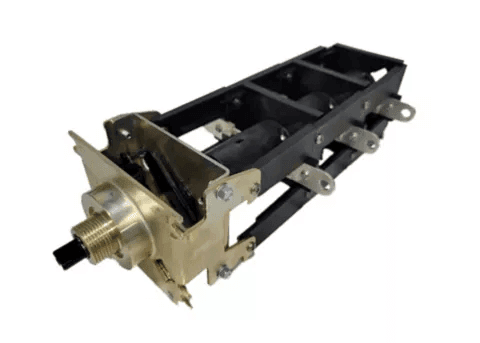

2. Coils (Windings)

Within every transformer, precisely wound copper or aluminum conductors form the primary and secondary coils around the iron core. These windings are far more than simple loops of wire—they are meticulously designed to carry substantial electrical currents while offering optimal conductivity, thermal performance, and mechanical resilience.

Connected to the high-voltage input, the primary winding carries alternating current, producing a varying magnetic field within the core.

This magnetic field then intersects the secondary winding, where—through electromagnetic induction—a transformed voltage is generated, tailored to the needs of the load being supplied.

Material selection is critical to transformer performance:

- Copper windings excel in conductivity, mechanical robustness, and resistance to overload, and are often specified for heavy industrial applications.

- Aluminum windings provide a lightweight, economical alternative with sufficient performance for applications where cost efficiency is essential.

Through the synergy of these windings and the magnetic core, transformers achieve high energy efficiency, reduced losses, and extended operational life—qualities that cement their essential role in global power infrastructure.

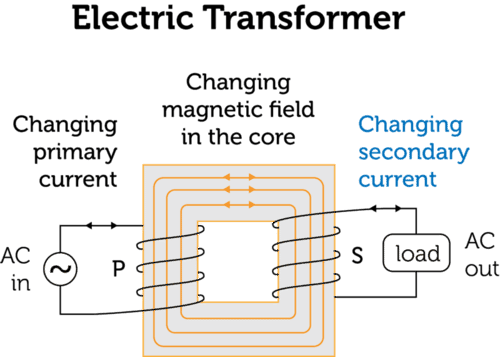

3. Bushings

Insulation bushings are specialized fittings that allow electrical conductors to safely pass through the transformer tank. They provide a fully insulated path, preventing current leakage, safeguarding the internal insulating oil, and maintaining secure connections for both high and low voltage circuits under all operating conditions.

Constructed from durable materials such as porcelain, epoxy resin, or composite polymers, these bushings are designed to endure electrical stress, mechanical forces, and harsh environments, ensuring long-term safety and reliability in power distribution systems.

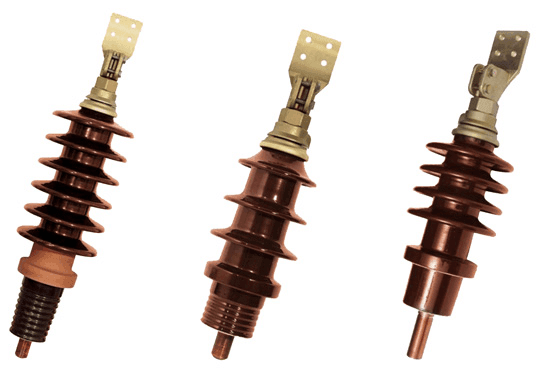

4. Fuses

Fuses serve as essential safety devices within the electrical system. When current rises beyond the designated safe limit, the fuse element automatically melts, breaking the circuit.

This quick interruption protects the transformer and connected equipment from potential overloads, short circuits, and costly damage.

5. Voltage Taps

Voltage taps are access points integrated into a transformer’s primary winding, enabling operators to adjust the number of active turns in the coil. This allows precise regulation of the output voltage to align with grid conditions or load demand. A tap changer—either a manual switch or an automatic on-load mechanism in larger units—facilitates this adjustment.

By utilizing these taps, grid operators and facility managers can effectively respond to input voltage variations, seasonal load shifts, or voltage drops across long distribution lines. This ensures consistent and optimized voltage supply to downstream equipment.

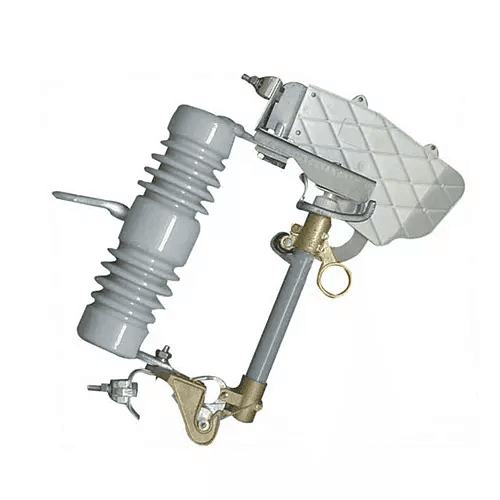

6. Load Break Switch

This device is a rotary load-break switch, designed to safely disconnect the transformer from the live power grid. It enables operators to isolate the equipment even under electrical load, ensuring secure conditions for maintenance, preventing damage to components, and strengthening system-wide protection.

