Description

As a professional 20kV Oil Immersed Transformer supplier and manufacturer, we provide medium voltage power transformers designed for stable operation, high efficiency, and long service life. This product page presents our export-ready 20kV oil type transformers, suitable for utility grids, industrial plants, and EPC power projects requiring reliable medium voltage distribution.

20KV Oil Immersed Transformer Description

Oil Immersed Transformer is a piece of power equipment cooled and insulated by insulating oil, typically used in high-power transmission and distribution systems. The insulating oil not only helps with thermal dissipation and temperature regulation, but also enhances the transformer’s electrical insulation performance and dielectric strength, thereby extending the power equipment’s lifespan and improving its operational reliability in high-voltage systems.

We specially designed the S11 series 20kV power transformer to meet the demands for high efficiency, energy conservation, low noise, and high reliability. Power companies and industrial users widely apply it in urban and rural distribution networks, industrial parks, and various high-load operation scenarios. This series of transformers is based on advanced technology and high-quality materials, featuring outstanding electrical performance and operational stability.

20kV Oil-Immersed Transformer: High-Performance Power Distribution Solutions

As a leading manufacturer in the power industry, our 20kV oil-immersed transformers (including the popular S11-M and SL11-M series) are engineered to provide stable and efficient voltage regulation for industrial, commercial, and renewable energy projects. This 3150kVA unit is specifically designed to step down 20kV input voltage to 0.8kV, making it an ideal choice for solar PV plants and large-scale manufacturing facilities.

Why Choose Our 20kV Oil-Filled Transformers?

Superior Efficiency & Low Loss: Utilizing high-quality silicon steel sheets, our transformers significantly reduce no-load losses and load losses, ensuring long-term energy savings and lower operational costs.

Robust Cooling System: Equipped with an ONAN (Oil Natural Air Natural) cooling-down method, these units maintain optimal temperatures even under heavy load conditions, extending the equipment’s lifespan.

Full Compliance & Safety: Every unit is manufactured to meet IEC standards and JB/T 10088-2016 noise level specifications, ensuring a quiet and safe environment for indoor or outdoor installation.

Customization Options: Whether you require specific Vector Groups (like Dyn11), different altitude ratings (up to 1000m or higher), or specialized protection accessories, we provide tailored solutions to meet your grid requirements.

20kV Transformer Price and Quotation

When evaluating the 20kV transformer price, it is essential to consider the total cost of ownership, including efficiency ratings and maintenance requirements. While the market price for a 3150kVA oil transformer fluctuates based on raw material costs (copper and steel), we offer competitive factory-direct pricing without compromising on quality.

To get an accurate 20kV oil-immersed transformer quote, please provide your specific requirements:

Required Rated Capacity (kVA).

Input/Output voltage specifications.

Installation environment (indoor or outdoor).

Specific vector group or impedance requirements.

Reliability for Renewable Energy Projects

Our transformers are widely used in solar power distribution systems. With a 1-year warranty and a design optimized for harsh environmental temperatures (-5°C to +40°C), our S11-M 20kV units ensure your solar farm stays connected to the grid with minimal downtime.

20KV Oil Immersed Transformer Series

| Technical Parameters | Specifications |

|---|---|

| Type | Oil immersed type |

| Model | S11-M / SL11-M |

| Installation Site | Indoor / Outdoor |

| Rated Capacity (kVA) | 3150 |

| Input Voltage (kV) | 20 |

| Output Voltage (kV) | 0.8 |

| Input Rated Current (A) | 90.93 |

| Output Rated Current (A) | 2273.38 |

| Rated Frequency (Hz) | 50 |

| Phase | 3-phase |

| Vector Group | Dyn11 |

| Endure Heat Levels | A |

| Open Circuit Losses (W) | 2975 |

| No-Load Current (%) | 0.5 |

| Load Losses (W) | 26425 |

| Short-Circuit Impedance (%) | 6 |

| Altitude (M) | 1000 |

| Cooling-Down Method | ONAN |

| Noise Level (Sound Power Level) dB | Implement JB/T 10088-2016 |

| Warranty | 1 Year |

| Environmental Temperature | -5 ~ +40°C |

This S11-M series 3150 kVA oil-immersed transformer features low no-load current and high efficiency for stable power distribution.

20KV Oil Immersed Transformer picture

Oil-immersed transformers play a vital role in power systems. They deliver reliable performance across diverse applications. We design them primarily to achieve seamless voltage conversion and efficient power transmission, enabling them to handle the high current and large capacity demands of modern power networks. With our cutting-edge engineering, you can experience unmatched stability and reliability.

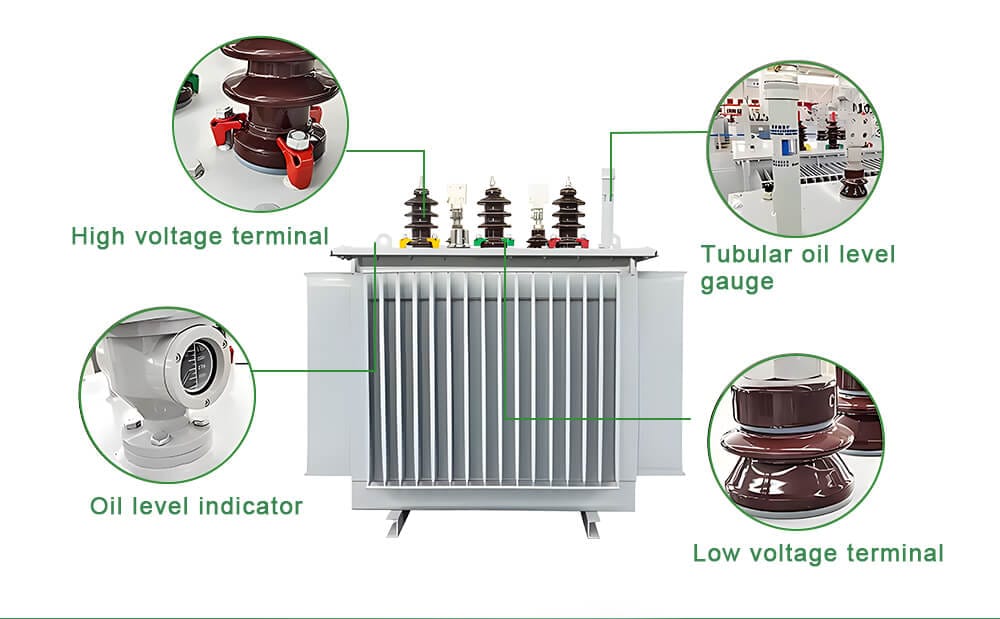

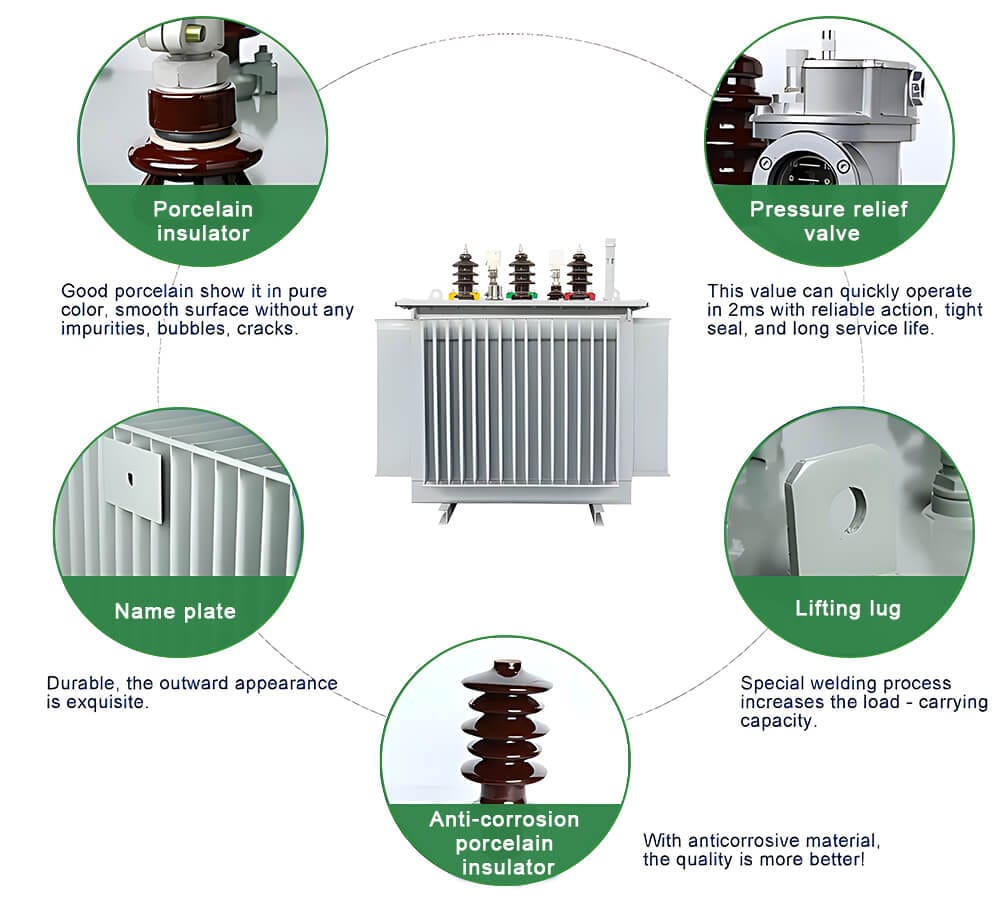

20KV Oil Immersed Transformer Details Images

1. Winding structure:

Our transformers adopt multi-layer cylindrical winding structures that enhance impact distribution, reduce magnetic leakage, and provide high mechanical strength and strong short-circuit resistance.