7. Transformer Fluid

Oil-immersed transformers utilize a high-grade insulating oil—either mineral-based or synthetic—that performs two essential roles: thermal management and electrical isolation. As the transformer operates, the oil flows around the active parts, absorbing heat caused by power losses and releasing it through the tank’s radiators or cooling fins. Simultaneously, it acts as a dielectric barrier, preventing arcs and short circuits between energized components.

The oil is contained within a sealed tank system that prevents exposure to humidity and contaminants. Enhanced external cooling surfaces facilitate efficient heat exchange with the ambient air. This integrated oil-based cooling and insulation system supports sustained operation under heavy loads and diverse environmental conditions, contributing to the transformer’s extended lifespan and operational reliability.

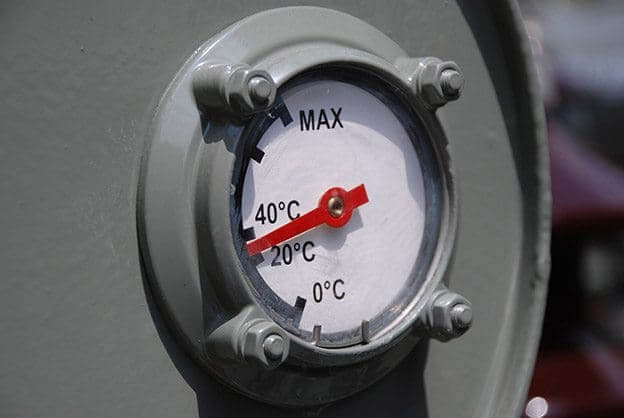

8. Gauges

Gauges are essential for real-time monitoring of transformer operating conditions. Standard instruments measure critical parameters including oil level, temperature, and internal pressure, offering operators early detection of abnormalities such as overheating, leaks, or gas buildup.

In larger or critical installations, these conventional gauges are often enhanced with digital monitoring systems. Equipped with sensors and remote communication features, these advanced systems continuously track performance, trigger alerts during irregularities, and can integrate with smart grid platforms to support predictive maintenance. This proactive approach improves operational safety and reliability while helping to extend the transformer’s service life.

9. Pressure Relief Device

This device functions as a pressure relief valve, engineered to shield the transformer from internal overpressure. In the event of abnormal operating conditions—such as extreme overheating or rapid gas generation—it automatically releases excess pressure in a controlled manner.

This action helps prevent catastrophic tank failure, protects adjacent equipment, and maintains the transformer’s operational safety and integrity.

10. Nameplate

Every transformer features a nameplate that acts as its unique technical identifier. It contains key operational specifications such as kVA rating, input and output voltages, number of phases, winding configuration, frequency, impedance, cooling class, and manufacturer information.

More than just an identification tag, the nameplate offers vital data required for proper installation, system compatibility assessment, and ongoing maintenance. Personnel can use these details to match the transformer with its intended application, prevent operational hazards, and comply with relevant international standards.

In Summary

Transformers form the core of today’s electrical systems, enabling the safe and efficient transmission of electric power from generation sites to end users. Although they don’t generate electricity, they play an essential role in adapting electrical energy to suitable voltage levels for a vast range of uses. This is how transformers work: from low-voltage applications like residential electricity and home devices, to medium-voltage supply for commercial facilities, industrial plants, and healthcare centers, all the way to high-voltage requirements for stadium lighting, computing infrastructure, and heavy equipment. Whether in a large power transformer or a distribution unit, the underlying transformer design determines how reliably and effectively electricity flows across the entire network.

The existence of worldwide power grids would be impractical without transformers. They make long-distance transmission feasible through high-voltage operation with reduced losses, and then lower the voltage to levels safe for consumption. In this way, transformers perform as unsung protectors of the electrical network. They operate ceaselessly behind the scenes, shielding delicate devices, improving energy efficiency, and guaranteeing continuous and dependable electricity supply.

For professionals like engineers and energy managers, understanding transformers is practical. It enables energy-efficient designs and reduces operating costs. It also helps build robust power systems. For the public, transformers are unseen daily technology. They power personal electronics and home appliances. They also maintain critical hospital equipment. This all relies on their quiet, reliable performance.

Need help choosing the right transformer for your project?

Contact our team today for expert guidance and tailored solutions.