2. Excellent core design:

We optimize the core design to significantly reduce no-load losses, minimize no-load current, and ensure efficient operation.

3. Strengthen fastening and prevent loosening:

We apply precise fastening techniques and use self-locking anti-loosening nuts to ensure stability during transportation.

To enhance durability, our team adopts a non-suspended center structure that effectively absorbs vibration.

Meanwhile, the fastening components consistently ensure long-term operational integrity, even under demanding conditions.

4. Advanced vacuum processing:

We vacuum-dry the coils and cores and perform vacuum oil injection with filtration to minimize internal moisture, thereby improving transformer performance and extending service life.

5. Ingenious fuel tank design:

We use corrugated plates with a breathing function in the oil tank to compensate for oil volume changes caused by temperature fluctuations. This design eliminates the need for an oil conservator and effectively lowers the transformer’s height.

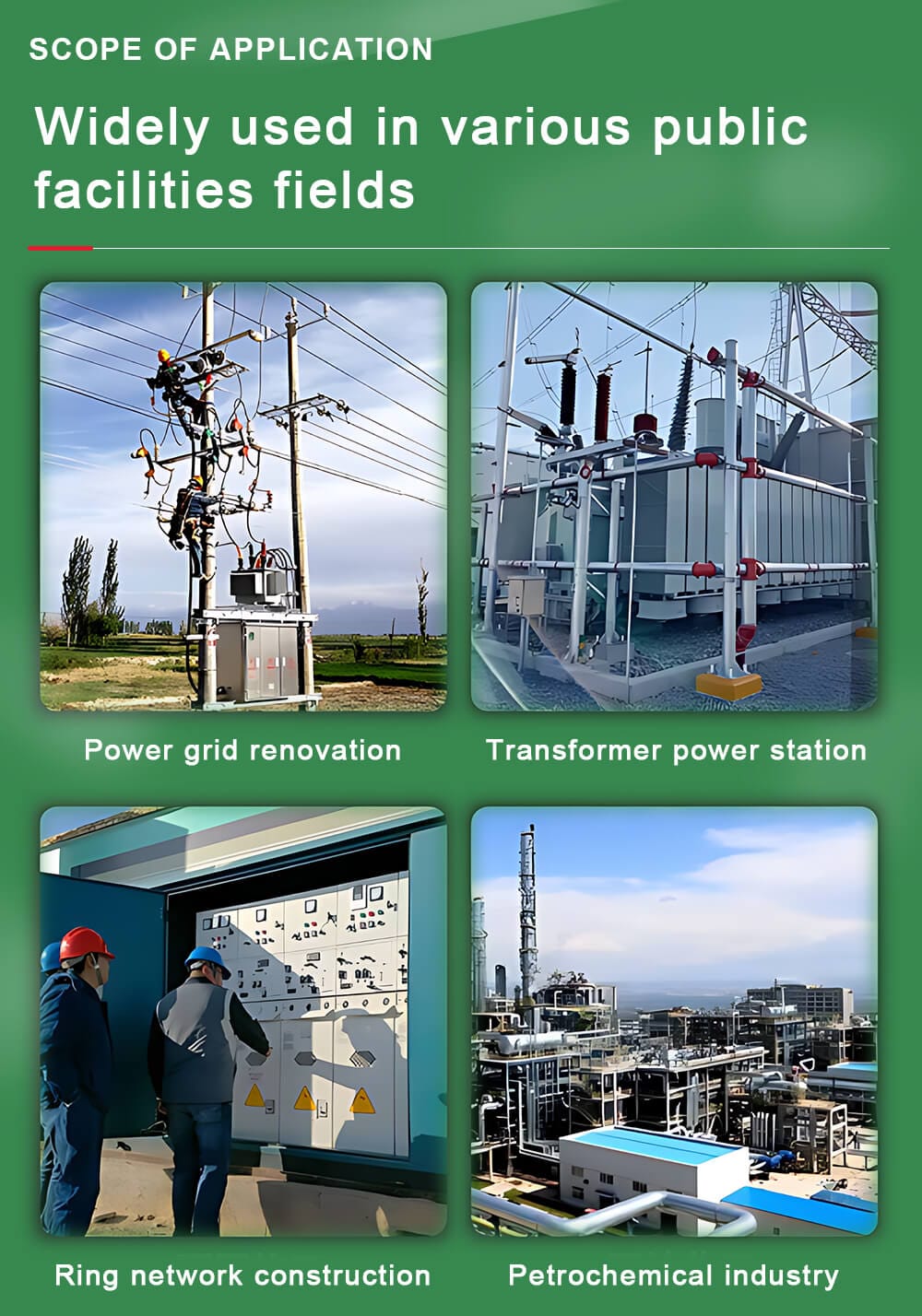

Applications of 20kV Oil Immersed Transformer

Power engineers and industrial planners widely apply the 20kV oil transformer in medium-voltage distribution projects that require high reliability, stable insulation performance, and long-term continuous operation. Its efficient oil cooling system and robust structural design make this transformer type well suited for demanding industrial and utility environments.

Power Grid Renovation

In power grid upgrading and renovation projects, the oil immersed transformer provides reliable voltage regulation and stable power output. It is commonly used to replace aging transformers, improving grid efficiency while meeting modern safety and performance standards.

Ring Network Construction

For medium voltage ring network systems, the oil immersed transformer supports flexible power distribution and enhanced supply reliability. Its stable insulation performance and load adaptability make it suitable for ring main units and urban distribution networks.

Transformer Power Stations

The oil immersed transformer is a standard solution for transformer power stations, offering efficient heat dissipation and long service life. It ensures continuous operation under variable load conditions, making it ideal for substations serving industrial and commercial facilities.

Petrochemical Industry

In petrochemical plants and heavy industrial environments, the oil immersed transformer delivers safe and stable power for critical equipment. The oil-immersed design enhances insulation and cooling performance, supporting reliable operation in harsh and high-demand industrial conditions.

Certifications

Our 20kV oil immersed transformer meets the highest international quality and safety standards. As a direct oil transformer manufacturer, we ensure that every unit is designed, manufactured, and tested according to IEC 60076 Power Transformer Standard and other relevant industry regulations.

All transformers undergo rigorous certification processes, including:

Routine and type testing to verify load loss, no-load loss, insulation resistance, and short-circuit impedance.

Dielectric strength testing of transformer insulating oil to guarantee stable insulation and long-term reliability.

Quality management audits in compliance with ISO 9001 standards to ensure full traceability and process control.

Environmental and safety compliance according to international industrial standards, ensuring safe operation in substations, industrial facilities, and infrastructure projects.

Our certifications are recognized globally, supporting export to industrial plants, urban substations, mining sites, and commercial buildings. Learn more about the relevant international standards and transformer safety guidelines:

IEC 60076 Power Transformer Standard – International standard for transformer design, testing, and operation.

ISO 9001 Quality Management – Standard for manufacturing quality and process control.

IEEE Transformer Standards – Recommended practices for power transformer performance and testing.

By maintaining strict certification compliance and factory-controlled production, we provide reliable, fully tested 20kV oil immersed transformers with stable performance, long service life, and safe operation across industrial, commercial, and infrastructure applications worldwide.

Cooperation

Over the years, many partners from Europe and other regions have visited our factory.

Moreover, they discussed long-term cooperation plans directly with the Solarasia team.

As a result, these photos demonstrate more than just business relationships.

They also highlight the trust and recognition we’ve steadily earned from global clients.

Interested in real project stories or client feedback?

Click here to explore our global partnerships and success cases.

FAQ

What is a 20kV oil immersed transformer used for?

Power utilities widely deploy 20kV oil-immersed transformers in substations, factories, and critical infrastructure for stable, continuous supply.

Is the 20kV oil power transformer suitable for outdoor installation?

Yes. The oil-immersed design ensures superior insulation and cooling, enabling reliable 20kV transformer performance in outdoor and harsh conditions.

Can you customize the 20kV oil power transformer?

Yes. As a professional transformer manufacturer, we customize oil-immersed transformers according to voltage class, capacity, cooling method, and project requirements.

Do you supply 20kV oil power transformers for export projects?

Yes. We supply export-standard 20kV oil transformers with international packaging, test reports, and documentation for overseas EPC and utility projects.

Get a Quote for 20kV Oil Immersed Transformer

Contact our team to receive technical specifications, pricing, and project support for your medium voltage transformer requirements.

Reviews

There are no reviews yet.